ASTM E606-92(2004)e1

(Practice)Standard Practice for Strain-Controlled Fatigue Testing

Standard Practice for Strain-Controlled Fatigue Testing

SCOPE

1.1 This practice covers the determination of fatigue properties of nominally homogeneous materials by the use of uniaxially loaded test specimens. It is intended as a guide for fatigue testing performed in support of such activities as materials research and development, mechanical design, process and quality control, product performance, and failure analysis. While this practice is intended primarily for strain-controlled fatigue testing, some sections may provide useful information for load-controlled or stress-controlled testing.

1.2 The use of this practice is limited to specimens and does not cover testing of full-scale components, structures, or consumer products.

1.3 This practice is applicable to temperatures and strain rates for which the magnitudes of time-dependent inelastic strains are on the same order or less than the magnitudes of time-independent inelastic strains. No restrictions are placed on environmental factors such as temperature, pressure, humidity, medium, and others, provided they are controlled throughout the test, do not cause loss of or change in dimension with time, and are detailed in the data report. Note 1-The term inelastic is used herein to refer to all nonelastic strains. The term plastic is used herein to refer only to the time-independent (that is, noncreep) component of inelastic strain. To truly determine a time-independent strain the load would have to be applied instantaneously, which is not possible. A useful engineering estimate of time-independent strain can be obtained when the strain rate exceeds some value. For example, a strain rate of 1 X 10 -3 sec -1 is often used for this purpose. This value should increase with increasing test temperature.

1.4 This practice is restricted to the testing of axially loaded uniform gage section test specimens as shown in Fig. 1(a). Testing is limited to strain-controlled cycling. The practice may be applied to hourglass specimens, see Fig. 1(b), but the user is cautioned about uncertainties in data analysis and interpretation. Testing is done primarily under constant amplitude cycling and may contain interspersed hold times at repeated intervals. The practice may be adapted to guide testing for more general cases where strain or temperature may vary according to application specific histories. Data analysis may not follow this practice in such cases.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 606 – 92 (Reapproved 2004)

Standard Practice for

Strain-Controlled Fatigue Testing

This standard is issued under the fixed designation E 606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout in August 2004.

1. Scope repeated intervals. The practice may be adapted to guide

testing for more general cases where strain or temperature may

1.1 This practice covers the determination of fatigue prop-

vary according to application specific histories. Data analysis

erties of nominally homogeneous materials by the use of test

may not follow this practice in such cases.

specimens subjected to uniaxial forces. It is intended as a guide

for fatigue testing performed in support of such activities as

2. Referenced Documents

materials research and development, mechanical design, pro-

2.1 ASTM Standards:

cess and quality control, product performance, and failure

A 370 Test Methods and Definitions for Mechanical Testing

analysis. While this practice is intended primarily for strain-

of Steel Products

controlled fatigue testing, some sections may provide useful

E 3 Practice for Preparation of Metallographic Specimens

information for force-controlled or stress-controlled testing.

E 4 Practices for Force Verification of Testing Machines

1.2 The use of this practice is limited to specimens and does

E 8 Test Methods for Tension Testing of Metallic Materials

not cover testing of full-scale components, structures, or

E 9 Test Methods of Compression Testing of Metallic Ma-

consumer products.

terials at Room Temperature

1.3 This practice is applicable to temperatures and strain

E 83 Practice for Verification and Classification of Exten-

rates for which the magnitudes of time-dependent inelastic

someter System

strains are on the same order or less than the magnitudes of

E 111 Test Method for Young’s Modulus, Tangent Modulus,

time-independent inelastic strains. No restrictions are placed

and Chord Modulus

on environmental factors such as temperature, pressure, hu-

E 112 Test Methods for Determining Average Grain Size

midity, medium, and others, provided they are controlled

E 132 Test Method for Poisson’s Ratio at Room Tempera-

throughout the test, do not cause loss of or change in dimension

ture

with time, and are detailed in the data report.

E 157 Practice for Assigning Crystallographic Phase Desig-

NOTE 1—The term inelastic is used herein to refer to all nonelastic

nations in Metallic Systems

strains. The term plastic is used herein to refer only to the time-

E 209 Practice for Compression Tests of Metallic Materials

independent (that is, noncreep) component of inelastic strain. To truly

at Elevated Temperatures with Conventional or Rapid

determine a time-independent strain the force would have to be applied

Heating Rates and Strain Rates

instantaneously, which is not possible. A useful engineering estimate of

E 337 Test Method for Measuring Humidity with a Psy-

time-independent strain can be obtained when the strain rate exceeds some

−3 −1

value. For example, a strain rate of 1 3 10 sec is often used for this chrometer (the Measurement of Wet- and Dry-Bulb Tem-

purpose. This value should increase with increasing test temperature.

peratures)

E 384 Test Method for Microindentation Hardness of Ma-

1.4 This practice is restricted to the testing of uniform gage

terials

section test specimens subjected to axial forces as shown in

E 399 Test Method for Plane-Strain Fracture Toughness of

Fig. 1(a). Testing is limited to strain-controlled cycling. The

Metallic Materials

practice may be applied to hourglass specimens, see Fig. 1(b),

E 466 Practice for Conducting Force Controlled Constant

but the user is cautioned about uncertainties in data analysis

Amplitude Axial Fatigue Tests of Metallic Materials

and interpretation. Testing is done primarily under constant

amplitude cycling and may contain interspersed hold times at

1 2

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Deformation and Fatigue Crack Formation. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2004. Published July 2004. Originally approved the ASTM website.

in 1977. Last previous edition approved in 1998 as E 606 – 92(1998). Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E 606 – 92 (2004)

NOTE 1—* Dimension d is recommended to be 6.35 mm (0.25 in.). See 7.1. Centers permissible. ** This diameter may be made greater or less than

2d depending on material hardness. In typically ductile materials diameters less than 2d are often employed and in typically brittle materials diameters

greater than 2d may be found desirable.

FIG. 1 Recommended Low-Cycle Fatigue Specimens

E 467 Practice for Verification of Constant Amplitude Dy- 3.2.2 inelastic strain, e —the strain that is not elastic. For

in

namic Forces in an Axial Fatigue Testing System isothermal conditions, e is calculated by subtracting the

in

E 468 Practice for Presentation of Constant Amplitude Fa-

elastic strain from the total strain.

tigue Test Results for Metallic Materials

3.2.3 total cycle period, t —the time for the completion of

t

E 739 Practice for Statistical Analysis of Linear or Linear-

one cycle. The parameter t can be separated into hold and

t

ized Stress-Life (S-N) and Strain-Life (e-N) Fatigue Data

nonhold components:

E 1012 Practice for Verification of Specimen Alignment

t 5 (t 1 (t (1)

t h nh

Under Tensile Loading

E 1049 Practices for Cycle Counting in Fatigue Analysis

where:

E 1823 Terminology Realating to Fatigue and Fracture

(t = sum of all the hold portions of the cycle and

h

Testing

(t = sum of all the nonhold portions of the cycle.

nh

t also is equal to the reciprocal of the overall frequency when

t

3. Terminology

the frequency is held constant.

3.1 The definitions in this practice are in accordance with

3.2.4 The following equations are often used to define the

Terminology E 1823.

instantaneous stress and strain relationships for many metals

3.2 Additional definitions associated with time-dependent

and alloys:

deformation behavior observed in tests at elevated homologous

e5e 1e (2)

in e

temperatures are as follows:

3.2.1 hold period, t —the time interval within a cycle

s

h

e 5 ~see Note 2!

e

during which the stress or strain is held constant.

E*

e1

E 606 – 92 (2004)

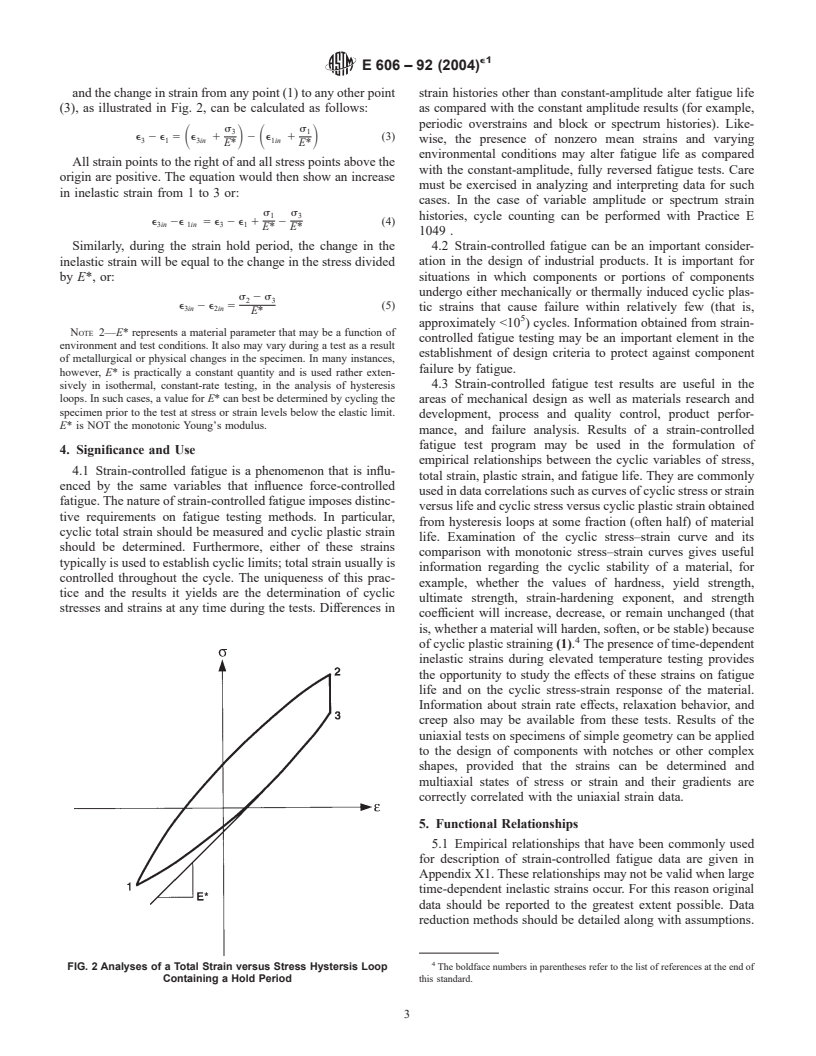

and the change in strain from any point (1) to any other point strain histories other than constant-amplitude alter fatigue life

(3), as illustrated in Fig. 2, can be calculated as follows: as compared with the constant amplitude results (for example,

periodic overstrains and block or spectrum histories). Like-

s s

3 1

e 2e 5 e 1 2 e 1 (3)

S D S D

3 1 3in 1in wise, the presence of nonzero mean strains and varying

E* E*

environmental conditions may alter fatigue life as compared

All strain points to the right of and all stress points above the

with the constant-amplitude, fully reversed fatigue tests. Care

origin are positive. The equation would then show an increase

must be exercised in analyzing and interpreting data for such

in inelastic strain from 1 to 3 or:

cases. In the case of variable amplitude or spectrum strain

s s

1 3

histories, cycle counting can be performed with Practice E

e 2e 5e 2e 1 2 (4)

3in 1in 3 1

E* E*

1049 .

Similarly, during the strain hold period, the change in the 4.2 Strain-controlled fatigue can be an important consider-

inelastic strain will be equal to the change in the stress divided ation in the design of industrial products. It is important for

by E*, or: situations in which components or portions of components

undergo either mechanically or thermally induced cyclic plas-

s 2s

2 3

e 2e 5 (5)

3in 2in tic strains that cause failure within relatively few (that is,

E*

approximately <10 ) cycles. Information obtained from strain-

NOTE 2—E* represents a material parameter that may be a function of

controlled fatigue testing may be an important element in the

environment and test conditions. It also may vary during a test as a result

establishment of design criteria to protect against component

of metallurgical or physical changes in the specimen. In many instances,

failure by fatigue.

however, E* is practically a constant quantity and is used rather exten-

4.3 Strain-controlled fatigue test results are useful in the

sively in isothermal, constant-rate testing, in the analysis of hysteresis

loops. In such cases, a value for E* can best be determined by cycling the

areas of mechanical design as well as materials research and

specimen prior to the test at stress or strain levels below the elastic limit.

development, process and quality control, product perfor-

E* is NOT the monotonic Young’s modulus.

mance, and failure analysis. Results of a strain-controlled

fatigue test program may be used in the formulation of

4. Significance and Use

empirical relationships between the cyclic variables of stress,

4.1 Strain-controlled fatigue is a phenomenon that is influ-

total strain, plastic strain, and fatigue life. They are commonly

enced by the same variables that influence force-controlled

used in data correlations such as curves of cyclic stress or strain

fatigue. The nature of strain-controlled fatigue imposes distinc-

versus life and cyclic stress versus cyclic plastic strain obtained

tive requirements on fatigue testing methods. In particular,

from hysteresis loops at some fraction (often half) of material

cyclic total strain should be measured and cyclic plastic strain

life. Examination of the cyclic stress–strain curve and its

should be determined. Furthermore, either of these strains

comparison with monotonic stress–strain curves gives useful

typically is used to establish cyclic limits; total strain usually is

information regarding the cyclic stability of a material, for

controlled throughout the cycle. The uniqueness of this prac-

example, whether the values of hardness, yield strength,

tice and the results it yields are the determination of cyclic

ultimate strength, strain-hardening exponent, and strength

stresses and strains at any time during the tests. Differences in

coefficient will increase, decrease, or remain unchanged (that

is, whether a material will harden, soften, or be stable) because

of cyclic plastic straining (1). The presence of time-dependent

inelastic strains during elevated temperature testing provides

the opportunity to study the effects of these strains on fatigue

life and on the cyclic stress-strain response of the material.

Information about strain rate effects, relaxation behavior, and

creep also may be available from these tests. Results of the

uniaxial tests on specimens of simple geometry can be applied

to the design of components with notches or other complex

shapes, provided that the strains can be determined and

multiaxial states of stress or strain and their gradients are

correctly correlated with the uniaxial strain data.

5. Functional Relationships

5.1 Empirical relationships that have been commonly used

for description of strain-controlled fatigue data are given in

Appendix X1. These relationships may not be valid when large

time-dependent inelastic strains occur. For this reason original

data should be reported to the greatest extent possible. Data

reduction methods should be detailed along with assumptions.

FIG. 2 Analyses of a Total Strain versus Stress Hystersis Loop The boldface numbers in parentheses refer to the list of references at the end of

Containing a Hold Period this standard.

e1

E 606 – 92 (2004)

Sufficient information should be developed and reported to of the specimen ends about axes perpendicular to the specimen

permit analysis, interpretation, and comparison with results for axis. An additional set of gages should be placed away from the

other materials analyzed using currently popular methods.

gage-length center to detect relative lateral displacement of the

5.2 If use is made of hourglass geometries, original data

specimen ends. The lower the bending strain, the more repeat-

should be reported along with results analyzed using the

able the test results will be from specimen to specimen. This is

relationships in Appendix X2.

especially important for materials with low ductility where

much better alignment may be needed (that is, bending strains

6. Methodology

should not exceed 5 % of the minimum strain amplitude).

6.1 Testing Machine—Testing should be conducted with a

NOTE 6—This section refers to Practice E 1012 Type A tests.

tension-compression fatigue testing machine that has been

NOTE 7—Four strain measurements, 90° opposed to each other, are

verified in accordance with Practices E 4 and E 467, unless

required to ensure that bending strains are not large. Utilization of a single

more stringent requirements are called for in this specification.

extensometer with dual axial outputs will allow for only two specimen

The testing machine, together with any fixtures used in the test

loadings to gather the required four strain readings, without the necessity

program, must meet the bending strain criteria in 6.3.1. The

of strain gaging specimens.

machine should be one in which specific measures have been

6.3.2 Several commonly used fixturing techniques are

taken to minimize backlash in the loading train.

shown schematically in Fig. 3. The selection of any one

NOTE 3—Force measuring capability of 45 kN (approximately 10 kips)

fixturing technique depends primarily upon the user’s speci-

or greater would be sufficient for the recommended specimens (Section 7)

men design. Fixtures should be constructed of hardened steel

and most test materials. The machine force capacity used for these

for high strength and abrasion resistance. The collet type grip

specimens would not be required to exceed 110 kN (approximately 25

kips); however, large-capacity fatigue machines may be beneficial because

shown, or other fixturing techniques that provide high preci-

of increased axial stiffness and decreased lateral deflection of these

sion lateral stiffness to hold precise alignment are acceptable.

systems. Achieving a change in axial concentricity of less than o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.