ASTM B32-08(2014)

(Specification)Standard Specification for Solder Metal

Standard Specification for Solder Metal

ABSTRACT

This specification covers solder metal alloys (also known as soft solders) used in non-electronic applications, including but not limited to, tin-lead, tin-antimony, tin-antimony-copper-silver, tin-antimony-copper-silver-nickel, tin-silver, tin-copper-silver, and lead-tin-silver, used for the purpose of joining together two or more metals at temperatures below their melting points. Included here are solders in the form of solid bars, ingots, powder and special forms, and in the form of solid and flux-core ribbons, wires, and solder pastes. Electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications are not taken into account here. Solder alloys shall adhere to chemical composition requirements specified for the following flux types: Types R, RMA, and RA, which are composed of Grade WW or WG gum rosin; Type OA, which is composed of water-soluble organic materials; Type OS, which is composed of water-insoluble organic materials; and Type IS, which is composed of inorganic saltsor acids. Solders shall also meet physical property requirements such as paste texture, powder mesh size, viscosity, solder pool, and dryness, and pass performance requirements such as chlorides and bromides test, copper mirror test, and visual inspection. Other properties to which the alloys should conform to are dimensions and unit weights, spread factor, and resistivity of water extract.

SCOPE

1.1 This specification covers solder metal alloys (commonly known as soft solders) used in non-electronic applications, including but not limited to, tin-lead, tin-antimony, tin-antimony-copper-silver, tin-antimony-copper-silver-nickel, tin-silver, tin-copper-silver, and lead-tin-silver, used for the purpose of joining together two or more metals at temperatures below their melting points. Electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications are not covered by this specification as they are under the auspices of IPC – Association Connecting Electronic Industries.

1.1.1 These solders include those alloys having a liquidus temperature not exceeding 800°F (430°C).

1.1.2 This specification includes solders in the form of solid bars, ingots, powder and special forms, and in the form of solid and flux-core ribbon, wire, and solder paste.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B32 −08 (Reapproved 2014)

Standard Specification for

Solder Metal

ThisstandardisissuedunderthefixeddesignationB32;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D269Test Method for Insoluble Matter in Rosin and Rosin

Derivatives

1.1 Thisspecificationcoverssoldermetalalloys(commonly

D464Test Methods for Saponification Number of Naval

known as soft solders) used in non-electronic applications,

Store Products Including Tall Oil and Other Related

including but not limited to, tin-lead, tin-antimony, tin-

Products

antimony-copper-silver,tin-antimony-copper-silver-nickel,tin-

D465Test Methods for Acid Number of Naval Stores

silver, tin-copper-silver, and lead-tin-silver, used for the pur-

Products Including Tall Oil and Other Related Products

pose of joining together two or more metals at temperatures

D509Test Methods of Sampling and Grading Rosin

below their melting points. Electronic grade solder alloys and

E28Test Methods for Softening Point of Resins Derived

fluxed and non-fluxed solid solders for electronic soldering

from Pine Chemicals and Hydrocarbons, by Ring-and-

applications are not covered by this specification as they are

Ball Apparatus

undertheauspicesofIPC–AssociationConnectingElectronic

E29Practice for Using Significant Digits in Test Data to

Industries.

Determine Conformance with Specifications

1.1.1 These solders include those alloys having a liquidus

E46Test Methods for Chemical Analysis of Lead- and

temperature not exceeding 800°F (430°C).

Tin-Base Solder (Withdrawn 1994)

1.1.2 Thisspecificationincludessoldersintheformofsolid

E51Method for Spectrographic Analysis of Tin Alloys by

bars,ingots,powderandspecialforms,andintheformofsolid

the Powder Technique (Withdrawn 1983)

and flux-core ribbon, wire, and solder paste.

E55Practice for Sampling Wrought Nonferrous Metals and

1.2 The values stated in inch-pound units are to be regarded

Alloys for Determination of Chemical Composition

as standard. The values given in parentheses are mathematical

E87MethodsforChemicalAnalysisofLead,Tin,Antimony

conversions to SI units that are provided for information only

and Their Alloys (Photometric Method) (Withdrawn

and are not considered standard. 3

1983)

1.3 This standard does not purport to address all of the E88Practice for Sampling Nonferrous Metals andAlloys in

safety concerns, if any, associated with its use. It is the

Cast Form for Determination of Chemical Composition

responsibility of the user of this standard to become familiar

2.2 Federal Standard:

with all hazards including those identified in the appropriate

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

Material Safety Data Sheet (MSDS) for this product/material

2.3 Military Standard:

as provided by the manufacturer, to establish appropriate

MIL-STD-129Marking for Shipment and Storage

safety and health practices, and determine the applicability of

regulatory limitations prior to use.

3. Terminology

2. Referenced Documents 3.1 Definitions:

2 3.1.1 producer, n—the primary manufacturer of the mate-

2.1 ASTM Standards:

rial.

3.2 Definitions of Terms Specific to This Standard:

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

Current edition approved Oct. 1, 2014. Published October 2014. Originally The last approved version of this historical standard is referenced on

approved in 1919. Last previous edition approved in 2008 as B32– 08. DOI: www.astm.org.

10.1520/B0032-08R14. Available from Global Engineering Documents, 15 Inverness Way, East

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Englewood, CO 80112-5704, http://global.ihs.com.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B32−08 (2014)

3.2.1 lot, n—The term “lot” as used in this specification is 7. Chemical Composition

defined as follows:

7.1 Solder Alloy—The solder alloy composition is as speci-

3.2.1.1 Discussion—For solid solder metal, a lot consists of

fied in Table 1.

all solder of the same type designation, produced from the

same batch of raw materials under essentially the same NOTE 1—By mutual agreement between supplier and purchaser, analy-

sis may be required and limits established for elements or compounds not

conditions, and offered for inspection at one time.

specified in Table 1.

3.2.1.2 Discussion—For flux–core solder, a lot consists of

7.2 Flux (applicable to flux-core ribbon, wire, and solder

all solder of the same core mixture, produced from the same

batch of raw materials under essentially the same conditions paste):

and offered for inspection at one time. 7.2.1 Type R—The flux is composed of Grade WW or WG

gum rosin of Test Methods D509. The rosin shall have a

3.2.2 lot number,, n—The term “lot number” as used in this

toluene–insoluble matter content of not more than 0.05

specification refers to an alphanumeric or numerical designa-

weight% in accordance with Test Method D269, a minimum

tion for a lot which is traceable to a date of manufacture.

acid number of 160 mg KOH/1 g sample in accordance with

4. Classification Test Methods D465, a minimum softening point of 70°C in

accordance with Test Methods E28, and a minimum saponifi-

4.1 Type Designation—The type designation uses the fol-

cation number of 166 in accordance with Test Methods D464.

lowing symbols to properly identify the material:

Whensolventsorplasticizersareadded,theymustbenonchlo-

4.1.1 Alloy Composition—The composition is identified by

rinated.

atwo-lettersymbolandanumber.Theletterstypicallyindicate

7.2.2 Type RMA—Thefluxiscomposedofrosinconforming

the chemical symbol for the critical element in the solder and

to 7.2.1. Incorporated additives provide a material meeting the

thenumberindicatesthenominalpercentage,byweight,ofthe

requirements of 8.1.2 for type RMA. When solvents or

critical element in the solder. The designation followed by the

plasticizers are added, they must be nonchlorinated.

letters A or B distinguishes between different alloy grades of

7.2.3 Type RA—The flux is composed of rosin conforming

similar composition (see Table 1).

to 7.2.1. Incorporated additives provide a material meeting the

4.1.2 Form—The form is indicated by a single letter in

requirements of 8.1.2 for Type RA. When solvents or plasti-

accordance with Table 2.

cizers are added, they must be nonchlorinated.

4.1.3 Flux Type—The flux type is indicated by a letter or

7.2.4 Type OA—The flux is composed of one or more

combination of letters in accordance with Table 3.

water-soluble organic materials.

4.1.4 Core Condition and Flux Percentage (applicable only

to flux-cored solder)—The core condition and flux percentage

7.2.5 Type OS—The flux is composed of one or more

is identified by a single letter and a number in accordance with water-insoluble organic materials, other than Types R, RMA,

Table 4.

and RA, which are soluble in organic solvents.

4.1.5 Powder Mesh Size and Flux Percentage (applicable

7.2.6 Type IS—The flux is composed of one or more

only to solder paste)—The powder mesh size and flux percent-

inorganic salts or acids with or without an organic binder and

age is identified by a single letter and a number in accordance

solvents.

with Table 5.

8. Physical Properties and Performance Requirements

5. Ordering Information

8.1 Solder Paste—Solder paste must exhibit smoothness of

5.1 Orders for material under this specification indicate the

texture (no lumps) and the absence of caking and drying.

following information, as required, to adequately describe the

8.1.1 Powder Mesh Size—The solder powder mesh size

desired material.

shall be as specified (see 5.1.1 and 4.1.5) when the extracted

5.1.1 Type designation (see 4.1),

solder powder is tested as specified in 13.4.

5.1.2 Detailed requirements for special forms,

8.1.2 Viscosity—The viscosity of solder paste and the

5.1.3 Dimensions of ribbon and wire solder (see 9.2),

method used to determine the viscosity must be agreed upon

5.1.4 Unit weight,

between the supplier and purchaser. The following variables

5.1.5 Packaging (see Section 18),

must be taken into account when relating one viscosity

5.1.6 Marking (see Section 17),

measurement to another type of viscometer used, spindle size

5.1.7 ASTM specification number and issue, marked on (a)

andshape,speed(r/min),temperatureofsample,andtheuseor

purchase order and (b) package or spool, and

non-use of a helipath.

5.1.8 Special requirements, as agreed upon between sup-

plier and purchaser.

8.2 Requirements for Flux—Thefluxmustmeetthephysical

and performance requirements specified in Table 6 as appli-

6. Materials and Manufacture

cable.

6.1 The producer must have each lot of solder metal as 8.2.1 Solder Pool—When solder is tested as specified in

uniforminqualityaspracticableandofsatisfactoryappearance 13.3.2, there must be no spattering, as indicated by the

in accordance with best industrial practices. Each bar, ingot, or presenceoffluxparticlesoutsidethemainpoolofresidue.The

other form in which the solder is sold must be uniform in flux must promote spreading of the molten solder over the

composition with the entire lot. coupon to form integrally thereon a coat of solder that shall

B32−08 (2014)

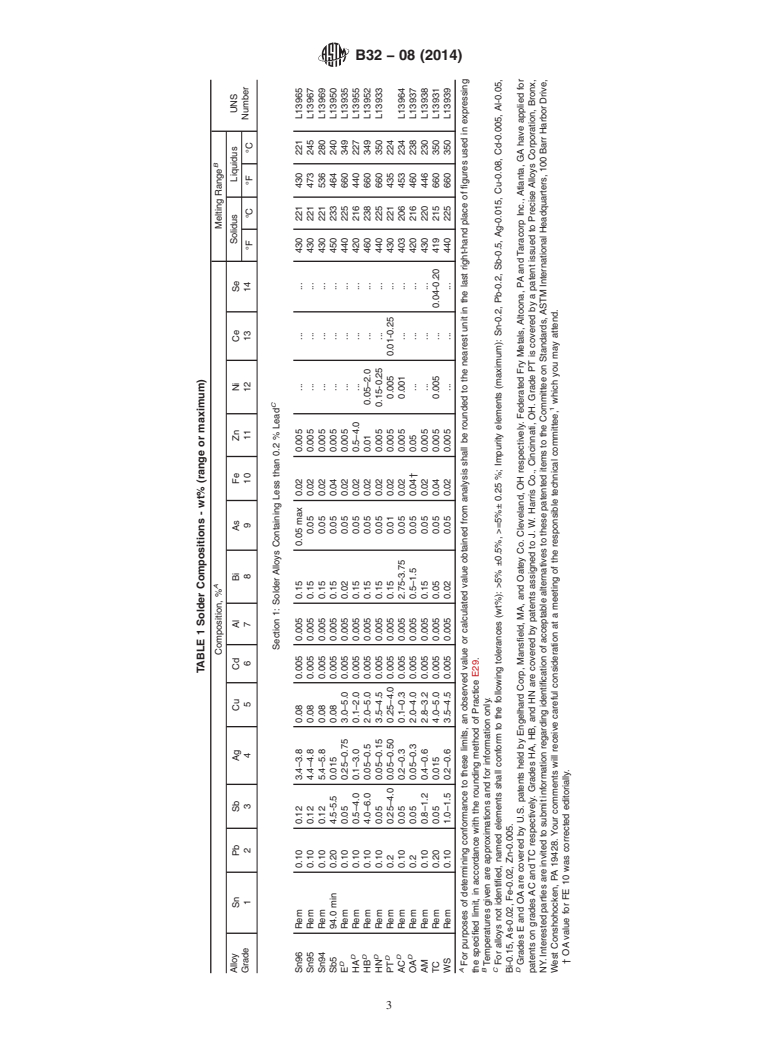

TABLE 1 Solder Compositions - wt% (range or maximum)

A B

Composition, % Melting Range

Alloy Solidus Liquidus UNS

Sn Pb Sb Ag Cu Cd Al Bi As Fe Zn Ni Ce Se

Grade Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14

°F °C °F °C

C

Section 1: Solder Alloys Containing Less than 0.2 % Lead

Sn96 Rem 0.10 0.12 3.4–3.8 0.08 0.005 0.005 0.15 0.05 max 0.02 0.005 . . . 430 221 430 221 L13965

Sn95 Rem 0.10 0.12 4.4–4.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 473 245 L13967

Sn94 Rem 0.10 0.12 5.4–5.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 536 280 L13969

Sb5 94.0 min 0.20 4.5-5.5 0.015 0.08 0.005 0.005 0.15 0.05 0.04 0.005 . . . 450 233 464 240 L13950

D

E Rem 0.10 0.05 0.25–0.75 3.0–5.0 0.005 0.005 0.02 0.05 0.02 0.005 . . . 440 225 660 349 L13935

D

HA Rem 0.10 0.5–4.0 0.1–3.0 0.1–2.0 0.005 0.005 0.15 0.05 0.02 0.5–4.0 . . . 420 216 440 227 L13955

D

HB Rem 0.10 4.0–6.0 0.05–0.5 2.0–5.0 0.005 0.005 0.15 0.05 0.02 0.01 0.05–2.0 . . 460 238 660 349 L13952

D

HN Rem 0.10 0.05 0.05–0.15 3.5–4.5 0.005 0.005 0.15 0.05 0.02 0.005 0.15-0.25 . . 440 225 660 350 L13933

D

PT Rem 0.2 0.25–4.0 0.05–0.50 0.25–4.0 0.005 0.005 0.15 0.01 0.02 0.005 0.005 0.01-0.25 . 430 221 435 224

D

AC Rem 0.10 0.05 0.2–0.3 0.1–0.3 0.005 0.005 2.75-3.75 0.05 0.02 0.005 0.001 . . 403 206 453 234 L13964

D

OA Rem 0.2 0.05 0.05–0.3 2.0–4.0 0.005 0.005 0.5–1.5 0.05 0.04† 0.05 . . . 420 216 460 238 L13937

AM Rem 0.10 0.8–1.2 0.4–0.6 2.8–3.2 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 220 446 230 L13938

TC Rem 0.20 0.05 0.015 4.0–5.0 0.005 0.005 0.05 0.05 0.04 0.005 0.005 . 0.04-0.20 419 215 660 350 L13931

WS Rem 0.10 1.0–1.5 0.2–0.6 3.5–4.5 0.005 0.005 0.02 0.05 0.02 0.005 . . . 440 225 660 350 L13939

A

For purposes of determining conformance to these limits, an observed value or calculated value obtained from analysis shall be rounded to the nearest unit in the last right-hand place of figures used in expressing

the specified limit, in accordance with the rounding method of Practice E29.

B

Temperatures given are approximations and for information only.

C

For alloys not identified, named elements shall conform to the following tolerances (wt%): >5% ±0.5%, >=5%± 0.25 %; Impurity elements (maximum): Sn-0.2, Pb-0.2, Sb-0.5, Ag-0.015, Cu-0.08, Cd-0.005, Al-0.05,

Bi-0.15, As-0.02, Fe-0.02, Zn-0.005.

D

Grades E and OA are covered by U.S. patents held by Engelhard Corp, Mansfield, MA, and Oatey Co. Cleveland, OH respectively. Federated Fry Metals, Altoona, PA and Taracorp Inc., Atlanta, GA have applied for

patents on grades AC and TC respectively. Grades HA, HB, and HN are covered by patents assigned to J. W. Harris Co., Cincinnati, OH. Grade PT is covered by a patent issued to Precise Alloys Corporation, Bronx,

NY. Interested parties are invited to submit information regarding identification of acceptable alternatives to these patented items to the Committee on Standards, ASTM International Headquarters, 100 Barr Harbor Drive,

West Conshohocken, PA 19428. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

† OA value for FE 10 was corrected editorially.

B32−08 (2014)

TABLE 1 Solder Compositions - wt% (range or maximum) (continued)

A B

Composition, % Melting Range

Alloy Solidus Liquidus UNS

Sn Pb Sb Ag Cu Cd Al Bi As Fe Zn Ni Ce Se

Grade Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14

°F °C °F °C

Section 2: Solder Alloys Containing Lead

Sn70 69.5–71.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 377 193 L13700

Sn63 62.5–63.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 361 183 L13630

Sn62 61.5–62.5 Rem 0.50 1.75–2.25 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 354 179 372 189 L13620

Sn60 59.5–61.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 374 190 L13600

Sn50 49.5–51.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.025 0.02 0.005 . . . 361 183 421 216 L55031

Sn45 44.5–46.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.025 0.02 0.005 . . . 361 183 441 227 L54951

Sn40A 39.5–41.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.02 0.02 0.005 . . . 361 183 460 238 L54916

Sn40B 39.5–41.5 Rem 1.8–2.4 0.015 0.08 0.001 0.005 0.25 0.02 0.02 0.005 . . . 365 185 448 231 L54918

Sn35A 34.5–36.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.02 0.02 0.005 . . . 361 183 447 247 L54851

Sn35B 34.5–36.5 Rem 1.6–2.0 0.015 0.08 0.001 0.005 0.25 0.02 0.02 0.005 . . . 365 185 470 243 L54852

Sn30A 29.5–31.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.02 0.02 0.005 . . . 361 183 491 255 L54821

Sn30B 29.5–31.5 Rem 1.4–1.8 0.015 0.08 0.001 0.005 0.25 0.02 0.02 0.005 . . . 365 185 482 250

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B32 − 08 B32 − 08 (Reapproved 2014)

Standard Specification for

Solder Metal

This standard is issued under the fixed designation B32; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers solder metal alloys (commonly known as soft solders) used in non-electronic applications,

including but not limited to, tin-lead, tin-antimony, tin-antimony-copper-silver, tin-antimony-copper-silver-nickel, tin-silver,

tin-copper-silver, and lead-tin-silver, used for the purpose of joining together two or more metals at temperatures below their

melting points. Electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications are not

covered by this specification as they are under the auspices of IPC – Association Connecting Electronic Industries.

1.1.1 These solders include those alloys having a liquidus temperature not exceeding 800°F (430°C).

1.1.2 This specification includes solders in the form of solid bars, ingots, powder and special forms, and in the form of solid

and flux-core ribbon, wire, and solder paste.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D269 Test Method for Insoluble Matter in Rosin and Rosin Derivatives

D464 Test Methods for Saponification Number of Naval Store Products Including Tall Oil and Other Related Products

D465 Test Methods for Acid Number of Naval Stores Products Including Tall Oil and Other Related Products

D509 Test Methods of Sampling and Grading Rosin

E28 Test Methods for Softening Point of Resins Derived from Pine Chemicals and Hydrocarbons, by Ring-and-Ball Apparatus

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E46 Test Methods for Chemical Analysis of Lead- and Tin-Base Solder (Withdrawn 1994)

E51 Method for Spectrographic Analysis of Tin Alloys by the Powder Technique (Withdrawn 1983)

E55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

E87 Methods for Chemical Analysis of Lead, Tin, Antimony and Their Alloys (Photometric Method) (Withdrawn 1983)

E88 Practice for Sampling Nonferrous Metals and Alloys in Cast Form for Determination of Chemical Composition

2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.02 on Refined

Lead, Tin, Antimony, and Their Alloys.

Current edition approved May 1, 2008Oct. 1, 2014. Published May 2008October 2014. Originally approved in 1919. Last previous edition approved in 20042008 as

B32 - 04.B32– 08. DOI: 10.1520/B0032-08.10.1520/B0032-08R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from Global Engineering Documents, 15 Inverness Way, East Englewood, CO 80112-5704, http://global.ihs.com.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B32 − 08 (2014)

3. Terminology

3.1 Definitions:

3.1.1 producer, n—the primary manufacturer of the material.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 lot, n—The term “lot” as used in this specification is defined as follows:

3.2.1.1 Discussion—

For solid solder metal, a lot consists of all solder of the same type designation, produced from the same batch of raw materials

under essentially the same conditions, and offered for inspection at one time.

3.2.1.2 Discussion—

For flux–core solder, a lot consists of all solder of the same core mixture, produced from the same batch of raw materials under

essentially the same conditions and offered for inspection at one time.

3.2.2 lot number,, n—The term “lot number” as used in this specification refers to an alphanumeric or numerical designation

for a lot which is traceable to a date of manufacture.

4. Classification

4.1 Type Designation—The type designation uses the following symbols to properly identify the material:

4.1.1 Alloy Composition—The composition is identified by a two-letter symbol and a number. The letters typically indicate the

chemical symbol for the critical element in the solder and the number indicates the nominal percentage, by weight, of the critical

element in the solder. The designation followed by the letters A or B distinguishes between different alloy grades of similar

composition (see Table 1).

4.1.2 Form—The form is indicated by a single letter in accordance with Table 2.

4.1.3 Flux Type—The flux type is indicated by a letter or combination of letters in accordance with Table 3.

4.1.4 Core Condition and Flux Percentage (applicable only to flux-cored solder)—The core condition and flux percentage is

identified by a single letter and a number in accordance with Table 4.

4.1.5 Powder Mesh Size and Flux Percentage (applicable only to solder paste)—The powder mesh size and flux percentage is

identified by a single letter and a number in accordance with Table 5.

5. Ordering Information

5.1 Orders for material under this specification indicate the following information, as required, to adequately describe the

desired material.

5.1.1 Type designation (see 4.1),

5.1.2 Detailed requirements for special forms,

5.1.3 Dimensions of ribbon and wire solder (see 9.2),

5.1.4 Unit weight,

5.1.5 Packaging (see Section 18),

5.1.6 Marking (see Section 17),

5.1.7 ASTM specification number and issue, marked on (a) purchase order and (b) package or spool, and

5.1.8 Special requirements, as agreed upon between supplier and purchaser.

6. Materials and Manufacture

6.1 The producer must have each lot of solder metal as uniform in quality as practicable and of satisfactory appearance in

accordance with best industrial practices. Each bar, ingot, or other form in which the solder is sold must be uniform in composition

with the entire lot.

7. Chemical Composition

7.1 Solder Alloy—The solder alloy composition is as specified in Table 1.

NOTE 1—By mutual agreement between supplier and purchaser, analysis may be required and limits established for elements or compounds not

specified in Table 1.

7.2 Flux (applicable to flux-core ribbon, wire, and solder paste):

7.2.1 Type R—The flux is composed of Grade WW or WG gum rosin of Test Methods D509. The rosin shall have a

toluene–insoluble matter content of not more than 0.05 weight % in accordance with Test Method D269, a minimum acid number

B32 − 08 (2014)

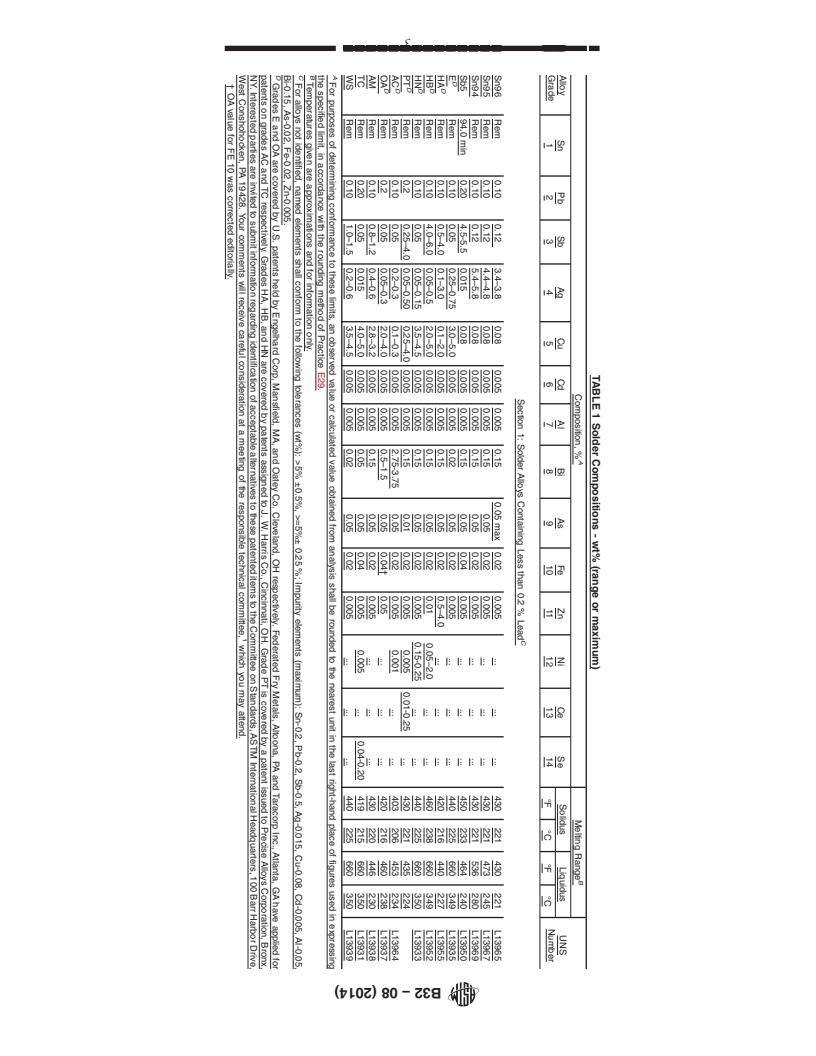

TABLE 1 Solder Compositions - wt% (range or maximum)

A B

Composition, % Melting Range

Alloy Solidus Liquidus UNS

Sn Pb Sb Ag Cu Cd Al Bi As Fe Zn Ni Ce Se

Grade Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14

°F °C °F °C

C

Section 1: Solder Alloys Containing Less than 0.2 % Lead

Sn96 Rem 0.10 0.12 3.4–3.8 0.08 0.005 0.005 0.15 0.05 max 0.02 0.005 . . . 430 221 430 221 L13965

Sn95 Rem 0.10 0.12 4.4–4.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 473 245 L13967

Sn94 Rem 0.10 0.12 5.4–5.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 536 280 L13969

Sb5 94.0 min 0.20 4.5-5.5 0.015 0.08 0.005 0.005 0.15 0.05 0.04 0.005 . . . 450 233 464 240 L13950

D

E Rem 0.10 0.05 0.25–0.75 3.0–5.0 0.005 0.005 0.02 0.05 0.02 0.005 . . . 440 225 660 349 L13935

D

HA Rem 0.10 0.5–4.0 0.1–3.0 0.1–2.0 0.005 0.005 0.15 0.05 0.02 0.5–4.0 . . . 420 216 440 227 L13955

D

HB Rem 0.10 4.0–6.0 0.05–0.5 2.0–5.0 0.005 0.005 0.15 0.05 0.02 0.01 0.05–2.0 . . 460 238 660 349 L13952

D

HN Rem 0.10 0.05 0.05–0.15 3.5–4.5 0.005 0.005 0.15 0.05 0.02 0.005 0.15-0.25 . . 440 225 660 350 L13933

D

PT Rem 0.2 0.25–4.0 0.05–0.50 0.25–4.0 0.005 0.005 0.15 0.01 0.02 0.005 0.005 0.01-0.25 . 430 221 435 224

D

AC Rem 0.10 0.05 0.2–0.3 0.1–0.3 0.005 0.005 2.75-3.75 0.05 0.02 0.005 0.001 . . 403 206 453 234 L13964

D

OA Rem 0.2 0.05 0.05–0.3 2.0–4.0 0.005 0.005 0.5–1.5 0.05 0.04† 0.05 . . . 420 216 460 238 L13937

AM Rem 0.10 0.8–1.2 0.4–0.6 2.8–3.2 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 220 446 230 L13938

TC Rem 0.20 0.05 0.015 4.0–5.0 0.005 0.005 0.05 0.05 0.04 0.005 0.005 . 0.04-0.20 419 215 660 350 L13931

WS Rem 0.10 1.0–1.5 0.2–0.6 3.5–4.5 0.005 0.005 0.02 0.05 0.02 0.005 . . . 440 225 660 350 L13939

A

For purposes of determining conformance to these limits, an observed value or calculated value obtained from analysis shall be rounded to the nearest unit in the last right-hand place of figures used in expressing

the specified limit, in accordance with the rounding method of Practice E29.

B

Temperatures given are approximations and for information only.

C

For alloys not identified, named elements shall conform to the following tolerances (wt%): >5% ±0.5%, >=5%± 0.25 %; Impurity elements (maximum): Sn-0.2, Pb-0.2, Sb-0.5, Ag-0.015, Cu-0.08, Cd-0.005, Al-0.05,

Bi-0.15, As-0.02, Fe-0.02, Zn-0.005.

D

Grades E and OA are covered by U.S. patents held by Engelhard Corp, Mansfield, MA, and Oatey Co. Cleveland, OH respectively. Federated Fry Metals, Altoona, PA and Taracorp Inc., Atlanta, GA have applied for

patents on grades AC and TC respectively. Grades HA, HB, and HN are covered by patents assigned to J. W. Harris Co., Cincinnati, OH. Grade PT is covered by a patent issued to Precise Alloys Corporation, Bronx,

NY. Interested parties are invited to submit information regarding identification of acceptable alternatives to these patented items to the Committee on Standards, ASTM International Headquarters, 100 Barr Harbor Drive,

West Conshohocken, PA 19428. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

† OA value for FE 10 was corrected editorially.

B32 − 08 (2014)

TABLE 1 Solder Compositions - wt% (range or maximum) (continued)

colwidth="7.26*"/COLSPECcolwidth="6.81*"/COLSPECcolwidth="6.20*"/COLSPECcolwidth="5.44*"/

A B

Composition, % Melting Range

COLSPECcolwidth="5.86*"/COLSPECcolwidth="3.38*"/COLSPECcolwidth="3.41*"/COLSPECcolwidth="6.50*"/COLSPEC

Alloy Solidus Liquidus UNS

Sn Pb Sb Ag Cu Cd Al Bi As Fe Zn Ni Ce Se

Grade Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14

°F °C °F °C

C

Section 1: Solder Alloys Containing Less than 0.2 % Lead

Sn96 Rem 0.10 0.12 3.4–3.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 430 221 L13965

max

Sn95 Rem 0.10 0.12 4.4–4.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 473 245 L13967

Sn94 Rem 0.10 0.12 5.4–5.8 0.08 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 221 536 280 L13969

Sb5 94.0 min 0.20 4.5-5.5 0.015 0.08 0.005 0.005 0.15 0.05 0.04 0.005 . . . 450 233 464 240 L13950

D

E Rem 0.10 0.05 0.25–0.75 3.0–5.0 0.005 0.005 0.02 0.05 0.02 0.005 . . . 440 225 660 349 L13935

D

HA Rem 0.10 0.5–4.0 0.1–3.0 0.1–2.0 0.005 0.005 0.15 0.05 0.02 0.5–4.0 . . . 420 216 440 227 L13955

D

HB Rem 0.10 4.0–6.0 0.05–0.5 2.0–5.0 0.005 0.005 0.15 0.05 0.02 0.01 0.05–2.0 . . 460 238 660 349 L13952

D

HN Rem 0.10 0.05 0.05–0.15 3.5–4.5 0.005 0.005 0.15 0.05 0.02 0.005 0.15-0.25 . . 440 225 660 350 L13933

D

PT Rem 0.2 0.25–4.0 0.05–0.50 0.25–4.0 0.005 0.005 0.15 0.01 0.02 0.005 0.005 0.01– . 430 221 435 224

0.25

D

AC Rem 0.10 0.05 0.2–0.3 0.1–0.3 0.005 0.005 2.75– 0.05 0.02 0.005 0.001 . . 403 206 453 234 L13964

3.75

D

OA Rem 0.2 0.05 0.05–0.3 2.0–4.0 0.005 0.005 0.5–1.5 0.05 0.04† 0.05 . . . 420 216 460 238 L13937

AM Rem 0.10 0.8–1.2 0.4–0.6 2.8–3.2 0.005 0.005 0.15 0.05 0.02 0.005 . . . 430 220 446 230 L13938

TC Rem 0.20 0.05 0.015 4.0–5.0 0.005 0.005 0.05 0.05 0.04 0.005 0.005 . 0.04– 419 215 660 350 L13931

0.20

WS Rem 0.10 1.0–1.5 0.2–0.6 3.5–4.5 0.005 0.005 0.02 0.05 0.02 0.005 . . . 440 225 660 350 L13939

Section 2: Solder Alloys Containing Lead

Section 2: Solder Alloys Containing Lead

Sn70 69.5–71.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 377 193 L13700

Sn63 62.5–63.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 361 183 L13630

Sn63 62.5–63.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 361 183 L13630

Sn62 61.5–62.5 Rem 0.50 1.75–2.25 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 354 179 372 189 L13620

Sn62 61.5–62.5 Rem 0.50 1.75–2.25 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 354 179 372 189 L13620

Sn60 59.5–61.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 374 190 L13600

Sn60 59.5–61.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.03 0.02 0.005 . . . 361 183 374 190 L13600

Sn50 49.5–51.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.025 0.02 0.005 . . . 361 183 421 216 L55031

Sn50 49.5–51.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.025 0.02 0.005 . . . 361 183 421 216 L55031

Sn45 44.5–46.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.025 0.02 0.005 . . . 361 183 441 227 L54951

Sn45 44.5–46.5 Rem 0.50 0.015 0.08 0.001 0.005 0.25 0.025 0.02 0.005 . . . 361 183 441 227 L54951

Sn40A 39.5–41.5 Rem 0.50 0.015 0.08 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.