ASTM D482-12

(Test Method)Standard Test Method for Ash from Petroleum Products

Standard Test Method for Ash from Petroleum Products

SIGNIFICANCE AND USE

4.1 Knowledge of the amount of ash-forming material present in a product can provide information as to whether or not the product is suitable for use in a given application. Ash can result from oil or water-soluble metallic compounds or from extraneous solids such as dirt and rust.

SCOPE

1.1 This test method covers the determination of ash in the range 0.001–0.180 mass %, from distillate and residual fuels, gas turbine fuels, crude oils, lubricating oils, waxes, and other petroleum products, in which any ash-forming materials present are normally considered to be undesirable impurities or contaminants (Note 1). The test method is limited to petroleum products which are free from added ash-forming additives, including certain phosphorus compounds (Note 2). Note 1—In certain types of samples, all of the ash-forming metals are not retained quantitatively in the ash. This is particularly true of distillate oils, which require a special ash procedure in order to retain metals quantitatively.Note 2—This test method is not intended for the analysis of unused lubricating oils containing additives; for such samples use Test Method D874. Neither is it intended for the analysis of lubricating oils containing lead nor for used engine crankcase oils.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. The preferred expression of the property is mass %.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D482 − 12

Designation:4/96

Standard Test Method for

1

Ash from Petroleum Products

This standard is issued under the fixed designation D482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This test method covers the determination of ash in the

D4177 Practice for Automatic Sampling of Petroleum and

range 0.001–0.180 mass %, from distillate and residual fuels,

Petroleum Products

gas turbine fuels, crude oils, lubricating oils, waxes, and other

D4928 Test Method for Water in Crude Oils by Coulometric

petroleum products, in which any ash-forming materials pres-

Karl Fischer Titration

ent are normally considered to be undesirable impurities or

D6299 Practice for Applying Statistical Quality Assurance

contaminants (Note 1).The test method is limited to petroleum

and Control Charting Techniques to Evaluate Analytical

products which are free from added ash-forming additives,

Measurement System Performance

including certain phosphorus compounds (Note 2).

D6792 Practice for Quality System in Petroleum Products

NOTE 1—In certain types of samples, all of the ash-forming metals are

and Lubricants Testing Laboratories

not retained quantitatively in the ash. This is particularly true of distillate

oils, which require a special ash procedure in order to retain metals

3. Summary of Test Method

quantitatively.

NOTE 2—This test method is not intended for the analysis of unused

3.1 The sample contained in a suitable vessel is ignited and

lubricating oils containing additives; for such samples use Test Method

allowed to burn until only ash and carbon remain. The

D874. Neither is it intended for the analysis of lubricating oils containing

carbonaceous residue is reduced to an ash by heating in a

lead nor for used engine crankcase oils.

muffle furnace at 775°C, cooled and weighed.

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4. Significance and Use

only. The preferred expression of the property is mass %.

4.1 Knowledge of the amount of ash-forming material

1.3 This standard does not purport to address all of the

present in a product can provide information as to whether or

safety concerns, if any, associated with its use. It is the

not the product is suitable for use in a given application. Ash

responsibility of the user of this standard to establish appro-

can result from oil or water-soluble metallic compounds or

priate safety and health practices and determine the applica-

from extraneous solids such as dirt and rust.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Documents

2

5.1 EvaporatingDishorCrucible,madeofplatinum,silica,

2.1 ASTM Standards:

or porcelain, of 90 mL minimum capacity to 120-mL maxi-

D874 Test Method for Sulfated Ash from Lubricating Oils

mum capacity.

and Additives

5.2 Electric Muffle Furnace, capable of maintaining a tem-

perature of 775 6 25°C and preferably having suitable

1

This test method is under the jurisdiction of ASTM Committee D02 on

apertures at the front and rear so as to allow a slow natural

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

draught of air to pass through.

Current edition approved Dec. 1, 2012. Published March 2013. Originally

5.3 Meeker Gas Burner, or equivalent.

approved in 1938. Last previous edition approved in 2007 as D482–07. DOI:

10.1520/D0482-12.

5.4 Mechanical Shaker.

In the IP, this test method is under the jurisdiction of the Standardization

Committee. This test method was adopted as a joint ASTM-IP standard in 1965.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Reagents

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Propan-2-ol— (Warning—Flammable, can be explo-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. sive when evaporated to or near dryness.)

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D482 − 12

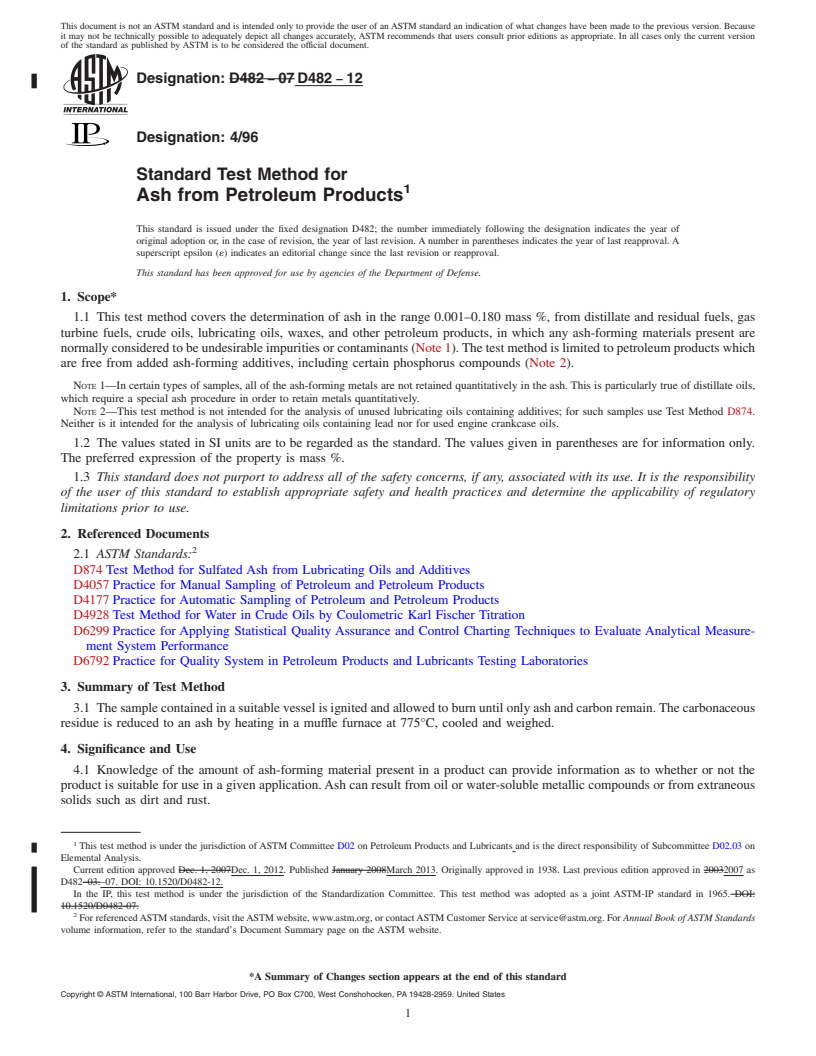

TABLE 1 Test Specimen Mass versus Ash

6.2 Toluene—(Warning—Flammable, toxic.)

Test Specimen,

6.3 Quality Control (QC) Samples , preferably are portions Expected Ash, mass % Ash Mass, mg

mass, g

of one or more liqui

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D482 − 07 D482 − 12

Designation: 4/96

Standard Test Method for

1

Ash from Petroleum Products

This standard is issued under the fixed designation D482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the determination of ash in the range 0.001–0.180 mass %, from distillate and residual fuels, gas

turbine fuels, crude oils, lubricating oils, waxes, and other petroleum products, in which any ash-forming materials present are

normally considered to be undesirable impurities or contaminants (Note 1). The test method is limited to petroleum products which

are free from added ash-forming additives, including certain phosphorus compounds (Note 2).

NOTE 1—In certain types of samples, all of the ash-forming metals are not retained quantitatively in the ash. This is particularly true of distillate oils,

which require a special ash procedure in order to retain metals quantitatively.

NOTE 2—This test method is not intended for the analysis of unused lubricating oils containing additives; for such samples use Test Method D874.

Neither is it intended for the analysis of lubricating oils containing lead nor for used engine crankcase oils.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

The preferred expression of the property is mass %.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D874 Test Method for Sulfated Ash from Lubricating Oils and Additives

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4928 Test Method for Water in Crude Oils by Coulometric Karl Fischer Titration

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

3. Summary of Test Method

3.1 The sample contained in a suitable vessel is ignited and allowed to burn until only ash and carbon remain. The carbonaceous

residue is reduced to an ash by heating in a muffle furnace at 775°C, cooled and weighed.

4. Significance and Use

4.1 Knowledge of the amount of ash-forming material present in a product can provide information as to whether or not the

product is suitable for use in a given application. Ash can result from oil or water-soluble metallic compounds or from extraneous

solids such as dirt and rust.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved Dec. 1, 2007Dec. 1, 2012. Published January 2008March 2013. Originally approved in 1938. Last previous edition approved in 20032007 as

D482–03.–07. DOI: 10.1520/D0482-12.

In the IP, this test method is under the jurisdiction of the Standardization Committee. This test method was adopted as a joint ASTM-IP standard in 1965. DOI:

10.1520/D0482-07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D482 − 12

5. Apparatus

5.1 Evaporating Dish or Crucible , made of platinum, silica, or porcelain, of 90 mL minimum capacity to 120-mL maximum

capacity.

5.2 Electric Muffle Furnace, capable of maintaining a temperature of 775 6 25°C and preferably having suitable apertures at

the front and rear so as to allow a slow natural draught of air to pass through.

5.3 Meeker Gas Burner, or equivale

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.