ASTM D3485-22

(Specification)Standard Specification for Coilable High Density Polyethylene (HDPE) Cable in Conduit (CIC)

Standard Specification for Coilable High Density Polyethylene (HDPE) Cable in Conduit (CIC)

SCOPE

1.1 This specification covers cable in conduit (CIC), which is a smooth-walled, coilable, high-density polyethylene (HDPE) conduit (duct) that contains preassembled wires and cables. The outside diameter of the conduit is controlled and the wire or cable encased within may be comprised of single or multiple configurations consisting of electrical/power wires or cables, fiber optic, traditional copper communication, coaxial cable, or any combination thereof. CIC configurations are preassembled into the conduit during the extrusion process and in industry-specific designs for use in commercial, industrial, transportation, government, and utility applications

1.2 This specification does not attempt to identify every possible preassembled conduit/cable configuration but is intended to identify material and minimum assembled product properties for optimizing reliability and service life.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 1: UL 1990 and CSA C22.2 No.327 have a similar scope to D3485; however, there are differences in scope and requirements.

Note 2: End users may elect to field install single or multiple wire or cable configurations into field-installed conduit. In the case where polyethylene conduit is to have the wire or cable configurations field installed, then the more appropriate specifications to select for establishing the conduit’s material, dimensional, workmanship, and property tests would be Specification F2160, UL 651A, CSA C22.2 No.327 or NEMA TC-7.

Note 3: Whenever two sets of values are presented, in different units, the imperial units are the standard, while those in the parentheses (metric units) are provided for informational purposes.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3485 −22 An American National Standard

Standard Specification for

Coilable High Density Polyethylene (HDPE) Cable in Conduit

1

(CIC)

This standard is issued under the fixed designation D3485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This specification covers cable in conduit (CIC), which

ization established in the Decision on Principles for the

is a smooth-walled, coilable, high-density polyethylene

Development of International Standards, Guides and Recom-

(HDPE) conduit (duct) that contains preassembled wires and

mendations issued by the World Trade Organization Technical

cables. The outside diameter of the conduit is controlled and

Barriers to Trade (TBT) Committee.

the wire or cable encased within may be comprised of single or

multiple configurations consisting of electrical/power wires or

2. Referenced Documents

cables, fiber optic, traditional copper communication, coaxial

2

2.1 ASTM Standards:

cable, or any combination thereof. CIC configurations are

D618 Practice for Conditioning Plastics for Testing

preassembled into the conduit during the extrusion process and

D638 Test Method for Tensile Properties of Plastics

in industry-specific designs for use in commercial, industrial,

D790 Test Methods for Flexural Properties of Unreinforced

transportation, government, and utility applications

and Reinforced Plastics and Electrical Insulating Materi-

1.2 This specification does not attempt to identify every

als

possible preassembled conduit/cable configuration but is in-

D792 Test Methods for Density and Specific Gravity (Rela-

tended to identify material and minimum assembled product

tive Density) of Plastics by Displacement

properties for optimizing reliability and service life.

D1238 Test Method for Melt Flow Rates of Thermoplastics

1.3 The values stated in inch-pound units are to be regarded by Extrusion Plastometer

as standard. The values given in parentheses are mathematical

D1505 Test Method for Density of Plastics by the Density-

conversions to SI units that are provided for information only Gradient Technique

and are not considered standard.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

tics

NOTE 1—UL 1990 and CSA C22.2 No.327 have a similar scope to

D1693 Test Method for Environmental Stress-Cracking of

D3485; however, there are differences in scope and requirements.

NOTE 2—End users may elect to field install single or multiple wire or Ethylene Plastics

cable configurations into field-installed conduit. In the case where

D2122 Test Method for Determining Dimensions of Ther-

polyethylene conduit is to have the wire or cable configurations field

moplastic Pipe and Fittings

installed,thenthemoreappropriatespecificationstoselectforestablishing

D2412 Test Method for Determination of External Loading

the conduit’s material, dimensional, workmanship, and property tests

Characteristics of Plastic Pipe by Parallel-Plate Loading

would be Specification F2160, UL 651A, CSA C22.2 No.327 or NEMA

TC-7.

D2444 Practice for Determination of the Impact Resistance

NOTE 3—Whenever two sets of values are presented, in different units,

of Thermoplastic Pipe and Fittings by Means of a Tup

the imperial units are the standard, while those in the parentheses (metric

(Falling Weight)

units) are provided for informational purposes.

D3350 Specification for Polyethylene Plastics Pipe and Fit-

1.4 This standard does not purport to address all of the

tings Materials

safety concerns, if any, associated with its use. It is the

D4883 Test Method for Density of Polyethylene by the

responsibility of the user of this standard to establish appro-

Ultrasound Technique

priate safety, health, and environmental practices and deter-

F2160 Specification for Solid Wall High Density Polyethyl-

mine the applicability of regulatory limitations prior to use.

ene (HDPE) Conduit Based on Controlled Outside Diam-

eter (OD)

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systemsand is the direct responsibility of Subcommittee F17.26 on Olefin

2

Based Pipe. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2022. Published July 2022. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

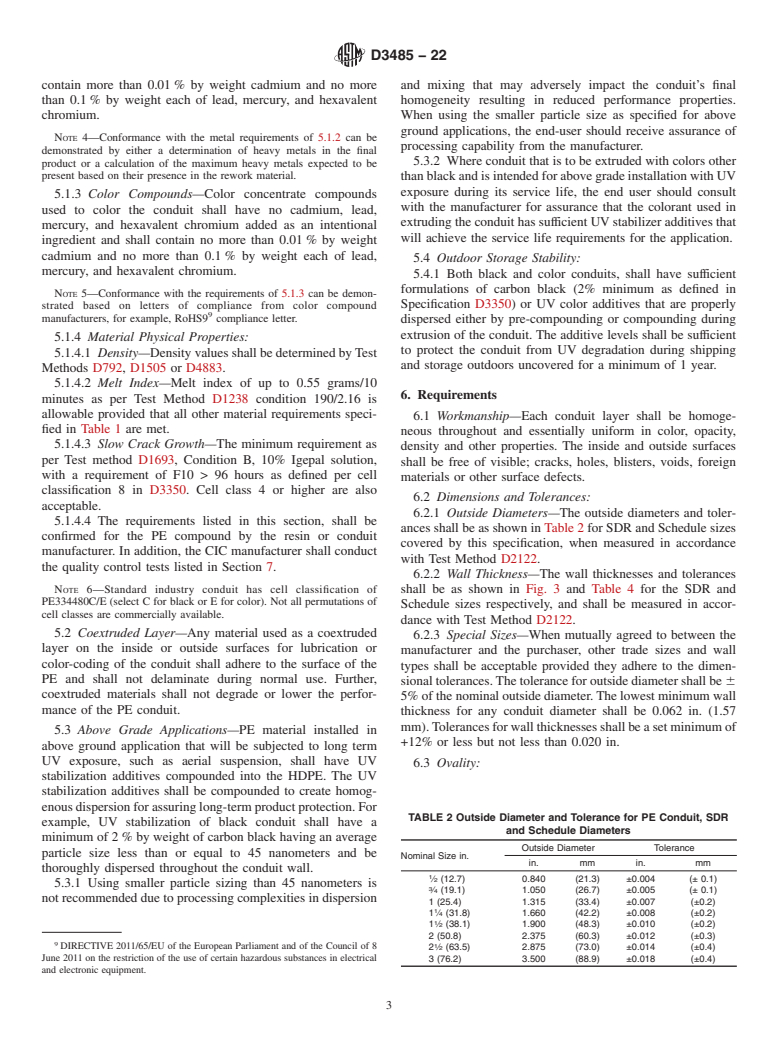

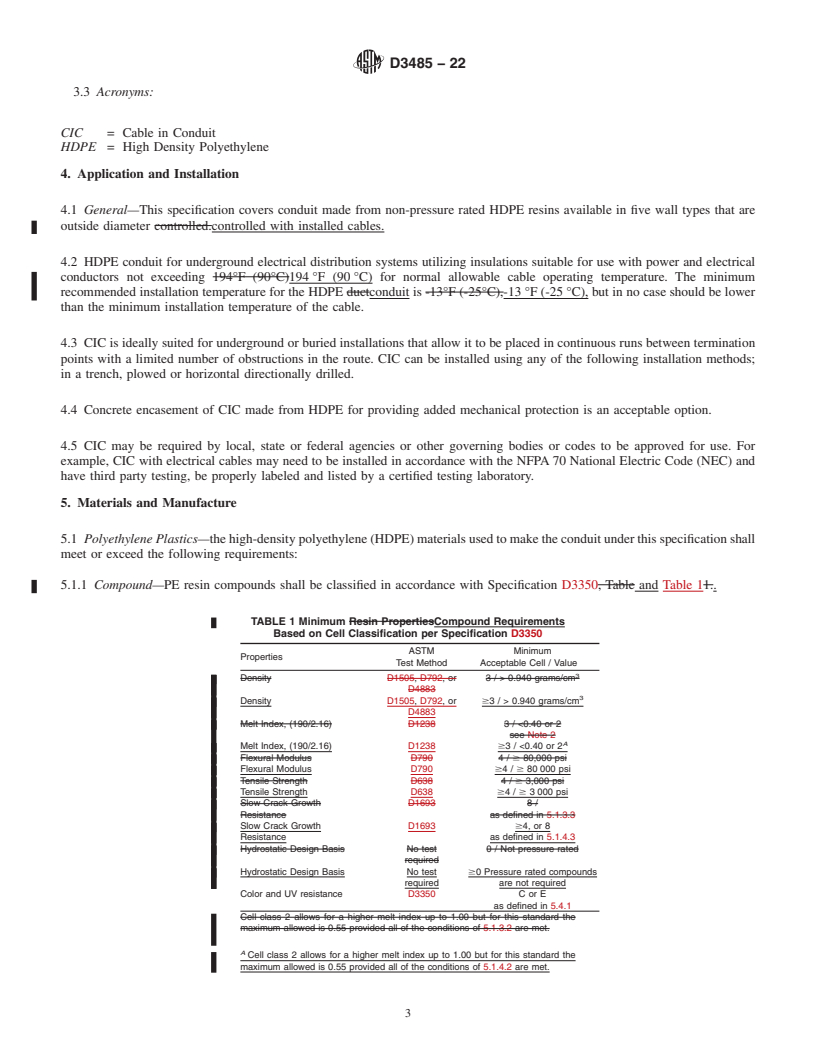

in 1976. Last previous edition app

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3485 − 15 D3485 − 22 An American National Standard

Standard Specification for

Coilable High Density Polyethylene (HDPE) Cable in Conduit

1

(CIC)

This standard is issued under the fixed designation D3485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers cable in conduit (CIC), which is a smooth-walled, coilable, high-density polyethylene (HDPE)

conduit (duct) that contains preassembled wires and cables. The outside diameter of the conduit is controlled and the wire or cable

encased within may be comprised of single or multiple configurations consisting of electrical/power wires or cables, fiber optic,

traditional copper communication, coaxial cable, or any combination thereof. CIC configurations are preassembled into the conduit

during the extrusion process and in industry-specific designs for use in commercial, industrial, transportation, government, and

utility applications

1.2 This specification does not attempt to identify every possible preassembled conduit/cable configuration but is intended to

identify material and minimum assembled product properties for optimizing reliability and service life.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

NOTE 1—Whenever two sets of values are presented, in different units, the imperial units are the standard, while those in the parentheses (metric unites)

are provided for informational purposes.UL 1990 and CSA C22.2 No.327 have a similar scope to D3485; however, there are differences in scope and

requirements.

NOTE 2—End users may elect to field install single or multiple wire or cable configurations into field-installed conduit. In the case where polyethylene

conduit is to have the wire or cable configurations field installed, then the more appropriate specifications to select for establishing the conduit’s material,

dimensional, workmanship, and property tests would be Specification F2160, UL 651A, CSA C22.2 No.327 or NEMA TC-7.

NOTE 3—Whenever two sets of values are presented, in different units, the imperial units are the standard, while those in the parentheses (metric units)

are provided for informational purposes.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systemsand is the direct responsibility of Subcommittee F17.26 on Olefin Based

Pipe.

Current edition approved March 1, 2015July 1, 2022. Published May 2015July 2022. Originally approved in 1976. Last previous edition approved in 20082015 as

D3485– 02 which was withdrawn in July 2011 and reinstated in March 2014. DOI:10.1520/D3485-15.– 15. DOI:10.1520/D3485-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3485 − 22

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1693 Test Method for Environmental Stress-Cracking of Ethylene Plastics

D2122

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.