ASTM A774/A774M-14(2019)

(Specification)Standard Specification for As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and Moderate Temperatures

Standard Specification for As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and Moderate Temperatures

ABSTRACT

This specification covers five grades of as-welded, wrought austenitic stainless steel fittings for low-pressure piping and for low and moderate temperatures and general corrosive service. The fittings shall be made from flat-rolled steel which shall be in the solution annealed condition. The fittings shall be formed by a hot or cold process and shall be welded by a shielded welding process with or without the addition of filler metal. Heat analysis and product analysis shall be performed where in the steel fittings shall conform to the required chemical compositions of carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, molybdenum, titanium, columbium, tantalum, and nitrogen. The steel materials shall also undergo mechanical tests and shall conform to the required values of tensile strength, yield strength, elongation, and hardness.

SCOPE

1.1 This specification covers five grades of as-welded, wrought austenitic stainless steel fittings for low-pressure piping and intended for low and moderate temperatures and general corrosive service. Users should note that certain corrosive conditions may restrict the use of one or more grades. For applications requiring a product that requires heat treatment or full pressure rating, refer to Specification A403/A403M. The term “fittings” applies to butt and socket welding parts such as 45° and 90° elbows, tees, reducers, wyes, laterals, crosses, and stub ends.

1.2 This specification covers as-welded fittings 3 through 48 in. [75 through 1225 mm] in outside diameter and in nominal wall thicknesses 0.062 through 0.500 in. [1.6 through 12.7 mm]. Table 1 and Table 2 list the common diameters and nominal thicknesses of fittings in this specification.

1.3 This specification does not apply to cast fittings. Cast austenitic steel fittings are covered by Specification A351/A351M.

1.4 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. These supplementary requirements call for additional tests. When desired, one or more of these may be specified in the order.

1.5 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A774/A774M −14 (Reapproved 2019)

Standard Specification for

As-Welded Wrought Austenitic Stainless Steel Fittings for

General Corrosive Service at Low and Moderate

Temperatures

This standard is issued under the fixed designationA774/A774M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the

1.1 This specification covers five grades of as-welded,

standard.

wrought austenitic stainless steel fittings for low-pressure

1.7 This international standard was developed in accor-

piping and intended for low and moderate temperatures and

dance with internationally recognized principles on standard-

general corrosive service. Users should note that certain

ization established in the Decision on Principles for the

corrosiveconditionsmayrestricttheuseofoneormoregrades.

Development of International Standards, Guides and Recom-

For applications requiring a product that requires heat treat-

mendations issued by the World Trade Organization Technical

ment or full pressure rating, refer to Specification A403/

Barriers to Trade (TBT) Committee.

A403M. The term “fittings” applies to butt and socket welding

parts such as 45° and 90° elbows, tees, reducers, wyes, laterals,

2. Referenced Documents

crosses, and stub ends.

2.1 In addition to those reference documents listed in

1.2 Thisspecificationcoversas-weldedfittings3through48

Specification A960/A960M, the following list of standards

in. [75 through 1225 mm] in outside diameter and in nominal

apply to this specification:

wall thicknesses 0.062 through 0.500 in. [1.6 through 12.7

mm]. Table 1 and Table 2 list the common diameters and

2.2 ASTM Standards:

nominal thicknesses of fittings in this specification.

A240/A240M Specification for Chromium and Chromium-

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

1.3 This specification does not apply to cast fittings. Cast

Vessels and for General Applications

austenitic steel fittings are covered by Specification A351/

A351/A351M Specification for Castings, Austenitic, for

A351M.

Pressure-Containing Parts

1.4 Optional supplementary requirements are provided for

A403/A403M SpecificationforWroughtAusteniticStainless

fittings where a greater degree of examination is desired.These

Steel Piping Fittings

supplementary requirements call for additional tests. When

A960/A960M Specification for Common Requirements for

desired, one or more of these may be specified in the order.

Wrought Steel Piping Fittings

E527 Practice for Numbering Metals and Alloys in the

1.5 This specification is expressed in both inch-pound units

Unified Numbering System (UNS)

and in SI units. However, unless the order specifies the

applicable “M” specification designation (SI units), the mate-

2.3 ASME Standard:

rial shall be furnished to inch-pound units.

Section IX ASME Boiler and Pressure Vessel Code

2.4 MSS Standard:

1.6 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. Within the text, the SP 43 Wrought Stainless Steel Butt Welding Fittings

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction of ASTM Committee A01 on Steel, the ASTM website.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Available from American Society of Mechanical Engineers (ASME), ASME

A01.22 on Steel Forgings and Wrought Fittings for PipingApplications and Bolting International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Materials for Piping and Special Purpose Applications. www.asme.org.

Current edition approved Dec. 1, 2019. Published December 2019. Originally AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

approved in 1980. Last previous edition approved in 2014 as A774/A774M – 14. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

DOI: 10.1520/A0774_A0774M-14R19. hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A774/A774M−14 (2019)

A

TABLE 1 Common Tubular Fittings Sizes, Outside Diameter

5. Manufacture

in. [mm] in. [mm]

5.1 The fittings shall be made from flat-rolled steel, such as

in Specification A240/A240M. The flat rolled steel shall be in

3 [76] 12 ⁄4 [325]

the solution annealed condition unless other heat treat condi-

3 ⁄2 [90] 14 [355]

tions are agreed upon by the manufacturer and the purchaser.

4 [100] 16 [405]

The fittings shall be formed by a hot or cold process, and

4 ⁄2 [115] 18 [460]

6 [150] 20 [510] welded by a shielded welding process with or without the

6 ⁄8 [170] 24 [610]

addition of filler metal.

8 [205] 30 [760]

8 ⁄8 [220] 36 [915]

5.2 Fittings shall be furnished clean and free of scale.

10 [255] 40 [1015]

10 ⁄4 [275] 42 [1070] 5.3 Welding:

12 [305] 48 [1220]

5.3.1 The joints shall be full penetration double-welded or

A

Other sizes may be furnished provided they comply with all other requirements

single-welded butt joints employing fusion-welding processes

of this specification.

with or without the addition of filler metal as defined under

Definitions, ASME Boiler and Pressure Vessel Code, Section

IX. This specification makes no provision for any difference in

A

TABLE 2 Common Tubular Fittings Nominal Thicknesses

weld quality requirements regardless of the weld joint-type

in. or gauge in. [mm]

employed (single or double) in making the weld. Welding

16 gauge 0.062 [1.6]

procedures and welding operators shall be qualified in accor-

14 gauge 0.078 [2.0]

12 gauge 0.109 [2.8]

dance with ASME Boiler and Pressure Vessel Code, Section

11 gauge 0.125 [3.2]

IX.

10 gauge 0.140 [3.6]

5.3.2 For fittings employing multiple passes, the root-pass

8 gauge 0.172 [4.4]

⁄16 in. 0.187 [4.8]

may be made without the addition of filler metal.

⁄4 in. 0.250 [6.4]

5.3.3 The alloy content (chromium, nickel, molybdenum,

⁄16 in. 0.312 [8.0]

3 niobium, and tantalum) of the deposited weld metal shall

⁄8 in. 0.375 [9.5]

⁄2 in. 0.500 [12.5]

conform to that required of the base metal or for equivalent

A

Other thicknesses may be furnished provided they comply with all other weld metal as given in theAWS filler metal specificationA5.4

requirements of this specification.

orA5.9, except that, when welding on Types 304L base metal,

the deposited weld metal shall correspond, respectively, to

AWS Types E308L(ER308L) and, when welding on Type 321

2.5 AWS Standards:

base metal, the weld metal shall correspond to AWS Types

A5.4 Corrosion-Resisting Chromium and Chromium-Nickel

E347 (ER347 or ER321).

Steel Covered Welding Electrodes

A5.9 Corrosion-Resisting Chromium and Chromium-Nickel 6. Chemical Composition

Steel Welding Rods and Bare Electrodes

6.1 The steel shall conform to requirements of chemical

2.6 SAE Standard:

composition for the respective material prescribed in Table 3.

J1086 Unified Numbering System for Metals and Alloys

6.2 The purchaser may make a product analysis on products

made to this specification in accordance with Specification

3. Ordering Information

A960/A960M.

3.1 See Specification A960/A960M and the following:

6.3 The steel shall not contain any unspecified elements for

3.1.1 Dimensions (outside diameter and specified wall

the ordered grade to the extent that it conforms to the

thickness, see Table 1 and Table 2),

requirements of another grade for which that element is a

3.1.2 Grade (Table 3), and

specified element having a required minimum content.

3.1.3 End use, if known.

6.4 Mill certificates of analysis of each heat of steel shall be

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A774/A774M − 14 (Reapproved 2019)

Standard Specification for

As-Welded Wrought Austenitic Stainless Steel Fittings for

General Corrosive Service at Low and Moderate

Temperatures

This standard is issued under the fixed designation A774/A774M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the

1.1 This specification covers five grades of as-welded,

standard.

wrought austenitic stainless steel fittings for low-pressure

1.7 This international standard was developed in accor-

piping and intended for low and moderate temperatures and

dance with internationally recognized principles on standard-

general corrosive service. Users should note that certain

ization established in the Decision on Principles for the

corrosive conditions may restrict the use of one or more grades.

Development of International Standards, Guides and Recom-

For applications requiring a product that requires heat treat-

mendations issued by the World Trade Organization Technical

ment or full pressure rating, refer to Specification A403/

Barriers to Trade (TBT) Committee.

A403M. The term “fittings” applies to butt and socket welding

parts such as 45° and 90° elbows, tees, reducers, wyes, laterals,

2. Referenced Documents

crosses, and stub ends.

2.1 In addition to those reference documents listed in

1.2 This specification covers as-welded fittings 3 through 48

Specification A960/A960M, the following list of standards

in. [75 through 1225 mm] in outside diameter and in nominal

apply to this specification:

wall thicknesses 0.062 through 0.500 in. [1.6 through 12.7

mm]. Table 1 and Table 2 list the common diameters and

2.2 ASTM Standards:

nominal thicknesses of fittings in this specification.

A240/A240M Specification for Chromium and Chromium-

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

1.3 This specification does not apply to cast fittings. Cast

Vessels and for General Applications

austenitic steel fittings are covered by Specification A351/

A351/A351M Specification for Castings, Austenitic, for

A351M.

Pressure-Containing Parts

1.4 Optional supplementary requirements are provided for

A403/A403M Specification for Wrought Austenitic Stainless

fittings where a greater degree of examination is desired. These

Steel Piping Fittings

supplementary requirements call for additional tests. When

A960/A960M Specification for Common Requirements for

desired, one or more of these may be specified in the order.

Wrought Steel Piping Fittings

E527 Practice for Numbering Metals and Alloys in the

1.5 This specification is expressed in both inch-pound units

Unified Numbering System (UNS)

and in SI units. However, unless the order specifies the

applicable “M” specification designation (SI units), the mate-

2.3 ASME Standard:

rial shall be furnished to inch-pound units.

Section IX ASME Boiler and Pressure Vessel Code

1.6 The values stated in either SI units or inch-pound units 2.4 MSS Standard:

SP 43 Wrought Stainless Steel Butt Welding Fittings

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction of ASTM Committee A01 on Steel, the ASTM website.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Available from American Society of Mechanical Engineers (ASME), ASME

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Materials for Piping and Special Purpose Applications. www.asme.org.

Current edition approved Dec. 1, 2019. Published December 2019. Originally Available from Manufacturers Standardization Society of the Valve and Fittings

approved in 1980. Last previous edition approved in 2014 as A774/A774M – 14. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

DOI: 10.1520/A0774_A0774M-14R19. hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A774/A774M − 14 (2019)

A

TABLE 1 Common Tubular Fittings Sizes, Outside Diameter

5. Manufacture

in. [mm] in. [mm]

5.1 The fittings shall be made from flat-rolled steel, such as

in Specification A240/A240M. The flat rolled steel shall be in

3 [76] 12 ⁄4 [325]

the solution annealed condition unless other heat treat condi-

3 ⁄2 [90] 14 [355]

tions are agreed upon by the manufacturer and the purchaser.

4 [100] 16 [405]

The fittings shall be formed by a hot or cold process, and

4 ⁄2 [115] 18 [460]

6 [150] 20 [510] welded by a shielded welding process with or without the

6 ⁄8 [170] 24 [610]

addition of filler metal.

8 [205] 30 [760]

8 ⁄8 [220] 36 [915]

5.2 Fittings shall be furnished clean and free of scale.

10 [255] 40 [1015]

10 ⁄4 [275] 42 [1070] 5.3 Welding:

12 [305] 48 [1220]

5.3.1 The joints shall be full penetration double-welded or

A

Other sizes may be furnished provided they comply with all other requirements

single-welded butt joints employing fusion-welding processes

of this specification.

with or without the addition of filler metal as defined under

Definitions, ASME Boiler and Pressure Vessel Code, Section

IX. This specification makes no provision for any difference in

A

TABLE 2 Common Tubular Fittings Nominal Thicknesses

weld quality requirements regardless of the weld joint-type

in. or gauge in. [mm]

employed (single or double) in making the weld. Welding

16 gauge 0.062 [1.6]

procedures and welding operators shall be qualified in accor-

14 gauge 0.078 [2.0]

12 gauge 0.109 [2.8]

dance with ASME Boiler and Pressure Vessel Code, Section

11 gauge 0.125 [3.2]

IX.

10 gauge 0.140 [3.6]

5.3.2 For fittings employing multiple passes, the root-pass

8 gauge 0.172 [4.4]

⁄16 in. 0.187 [4.8]

may be made without the addition of filler metal.

⁄4 in. 0.250 [6.4]

5.3.3 The alloy content (chromium, nickel, molybdenum,

⁄16 in. 0.312 [8.0]

niobium, and tantalum) of the deposited weld metal shall

⁄8 in. 0.375 [9.5]

⁄2 in. 0.500 [12.5]

conform to that required of the base metal or for equivalent

A

Other thicknesses may be furnished provided they comply with all other

weld metal as given in the AWS filler metal specification A5.4

requirements of this specification.

or A5.9, except that, when welding on Types 304L base metal,

the deposited weld metal shall correspond, respectively, to

AWS Types E308L (ER308L) and, when welding on Type 321

2.5 AWS Standards:

base metal, the weld metal shall correspond to AWS Types

A5.4 Corrosion-Resisting Chromium and Chromium-Nickel

E347 (ER347 or ER321).

Steel Covered Welding Electrodes

6. Chemical Composition

A5.9 Corrosion-Resisting Chromium and Chromium-Nickel

Steel Welding Rods and Bare Electrodes

6.1 The steel shall conform to requirements of chemical

2.6 SAE Standard:

composition for the respective material prescribed in Table 3.

J1086 Unified Numbering System for Metals and Alloys

6.2 The purchaser may make a product analysis on products

made to this specification in accordance with Specification

3. Ordering Information

A960/A960M.

3.1 See Specification A960/A960M and the following:

6.3 The steel shall not contain any unspecified elements for

3.1.1 Dimensions (outside diameter and specified wall

the ordered grade to the extent that it conforms to the

thickness, see Table 1 and Table 2),

requirements of another grade for which that element is a

3.1.2 Grade (Table 3), and

specified element having a required minimum content.

3.1.3 End use, if known.

6.4 Mill certificates of analysis of each heat of steel shall be

4. General Requirements

furnished on request.

4.1 Product furnished to this specification shall conform to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A774/A774M − 14 A774/A774M − 14 (Reapproved 2019)

Standard Specification for

As-Welded Wrought Austenitic Stainless Steel Fittings for

General Corrosive Service at Low and Moderate

Temperatures

This standard is issued under the fixed designation A774/A774M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers five grades of as-welded, wrought austenitic stainless steel fittings for low-pressure piping and

intended for low and moderate temperatures and general corrosive service. Users should note that certain corrosive conditions may

restrict the use of one or more grades. For applications requiring a product that requires heat treatment or full pressure rating, refer

to Specification A403/A403M. The term “fittings” applies to butt and socket welding parts such as 45° and 90° elbows, tees,

reducers, wyes, laterals, crosses, and stub ends.

1.2 This specification covers as-welded fittings 3 through 48 in. [75 through 1225 mm] in outside diameter and in nominal wall

thicknesses 0.062 through 0.500 in. [1.6 through 12.7 mm]. Table 1 and Table 2 list the common diameters and nominal thicknesses

of fittings in this specification.

1.3 This specification does not apply to cast fittings. Cast austenitic steel fittings are covered by Specification A351/A351M.

1.4 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. These

supplementary requirements call for additional tests. When desired, one or more of these may be specified in the order.

1.5 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable

“M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 In addition to those reference documents listed in Specification A960/A960M, the following list of standards apply to this

specification:

2.2 ASTM Standards:

A240/A240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and

for General Applications

A351/A351M Specification for Castings, Austenitic, for Pressure-Containing Parts

A403/A403M Specification for Wrought Austenitic Stainless Steel Piping Fittings

A960/A960M Specification for Common Requirements for Wrought Steel Piping Fittings

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved Oct. 1, 2014Dec. 1, 2019. Published October 2014December 2019. Originally approved in 1980. Last previous edition approved in 20132014

as A774/A774M – 13.A774/A774M – 14. DOI: 10.1520/A0774_A0774M-14.10.1520/A0774_A0774M-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A774/A774M − 14 (2019)

2.3 ASME Standard:

Section IX ASME Boiler and Pressure Vessel Code

2.4 MSS Standard:

SP 43 Wrought Stainless Steel Butt Welding Fittings

2.5 AWS Standards:

A5.4 Corrosion-Resisting Chromium and Chromium-Nickel Steel Covered Welding Electrodes

A5.9 Corrosion-Resisting Chromium and Chromium-Nickel Steel Welding Rods and Bare Electrodes

2.6 SAE Standard:

J1086 Unified Numbering System for Metals and Alloys

A

TABLE 1 Common Tubular Fittings Sizes, Outside Diameter

in. [mm] in. [mm]

3 [76] 12 ⁄4 [325]

3 ⁄2 [90] 14 [355]

4 [100] 16 [405]

4 ⁄2 [115] 18 [460]

6 [150] 20 [510]

6 ⁄8 [170] 24 [610]

8 [205] 30 [760]

8 ⁄8 [220] 36 [915]

10 [255] 40 [1015]

10 ⁄4 [275] 42 [1070]

12 [305] 48 [1220]

A

Other sizes may be furnished provided they comply with all other requirements

of this specification.

A

TABLE 2 Common Tubular Fittings Nominal Thicknesses

in. or gauge in. [mm]

16 gauge 0.062 [1.6]

14 gauge 0.078 [2.0]

12 gauge 0.109 [2.8]

11 gauge 0.125 [3.2]

10 gauge 0.140 [3.6]

8 gauge 0.172 [4.4]

⁄16 in. 0.187 [4.8]

⁄4 in. 0.250 [6.4]

⁄16 in. 0.312 [8.0]

⁄8 in. 0.375 [9.5]

⁄2 in. 0.500 [12.5]

A

Other thicknesses may be furnished provided they comply with all other

requirements of this specification.

3. Ordering Information

3.1 See Specification A960/A960M and the following:

3.1.1 Dimensions (outside diameter and specified wall thickness, see Table 1 and Table 2),

3.1.2 Grade (Table 3), and

3.1.3 End use, if known.

4. General Requirements

4.1 Product furnished to this specification shall conform to the requirements of Specification A960/A960M, including any

supplementary requirements that are indicated in the purchase order. Failure to comply with the requirements of Specification

A960/A960M constitutes non-conformance with this specification. In case of a conflict between the requirements of this

specification and Specification A960/A960M, this specification shall prevail.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-hq.com.

Available from American Welding Society (AWS), 550 NW LeJeune Rd., Miami, FL 33126, http://www.aws.org.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

A774/A774M − 14 (2019)

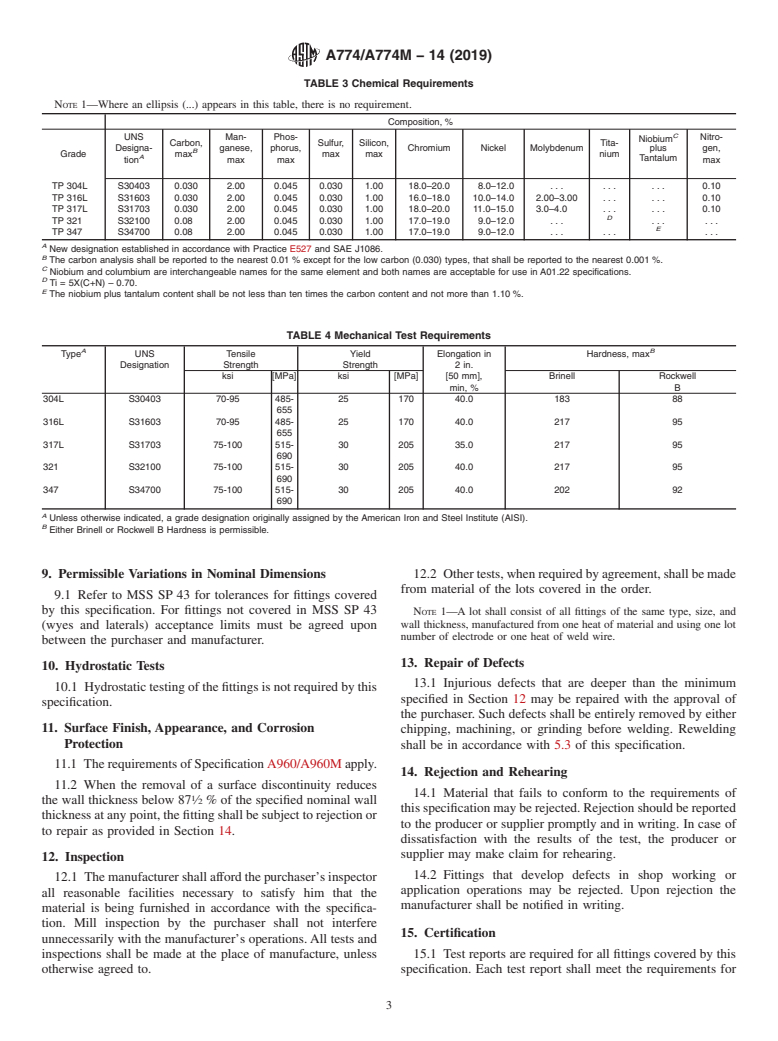

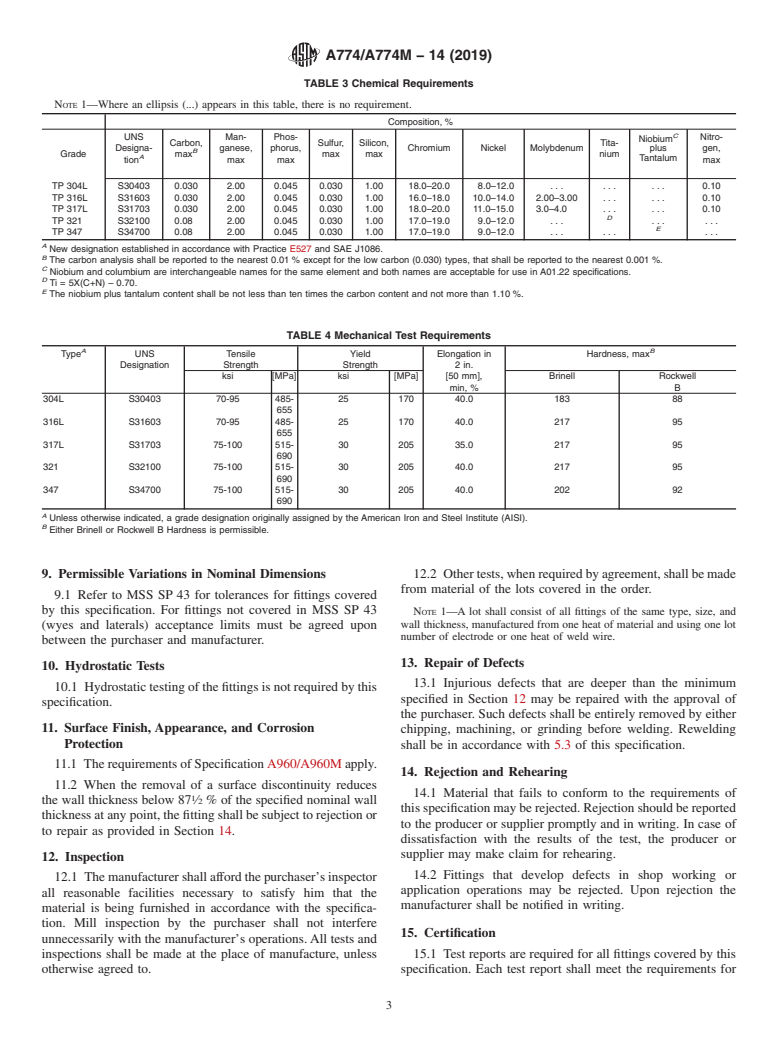

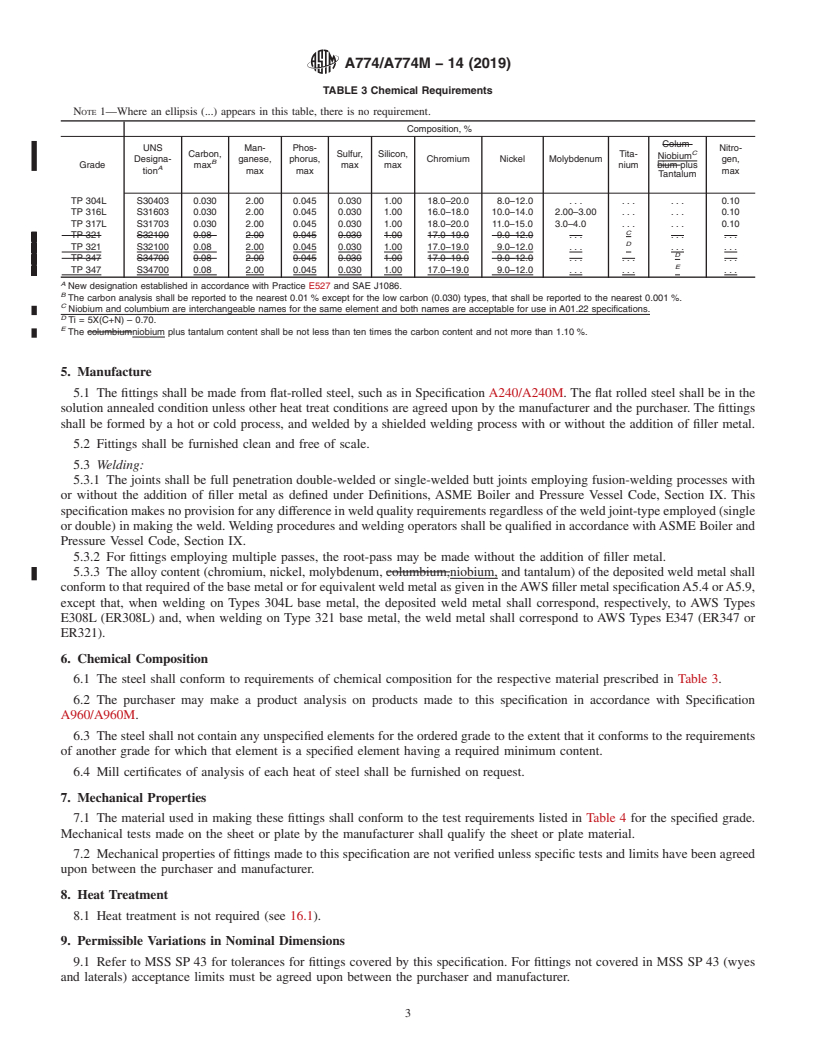

TABLE 3 Chemical Requirements

NOTE 1—Where an ellipsis (.) appears in this table, there is no requirement.

Composition, %

Colum-

UNS Man- Phos- Nitro-

C

Carbon, Sulfur, Silicon, Tita-

Niobium

Designa- ganese, phorus, Chromium Nickel Molybdenum gen,

B

Grade max max max nium bium plus

A

tion max max max

Tantalum

TP 304L S30403 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–12.0 . . . . . . . . . 0.10

TP 316L S31603 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 . . . . . . 0.10

TP 317L S31703 0.030 2.00 0.045 0.030 1.00 18.0–20.0 11.0–15.0 3.0–4.0 . . . . . . 0.10

C

TP 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . . . .

D

TP 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . . . .

D

TP 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . . . .

E

TP 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . . . .

A

New designation established in accordance with Practice E527 and SAE J1086.

B

The carbon analysis shall be reported to the nearest 0.01 % except for the low carbon (0.030) types, that shall be reported to the nearest 0.001 %.

C

Niobium and columbium are interchangeable names for the same element and both names are acceptable for use in A01.22 specifications.

D

Ti = 5X(C+N) – 0.70.

E

The columbiumniobium plus tantalum content shall be not less than ten times the carbon content and not more than 1.10 %.

5. Manufacture

5.1 The fittings shall be made from flat-rolled steel, such as in Specification A240/A240M. The flat rolled steel shall be in the

solution annealed condition unless other heat treat conditions are agreed upon by the manufacturer and the purchaser. The fittings

shall be formed by a hot or cold process, and welded by a shielded welding process with or without the addit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.