ASTM D7873-13

(Test Method)Standard Test Method for Determination of Oxidation Stability and Insolubles Formation of Inhibited Turbine Oils at 120°C Without the Inclusion of Water (Dry TOST Method)

Standard Test Method for Determination of Oxidation Stability and Insolubles Formation of Inhibited Turbine Oils at 120°C Without the Inclusion of Water (Dry TOST Method)

SIGNIFICANCE AND USE

5.1 Insoluble material may form in oils that are subjected to oxidizing conditions.

5.2 Significant formation of oil insolubles or metal corrosion products, or both, during this test may indicate that the oil will form insolubles or corrode metals, or both, resulting in varnish formation during field service. The level of varnish formation in service will be dependent on many factors (turbine design, reservoir temperature, duty-cycle, for example. peaking, cycling, or base-load duty, maintenance, and so forth) and a direct correlation between results in this test and field varnish formation are yet to be established.

5.3 Oxidation condition at 120 °C under accelerated oxidation environment of Test Method D4310 and measurement of sludge and RPVOT value could reflect a practical oil quality in actual turbine operations. Results from this test should be used together with other key lubricant performance indicators (including other established oxidation and corrosion tests) to indicate suitability for service.

SCOPE

1.1 This test method is used to evaluate the sludging tendencies of steam and gas turbine lubricants during the oxidation process in the presence of oxygen and metal catalyst (copper and iron) at an elevated temperature. This test method may be used to evaluate industrial oils (for example, circulating oils and so forth).

1.2 This test method is a modification of Test Method D4310 where the sludging and corrosion tendencies of the same kinds of oils are determined after 1000 h at 95 °C in the presence of water. Water is omitted in this modification.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—The values in parentheses in some of the figures are provided for information only for those using old equipment based on non-SI units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7873 − 13

StandardTest Method for

Determination of Oxidation Stability and Insolubles

Formation of Inhibited Turbine Oils at 120 °C Without the

Inclusion of Water (Dry TOST Method)

This standard is issued under the fixed designation D7873; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method is used to evaluate the sludging

A510M Specification for General Requirements for Wire

tendencies of steam and gas turbine lubricants during the

Rods and Coarse Round Wire, Carbon Steel (Metric)

oxidation process in the presence of oxygen and metal catalyst

(Withdrawn 2011)

(copper and iron) at an elevated temperature. This test method

B1 Specification for Hard-Drawn Copper Wire

may be used to evaluate industrial oils (for example, circulat-

D943 Test Method for Oxidation Characteristics of Inhibited

ing oils and so forth).

Mineral Oils

1.2 This test method is a modification of Test Method

D1193 Specification for Reagent Water

D4310 where the sludging and corrosion tendencies of the

D2272 Test Method for Oxidation Stability of Steam Tur-

same kinds of oils are determined after 1000 h at 95 °C in the

bine Oils by Rotating Pressure Vessel

presence of water. Water is omitted in this modification.

D4057 Practice for Manual Sampling of Petroleum and

1.3 The values stated in SI units are to be regarded as Petroleum Products

D4310 Test Method for Determination of Sludging and

standard. No other units of measurement are included in this

standard. Corrosion Tendencies of Inhibited Mineral Oils

E1 Specification for ASTM Liquid-in-Glass Thermometers

1.3.1 Exception—The values in parentheses in some of the

E230 Specification and Temperature-Electromotive Force

figures are provided for information only for those using old

(EMF) Tables for Standardized Thermocouples

equipment based on non-SI units.

2.2 Other Standards:

1.4 This standard does not purport to address all of the

Specification for IP Standard Thermometers

safety concerns, if any, associated with its use. It is the

ISO 3696 Water for Analytical Laboratory Use—

responsibility of the user of this standard to establish appro-

Specification and Test Methods

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

1.5 WARNING—Mercury has been designated by many

3.1 Definitions:

regulatory agencies as a hazardous material that can cause

3.1.1 sludge, n—a precipitate or sediment from oxidized

central nervous system, kidney and liver damage. Mercury, or

mineral oil that is insoluble in n-heptane. D943

its vapor, may be hazardous to health and corrosive to

materials.Cautionshouldbetakenwhenhandlingmercuryand

4. Summary of Test Method

mercury containing products. See the applicable product Ma-

4.1 Atotalofsixtoeighttubescontaining360mLofsample

terial Safety Data Sheet (MSDS) for details and EPA’s

each are heated at 120 °C with oxygen in the presence of an

website—http://www.epa.gov/mercury/faq.htm—for addi-

tional information. Users should be aware that selling mercury

and/or mercury containing products into your state or country

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

may be prohibited by law.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

This test method is under the jurisdiction of ASTM Committee D02 on www.astm.org.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

Subcommittee D02.09.0C on Oxidation of Turbine Oils. U.K., http://www.energyinst.org.

Current edition approved Dec. 1, 2013. Published January 2014. DOI: 10.1520/ Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

D7873-13. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7873 − 13

iron-copper catalyst. Each tube is removed over time and the includedinthedesign,thisviewingwindowshallbefittedwith

sample is analyzed by Test Method D2272 and the insolubles a suitable opaque cover and be kept closed when no observa-

are measured until the RPVOT residual ratio reaches below tion is being made.

25 % or an agreed-upon percentage or specified time. Test run

6.2.1.2 If glass heating baths are used, the bath shall be

for a specified time(s) may be run using a single tube or as

wrapped with aluminum foil or other opaque material.

many as specified by the requestor. The mass of insoluble

6.2.1.3 Bright light entering the test cell from directly

material of each oil sample is determined gravimetrically by

overhead can be eliminated by use of an opaque shield.

filtration of a 100 g oil sample through a membrane filter with

6.3 Flowmeter, with a flow capacity of at least 3 L of

pore size 1 µm. The insoluble mass (mg/kg oil) is plotted

oxygen/hour, and an accuracy of 60.1 L/h.

against RPVOT residual ratio. The insoluble mass in milli-

grams per kilogram oil at 25 % or an agreed-upon RPVOT

6.4 Heating Bath Thermometer,ASTMSolventsDistillation

residual ratio or specified time is reported.

Thermometer having a range from 98 °C to 152 °C and

conforming to the requirements for Thermometer 41C as

5. Significance and Use

prescribed in Specification E1, or for Thermometer 81C as

prescribed in Specifications for IP Standard Thermometers.

5.1 Insoluble material may form in oils that are subjected to

Alternatively,temperature-measuringdevicesofequalorbetter

oxidizing conditions.

accuracy and precision may be used.

5.2 Significant formation of oil insolubles or metal corro-

6.5 Oxidation Cell Thermometer, A 76 mm immersion LIG

sion products, or both, during this test may indicate that the oil

having a range of 110 °C to 130 °C, graduated in 0.1 °C, total

will form insolubles or corrode metals, or both, resulting in

lengthof300mm 65mm,andstemdiameterof6.0 mmto7.0

varnish formation during field service. The level of varnish

mm. Alternatively, temperature-measuring devices or DCT, of

formation in service will be dependent on many factors

equal or better accuracy and precision may be used. Tempera-

(turbinedesign,reservoirtemperature,duty-cycle,forexample.

ture of the sample shall be measured at 76 mm from the top of

peaking, cycling, or base-load duty, maintenance, and so forth)

the sample. See Fig. 2 and Fig. 3.

and a direct correlation between results in this test and field

NOTE 1—Temperature gradient within the sample may exist from the

varnish formation are yet to be established.

heating system and temperature control design.

5.3 Oxidation condition at 120 °C under accelerated oxida-

6.6 Wire Coiling Mandrel, as shown in Fig. 4.

tion environment of Test Method D4310 and measurement of

6.7 Thermometer Bracket, for holding the oxidation cell

sludge and RPVOTvalue could reflect a practical oil quality in

thermometer, of 18-8 stainless steel, having the dimensions

actual turbine operations. Results from this test should be used

shown in Fig. 5.The thermometer is held in the bracket by two

together with other key lubricant performance indicators (in-

fluoro-elastomer O-rings of approximately 5 mm inside diam-

cluding other established oxidation and corrosion tests) to

indicate suitability for service. eter. Alternatively, thin stainless steel wire may be used.

6.8 Abrasive Cloth, silicon carbide, 100 grit with cloth

6. Apparatus

backing.

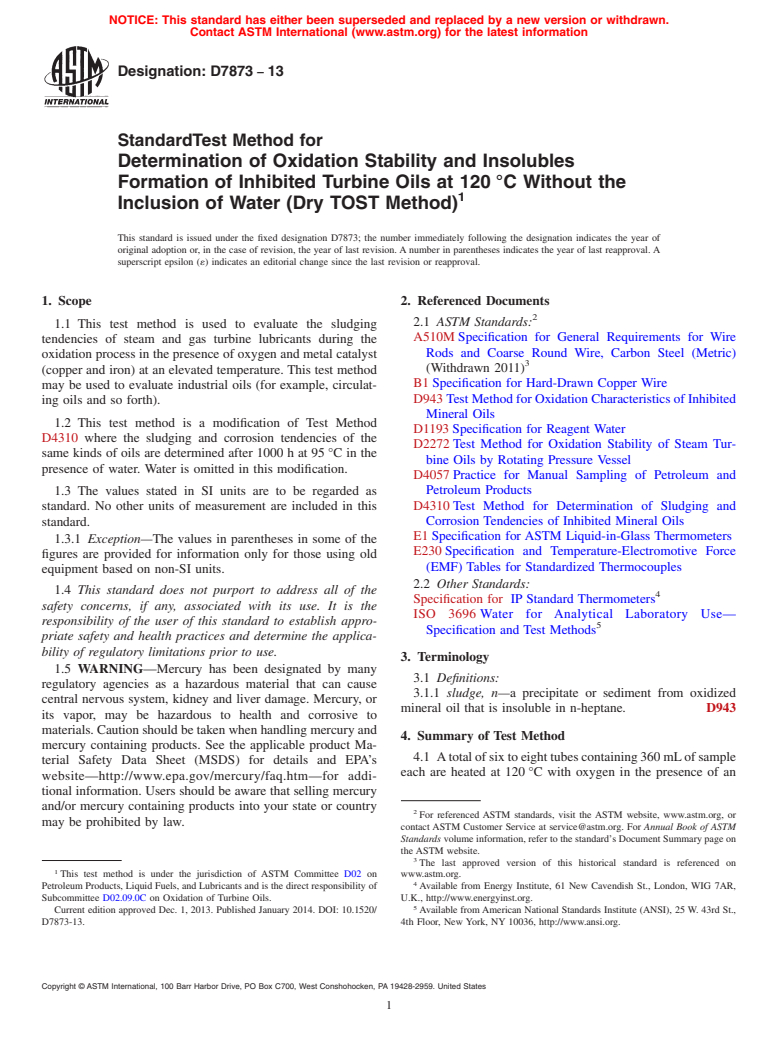

6.1 Oxidation Cell, of borosilicate glass, as shown in Fig. 1,

6.9 Flexible Tubing, poly vinyl chloride approximately 6.4

consisting of a test tube, condenser, and oxygen delivery tube.

1 3

mm ( ⁄4 in.) inside diameter with a 2.4 mm ( ⁄32 in.) wall for

It is recommended to have a test tube with a calibration line at

delivery of oxygen to the oxidation cell.

360 mL(maximum error 1 mL). This calibration applies to the

6.10 Membrane Filters, white, plain, 47 mm in diameter,

test tube without inserts at 20 °C.

pore size 1 µm. The recommended membrane filters are PTFE

6.2 Heating Bath, thermostatically controlled, capable of

and cellulose acetate plus nitrocellulose material.

maintaining the oil sample in the oxidation cell at a tempera-

6.11 Filter Holder, 47 mm, consisting of a borosilicate glass

ture of 120 °C 6 0.5 °C, fitted with a suitable stirring device to

funnel and a funnel base with a coarse grade fritted-glass filter

provide a uniform temperature throughout the bath, and large

support with a length of 40 µm to 60 µm, or stainless steel

enoughtoholdthedesirednumberofoxidationcellsimmersed

screen support such that the filter can be clamped between the

in the heating bath to a depth of 355 mm 6 10 mm. Heated

ground-glass sealing surfaces of the funnel and its base by

metal block baths meeting the test method requirements may

means of a metal clamp.

also be used.

6.2.1 Studies have suggested that direct sunlight or artificial

6.12 Weighing Bottle, cylindrical body with ground-glass

light may adversely influence the results of this test. To

stopper; approximate inside diameter 65 mm, height of body

minimize effects of light exposure on the lubricant being

45 mm , capacity 60 mL.

tested, light shall be excluded from the lubricant by one or

6.13 Vacuum Source, to provide pressure reduction to

more of the following ways:

13.3 kPa 6 0.7 kPa (100 mm 6 5 mm Hg) absolute pressure.

6.2.1.1 Use of heated liquid baths that are designed and

constructed of metal, or combinations of metals and other 6.14 Cooling Vessel, A desiccator or other type of tightly

suitable opaque materials, that prevent light from entering the covered vessel for cooling the weighing vessels before weigh-

test cell from the sides is preferred. If a viewing window is ing. The use of a drying agent is not recommended.

D7873 − 13

NOTE 1—All dimensions are in millimetres (inches).

NOTE 2—The oxidation test tube has a calibration line at 360 mL. This calibration applies to the test tube alone at 20 °C.

NOTE 3—Open tube ends to be ground and fire-polished.

FIG. 1 Oxidation Cell

D7873 − 13

all reagents shall conform to the specifications of the commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available.

7.2 Reagent Water, Unless otherwise indicated, reference to

water shall be understood to mean distilled, deionized water as

defined by Type I or Type II in Specification D1193 or Grade

3 in ISO 3696.

7.3 Acetone, Reagent grade. (Warning—Health hazard,

flammable.)

7.4 Cleaning Reagent, cleaning by a 24 h soak at room

temperature in a free rinsing liquid acid cleaner with a pH of 2

to 4.5.

7.5 n-heptane, Reagent grade. (Warning—Flammable.

Harmful if inhaled.)

7.6 Isopropyl Alcohol, Reagent grade. (Warning—

Flammable.)

7.7 Catalyst Wires,

7.7.1 Low-Metalloid Steel Wire—1.59 mm (0.0625 in.) in

diameter (No. 16 Washburn and Moen Gage).

NOTE 2—Carbon steel wire, soft bright annealed and free from rust of

Grade 1008 as described in Specification A510M is satisfactory. Similar

wire conforming to Specification E230 is also satisfactory

7.8 Electrolytic Copper Wire, 1.63 mm (0.064 in.) in diam-

eter (No. 16 Imperial Standard Wire Gage or No. 14American

Wire Gage), 99.9 % purity, conforming to Specification B1.

NOTE 3—Alternatively, suitably prepared steel and copper catalyst coils

may be purchased from a supplier.

7.9 Detergent, free rinsing, water-soluble, anionic detergent

with a pH of 9.5 to 11.

7.10 Oxygen—(Warning—Oxygen vigorously accelerates

combustion.) 99.5 % minimum purity, with pressure regulation

FIG. 2 Oxidation Cell with Thermometer

adequate to maintain a constant flow of gas through the

apparatus. The use of a two-stage pressure regulator on tank

oxygen is recommended.

8. Sampling

8.1 Samples for this test can come from tanks, drums, small

containers, or even operating equipment. Therefore, use the

applicable apparatus and techniques described in Practice

D4057.

8.2 For one single determination at a specified time the

minimum required sample size is 360 mL. However, 6 to 8

tubes will be required to develop the data points to obtain the

sludge mass at 25 % or agreed-upon residual RPVOT ratio by

FIG. 3 76 mm Immersion LIG Thermometer

logarithmic interpolation. Therefore, approximately 2200 mL

to 2900 mL will be required for this test.

6.15 Drying Oven, capable of maintaining a temperature of

9. Preparation of Apparatus

70 °C 6 5 °C.

9.1 Cleaning Catalyst—Immediately prior to winding a

6.16 Forceps, having unserrated tips.

catalyst coil, clean a 3.00 m 6 0.01 m length of iron wire and

6.17 Rubber Policeman.

6.18 Pipette Bulb.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

7. Reagents and Materials listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.1 Purity of Reagents—Reagent grade chemicals shall be

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

used in all tests. Unless otherwise indicated, it is intended that MD.

D7873 − 13

FIG. 4 Mandrel for Winding Catalyst Coils

showninFig.4isdesignedtoproducesuchacoil.Usingthismandrel,the

an equal length of copper wire with wads of absorbent cotton

ironwireiswoundonathreadof14.98mm(0.590in.)diameter,whilethe

wet with n-heptane and follow by abrasion with abrasive cloth

copper wire is wound on a thread of 15.9 mm (0.625 in.) diameter. The

until a fresh metal surface is exposed. Then wipe with dry

smaller diameter is to allow for “springback” of the steel wire after

absorbent cotton until all loose particles of metal and abrasive

winding, so as to give 15.9 mm consistent inside diameter. Use of a very

have been removed. In subsequent operations, handle the softannealedsteelwiremayallowuseofidenticalthreaddiametersforthe

two wires.Any arrangement that leads to the coil configuration described

catalyst wires with clean gloves (cotton, rubber, or plastic) to

above is satisfactory.

prevent contact with the skin.

9.3 Catalyst Storage—The catalyst coil may be stored in a

9.2 Preparation of Catalyst Coil—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.