ASTM D6817/D6817M-17(2021)

(Specification)Standard Specification for Rigid Cellular Polystyrene Geofoam

Standard Specification for Rigid Cellular Polystyrene Geofoam

ABSTRACT

This specification presents the types, physical properties, and dimensions of rigid cellular polystyrene (RCPS) intended for use as geofoam. This specification, however, does not address the layout, placement, and workmanship for proper installation and performance of the geofoams. RCPS geofoams shall be formed by the expansion of polystyrene resin beads or granules in a molding process (EPS), or by the expansion of polystyrene base resin in an extrusion process (XPS). They may also be manufactured with reprocessed polystyrene foam (regrind). The RCPS geofoams shall meet combustibility and curing requirements and, when tested, shall adhere to physical property requirements such as dimensions and density, compressive resistance, flexural strength, and oxygen index. Final products should also meet surface damage, volume damage, and UV degradation limits.

SCOPE

1.1 This specification covers the types, physical properties, and dimensions of rigid cellular polystyrene intended for use as geofoam.

1.2 This specification does not cover the layout, placement, and workmanship for proper installation and performance of rigid cellular polystyrene geofoam.

1.3 Rigid cellular polystyrene geofoam covered by this specification may need protection from certain chemicals, environmental exposure, and concentrated loads. Additional design considerations may include thermal conductivity and buoyancy. Guidelines regarding these end-use considerations are included in Appendix X1.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6817/D6817M −17 (Reapproved 2021)

Standard Specification for

Rigid Cellular Polystyrene Geofoam

This standard is issued under the fixed designation D6817/D6817M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C165 Test Method for Measuring Compressive Properties of

Thermal Insulations

1.1 This specification covers the types, physical properties,

C203 Test Methods for Breaking Load and Flexural Proper-

anddimensionsofrigidcellularpolystyreneintendedforuseas

ties of Block-Type Thermal Insulation

geofoam.

C303 Test Method for Dimensions and Density of Pre-

1.2 This specification does not cover the layout, placement,

formed Block and Board–Type Thermal Insulation

and workmanship for proper installation and performance of

C390 Practice for Sampling and Acceptance of Thermal

rigid cellular polystyrene geofoam.

Insulation Lots

1.3 Rigid cellular polystyrene geofoam covered by this

C578 Specification for Rigid, Cellular Polystyrene Thermal

specification may need protection from certain chemicals,

Insulation

environmental exposure, and concentrated loads. Additional

D1621 Test Method for Compressive Properties of Rigid

design considerations may include thermal conductivity and

Cellular Plastics

buoyancy. Guidelines regarding these end-use considerations

D1622/D1622M Test Method forApparent Density of Rigid

are included in Appendix X1.

Cellular Plastics

1.4 The values stated in either SI units or inch-pound units

D2863 Test Method for Measuring the Minimum Oxygen

are to be regarded separately as standard. The values stated in

Concentration to Support Candle-Like Combustion of

each system are not necessarily exact equivalents; therefore, to

Plastics (Oxygen Index)

ensure conformance with the standard, each system shall be

D4439 Terminology for Geosynthetics

used independently of the other, and values from the two

D7557/D7557M Practice for Sampling of Expanded Poly-

systems shall not be combined.

styrene Geofoam Specimens

1.5 This standard does not purport to address all of the

E177 Practice for Use of the Terms Precision and Bias in

safety concerns, if any, associated with its use. It is the

ASTM Test Methods

responsibility of the user of this standard to establish appro-

E691 Practice for Conducting an Interlaboratory Study to

priate safety, health, and environmental practices and deter-

Determine the Precision of a Test Method

mine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.1 Definitions:

Development of International Standards, Guides and Recom-

3.1.1 Terms used in this specification are defined in Termi-

mendations issued by the World Trade Organization Technical

nology D4439.

Barriers to Trade (TBT) Committee.

3.1.2 geofoam—block or planar rigid cellular foam poly-

meric material used in geotechnical engineering applications.

2. Referenced Documents

2.1 ASTM Standards: 3.2 Definitions of Terms Specific to This Standard:

3.2.1 EPS, XX—number designation for expanded polysty-

rene geofoam type(s) having a minimum density of XX kg/m

This specification is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.06 on Geosyn-

[lb/ft ].

thetic Specifications.

Current edition approved May 1, 2021. Published May 2021. Originally

3.2.2 RCPS—letter designation for EPS and XPS rigid

approved in 2002. Last previous edition approved in 2017 as D6817/D6817M – 17.

cellular polystyrene geofoam covered by this specification.

DOI: 10.1520/D6817_D6817M-17R21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.3 XPS, XX—number designation for extruded polysty-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

rene geofoam type(s) having a minimum density of XX kg/m

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. [lb/ft ].

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6817/D6817M−17 (2021)

A

TABLE 1 Physical Property Requirements of RCPS Geofoam

Type EPS12 EPS15 EPS19 EPS22 EPS29 EPS39 EPS46 XPS20 XPS21 XPS26 XPS29 XPS36 XPS48

Density, min., 11.2 14.4 18.4 21.6 28.8 38.4 45.7 19.2 20.8 25.6 28.8 35.2 48.0

3 3

kg/m [lb/ft ] [0.70] [0.90] [1.15] [1.35] [1.80] [2.40] [2.85] [1.20] [1.30] [1.60] [1.80] [2.20] [3.00]

Compressive 15 25 40 50 75 103 128 20 35 75 105 160 280

Resistance, [2.2] [3.6] [5.8] [7.3] [10.9] [15.0] [18.6] [2.9] [5.1] [10.9] [15.2] [23.2] [40.6]

min., kPa [psi]

at 1 % strain

Flexural 69 172 207 240 345 414 517 276 276 345 414 517 689

Strength, min., [10.0] [25.0] [30.0] [35] [50.0] [60.0] [75.0] [40.0] [40.0] [50.0] [60.0] [75.0] [100.0]

kPa [psi]

Oxygen Index, 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0

min.,

volume %

A

For products that have an external skin, testing shall be undertaken with skins intact.

4. Ordering Information shown in Table 2. Specific RCPS geofoam block dimensions

vary by manufacturer equipment characteristics.

4.1 Acquisition documents shall specify the following:

4.1.1 Title, number, and year of this specification. 7.2 Dimensional Tolerance—Unlessotherwisespecified,the

4.1.2 Type, as per Table 1. acceptable length, width, thickness, flatness, and squareness

4.1.3 Total product volume required of each type. tolerance criteria on RCPS geofoam shall not exceed 60.5 %.

5. Materials and Manufacture

8. Damage and Degradation

5.1 RCPS geofoam shall be formed by the expansion of

8.1 Damage—RCPSgeofoamasdeliveredtotheprojectsite

polystyrene resin beads or granules in a molding process (EPS)

shall have no defects that will adversely affect its service and

or by the expansion of polystyrene base resin in an extrusion

workability qualities. Material units that manifest unacceptable

process (XPS). RCPS geofoam may be manufactured with

surface or volumetric damage shall be replaced.

reprocessed polystyrene foam (regrind).

8.1.1 Surface Damage—Damage to load-bearing RCPS

geofoam surfaces shall be limited to less than 20 % of the

5.2 RCPS geofoam shall be of uniform density and have

equivalent load-bearing area of the unit.

essentially closed cells. RCPS geofoam is an organic material

8.1.2 Volume Damage—Volumetric damage of RCPS geo-

and is considered combustible. It should not be exposed to

foam shall be limited to less than 1 % of the volume of a single

flames or other ignition sources.

unit.

8.1.3 UV (Ultraviolet) Degradation—Discoloration and

6. Qualification Requirements

dusting of RCPS geofoam caused by the extensive exposure to

6.1 The physical properties listed in Table 1 constitute the

sunlight is a defect that will adversely affect its service and is

minimum product qualification requirements for commonly

grounds for rejection. Refer to X1.6.

manufactured types of RCPS geofoam. The compressive resis-

tance at 1 % strain is typically within the elastic limit of the

9. Inspection

geofoam product types in Table 1 and is accepted as the

9.1 Sampling—Unless otherwise specified in the purchase

compressive resistance to limit long-term deformation under

order or contract, the material shall be sampled for inspection

structural load.

in accordance with Practice D7557/D7557M for EPS types or

6.2 RCPS Geofoam Types—It is the user’s responsibility to

Practice C390 for XPS types.

specify the required type as in Table 1 and to obtain supporting

9.2 Weight—Determine the weight of selected full-size units

documentation regarding physical properties from the material

in accordance with Test Method D1622/D1622M, or as speci-

supplier.

fied.

6.3 Combustibility Requirements—All RCPS geofoam shall

9.3 Dimensions—Verify specified dimensions and

contain sufficient flame retardants to meet a minimum oxygen

tolerances, as prescribed in Test Method D1622/D1622M and

index as required in Table 1.

7.2 of this specification.

6.4 Curing—Unless otherwise specified in the contract,

9.4 Density—Compute the density of test samples in accor-

RCPS geofoam shall be cured for a minimum of 24 h before

dance with Test Method D1622/D1622M.

delivery and inspection.

7. Availability and Dimensional Tolerance 10. Acceptance or Rejection

7.1 Availability—The RCPS geofoam materials covered by 10.1 Material that fails to conform to this specification shall

this specification are commonly available in the size range be rejected promptly in writing. The manufacturer or supplier

D6817/D6817M−17 (2021)

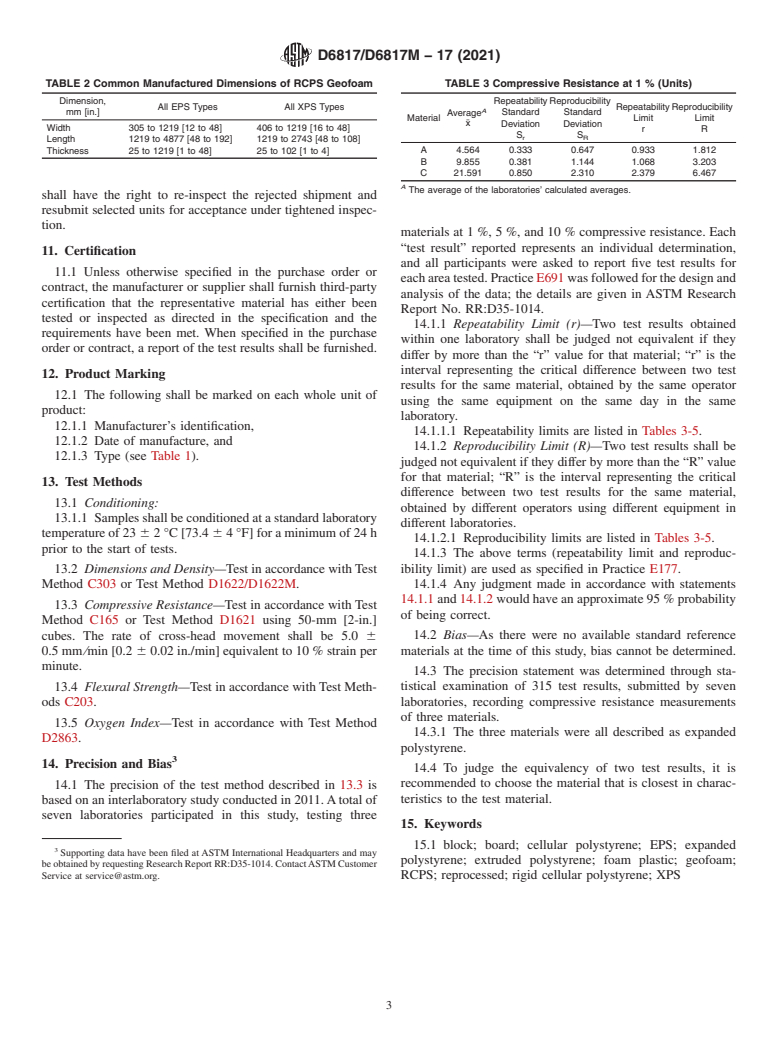

TABLE 2 Common Manufactured Dimensions of RCPS Geofoam TABLE 3 Compressive Resistance at 1 % (Units)

Dimension, RepeatabilityReproducibility

All EPS Types All XPS Types RepeatabilityReproducibility

A

mm [in.] Standard Standard

Average

Materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.