ASTM D578-05

(Specification)Standard Specification for Glass Fiber Strands

Standard Specification for Glass Fiber Strands

ABSTRACT

This specification covers the requirements for continuous fiber and staple fiber glass strands, including single, plied and multiple wound. It also covers textured glass fiber yarns. It is one of a series to provide a substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, Sleeving, Cloth and Tape-Glass; and MIL-C-9084 Cloth, Glass Finished for Resin Laminates. The nominal twist in S and Z directions and breaking strength of the continuous filament yarns shall conform to the specified requirements. The fibers shall be free of any free alkali metal oxides, such as soda or potash, and from foreign particles, dirt, and other impurities. The direction of twist, twist level, filament diameter, breaking strength, and ignition loss (organic content) of the fiber shall be tested.

SCOPE

1.1 This specification covers the requirements for continuous fiber and staple fiber glass strands, including single, plied and multiple wound. It also covers textured glass fiber yarns.

1.2 Glass fibers are produced having various compositions. General applications are identified by means of a letter designation. The letter designation represents a family of glasses that have provided acceptable performance to the end-user in the intended application. For example, the composition limits stated for E-Glass in this specification representing the glass fiber family for general and most electrical applications is designated by the letter E. Military specifications, such as, MIL-R-60346, recognize the composition limits described in this specification as meeting the respective requirements for E-Glass strands used in reinforced plastic structure applications. This specification is intended to assist ultimate users by designating the general nomenclature for the strand products that are generally manufactured in the glass fiber industry.

1.3 Glass fiber strands have a variety of general uses under specific conditions, such as high physical or chemical stress, high moisture, high temperature, or electrical environments. Property requirements under specific conditions are agreed upon between the purchaser and the supplier. Electrical property requirements vary with specific end-use applications. For printed circuit board applications, other requirements may be needed such as the use of Institute for Interconnecting and Packaging Electronic Circuits (IPC) Specification EG-4412 for finished fabric woven from E-Glass for printed circuit boards, or Specification MIL-P-13949 for printed wiring boards applicable to glass fabric base.

1.4 This specification shows the values in both SI units and inch-pound units. "SI" units is the technically correct name for the system of metric units known as the International System of Units." Inch-pound units" is the technically correct name for the customary units used in the United States. The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values expressed in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way.

1.5 This specification is one of a series to provide a substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, Sleeving, Cloth and Tape-Glass; and MIL-C-9084 Cloth, Glass Finished for Resin Laminates.

1.6 Additional ASTM specifications in this series have been drafted and appear in current editions of the Annual Book of ASTM Standards. These include finished glass fabrics, unfinished glass fabrics, glass tapes, glass sleevings, glass cords, glass sewing threads, and finished laminates made from finished glass fabrics.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D578 – 05

Standard Specification for

1

Glass Fiber Strands

This standard is issued under the fixed designation D578; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope in either acceptable metric units or in other units shall be

regarded separately as standard. The values expressed in each

1.1 This specification covers the requirements for continu-

system may not be exact equivalents; therefore, each system

ous fiber and staple fiber glass strands, including single, plied

must be used independently of the other, without combining in

and multiple wound. It also covers textured glass fiber yarns.

any way.

1.2 Glass fibers are produced having various compositions.

1.5 This specification is one of a series to provide a

General applications are identified by means of a letter

substitute for Military Specifications: MIL-Y-1140Yarn, Cord,

designation. The letter designation represents a family of

Sleeving,ClothandTape-Glass;andMIL-C-9084Cloth,Glass

glasses that have provided acceptable performance to the

Finished for Resin Laminates.

end-user in the intended application. For example, the compo-

1.6 AdditionalASTMspecificationsinthisserieshavebeen

sitionlimitsstatedforE-Glassinthisspecificationrepresenting

drafted and appear in current editions of the Annual Book of

the glass fiber family for general and most electrical applica-

ASTM Standards. These include finished glass fabrics, unfin-

tions is designated by the letter E. Military specifications, such

ished glass fabrics, glass tapes, glass sleevings, glass cords,

as, MIL-R-60346, recognize the composition limits described

glass sewing threads, and finished laminates made from fin-

in this specification as meeting the respective requirements for

ished glass fabrics.

E-Glass strands used in reinforced plastic structure applica-

1.7 This standard does not purport to address all of the

tions. This specification is intended to assist ultimate users by

safety concerns, if any, associated with its use. It is the

designating the general nomenclature for the strand products

responsibility of the user of this standard to establish appro-

that are generally manufactured in the glass fiber industry.

priate safety and health practices and determine the applica-

1.3 Glass fiber strands have a variety of general uses under

bility of regulatory limitations prior to use.

specific conditions, such as high physical or chemical stress,

high moisture, high temperature, or electrical environments.

2. Referenced Documents

Property requirements under specific conditions are agreed

2

2.1 ASTM Standards:

upon between the purchaser and the supplier. Electrical prop-

D76 Specification forTensileTesting Machines forTextiles

erty requirements vary with specific end-use applications. For

D123 Terminology Relating to Textiles

printed circuit board applications, other requirements may be

D1423 Test Method for Twist in Yarns by Direct-Counting

needed such as the use of Institute for Interconnecting and

D1907 Test Method for Linear Density of Yarn (Yarn

PackagingElectronicCircuits(IPC)SpecificationEG-4412for

Number) by the Skein Method

finished fabric woven from E-Glass for printed circuit boards,

D2256 Test Method for Tensile Properties of Yarns by the

or Specification MIL-P-13949 for printed wiring boards appli-

Single-Strand Method

cable to glass fabric base.

D2258 Practice for Sampling Yarn for Testing

1.4 This specification shows the values in both SI units and

D2904 Practice for Interlaboratory Testing of a Textile Test

inch-poundunits.“SI”unitsisthetechnicallycorrectnamefor

Method that Produces Normally Distributed Data

thesystemofmetricunitsknownastheInternationalSystemof

D2906 Practice for Statements on Precision and Bias for

Units.“ Inch-pound units” is the technically correct name for

3

Textiles

thecustomaryunitsusedintheUnitedStates.Thevaluesstated

1 2

This specification is under the jurisdiction of ASTM Committee D13 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

TextilesandisthedirectresponsibilityofSubcommitteeD13.18onGlassFiberand contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

its Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 15, 2005. Published October 2005. Originally the ASTM website.

3

approved in 1940. Last previous edition approved in 2000 as D578–00. DOI: Withdrawn. The last approved version of this historical standard is referenced

10.1520/D0578-05. on www.astm.org.

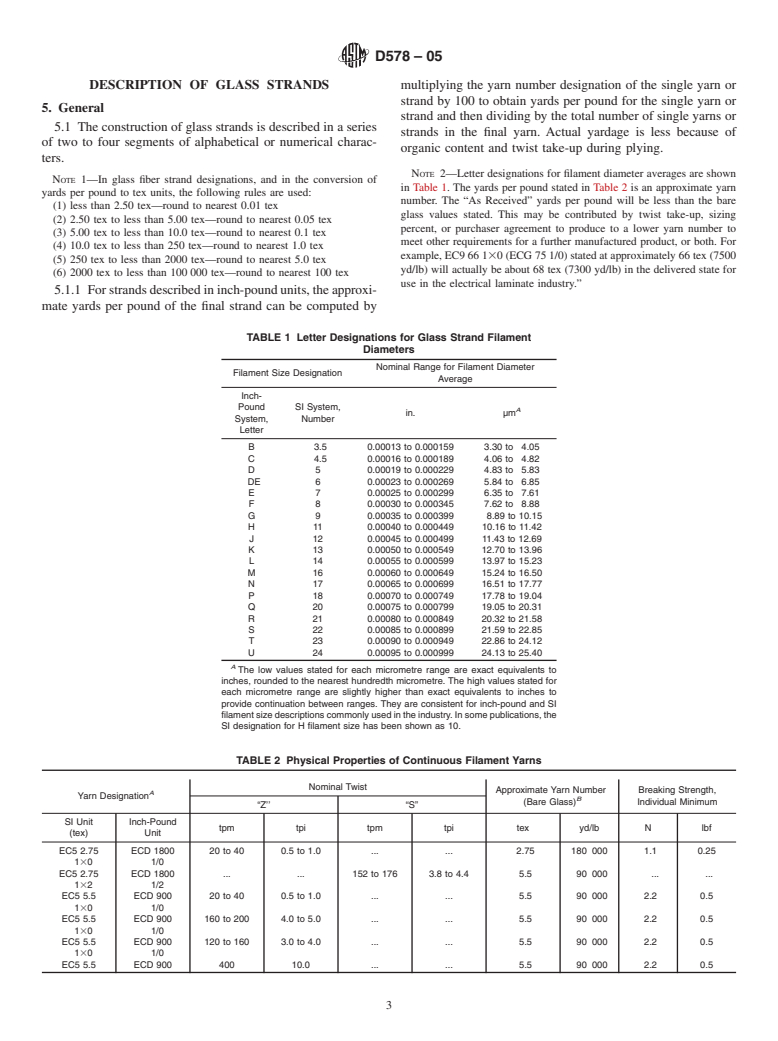

Co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.