ASTM B647-84(2000)

(Test Method)Standard Test Method for Indentation Hardness of Aluminum Alloys by Means of a Webster Hardness Gage

Standard Test Method for Indentation Hardness of Aluminum Alloys by Means of a Webster Hardness Gage

SCOPE

1.1 This test method covers the determination of indentation hardness of aluminum alloys with a Webster hardness gage, Model B.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

Note 1--Two other models, A and B-75, are in use, but are not covered in this test method. Model A does not provide numerical values of hardness and Model B-75 covers only a part of the range of interest for aluminum alloys.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B647–84 (Reapproved 2000)

Standard Test Method for

Indentation Hardness of Aluminum Alloys by Means of a

Webster Hardness Gage

This standard is issued under the fixed designation B 647; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of indentation 4.1 The Webster hardness gage is portable and therefore

hardness of aluminum alloys with a Webster hardness gage, useful for in situ determination of the hardness of fabricated

Model B. parts and individual test specimens for production control

1.2 The values stated in SI units are to be regarded as the purposes. It is not as sensitive as Rockwell or Brinell hardness

standard. The values given in parentheses are for information machines; see 10.2.

only. 4.2 This test method should be used only as cited in

applicable material specifications.

NOTE 1—Two other models,Aand B-75, are in use, but are not covered

in this test method. Model A does not provide numerical values of

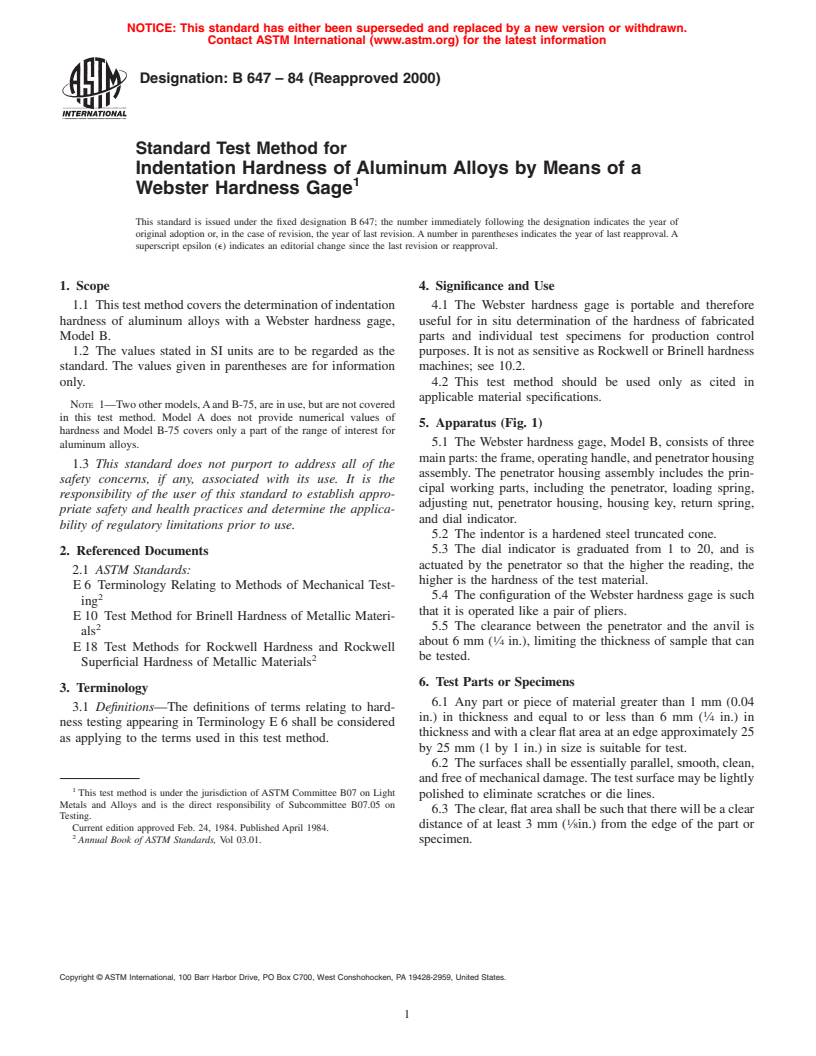

5. Apparatus (Fig. 1)

hardness and Model B-75 covers only a part of the range of interest for

5.1 The Webster hardness gage, Model B, consists of three

aluminum alloys.

mainparts:theframe,operatinghandle,andpenetratorhousing

1.3 This standard does not purport to address all of the

assembly. The penetrator housing assembly includes the prin-

safety concerns, if any, associated with its use. It is the

cipal working parts, including the penetrator, loading spring,

responsibility of the user of this standard to establish appro-

adjusting nut, penetrator housing, housing key, return spring,

priate safety and health practices and determine the applica-

and dial indicator.

bility of regulatory limitations prior to use.

5.2 The indentor is a hardened steel truncated cone.

5.3 The dial indicator is graduated from 1 to 20, and is

2. Referenced Documents

actuated by the penetrator so that the higher the reading, the

2.1 ASTM Standards:

higher is the hardness of the test material.

E 6 Terminology Relating to Methods of Mechanical Test-

2 5.4 The configuration of the Webster hardness gage is such

ing

that it is operated like a pair of pliers.

E 10 Test Method for Brinell Hardness of Metallic Materi-

2 5.5 The clearance between the penetrator and the anvil is

als

about 6 mm ( ⁄4 in.), limiting the thickness of sample that can

E 18 Test Methods for Rockwell Hardness and Rockwell

2 be tested.

Superficial Hardness of Metallic Materials

6. Test Parts or Specimens

3. Terminology

6.1 Any part or piece of material greater than 1 mm (0.04

3.1 Definitions—The definitions of terms relating to hard-

in.) in thickness and equal to or less than 6 mm ( ⁄4 in.) in

ness testing appearing in Terminology E 6 shall be considered

thickness and with a clear flat area at an edge approximately 25

as applying to the terms used in this test method.

by 25 mm (1 by 1 in.) in size is suitable for test.

6.2 The surfaces shall be essentially parallel, smooth, clean,

and free of mechanical damage.The test surface may be lightly

This test method is under the jurisdiction of ASTM Committee B07 on Light

polished to eliminate scratches or die lines.

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

6.3 The clear, flat area shall be such that there will be a clear

Testing.

distance of at least 3 mm ( ⁄8in.) from the edge of the part or

Current edition approved Feb. 24, 1984. Published April 1984.

Annual Book of ASTM Standards, Vol 03.01. specimen.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B647

FIG. 1 Webster Hardness Gage, Model B

6.4 Parts or specimens with a slight taper or curvature may

also be tested if a round anvil is used, as described in 8.1.1 and

Fig. 2.

7. Calibration

7.1 Zero Adjustment:

7.1.1 Operate the instrument against the bare anvil and note

whether or not the indicator gives the zero (full-scale) reading.

7.1.2 A correction in zero reading is normally not needed

except for one of the reasons listed below:

7.1.2.1 A new penetrator has been

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.