ASTM D3931-08(2015)

(Test Method)Standard Test Method for Determining Strength of Gap-Filling Adhesive Bonds in Shear by Compression Loading

Standard Test Method for Determining Strength of Gap-Filling Adhesive Bonds in Shear by Compression Loading

SIGNIFICANCE AND USE

4.1 Structural design based on strength-of-materials principles requires knowledge of the mechanical properties of the structural components, including adhesives. By nature of their use, the most important property of adhesive is shear strength.

4.2 Shear strength measured by this test method is suitable for use in adhesive development, manufacturing quality control, and in materials performance specifications, as well as structural design.

SCOPE

1.1 This test method covers the determination of comparative shear properties of gap-filling adhesives in wood-to-wood joints at specified thicknesses of bondline in the dry condition, when tested on standard specimens under specified conditions of preparation, conditioning, and loading in compression. This test method is intended as an evaluation of gap-filling adhesives such as those used to bond plywood to lumber, lumber to lumber, and other similar materials in building constructions.

1.2 This test method also may be used to determine shear properties of gap-filling adhesives in species of wood and in thicknesses of bondline other than those specified for the comparative tests of shear properties within this test method. All procedures specified herein are applicable, excepting requirements for wood species and specific gravity, and thicknesses of bondlines.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3931 − 08 (Reapproved 2015)

Standard Test Method for

Determining Strength of Gap-Filling Adhesive Bonds in

1

Shear by Compression Loading

This standard is issued under the fixed designation D3931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1151 Practice for Effect of Moisture and Temperature on

Adhesive Bonds

1.1 This test method covers the determination of compara-

E171 Practice for Conditioning and Testing Flexible Barrier

tive shear properties of gap-filling adhesives in wood-to-wood

Packaging

joints at specified thicknesses of bondline in the dry condition,

when tested on standard specimens under specified conditions

3. Terminology

of preparation, conditioning, and loading in compression. This

test method is intended as an evaluation of gap-filling adhe-

3.1 Definitions:

sives such as those used to bond plywood to lumber, lumber to

3.1.1 gap-filling adhesive, n—an adhesive capable of form-

lumber, and other similar materials in building constructions.

ing and maintaining a bond between surfaces that are not

1.2 This test method also may be used to determine shear close-fitting.

properties of gap-filling adhesives in species of wood and in

3.1.1.1 Discussion—Close-fitting is relative to a given ma-

thicknesses of bondline other than those specified for the

terial and industry; for example, standards in construction

comparative tests of shear properties within this test method.

differ from standards in electronics. Some adhesives will bond

All procedures specified herein are applicable, excepting re-

by bridging without completely filling the gap; others by filling

quirements for wood species and specific gravity, and thick-

the gap completely.

nesses of bondlines.

1.3 The values stated in inch-pound units are to be regarded 4. Significance and Use

as standard. The values given in parentheses are mathematical

4.1 Structural design based on strength-of-materials prin-

conversions to SI units that are provided for information only

ciples requires knowledge of the mechanical properties of the

and are not considered standard.

structural components, including adhesives. By nature of their

1.4 This standard does not purport to address all of the

use, the most important property of adhesive is shear strength.

safety concerns, if any, associated with its use. It is the

4.2 Shear strength measured by this test method is suitable

responsibility of the user of this standard to establish appro-

for use in adhesive development, manufacturing quality

priate safety and health practices and determine the applica-

control, and in materials performance specifications, as well as

bility of regulatory limitations prior to use.

structural design.

2. Referenced Documents

2 5. Apparatus

2.1 ASTM Standards:

D143 Test Methods for Small Clear Specimens of Timber

5.1 Testing Machine, having a capacity of about 15 000 lb

D905 Test Method for Strength Properties of Adhesive

(6818 kg) in compression or of sufficient capacity to test the

Bonds in Shear by Compression Loading

adhesive in use. The machine shall be fitted with a shearing

tool containing a self-aligning seat to ensure uniform lateral

distribution of the load. The machine shall be capable of

1

This test method is under the jurisdiction of ASTM Committee D14 on maintaining a uniform rate of loading such that the load may be

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

applied with a continuous motion of the movable head to

Adhesives.

maximum load at a rate of 9.20 in. (5.0 mm)/min with a

Current edition approved April 1, 2015. Published April 2015. Originally

permissible variation of 625 %. The shearing tool shown in

approved in 1980. Last previous edition approved in 2008 as D3931 – 08. DOI:

10.1520/D3931-08R15.

Fig. 1 of Test Method D905 has been found satisfactory. Locate

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the testing machine in an atmosphere such that the moisture

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

content of the specimens, developed under the conditions

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. prescribed in 7.3, is not noticeably altered during testing.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3931 − 08 (2015)

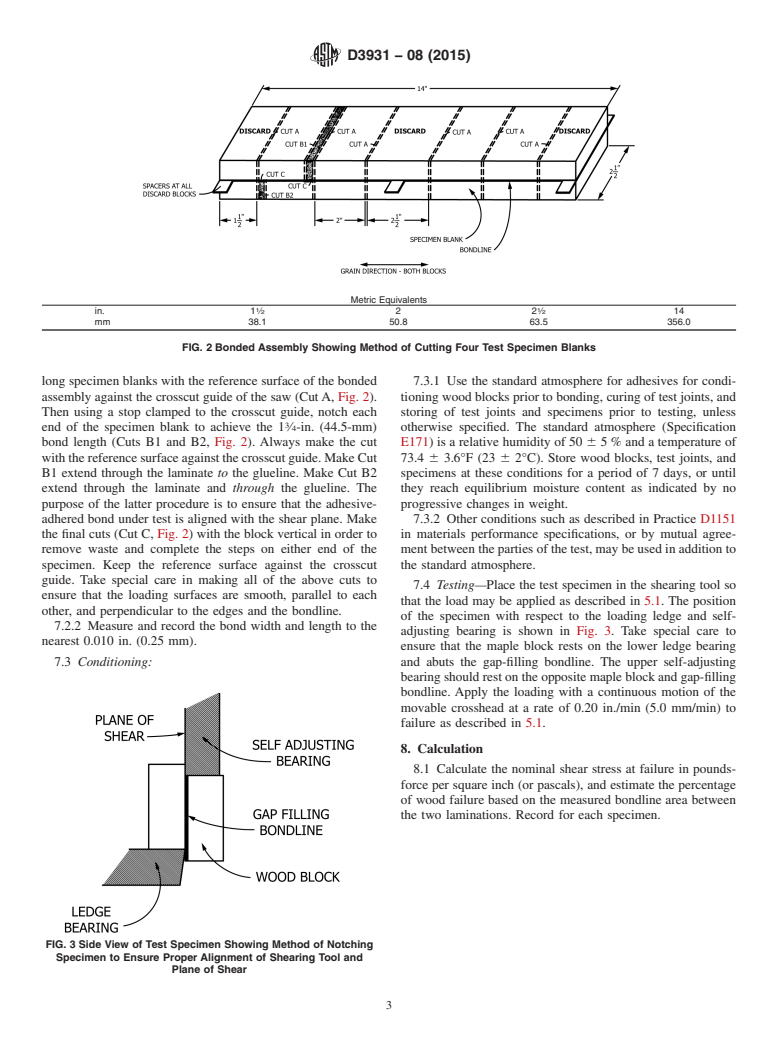

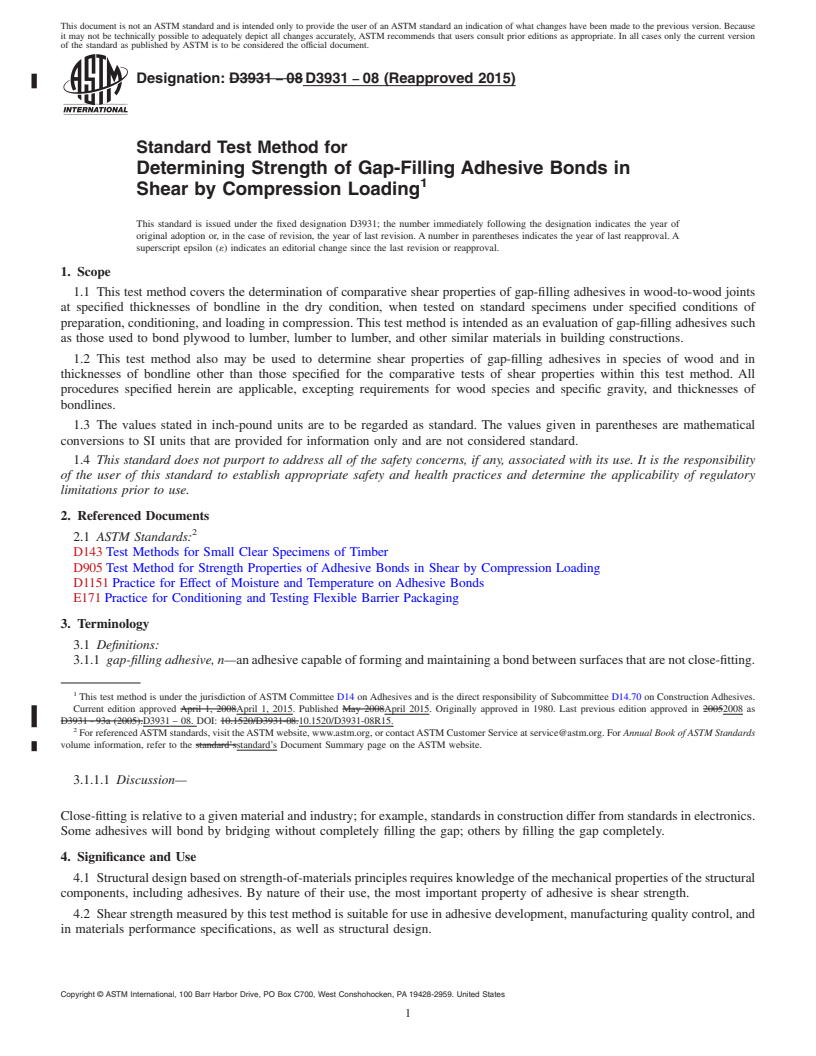

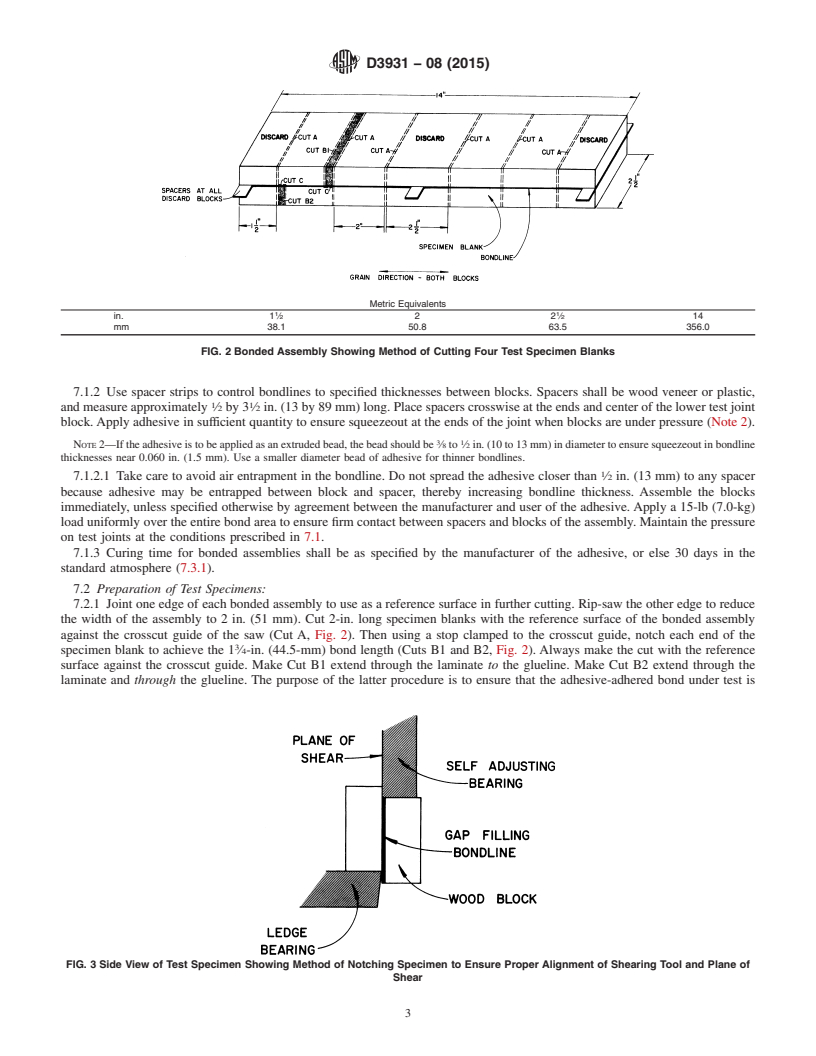

6. Test Specimen and Sample samples in accordance with the final measurement section

under radial and tangential shrinkag

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3931 − 08 D3931 − 08 (Reapproved 2015)

Standard Test Method for

Determining Strength of Gap-Filling Adhesive Bonds in

1

Shear by Compression Loading

This standard is issued under the fixed designation D3931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of comparative shear properties of gap-filling adhesives in wood-to-wood joints

at specified thicknesses of bondline in the dry condition, when tested on standard specimens under specified conditions of

preparation, conditioning, and loading in compression. This test method is intended as an evaluation of gap-filling adhesives such

as those used to bond plywood to lumber, lumber to lumber, and other similar materials in building constructions.

1.2 This test method also may be used to determine shear properties of gap-filling adhesives in species of wood and in

thicknesses of bondline other than those specified for the comparative tests of shear properties within this test method. All

procedures specified herein are applicable, excepting requirements for wood species and specific gravity, and thicknesses of

bondlines.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D143 Test Methods for Small Clear Specimens of Timber

D905 Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading

D1151 Practice for Effect of Moisture and Temperature on Adhesive Bonds

E171 Practice for Conditioning and Testing Flexible Barrier Packaging

3. Terminology

3.1 Definitions:

3.1.1 gap-filling adhesive, n—an adhesive capable of forming and maintaining a bond between surfaces that are not close-fitting.

1

This test method is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction Adhesives.

Current edition approved April 1, 2008April 1, 2015. Published May 2008April 2015. Originally approved in 1980. Last previous edition approved in 20052008 as

D3931 - 93a (2005).D3931 – 08. DOI: 10.1520/D3931-08.10.1520/D3931-08R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

Close-fitting is relative to a given material and industry; for example, standards in construction differ from standards in electronics.

Some adhesives will bond by bridging without completely filling the gap; others by filling the gap completely.

4. Significance and Use

4.1 Structural design based on strength-of-materials principles requires knowledge of the mechanical properties of the structural

components, including adhesives. By nature of their use, the most important property of adhesive is shear strength.

4.2 Shear strength measured by this test method is suitable for use in adhesive development, manufacturing quality control, and

in materials performance specifications, as well as structural design.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3931 − 08 (2015)

5. Apparatus

5.1 Testing Machine, having a capacity of about 15 000 lb (6818 kg) in compression or of sufficient capacity to test the adhesive

in use. The machine shall be fitted with a shearing tool containing a self-aligning seat to ensure uniform lateral distribution of the

load. The machine shall be capable of maintaining a uniform rate of loading such that the load may be applied with a continuous

motion of the movable head to maximum load at a rate of 9.20 in. (5.0 mm)/min with a permissible variation of 625 %. The

shearing tool shown in Fig. 1 of Test Method D905 has been

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.