ASTM E2226-15b(2019)

(Practice)Standard Practice for Application of Hose Stream

Standard Practice for Application of Hose Stream

SIGNIFICANCE AND USE

4.1 This practice is intended to standardize the apparatus used and the method or pattern of application of a standard hose stream to building elements as one part of the assessment and fire resistance of building elements.

4.1.1 This practice specifies the water pressure and duration of application of the hose stream to the test assembly.

4.2 This practice is intended to be used only after a test assembly has completed a prescribed standard fire-resistance test.

4.3 The practice exposes a test assembly to a standard hose stream under controlled laboratory conditions.

4.3.1 Pass/fail criteria are defined in the appropriate fire test method.

4.3.2 This exposure is not intended to replicate typical fire fighting operations or all applied or impact loads a system could be subjected to in field use and conditions.

4.4 Any variation from tested conditions has the potential of substantially changing the performance characteristics determined by this practice.

SCOPE

1.1 This practice is applicable to building elements required to be subjected to the impact, erosion, and cooling effects of a hose stream as part of a fire-test-response standard. Building elements include, but are not limited to, wall and partition assemblies, fire-resistive joint systems, and doors.

1.2 This practice shall register performance of the building element under specific hose stream conditions. It shall not imply that, either after exposure or under other conditions, the structural capability of the building element is intact or that the building element is suitable for use.

1.3 The result derived from this practice is one factor in assessing the integrity of building elements after fire exposure. The practice prescribes a standard hose stream exposure for comparing performance of building elements after fire exposure and evaluates various materials and construction techniques under common conditions.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this standard references notes which provide explanatory material. These notes shall not be considered as requirements of the standard.

1.6 This fire standard cannot be used to provide quantitative measures.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2226 − 15b (Reapproved 2019) An American National Standard

Standard Practice for

Application of Hose Stream

This standard is issued under the fixed designation E2226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Several fire-test-response standards (such as ASTM E119, E814, E2074, and E1966) in order to

assess the integrity of building elements after exposure to a specified test fire, require test specimens

tobeevaluatedbyexposuretoahosestream.Itisimportanttostandardizecertainelementsofthehose

stream to promote uniformity in requirements. To attain this goal, this practice describes a standard

apparatus for delivering a solid stream of water and prescribes a standard method of subjecting

building elements to a hose stream after fire exposure.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice is applicable to building elements required

responsibility of the user of this standard to establish appro-

to be subjected to the impact, erosion, and cooling effects of a

priate safety, health, and environmental practices and deter-

hose stream as part of a fire-test-response standard. Building

mine the applicability of regulatory limitations prior to use.

elements include, but are not limited to, wall and partition

1.8 This international standard was developed in accor-

assemblies, fire-resistive joint systems, and doors.

dance with internationally recognized principles on standard-

1.2 This practice shall register performance of the building

ization established in the Decision on Principles for the

element under specific hose stream conditions. It shall not

Development of International Standards, Guides and Recom-

imply that, either after exposure or under other conditions, the

mendations issued by the World Trade Organization Technical

structural capability of the building element is intact or that the

Barriers to Trade (TBT) Committee.

building element is suitable for use.

2. Referenced Documents

1.3 The result derived from this practice is one factor in

assessing the integrity of building elements after fire exposure.

2.1 ASTM Standards:

The practice prescribes a standard hose stream exposure for

E119 Test Methods for Fire Tests of Building Construction

comparing performance of building elements after fire expo-

and Materials

sure and evaluates various materials and construction tech-

E176 Terminology of Fire Standards

niques under common conditions.

E631 Terminology of Building Constructions

E814 Test Method for Fire Tests of Penetration Firestop

1.4 The values stated in inch-pound units are to be regarded

Systems

as standard. The values given in parentheses are mathematical

E1966 Test Method for Fire-Resistive Joint Systems

conversions to SI units that are provided for information only

E2074 Test Method for Fire Tests of Door Assemblies,

and are not considered standard.

Including Positive Pressure Testing of Side-Hinged and

1.5 The text of this standard references notes which provide 3

Pivoted Swinging Door Assemblies (Withdrawn 2007)

explanatory material. These notes shall not be considered as

2.2 UL Standard:

requirements of the standard.

UL 385 Standard for Safety Play Pipes for Water Supply

1.6 This fire standard cannot be used to provide quantitative

Testing in Fire-Protection Service

measures.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This practice is under the jurisdiction of ASTM Committee E05 on Fire Standards volume information, refer to the standard’s Document Summary page on

Standards and is the direct responsibility of Subcommittee E05.11 on Fire the ASTM website.

Resistance. The last approved version of this historical standard is referenced on

Current edition approved March 1, 2019. Published March 2019. Originally www.astm.org.

approved in 2002. Last previous edition approved in 2015 as E2226 – 15b. DOI: Available from Underwriters Laboratories (UL), Corporate Progress, 333

10.1520/E2226-15BR19. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2226 − 15b (2019)

3. Terminology 4.1.1 This practice specifies the water pressure and duration

of application of the hose stream to the test assembly.

3.1 Definitions—For definitions of terms used in this

practice, refer to Terminologies E176 and E631. 4.2 This practice is intended to be used only after a test

assembly has completed a prescribed standard fire-resistance

3.2 Definitions of Terms Specific to This Standard:

test.

3.2.1 building element, n—a component or assembly of

materials using products manufactured as independent units 4.3 The practice exposes a test assembly to a standard hose

capable of being joined with or placed within other compo- stream under controlled laboratory conditions.

nents or assemblies to create a structure. 4.3.1 Pass/fail criteria are defined in the appropriate fire test

method.

3.2.2 exposed area, n—the total surface area of the test

4.3.2 This exposure is not intended to replicate typical fire

assembly that is subjected to the fire-resistance test including,

fighting operations or all applied or impact loads a system

when required, the supporting construction.

could be subjected to in field use and conditions.

3.2.3 fully developed stream, n—a coherent, forceful projec-

4.4 Any variation from tested conditions has the potential of

tion of water similar in shape and intensity to the stream being

substantially changing the performance characteristics deter-

applied to the exposed side of the test assembly from the

mined by this practice.

nozzle.

3.2.4 supporting construction, n—construction required for

5. Apparatus

the testing of some building elements into which the test

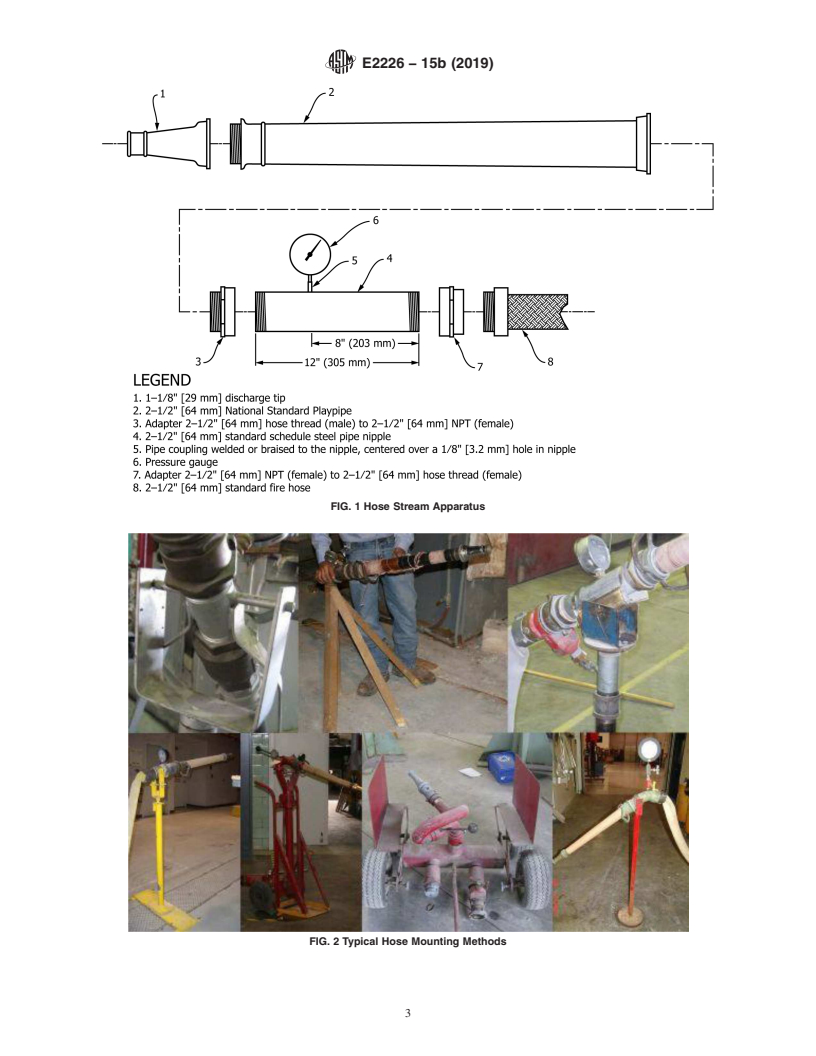

5.1 The apparatus used to apply the hose stream is shown in

specimenisassembled,forexample,thewallintowhichadoor

Fig.1andshallbecapableofdeliveringasolidstreamofwater

is fitted.

at the pressure specified in the fire-resistance test method.

3.2.5 test assembly, n—the building element or elements 1

5.1.1 The water stream shall be delivered through a 2 ⁄2-in.

being tested and, if applicable, the supporting construction.

(64-mm) hose discharging through a National Standard Play-

pipe of corresponding size equipped with a 1 ⁄8-in. (29-mm)

4. Significance and Use

discharge tip of standard taper, smooth-bore pattern without a

4.1 This practice is intended to standardize the apparatus shoulder at the orifice. Refer to UL 385.

used and the method or pattern of application of a standard 5.1.1.1 The playpipe shall be attached at its base to a rigid

hose stream to building elements as one part of the assessment support that permits the hose stream to be directed at the

and fire resistance of building elements. specimen from top to bottom and from side to side as required

FIG. 1 Hose Stream Apparatus

E2226 − 15b (2019)

in 8.4 without changing the location of the base of the playpipe 7. Nozzle Location

relative to the test specimen. The rigid base is permitted to be

7.1 The nozzle tip shall be located so that its axis is 90° to

a wheeled apparatus that is blocked to prevent movement

the center of the test assembly as shown in Fig. 3. However, if

during the hose stream application.

the axis is other than 90°, refer to 7.2.1.

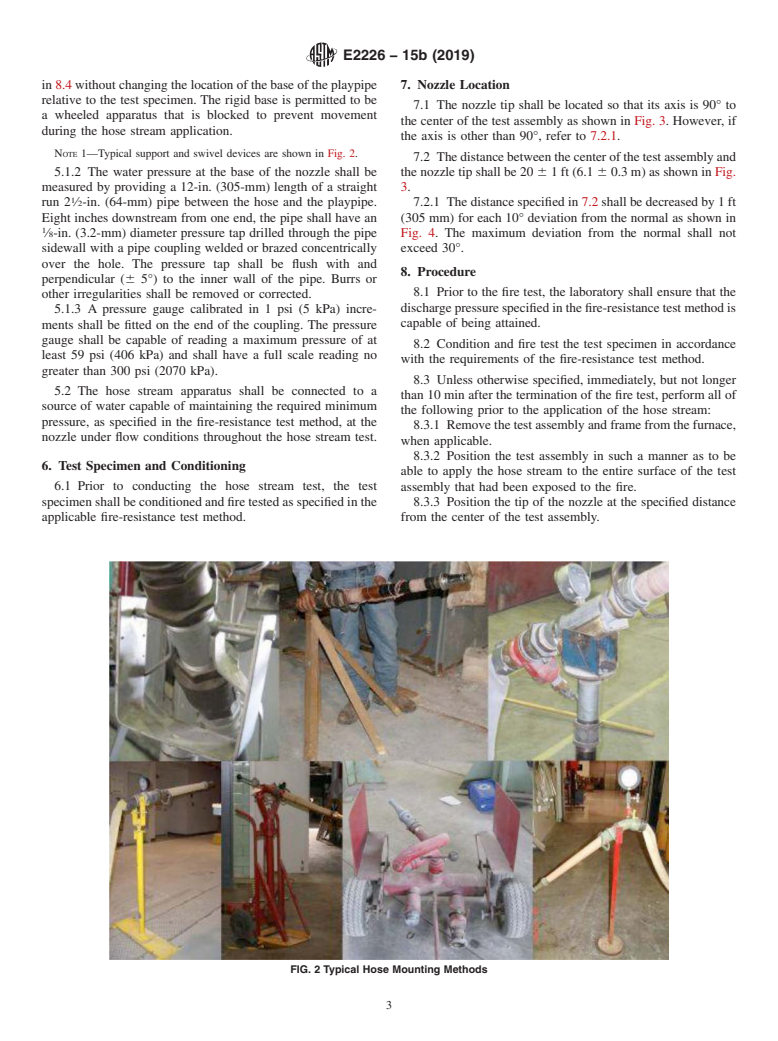

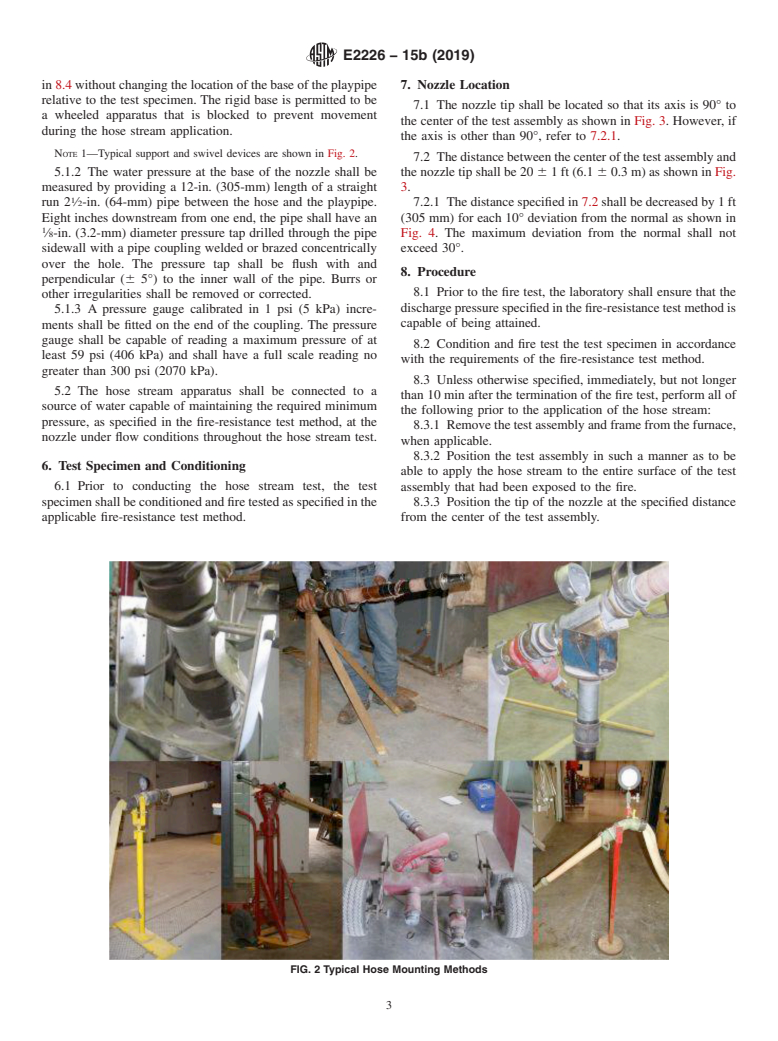

NOTE 1—Typical support

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2226 − 15b (Reapproved 2019) An American National Standard

Standard Practice for

Application of Hose Stream

This standard is issued under the fixed designation E2226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Several fire-test-response standards (such as ASTM E119, E814, E2074, and E1966) in order to

assess the integrity of building elements after exposure to a specified test fire, require test specimens

to be evaluated by exposure to a hose stream. It is important to standardize certain elements of the hose

stream to promote uniformity in requirements. To attain this goal, this practice describes a standard

apparatus for delivering a solid stream of water and prescribes a standard method of subjecting

building elements to a hose stream after fire exposure.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice is applicable to building elements required

responsibility of the user of this standard to establish appro-

to be subjected to the impact, erosion, and cooling effects of a

priate safety, health, and environmental practices and deter-

hose stream as part of a fire-test-response standard. Building

mine the applicability of regulatory limitations prior to use.

elements include, but are not limited to, wall and partition

1.8 This international standard was developed in accor-

assemblies, fire-resistive joint systems, and doors.

dance with internationally recognized principles on standard-

1.2 This practice shall register performance of the building

ization established in the Decision on Principles for the

element under specific hose stream conditions. It shall not

Development of International Standards, Guides and Recom-

imply that, either after exposure or under other conditions, the

mendations issued by the World Trade Organization Technical

structural capability of the building element is intact or that the

Barriers to Trade (TBT) Committee.

building element is suitable for use.

2. Referenced Documents

1.3 The result derived from this practice is one factor in

assessing the integrity of building elements after fire exposure.

2.1 ASTM Standards:

The practice prescribes a standard hose stream exposure for

E119 Test Methods for Fire Tests of Building Construction

comparing performance of building elements after fire expo-

and Materials

sure and evaluates various materials and construction tech-

E176 Terminology of Fire Standards

niques under common conditions.

E631 Terminology of Building Constructions

E814 Test Method for Fire Tests of Penetration Firestop

1.4 The values stated in inch-pound units are to be regarded

Systems

as standard. The values given in parentheses are mathematical

E1966 Test Method for Fire-Resistive Joint Systems

conversions to SI units that are provided for information only

E2074 Test Method for Fire Tests of Door Assemblies,

and are not considered standard.

Including Positive Pressure Testing of Side-Hinged and

1.5 The text of this standard references notes which provide 3

Pivoted Swinging Door Assemblies (Withdrawn 2007)

explanatory material. These notes shall not be considered as

2.2 UL Standard:

requirements of the standard.

UL 385 Standard for Safety Play Pipes for Water Supply

1.6 This fire standard cannot be used to provide quantitative

Testing in Fire-Protection Service

measures.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This practice is under the jurisdiction of ASTM Committee E05 on Fire Standards volume information, refer to the standard’s Document Summary page on

Standards and is the direct responsibility of Subcommittee E05.11 on Fire the ASTM website.

Resistance. The last approved version of this historical standard is referenced on

Current edition approved March 1, 2019. Published March 2019. Originally www.astm.org.

approved in 2002. Last previous edition approved in 2015 as E2226 – 15b. DOI: Available from Underwriters Laboratories (UL), Corporate Progress, 333

10.1520/E2226-15BR19. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2226 − 15b (2019)

3. Terminology 4.1.1 This practice specifies the water pressure and duration

of application of the hose stream to the test assembly.

3.1 Definitions—For definitions of terms used in this

practice, refer to Terminologies E176 and E631. 4.2 This practice is intended to be used only after a test

assembly has completed a prescribed standard fire-resistance

3.2 Definitions of Terms Specific to This Standard:

test.

3.2.1 building element, n—a component or assembly of

materials using products manufactured as independent units 4.3 The practice exposes a test assembly to a standard hose

capable of being joined with or placed within other compo- stream under controlled laboratory conditions.

nents or assemblies to create a structure. 4.3.1 Pass/fail criteria are defined in the appropriate fire test

method.

3.2.2 exposed area, n—the total surface area of the test

4.3.2 This exposure is not intended to replicate typical fire

assembly that is subjected to the fire-resistance test including,

fighting operations or all applied or impact loads a system

when required, the supporting construction.

could be subjected to in field use and conditions.

3.2.3 fully developed stream, n—a coherent, forceful projec-

4.4 Any variation from tested conditions has the potential of

tion of water similar in shape and intensity to the stream being

substantially changing the performance characteristics deter-

applied to the exposed side of the test assembly from the

mined by this practice.

nozzle.

3.2.4 supporting construction, n—construction required for

5. Apparatus

the testing of some building elements into which the test

5.1 The apparatus used to apply the hose stream is shown in

specimen is assembled, for example, the wall into which a door

Fig. 1 and shall be capable of delivering a solid stream of water

is fitted.

at the pressure specified in the fire-resistance test method.

3.2.5 test assembly, n—the building element or elements

5.1.1 The water stream shall be delivered through a 2 ⁄2-in.

being tested and, if applicable, the supporting construction.

(64-mm) hose discharging through a National Standard Play-

pipe of corresponding size equipped with a 1 ⁄8-in. (29-mm)

4. Significance and Use

discharge tip of standard taper, smooth-bore pattern without a

4.1 This practice is intended to standardize the apparatus shoulder at the orifice. Refer to UL 385.

used and the method or pattern of application of a standard 5.1.1.1 The playpipe shall be attached at its base to a rigid

hose stream to building elements as one part of the assessment support that permits the hose stream to be directed at the

and fire resistance of building elements. specimen from top to bottom and from side to side as required

FIG. 1 Hose Stream Apparatus

E2226 − 15b (2019)

in 8.4 without changing the location of the base of the playpipe 7. Nozzle Location

relative to the test specimen. The rigid base is permitted to be

7.1 The nozzle tip shall be located so that its axis is 90° to

a wheeled apparatus that is blocked to prevent movement

the center of the test assembly as shown in Fig. 3. However, if

during the hose stream application.

the axis is other than 90°, refer to 7.2.1.

NOTE 1—Typical support and swivel devices are shown in Fig. 2.

7.2 The distance between the center of the test assemb

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2226 − 15b E2226 − 15b (Reapproved 2019) An American National Standard

Standard Practice for

Application of Hose Stream

This standard is issued under the fixed designation E2226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Several fire-test-response standards (such as ASTM E119, E814, E2074, and E1966) in order to

assess the integrity of building elements after exposure to a specified test fire, require test specimens

to be evaluated by exposure to a hose stream. It is important to standardize certain elements of the hose

stream to promote uniformity in requirements. To attain this goal, this practice describes a standard

apparatus for delivering a solid stream of water and prescribes a standard method of subjecting

building elements to a hose stream after fire exposure.

1. Scope

1.1 This practice is applicable to building elements required to be subjected to the impact, erosion, and cooling effects of a hose

stream as part of a fire-test-response standard. Building elements include, but are not limited to, wall and partition assemblies,

fire-resistive joint systems, and doors.

1.2 This practice shall register performance of the building element under specific hose stream conditions. It shall not imply that,

either after exposure or under other conditions, the structural capability of the building element is intact or that the building element

is suitable for use.

1.3 The result derived from this practice is one factor in assessing the integrity of building elements after fire exposure. The

practice prescribes a standard hose stream exposure for comparing performance of building elements after fire exposure and

evaluates various materials and construction techniques under common conditions.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this standard references notes which provide explanatory material. These notes shall not be considered as

requirements of the standard.

1.6 This fire standard cannot be used to provide quantitative measures.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E119 Test Methods for Fire Tests of Building Construction and Materials

E176 Terminology of Fire Standards

E631 Terminology of Building Constructions

E814 Test Method for Fire Tests of Penetration Firestop Systems

This practice is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.11 on Fire Resistance.

Current edition approved Oct. 1, 2015March 1, 2019. Published November 2015March 2019. Originally approved in 2002. Last previous edition approved in 2015 as

E2226E2226 – 15b.–15a. DOI: 10.1520/E2226-15B.10.1520/E2226-15BR19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2226 − 15b (2019)

E1966 Test Method for Fire-Resistive Joint Systems

E2074 Test Method for Fire Tests of Door Assemblies, Including Positive Pressure Testing of Side-Hinged and Pivoted Swinging

Door Assemblies (Withdrawn 2007)

2.2 UL Standard:

UL 385 Standard for Safety Play Pipes for Water Supply Testing in Fire-Protection Service

3. Terminology

3.1 Definitions—For definitions of terms used in this practice, refer to Terminologies E176 and E631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 building element, n—a component or assembly of materials using products manufactured as independent units capable of

being joined with or placed within other components or assemblies to create a structure.

3.2.2 exposed area, n—the total surface area of the test assembly that is subjected to the fire-resistance test including, when

required, the supporting construction.

3.2.3 fully developed stream, n—a coherent, forceful projection of water similar in shape and intensity to the stream being

applied to the exposed side of the test assembly from the nozzle.

3.2.4 supporting construction, n—construction required for the testing of some building elements into which the test specimen

is assembled, for example, the wall into which a door is fitted.

3.2.5 test assembly, n—the building element or elements being tested and, if applicable, the supporting construction.

4. Significance and Use

4.1 This practice is intended to standardize the apparatus used and the method or pattern of application of a standard hose stream

to building elements as one part of the assessment and fire resistance of building elements.

4.1.1 This practice specifies the water pressure and duration of application of the hose stream to the test assembly.

4.2 This practice is intended to be used only after a test assembly has completed a prescribed standard fire-resistance test.

4.3 The practice exposes a test assembly to a standard hose stream under controlled laboratory conditions.

4.3.1 Pass/fail criteria are defined in the appropriate fire test method.

4.3.2 This exposure is not intended to replicate typical fire fighting operations or all applied or impact loads a system could be

subjected to in field use and conditions.

4.4 Any variation from tested conditions has the potential of substantially changing the performance characteristics determined

by this practice.

5. Apparatus

5.1 The apparatus used to apply the hose stream is shown in Fig. 1 and shall be capable of delivering a solid stream of water

at the pressure specified in the fire-resistance test method.

5.1.1 The water stream shall be delivered through a 2-2 ⁄2 in. (64 mm) -in. (64-mm) hose discharging through a National

Standard Playpipe of corresponding size equipped with a 1-1 ⁄8 in. (29 mm) -in. (29-mm) discharge tip of standard taper,

smooth-bore pattern without a shoulder at the orifice. Refer to UL 385.

5.1.1.1 The playpipe shall be attached at its base to a rigid support that permits the hose stream to be directed at the specimen

from top to bottom and from side to side as required in 8.4 without changing the location of the base of the playpipe relative to

the test specimen. The rigid base is permitted to be a wheeled apparatus that is blocked to prevent movement during the hose stream

application.

NOTE 1—Typical support and swivel devices are shown in Fig. 2.

5.1.2 The water pressure at the base of the nozzle shall be measured by providing a 12 in. (305 mm) 12-in. (305-mm) length

of a straight run 2-2 ⁄2 in. (64 mm) -in. (64-mm) pipe between the hose and the playpipe. Eight inches downstream from one end,

the pipe shall have an ⁄8 in. (3.2 mm) -in. (3.2-mm) diameter pressure tap drilled through the pipe sidewall with a pipe coupling

welded or braze

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.