ASTM F1673-02

(Specification)Standard Specification for Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage Systems

Standard Specification for Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage Systems

SCOPE

1.1 This specification covers requirements for polyvinylidene drainage systems for corrosive applications. Requirements for material, pipe and fittings are included. Polyvinylidene fluoride includes emulsion/suspension polymerization and copolymers of vinylidene fluoride/hexafluoropropylene produced by either method.

1.2 These requirements apply to Schedule 40 and 80 IPS and SDR 21 pipe sizes. Pipe and fittings are to be joined by heat fusion or mechanical methods using the equipment supplied by the manufacturers.

1.3 This specification is not intended to provide for interchangeability between plastic pipe and fittings from different manufacturers, but it does allow for transition fittings for joining one manufacturer's product to another's product, provided the joining technique used is other than heat fusion.

1.4 This specification is not for polyvinylidene pressure systems.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.6 Notes and appendixes are not a mandatory part of this specification.

1.7 The following safety hazard caveat pertains only to the test method portion, Section 8, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1673 – 02

Standard Specification for

Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage

1

Systems

This standard is issued under the fixed designation F 1673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 543 Practice for Evaluating the Resistance of Plastics to

2

Chemical Reagents

1.1 This specification covers requirements for polyvi-

2

D 570 Test Method for Water Absorption of Plastics

nylidene drainage systems for corrosive applications. Require-

D 618 Practice for Conditioning Plastics and Electrical

ments for material, pipe and fittings are included. Polyvi-

2

Insulating Materials for Testing

nylidene fluoride includes emulsion/suspension polymerization

2

D 883 Terminology Relating to Plastics

and copolymers of vinylidene fluoride/hexafluoropropylene

D 1599 Test Method for Resistance to Short-Time Hydrau-

produced by either method.

3

lic Pressure of Plastic Pipe, Tubing, and Fittings

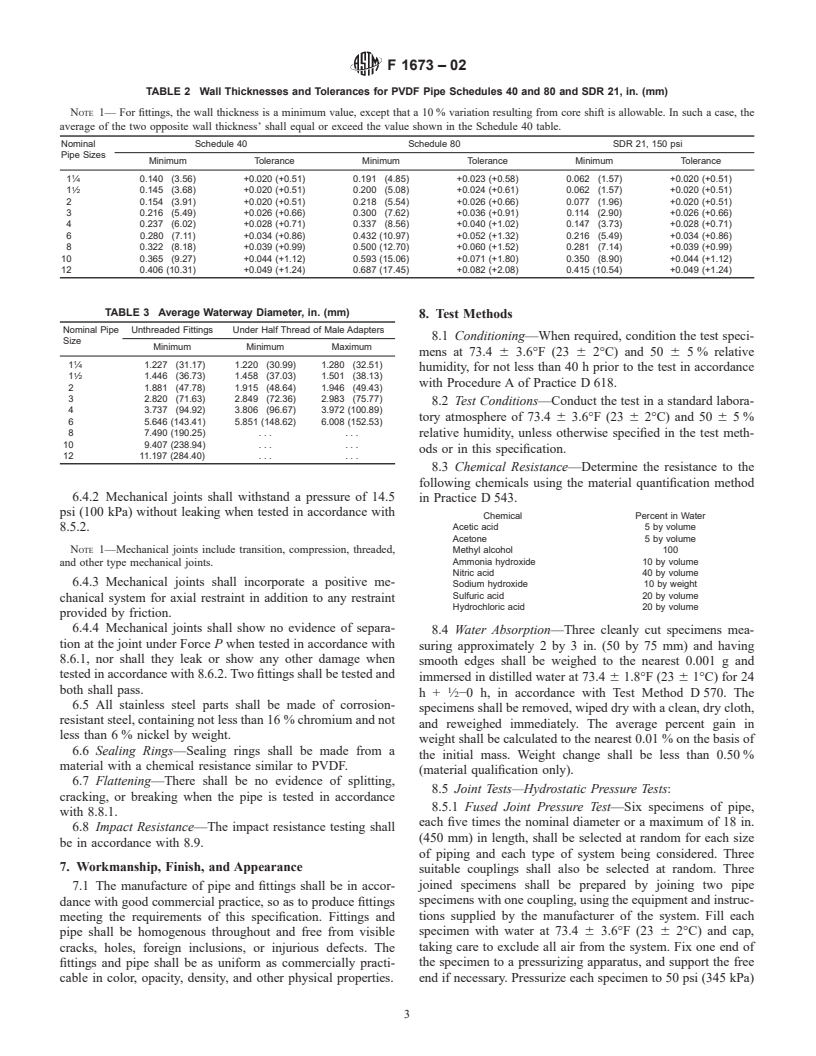

1.2 These requirements apply to Schedule 40 and 80 IPS

D 1600 Terminology for Abbreviated Terms Relating to

and SDR 21 pipe sizes. Pipe and fittings are to be joined by

2

Plastics

heat fusion or mechanical methods using the equipment

D 2122 Method for Determining Dimensions of Thermo-

supplied by the manufacturers.

3

plastic Pipe and Fittings

1.3 This specification is not intended to provide for inter-

D 2321 Practice for Underground Installation of Thermo-

changeability between plastic pipe and fittings from different

plastic Pipe for Sewer and Other Gravity-Flow Applica-

manufacturers, but it does allow for transition fittings for

3

tions

joining one manufacturer’s product to another’s product, pro-

D 2412 Test Method for Determination of External Loading

vided the joining technique used is other than heat fusion.

3

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.4 This specification is not for polyvinylidene pressure

D 2444 Test Method for Impact Resistance of Thermoplas-

systems.

3

tic Pipe and Fittings by Means of a Tup (Falling Weight)

1.5 The values stated in inch-pound units are to be regarded

D 2657 Practice for Heat Joining of Polyolefin Pipe and

as the standard. The values in parentheses are for information

3

Fittings

only.

D 3222 Specification for Unmodified Poly(Vinylidene

1.6 Notes and appendixes are not a mandatory part of this

Fluoride) (PVDF) Molding, Extrusion, and Coating Mate-

specification.

4

rials

1.7 The following safety hazard caveat pertains only to the

D 3311 Specification for Drain, Waste, and Vent (DWV)

test method portion, Section 8, of this specification: This

3

Plastic Fittings Patterns

standard does not purport to address all of the safety concerns,

D 5575 Specification for Copolymers of Vinylidene Fluo-

if any, associated with its use. It is the responsibility of the user

5

ride (VDF) with Other Fluorinated Monomers

of this standard to establish appropriate safety and health

3

F 412 Terminology Relating to Plastic Piping Systems

practices and determine the applicability of regulatory limita-

F 1290 Practice for Electrofusion Joining Polyolefin Pipe

tions prior to use.

3

and Fittings

2. Referenced Documents

F 1498 Specification for Taper Pipe Threads (60°) and

3

Thermoplastic Pipe and Fittings

2.1 ASTM Standards:

1 2

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Annual Book of ASTM Standards, Vol 08.01.

3

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. Annual Book of ASTM Standards, Vol 08.04.

4

Current edition approved Apr. 10, 2002. Published June 2002. Originally Annual Book of ASTM Standards, Vol 08.02.

5

published as F 1673 - 95. Last previous edition F 1673 - 95. Annual Book of ASTM Standards, Vol 08.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1673 – 02

TABLE 1 Outside Diameters and Tolerances for PVDF Pipe

2.2 Federal Standard:

6 Schedules 40 and 80 and SDR 21, in. (mm)

Fed. Std. No. 123 Marking for Shipment

Nominal Pipe Average Outside Tolerance Out-of-Roundness

2.3 Military Standard:

Size Diameter (Maximum Diameter

6

MIL-STD 129 Marking for Shipment and Storage

Minus Minimum

2.4 Other Standard:

Diameter)

7

Uniform Plumbing Code 1

1 ⁄4 1.660 (42.16) 60.005 (60.13) 0.050 (1.28)

1

1 ⁄2 1.900 (48.26) 60.006 (60.15) 0.060 (1.52)

2 2.375 (60.32) 60.006 (60.15) 0.070 (1.78)

3. Terminology

3 3.500 (88.90) 60.008 (60.20) 0.080 (2.04)

3.1 Definitions:

4 4.500 (114.30) 60.009 (60.23) 0.100 (2.54)

6 6.625 (168.28) 60.011 (60.28) 0.100 (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.