ASTM D3005-24

(Specification)Standard Specification for Low-Temperature Resistant Vinyl Chloride Plastic Pressure-Sensitive Electrical Insulating Tape

Standard Specification for Low-Temperature Resistant Vinyl Chloride Plastic Pressure-Sensitive Electrical Insulating Tape

ABSTRACT

This specification covers the properties and requirements for electrical insulating tape consisting of a backing of vinyl chloride plastic, coated on one side with a pressure-sensitive adhesive, for use at low temperatures. Four types are included providing two thicknesses at two operating temperatures. Selected from standard widths and lengths, the tapes shall conform to specified values of the following requirements: break strength; break and static elongation; dielectric breakdown; adhesion to both steel and backing; roll unwind; high-humidity insulation resistance; flammability; and behavior during flagging test.

SCOPE

1.1 This specification covers an electrical insulating tape for use at low temperature down to approximately -18 °C (0 °F). The tape consists of a backing of vinyl chloride plastic, coated on one side with a pressure-sensitive adhesive. Four types are included providing two thicknesses at two operating temperatures.

1.2 The values stated in SI units are the standard. The values given in parentheses are provided for information purposes only.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3005 − 24

Standard Specification for

Low-Temperature Resistant Vinyl Chloride Plastic Pressure-

1

Sensitive Electrical Insulating Tape

This standard is issued under the fixed designation D3005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 Type I—0.0178 mm (0.007 in.) standard backing for

use at low temperature down to -7 °C (19.4 °F).

1.1 This specification covers an electrical insulating tape for

4.1.2 Type II—0.216 mm (0.0085 in.) standard backing for

use at low temperature down to approximately -18 °C (0 °F).

use at low temperature down to -7 °C (19.4 °F).

The tape consists of a backing of vinyl chloride plastic, coated

4.1.3 Type III—0.0178 mm (0.007 in.) standard backing for

on one side with a pressure-sensitive adhesive. Four types are

use at low temperature down to -18 °C (0 °F).

included providing two thicknesses at two operating tempera-

4.1.4 Type IV—0.216 mm (0.0085 in.) standard backing for

tures.

use at low temperature down to -18 °C (0 °F).

1.2 The values stated in SI units are the standard. The values

5. Materials

given in parentheses are provided for information purposes

only.

5.1 The backing shall be vinyl chloride plastic, suitably

compounded to meet the requirements of this specification.

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard- The backing shall be smooth and uniform. The tape edges shall

be straight and unbroken.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.2 The pressure-sensitive adhesive coating shall be smooth

mendations issued by the World Trade Organization Technical

and uniform, and essentially free of lumps and bare spots.

Barriers to Trade (TBT) Committee.

There shall be no adhesive transfer when the tape is unwound

from the roll.

2. Referenced Documents

6. Physical Properties

2

2.1 ASTM Standards:

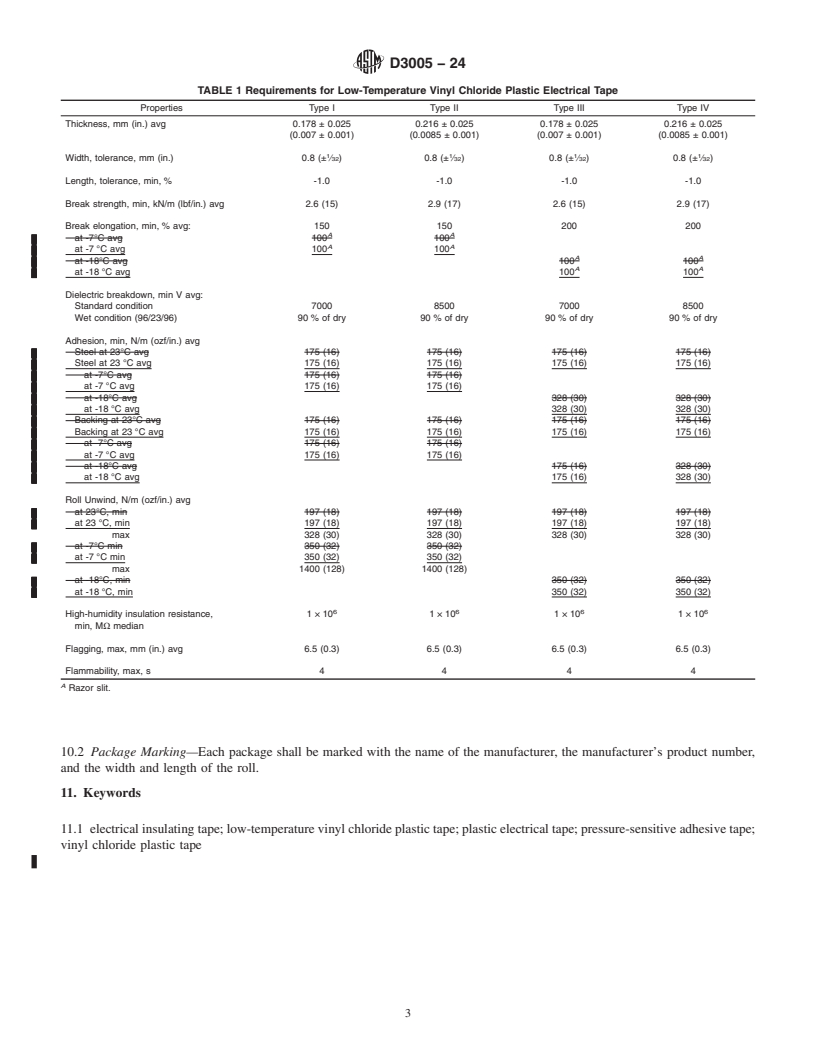

6.1 The tape shall meet the requirements given in Table 1.

D1000 Test Methods for Pressure-Sensitive Adhesive-

Coated Tapes Used for Electrical and Electronic Applica-

6.2 Black plastic backing shall be considered standard.

tions

Backing of a different color than black shall be specified on the

D1711 Terminology Relating to Electrical Insulation

purchase order.

7. Standard Rolls

3. Terminology

7.1 The standard widths and lengths shall be selected from

3.1 Definitions—For definitions of terms in this specifica-

the following:

tion refer to Terminology D1711.

7.1.1 Widths:

4. Classification mm in. mm in.

1 7

6 ⁄4 22 ⁄8

4.1 This specification covers two types of vinyl chloride 3

9 ⁄8 25 1

1 1

12 ⁄2 30 1 ⁄4

plastic tape of different thicknesses, as follows:

5 1

15 ⁄8 38 1 ⁄2

3

19 ⁄4 50 2

7.1.1.1 Widths greater than 2 in. (50 mm) shall be agreed

1

This specification is under the jurisdiction of ASTM Committee D09 on

upon between the purchaser and the seller.

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.07 on Electrical Insulating Materials. 7.1.2 Lengths:

Current edition approved March 1, 2024. Published March 2024. Originally

m ft

approved in 1972. Last previous edition approved in 2017 as D3005 – 17. DOI:

6 22

10.1520/D3005-24.

20 66

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

33 108

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1.2.1 Additional lengths shall be agreed upon between the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. purchaser and seller.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3005 − 24

TABLE 1 Requirements for Low-Temperature Vinyl Chloride Plastic Electrical Tape

Properties Type I Type II Type III Type IV

Thickness, mm (in.) avg 0.178 ± 0.025 0.216 ± 0.025 0.178 ± 0.025 0.216 ± 0.025

(0.007 ± 0.001) (0.0085 ± 0.001) (0.007 ± 0.001) (0.0085 ± 0.001)

1 1 1 1

Width, tolerance, mm (in.) 0.8 (± ⁄32) 0.8 (± ⁄32) 0.8 (± ⁄32) 0.8 (± ⁄32)

Length, tolerance, min, % -1.0 -1.0 -1.0 -1.0

Break strength, min, kN/m (lbf/in.) avg 2.6 (15) 2.9 (17) 2.6 (15) 2.9 (17)

Break elongation, min, % avg: 150 150 200 200

A A

at -7 °C avg 100 100

A A

at -18 °C avg 100 100

Dielectric breakdown, min V avg:

Standard condition 7000 8500 7000 8500

Wet condition (96/23/96)

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3005 − 17 D3005 − 24

Standard Specification for

Low-Temperature Resistant Vinyl Chloride Plastic Pressure-

1

Sensitive Electrical Insulating Tape

This standard is issued under the fixed designation D3005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers an electrical insulating tape for use at low temperature down to approximately -18°C (0°F).-18 °C

(0 °F). The tape consists of a backing of vinyl chloride plastic, coated on one side with a pressure-sensitive adhesive. Four types

are included providing two thicknesses at two operating temperatures.

1.2 The values stated in SI units are the standard. The values given in parentheses are provided for information purposes only.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1000 Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

D1711 Terminology Relating to Electrical Insulation

3. Terminology

3.1 Definitions—For definitions of terms in this specification refer to Terminology D1711.

4. Classification

4.1 This specification covers two types of vinyl chloride plastic tape of different thicknesses, as follows:

4.1.1 Type I—0.0178-mm (0.007-in.)0.0178 mm (0.007 in.) standard backing for use at low temperature down to -7°C

(19.4°F).-7 °C (19.4 °F).

4.1.2 Type II—0.216-mm (0.0085-in.)0.216 mm (0.0085 in.) standard backing for use at low temperature down to -7°C

(19.4°F).-7 °C (19.4 °F).

1

This specification is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.07 on Electrical Insulating Materials.

Current edition approved Feb. 15, 2017March 1, 2024. Published February 2017March 2024. Originally approved in 1972. Last previous edition approved in 20102017

as D3005 – 10.D3005 – 17. DOI: 10.1520/D3005-17.10.1520/D3005-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3005 − 24

4.1.3 Type III—0.0178-mm (0.007-in.)0.0178 mm (0.007 in.) standard backing for use at low temperature down to -18°C

(0°F).-18 °C (0 °F).

4.1.4 Type IV—0.216-mm (0.0085-in.)0.216 mm (0.0085 in.) standard backing for use at low temperature down to -18°C

(0°F).-18 °C (0 °F).

5. Materials

5.1 The backing shall be vinyl chloride plastic, suitably compounded to meet the requirements of this specification. The backing

shall be smooth and uniform. The tape edges shall be straight and unbroken.

5.2 The pressure-sensitive adhesive coating shall be smooth and uniform, and essentially free of lumps and bare spots. There shall

be no adhesive transfer when the tape is unwound from the roll.

6. Physical Properties

6.1 The tape shall meet the requirements given in Table 1.

6.2 Black plastic backing shall be considered standard. Backing of a different color than black shall be specified on the purchase

order.

7. Standard Rolls

7.1 The standard widths and lengths shall be selected from the following:

7.1.1 Widths:

mm in. mm in.

1 7

6 ⁄4 22 ⁄8

3

9 ⁄8 25 1

1 1

12 ⁄2 30 1 ⁄4

5 1

15 ⁄8 38 1 ⁄2

3

19 ⁄4 50 2

7.1.1.1 Widths greater than 2 in. (50 mm) shall be agreed upon between the purchaser and the seller.

7.1.2 Lengths:

m ft

6 22

20 66

33 108

7.1.2.1 Lengths greater than 33 m (108 ft) shall be in multiples of 108 ft. Additional lengths shall be agreed upon between the

purchaser and seller.

8. Test Methods

8.1 The selection of rolls, conditioning, and testing shall be in accordance with Test Methods D1000.

9. Rejection

9.1 If the test results of any roll do not conform to the requirements

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.