ASTM A623-22

(Specification)Standard Specification for Tin Mill Products, General Requirements

Standard Specification for Tin Mill Products, General Requirements

ABSTRACT

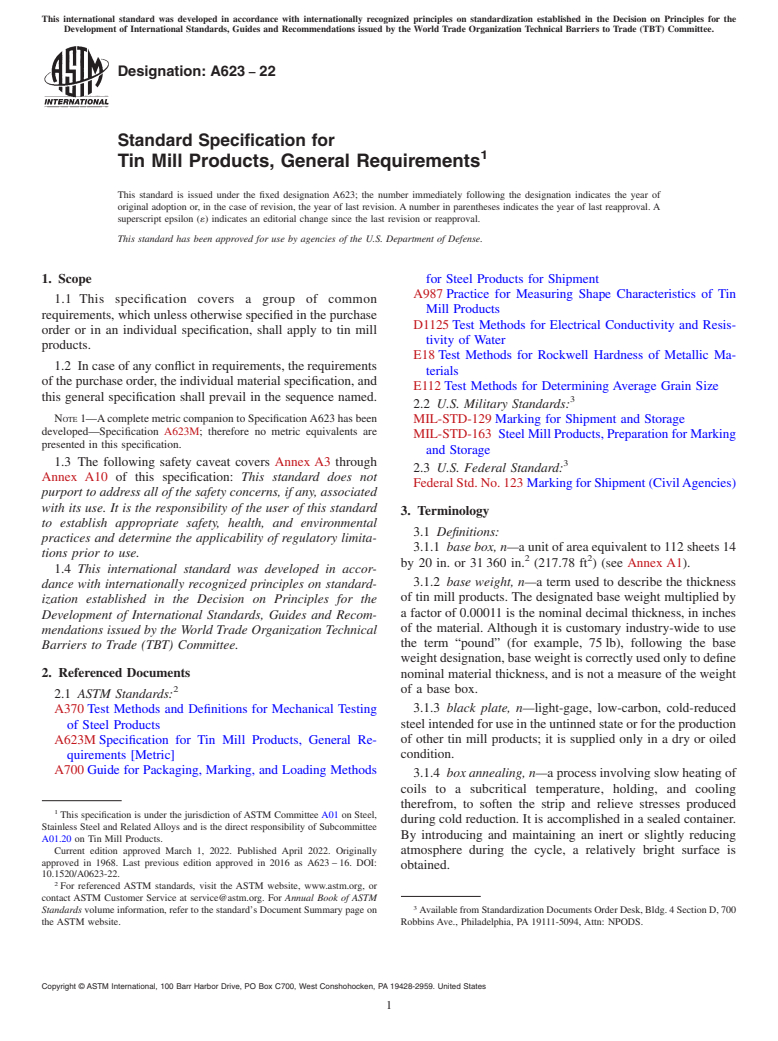

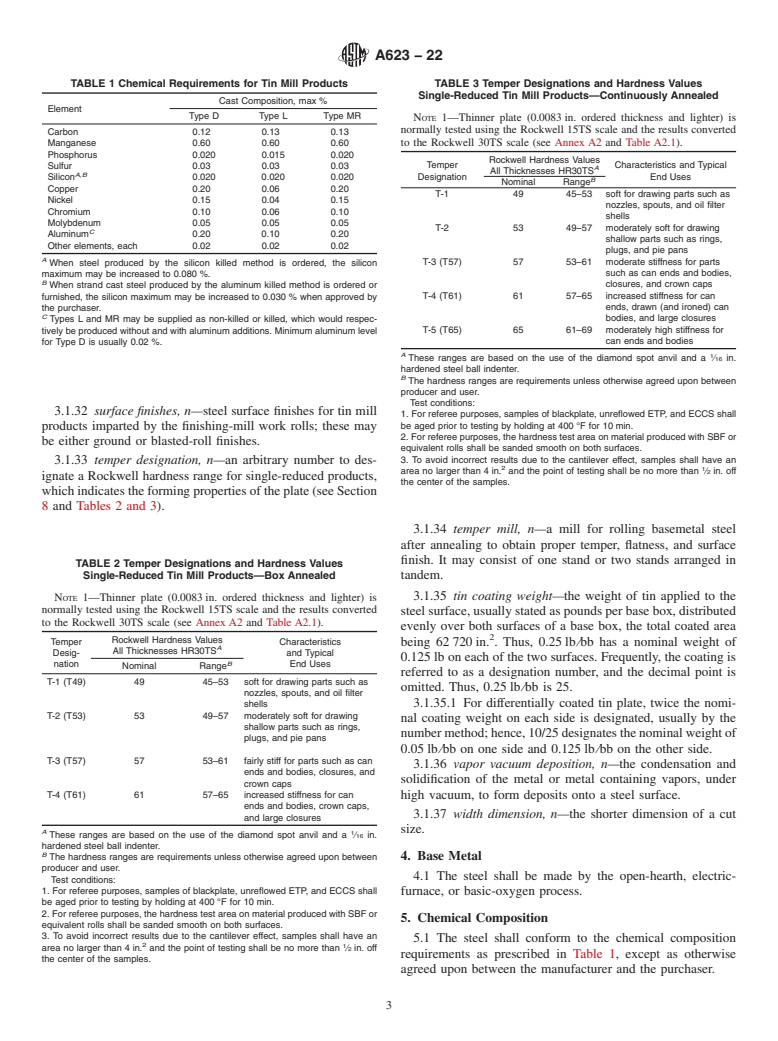

This specification covers a group of common requirements which shall apply to tin mill products. The steel shall be made by the open-hearth, electric-furnace, or basic-oxygen process. The steel shall conform to specified chemical composition requirements. Rockwell 30T hardness test shall be done to the plates. This test forms the basis for a system of temper designation. The mechanical properties of continuously annealed plate and batch annealed plate of the same Rockwell 30T temper designation are not identical. It is important to keep in mind, that the Rockwell 30T test does not measure all various factors which contribute to the fabrication characteristics of the plate.

SCOPE

1.1 This specification covers a group of common requirements, which unless otherwise specified in the purchase order or in an individual specification, shall apply to tin mill products.

1.2 In case of any conflict in requirements, the requirements of the purchase order, the individual material specification, and this general specification shall prevail in the sequence named.

Note 1: A complete metric companion to Specification A623 has been developed—Specification A623M; therefore no metric equivalents are presented in this specification.

1.3 The following safety caveat covers Annex A3 through Annex A10 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A623 −22

Standard Specification for

1

Tin Mill Products, General Requirements

This standard is issued under the fixed designation A623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope for Steel Products for Shipment

A987Practice for Measuring Shape Characteristics of Tin

1.1 This specification covers a group of common

Mill Products

requirements,whichunlessotherwisespecifiedinthepurchase

D1125Test Methods for Electrical Conductivity and Resis-

order or in an individual specification, shall apply to tin mill

tivity of Water

products.

E18Test Methods for Rockwell Hardness of Metallic Ma-

1.2 Incaseofanyconflictinrequirements,therequirements

terials

ofthepurchaseorder,theindividualmaterialspecification,and

E112Test Methods for Determining Average Grain Size

this general specification shall prevail in the sequence named.

3

2.2 U.S. Military Standards:

NOTE1—AcompletemetriccompaniontoSpecificationA623hasbeen MIL-STD-129Marking for Shipment and Storage

developed—Specification A623M; therefore no metric equivalents are

MIL-STD-163 SteelMillProducts,PreparationforMarking

presented in this specification.

and Storage

1.3 The following safety caveat covers Annex A3 through 3

2.3 U.S. Federal Standard:

Annex A10 of this specification: This standard does not

FederalStd.No.123MarkingforShipment(CivilAgencies)

purport to address all of the safety concerns, if any, associated

with its use. It is the responsibility of the user of this standard

3. Terminology

to establish appropriate safety, health, and environmental

3.1 Definitions:

practices and determine the applicability of regulatory limita-

3.1.1 base box, n—aunitofareaequivalentto112sheets14

tions prior to use.

2 2

by 20 in. or 31360 in. (217.78 ft ) (see Annex A1).

1.4 This international standard was developed in accor-

3.1.2 base weight, n—a term used to describe the thickness

dance with internationally recognized principles on standard-

of tin mill products. The designated base weight multiplied by

ization established in the Decision on Principles for the

a factor of 0.00011 is the nominal decimal thickness, in inches

Development of International Standards, Guides and Recom-

of the material. Although it is customary industry-wide to use

mendations issued by the World Trade Organization Technical

the term “pound” (for example, 75lb), following the base

Barriers to Trade (TBT) Committee.

weightdesignation,baseweightiscorrectlyusedonlytodefine

2. Referenced Documents nominal material thickness, and is not a measure of the weight

2

of a base box.

2.1 ASTM Standards:

3.1.3 black plate, n—light-gage, low-carbon, cold-reduced

A370Test Methods and Definitions for Mechanical Testing

steelintendedforuseintheuntinnedstateorfortheproduction

of Steel Products

of other tin mill products; it is supplied only in a dry or oiled

A623MSpecification for Tin Mill Products, General Re-

condition.

quirements [Metric]

A700Guide for Packaging, Marking, and Loading Methods

3.1.4 box annealing, n—aprocessinvolvingslowheatingof

coils to a subcritical temperature, holding, and cooling

therefrom, to soften the strip and relieve stresses produced

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

during cold reduction. It is accomplished in a sealed container.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

By introducing and maintaining an inert or slightly reducing

A01.20 on Tin Mill Products.

Current edition approved March 1, 2022. Published April 2022. Originally

atmosphere during the cycle, a relatively bright surface is

approved in 1968. Last previous edition approved in 2016 as A623–16. DOI:

obtained.

10.1520/A0623-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A623−22

3.1.5 bright finish, n—a surface that has a melted tin Lag (PL) (see Annex A3), Iron Solution Value (ISV) (see

coating.

...

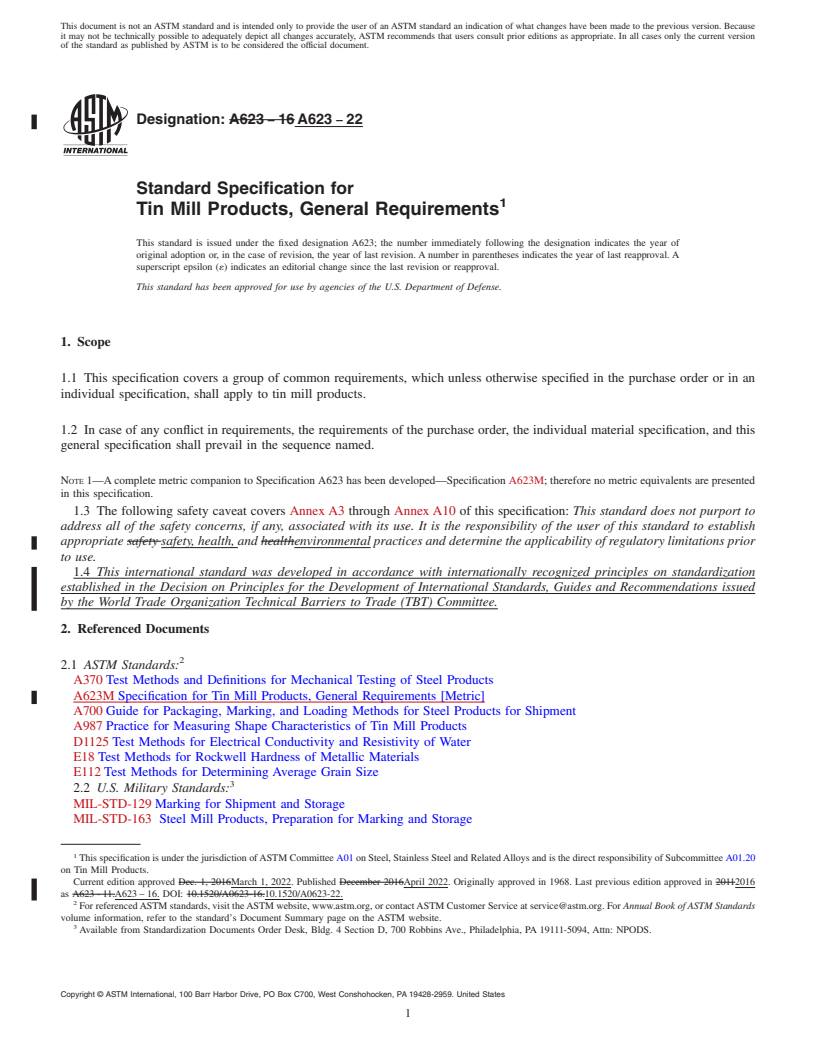

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A623 − 16 A623 − 22

Standard Specification for

1

Tin Mill Products, General Requirements

This standard is issued under the fixed designation A623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers a group of common requirements, which unless otherwise specified in the purchase order or in an

individual specification, shall apply to tin mill products.

1.2 In case of any conflict in requirements, the requirements of the purchase order, the individual material specification, and this

general specification shall prevail in the sequence named.

NOTE 1—A complete metric companion to Specification A623 has been developed—Specification A623M; therefore no metric equivalents are presented

in this specification.

1.3 The following safety caveat covers Annex A3 through Annex A10 of this specification: This standard does not purport to

address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory limitations prior

to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A623M Specification for Tin Mill Products, General Requirements [Metric]

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A987 Practice for Measuring Shape Characteristics of Tin Mill Products

D1125 Test Methods for Electrical Conductivity and Resistivity of Water

E18 Test Methods for Rockwell Hardness of Metallic Materials

E112 Test Methods for Determining Average Grain Size

3

2.2 U.S. Military Standards:

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products, Preparation for Marking and Storage

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.20

on Tin Mill Products.

Current edition approved Dec. 1, 2016March 1, 2022. Published December 2016April 2022. Originally approved in 1968. Last previous edition approved in 20112016

as A623 - 11.A623 – 16. DOI: 10.1520/A0623-16.10.1520/A0623-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

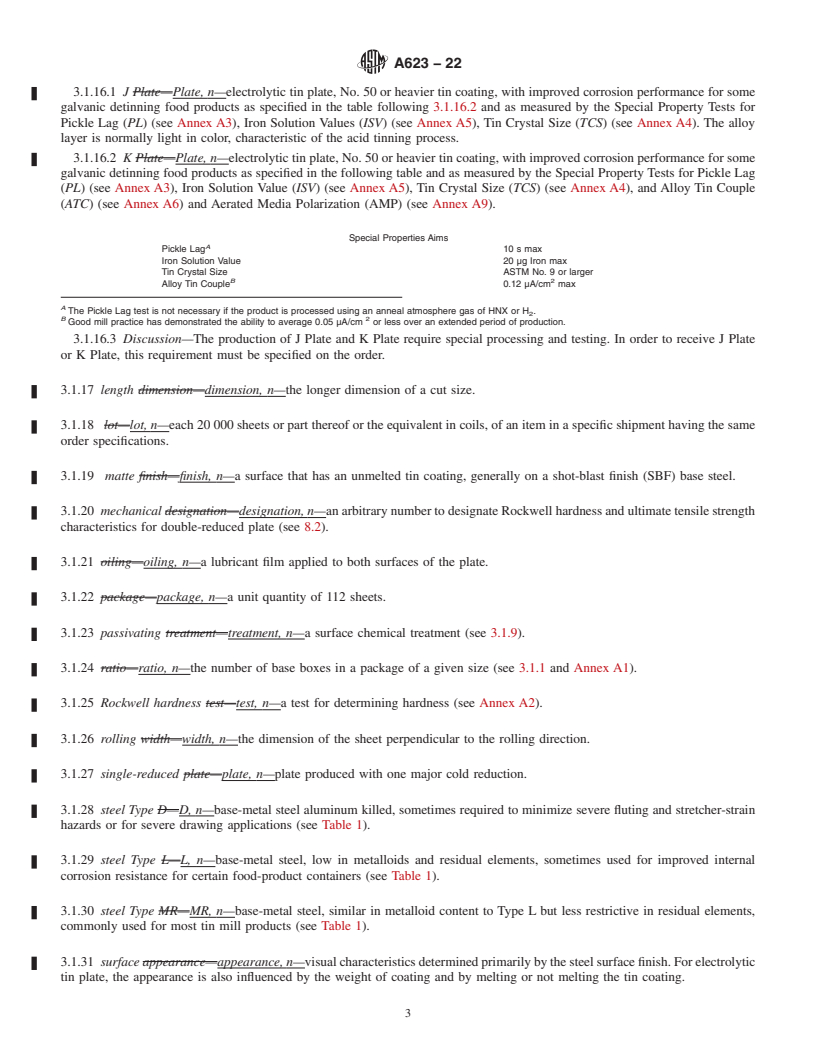

A623 − 22

3

2.3 U.S. Federal Standard:

Federal Std. No. 123 Marking for Shipment (Civil Agencies)

3. Terminology

3.1 Definitions:

2 2

3.1.1 base box, n—a unit of area equivalent to 112 sheets 14 by 20 in. or 31 360 in. (217.78 ft ) (see Annex A1).

3.1.2 base weight, n—a term used to describe the thickness of tin mill products. The designated base weight multiplied by a factor

of 0.00011 is the nominal decimal thickness, in inches of the material. Although it is customary industry-wide to use the term

“pound” (for example, 75 lb), 75 lb), following the base weight designation, base weight is correctly used only to define nominal

material thickness, and is not a measure of the weight of a base box.

3.1.3 black plate, n—light-gage, low-carbon, cold-reduced steel intended for use in the untinned state or for the production of other

tin mill products. Itproducts; it is supplied only in a dry or oiled condition.

3.1.4 box annealing, n—a process involving slow heating of coils to a subcritical temperature, holding, and cooling therefrom, to

soften the strip and relieve stresses produce

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.