ASTM D578-00

(Specification)Standard Specification for Glass Fiber Strands

Standard Specification for Glass Fiber Strands

SCOPE

1.1 This specification covers the requirements for continuous fiber and staple fiber glass strands, including single, plied and multiple wound. It also covers textured glass fiber yarns.

1.2 Glass fibers are produced having various compositions. General applications are identified by means of a letter designation. The letter designation represents a family of glasses that have provided acceptable performance to the end-user in the intended application. For example, the composition limits stated for E-Glass in this specification representing the glass fiber family for general and most electrical applications is designated by the letter. Military specifications, such as, MIL-R-60346, recognize the composition limits described in this specification as meeting the respective requirements for E-Glass strands used in reinforced plastic structure applications. This specification is intended to assist ultimate users by designating the general nomenclature for the strand products that are generally manufactured in the glass fiber industry.

1.3 Glass fiber strands have a variety of general uses under specific conditions, such as high physical or chemical stress, high moisture, high temperature, or electrical environments. Property requirements under specific conditions are agreed upon between the purchaser and the supplier. Electrical property requirements vary with specific end-use applications. For printed circuit board applications, other requirements may be desirable such as the use of Institute for Interconnecting and Packaging Electronic Circuits (IPC) Specification EG-140 for finished fabric woven from E-Glass for printed circuit boards, or Specification MIL-P-13949 for printed wiring boards applicable to glass fabric base.

1.4 This specification shows the values in both Si units and inch-pound units. "SI" units is the technically correct name for the system of metric units known as the International System of Units. "Inch-pound" units is the technically correct name for the customary units used in the United States. The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values expressed in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way.

1.5 This specification is one of a series to provide a substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, Sleeving, Cloth and Tape-Glass; and MIL-C-9084 Cloth, Glass Finished for Resin Laminates.

1.6 Additional ASTM specifications in this series have been drafted and appear in current editions of the Annual Book of ASTM Standards . These include finished glass fabrics, unfinished glass fabrics, glass tapes, glass sleevings, glass cords, glass sewing threads, and finished laminates made from finished glass fabrics.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 578 – 00

Standard Specification for

Glass Fiber Strands

This standard is issued under the fixed designation D578; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope system may not be exact equivalents; therefore, each system

must be used independently of the other, without combining in

1.1 This specification covers the requirements for continu-

any way.

ous fiber and staple fiber glass strands, including single, plied

1.5 This specification is one of a series to provide a

and multiple wound. It also covers textured glass fiber yarns.

substitute for Military Specifications: MIL-Y-1140Yarn, Cord,

1.2 Glass fibers are produced having various compositions.

Sleeving,ClothandTape-Glass;andMIL-C-9084Cloth,Glass

General applications are identified by means of a letter

Finished for Resin Laminates.

designation. The letter designation represents a family of

1.6 AdditionalASTMspecificationsinthisserieshavebeen

glasses that have provided acceptable performance to the

drafted and appear in current editions of the Annual Book of

end-user in the intended application. For example, the compo-

ASTM Standards. These include finished glass fabrics, unfin-

sitionlimitsstatedforE-Glassinthisspecificationrepresenting

ished glass fabrics, glass tapes, glass sleevings, glass cords,

the glass fiber family for general and most electrical applica-

glass sewing threads, and finished laminates made from fin-

tions is designated by the letter E. Military specifications, such

ished glass fabrics.

as, MIL-R-60346, recognize the composition limits described

1.7 This standard does not purport to address all of the

in this specification as meeting the respective requirements for

safety concerns, if any, associated with its use. It is the

E-Glass strands used in reinforced plastic structure applica-

responsibility of the user of this standard to establish appro-

tions. This specification is intended to assist ultimate users by

priate safety and health practices and determine the applica-

designating the general nomenclature for the strand products

bility of regulatory limitations prior to use.

that are generally manufactured in the glass fiber industry.

1.3 Glass fiber strands have a variety of general uses under

2. Referenced Documents

specific conditions, such as high physical or chemical stress,

2.1 ASTM Standards:

high moisture, high temperature, or electrical environments.

D76 Specification for Tensile Testing Machines for Tex-

Property requirements under specific conditions are agreed

tiles

upon between the purchaser and the supplier. Electrical prop-

D123 Terminology Relating to Textiles

erty requirements vary with specific end-use applications. For

D1423 TestMethodforTwistinYarnsbyDirectCounting

printed circuit board applications, other requirements may be

D 1907 Test Method for Yarn Number by the Skein

needed such as the use of Institute for Interconnecting and

Method

Packaging Electronic Circuits (IPC) Specification EG-140 for

D2256 Test Method for Tensile Properties of Yarns by the

finished fabric woven from E-Glass for printed circuit boards,

Single-Strand Method

or Specification MIL-P-13949 for printed wiring boards appli-

D2258 Practice for Sampling Yarn for Testing

cable to glass fabric base.

D2904 PracticeforInterlaboratoryTestingofaTextileTest

1.4 This specification shows the values in both SI units and

Method that Produces Normally Distributed Data

inch-pound units. “SI” units is the technically correct name for

D2906 Practice for Statements on Precision and Bias for

thesystemofmetricunitsknownastheInternationalSystemof

Textiles

Units.“ Inch-pound units” is the technically correct name for

D4963 Test Method for Ignition Loss of Glass Strands and

thecustomaryunitsusedintheUnitedStates.Thevaluesstated

Fabrics

in either acceptable metric units or in other units shall be

E171 Specification for Standard Atmospheres for Condi-

regarded separately as standard. The values expressed in each

tioning and Testing Flexible Barrier Materials

This specification is under the jurisdiction of ASTM Committee D-13 on

TextilesandisthedirectresponsibilityofSubcommitteeD13.18onGlassFiberand

Its Products. Annual Book of ASTM Standards, Vol 07.01.

Current edition approved March 10, 2000. Published May 2000. Originally Annual Book of ASTM Standards, Vol 07.02.

published as D578–40 T. Last previous edition D578–99. Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 578

2.2 ASTM Adjunct: 3.1.7 textured glass yarn, n—a yarn processed from con-

TEX-PAC tinuous filament yarn in such a manner to induce bulk to the

2.3 American National Standards: yarn by disorientation of the filaments.

MIL-STD-105 Sampling Procedures and Tables for Inspec- 3.1.8 For terminology of other textile terms used in this

tion by Attributes specification, refer to Terminology D123.

MIL-P-13949 Specification for Plastic Sheet, Laminated,

4. Classification of Glass Fiber

Metal-Clad For Printed Wiring Board

4.1 “C” Glass—Afamily of glasses composed primarily of

MIL-R-60346 Roving, Glass Fibrous (for Prepreg Tape,

the oxides of sodium, calcium, boron, aluminum, and silicon

Rovings, Filament Winding, and PultrusionApplications)

with a certified chemical composition which conforms to an

MIL-G-55656

applicablematerialspecificationandwhichproducesgoodacid

MIL-Y-1140 Specification for Yarn, Cord, Sleeving, Cloth,

resistance (excluding HF).

and Tape-Glass

4.2 “E” Glass—Afamily of glasses composed primarily of

MIL-C-9084 Specification for Cloth Finished for Resin

the oxides of calcium, aluminum, and silicon, which has the

Laminates

following certified chemical compositions.

2.4 Institute for Interconnecting and Packaging Circuits

4.2.1 The following certified chemical composition applies

Standard:

to glass fiber yarn products for printed circuit boards and

IPC-EG-140 Specification for Finished Fabric Woven from

7 aerospace.

E-Glass for Printed Circuit Boards

Chemical % by Weight

3. Terminology

B O 5to10

2 3

CaO 16 to 25

3.1 Definitions:

Al O 12 to 16

2 3

3.1.1 atmosphere for testing textiles, n—for glass, air main-

SiO 52 to 56

tained at a relative humidity of at least 48% and no greater MgO 0to5

Na O and K O 0 to 2

2 2

than 67%, and at a temperature of at least 20°C (68°F) and no

TiO 0to0.8

greater than 25°C (77°F).

Fe O 0.05 to

2 3

3.1.1.1 Discussion—Glass textiles are used in various prod- 0.4

Fluoride 0 to 1.0

ucts such as reinforced plastics, mat-like material, tire cords,

electrical insulation, etc. Each of these materials requires

4.2.2 The following certified chemical composition applies

differenttestingatmospheres.Itistheintentofthewidespread to glass fiber products used in general applications.

in testing atmosphere to allow testing of glass textiles in

Chemical % by Weight

respective laboratories where end product test atmosphere

B O 0to10

2 3

requirements differ. The test atmospheres for respective prod-

CaO 16 to 25

uctsshouldbecontrolledasspecifiedinSpecificationE171.It

Al O 12 to 16

2 3

SiO 52 to 62

is the opinion of Subcommittee D13.18 that the physical 2

MgO 0to5

properties cited in respective specifications would not be

Total alkali metal 0to2

affectedbytherangeselected.Inanyevent,thetestatmosphere

oxides

TiO 0to1.5

should be stated in the report.

Fe O 0.05 to 0.8

2 3

3.1.2 chopped strand, n— in glass textiles, a strand made

Fluoride 0 to 1.0

from short predetermined lengths of cut continuous filament

4.2.3 Electrical applications include a wide variety of uses.

and used as a reinforcing material. (See also strand).

Thecompositionin4.2.1isidenticaltoIPC-EG-140forprinted

3.1.3 continuous filament yarn, n—ayarnmadeoffilaments

circuit boards and to MIL-G-55636. Additionally, such fiber

that extend substantially throughout the length of the yarn.

glass products often are specified for aerospace applications.

3.1.4 roving, n—in glass textiles, a multiplicity of filaments

Productscoveredbythecompositionrangein4.2.2areusedin

or yarns gathered together into an approximately parallel

general applications, such as power company equipment, high

arrangement without twist.

voltage devices, residential electric boxes, third rail covers,

3.1.5 staple glass yarn, n—yarn made from filaments that

high voltage standoff rods, electrical pultrusion products, light

are nominally 200 to 380 mm (8 to 15 in.) in length.

poles, electrical tool covers, and electrical tape. Other applica-

3.1.6 strand, n—an ordered assemblage of textile fibers

tions include roofing, flooring, filtration, panel rovings, gun

having a high ratio of length to diameter and normally used as

rovings, smc rovings, chopped strand reinforcements, paper

a unit, including slivers, rovings, single yarns, plied yarns,

yarns, and industrial yarns.

cords, braids, ropes, etc.

4.2.4 The nomenclature “E-CR-Glass” is used for boron-

free modified E-Glass compositions for improved resistance to

corrosion by most acids.

4.3 “S” Glass—Afamily of glasses composed primarily of

PCprogramsonfloppydiskforanalyzingCommitteeD-13interlaboratorydata

are available through ASTM. Request ADJD2904.

the oxides of magnesium, aluminum, and silicon with a

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

certified chemical composition which conforms to an appli-

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

cablematerialspecificationandwhichproduceshighmechani-

Available from Institute for Interconnecting and Packaging Electronic Circuits,

7380 N. Lincoln Ave., Lincolnwood, IL 60646. cal strength.

D 578

DESCRIPTION OF GLASS STRANDS multiplying the yarn number designation of the single yarn or

strand by 100 to obtain yards per pound for the single yarn or

5. General

strand and then dividing by the total number of single yarns or

5.1 The construction of glass strands is described in a series

strands in the final yarn. Actual yardage is less because of

of two to four segments of alphabetical or numerical charac-

organic content and twist take-up during plying.

ters.

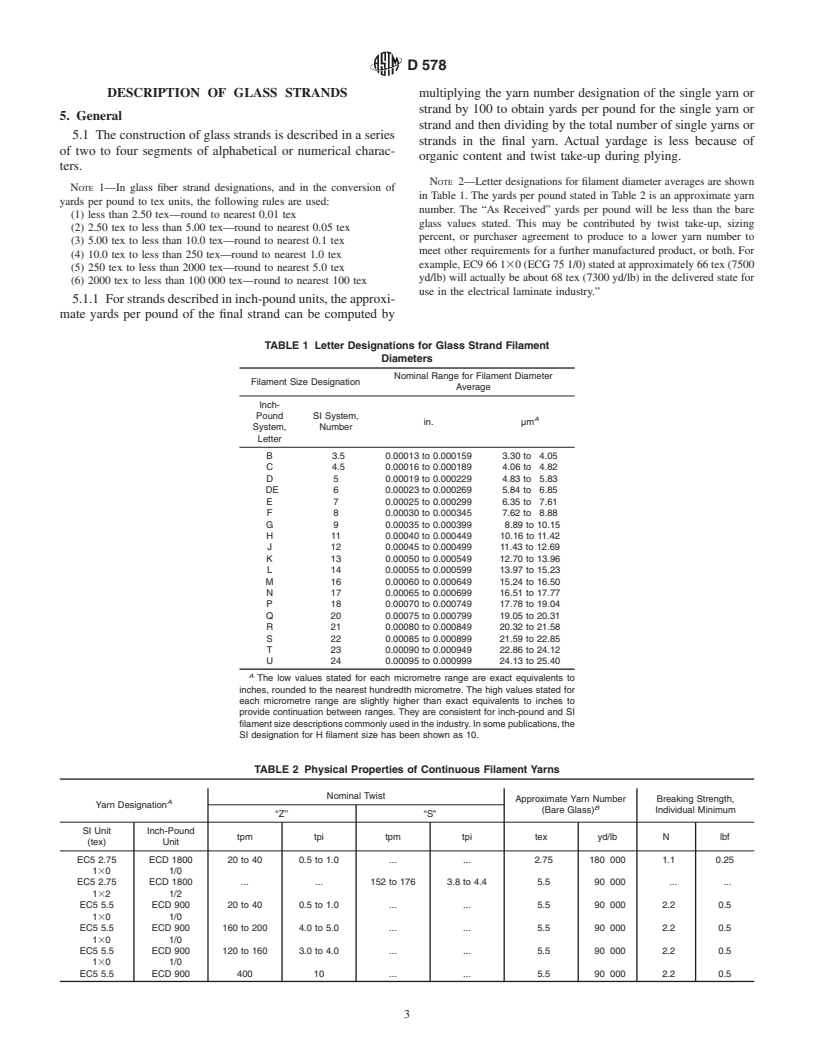

NOTE 2—Letter designations for filament diameter averages are shown

NOTE 1—In glass fiber strand designations, and in the conversion of

in Table 1. The yards per pound stated in Table 2 is an approximate yarn

yards per pound to tex units, the following rules are used:

number. The “As Received” yards per pound will be less than the bare

(1) less than 2.50 tex—round to nearest 0.01 tex

glass values stated. This may be contributed by twist take-up, sizing

(2) 2.50 tex to less than 5.00 tex—round to nearest 0.05 tex

percent, or purchaser agreement to produce to a lower yarn number to

(3) 5.00 tex to less than 10.0 tex—round to nearest 0.1 tex

meet other requirements for a further manufactured product, or both. For

(4) 10.0 tex to less than 250 tex—round to nearest 1.0 tex

example,EC966130(ECG751/0)statedatapproximately66tex(7500

(5) 250 tex to less than 2000 tex—round to nearest 5.0 tex

yd/lb) will actually be about 68 tex (7300 yd/lb) in the delivered state for

(6) 2000 tex to less than 100000 tex—round to nearest 100 tex

use in the electrical laminate industry.”

5.1.1 Forstrandsdescribedininch-poundunits,theapproxi-

mate yards per pound of the final strand can be computed by

TABLE 1 Letter Designations for Glass Strand Filament

Diameters

Nominal Range for Filament Diameter

Filament Size Designation

Average

Inch-

Pound SI System,

A

in. µm

System, Number

Letter

B 3.5 0.00013 to 0.000159 3.30 to 4.05

C 4.5 0.00016 to 0.000189 4.06 to 4.82

D 5 0.00019 to 0.000229 4.83 to 5.83

DE 6 0.00023 to 0.000269 5.84 to 6.85

E 7 0.00025 to 0.000299 6.35 to 7.61

F 8 0.00030 to 0.000345 7.62 to 8.88

G 9 0.00035 to 0.000399 8.89 to 10.15

H 11 0.00040 to 0.000449 10.16 to 11.42

J 12 0.00045 to 0.000499 11.43 to 12.69

K 13 0.00050 to 0.000549 12.70 to 13.96

L 14 0.00055 to 0.000599 13.97 to 15.23

M 16 0.00060 to 0.000649 15.24 to 16.50

N 17 0.00065 to 0.000699 16.51 to 17.77

P 18 0.00070 to 0.000749 17.78 to 19.04

Q 20 0.00075 to 0.000799 19.05 to 20.31

R 21 0.00080 to 0.000849 20.32 to 21.58

S 22 0.00085 to 0.000899 21.59 to 22.85

T 23 0.00090 to 0.000949 22.86 to 24.12

U 24 0.00095 to 0.000999 24.13 to 25.40

A

The low values stated for each micrometre range are exact equivalents to

inches, rounded to the nearest hundredth micrometre. The high values stated for

each micrometre range are slightly higher than exact equivalents to inches to

provide continuation between ranges. They are consistent for inch-pound and SI

filament size descriptions commonly used in the industry. In some publications, the

SI designation for H filament size has been shown as 10.

TABLE 2 Physical Properties of Continuous Filament Yarns

Nominal Twist

Approximate Yarn Number Breaking Strength,

A

Yarn Designation

B

(Bare Glass) Individual Minimum

“Z’’ “S”

SI Unit Inch-Pound

tpm tpi tpm tpi tex yd/lb N lbf

(tex) Unit

EC5 2.75 ECD 1800 20 to 40 0.5 to 1.0 . . 2.75 180 000 1.1 0.25

1301/0

EC5 2.75 ECD 1800 . . 152 to 176 3.8 to 4.4 5.5 90 000 . .

1321/2

EC5 5.5 ECD 900 20 to 40 0.5 to 1.0 . . 5.5 90 000 2.2 0.5

1301/0

EC5 5.5 ECD 900 160 to 200 4.0 to 5.0 . . 5.5 90 000 2.2 0.5

1301/0

EC5 5.5 ECD 900 120 to 160 3.0 to 4.0 . . 5.5 90 000 2.2 0.5

1301/0

EC5 5.5 ECD 900 400 10 . . 5.5 90 000 2.2 0.5

D 578

TABLE 2 Continued

Nominal Twist

Approximate Yarn Number Breaking Strength,

A

Yarn Designation

B

(Bare Glass) Individual Minimum

“Z’’ “S”

SI Unit Inch-Pound

tpm tpi tpm tpi tex yd/lb N lbf

(tex) Unit

1301/0

EC5 5.5 ECD 900 160 to 200 4.0 to 5.0 152 to 176 3.8 to 4.4 11 45 000 4.9 1.1

1321/2

EC5 5.5 ECD 900 . . 340 8.5 11 45 000 4.9 1.1

1321/2

EC5 11 ECD 450 20 to 40 0.5 to 1.0 . . 11 45 000 4.9 1.1

1301/0

EC5 11 ECD 450 40 to 80 1.0 to 2.0 . . 11 45 000 4.9 1.1

1301/0

EC5 11 ECD 450 80 to 120 2.0 to 3.0 . . 11 45 000 4.9 1.1

1301/0

EC5 11 ECD 450 160 to 200 4.0 to 5.0 . . 11 45 000 4.9 1.1

1301/0

EC5 11 ECD 450 400 10 . . 11 45 000 . .

1301/0

EC6 16 ECDE 300 20 to 40 0.5 to 1.0 . . 16 30 000 8.0 1.9

1301/0

EC5 5.5 ECD 900 . . 152 to 176 3.8 to 4.4 16.5 30 000 8.0 1.8

1331/3

EC5 5.5 ECD 900 . . 340 8.5 16.5 30 000 8.0 1.8

1331/3

EC5 11 ECD 450 160 to 200 4.0 to 5.0 . . 22 22 500 9.8 2.2

2302/0

EC5 11 ECD 450 . . 60 1.5 22 22 500 9.8 2.2

1321/2

EC5 11 ECD 450 160 to 200 4.0 to 5.0 152 to 176 3.8 to 4.4 22 22 500 9.8 2.2

1321/2

EC5 11 ECD 450 . . 340 8.5 22 22 500 9.8 2.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.