ASTM D5748-95(2007)

(Test Method)Standard Test Method for Protrusion Puncture Resistance of Stretch Wrap Film

Standard Test Method for Protrusion Puncture Resistance of Stretch Wrap Film

SIGNIFICANCE AND USE

Puncture resistance is very important in end-use performance of stretch wrap film used in consumer and industrial product applications. Puncture resistance is a measure of the energy-absorbing ability of a stretch wrap film in resisting a protrusion. The test method is designed to provide the user with a means of measuring the stretch wrap film’puncture resistance performance under essentially biaxial deformation conditions. A biaxial stress is representative of the type of stress encountered by stretch wrap products in many end-use applications.

Although this test method cannot be expected to duplicate all field experiences, since the rate of speed, weight, and configuration of such destructive forces vary widely, a generally reliable comparison of samples may be made from the data obtained.

SCOPE

1.1 This test method determines the resistance of a stretch wrap film to the penetration of a probe at a standard low rate, a single test velocity. Performed at standard conditions, the test method imparts a biaxial stress that is representative of the type of stress encountered in many product end-use applications. The maximum force, force at break, penetration distance, and energy to break are determined.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5748–95 (Reapproved 2007)

Standard Test Method for

Protrusion Puncture Resistance of Stretch Wrap Film

This standard is issued under the fixed designation D5748; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 energy—work to break.

3.2.3 maximum force—greatest force achieved.

1.1 This test method determines the resistance of a stretch

3.2.4 penetration distance—depth probe traveled in pen-

wrap film to the penetration of a probe at a standard low rate,

etrating film specimen, from initial probe contact with film

asingletestvelocity.Performedatstandardconditions,thetest

specimen, to penetration at break.

methodimpartsabiaxialstressthatisrepresentativeofthetype

3.2.5 protrusion puncture resistance—theabilityofaplastic

of stress encountered in many product end-use applications.

film to withstand the force exerted by a protrusion.

The maximum force, force at break, penetration distance, and

3.2.6 thickness (caliper, gage)—the perpendicular distance

energy to break are determined.

between the opposite surfaces of a plastic film.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Puncture resistance is very important in end-use perfor-

priate safety and health practices and determine the applica-

mance of stretch wrap film used in consumer and industrial

bility of regulatory limitations prior to use.

product applications. Puncture resistance is a measure of the

2. Referenced Documents energy-absorbing ability of a stretch wrap film in resisting a

protrusion. The test method is designed to provide the user

2.1 ASTM Standards:

with a means of measuring the stretch wrap film’s puncture

D618 Practice for Conditioning Plastics for Testing

resistance performance under essentially biaxial deformation

D996 Terminology of Packaging and Distribution Environ-

conditions. A biaxial stress is representative of the type of

ments

stress encountered by stretch wrap products in many end-use

D1898 Practice for Sampling of Plastics

applications.

D2103 Specification for Polyethylene Film and Sheeting

4.2 Although this test method cannot be expected to dupli-

E122 Practice for Calculating Sample Size to Estimate,

cate all field experiences, since the rate of speed, weight, and

With Specified Precision, the Average for a Characteristic

configuration of such destructive forces vary widely, a gener-

of a Lot or Process

allyreliablecomparisonofsamplesmaybemadefromthedata

E691 Practice for Conducting an Interlaboratory Study to

obtained.

Determine the Precision of a Test Method

5. Apparatus

3. Terminology

5.1 Universal Testing Apparatus.

3.1 Definitions—General definitions for packaging and dis-

5.2 Integrator and Chart Recorder.

tributions environments are found in Terminology D996.

5.3 Appropriate Load Cell—The test may be performed

3.2 Definitions of Terms Specific to This Standard:

using compression or tension load cell.

3.2.1 break force—force achieved at break.

5.4 Probe—A0.75 in. (19 mm) diameter pear-shaped TFE-

fluorocarboncoatedprobe (Fig.1),forgeneralapplicationand

This test method is under the jurisdiction of ASTM Committee D10 on

standard comparison of plastic films and interlaboratory re-

Packaging and is the direct responsibility of Subcommittee D10.25 on Palletizing

sults.

and Unitizing of Loads.

5.5 Specimen Clamping Fixture (Fig. 2).

Current edition approved April 1, 2007. Published May 2007. Originally

approved in 1995. Last previous edition approved in 2001 as D5748–95 (2001).

5.6 Micrometre, conforming to Specification D2103.

DOI: 10.1520/D5748-95R07.

5.7 Template, 6 by 6 in. (150 by 150 mm).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.8 Specimen Cutter.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced The probe is coated with duPont 954-101 Teflon S a thickness of 0.0015 in.

on www.astm.org. (0.0381 mm). Available from duPont.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

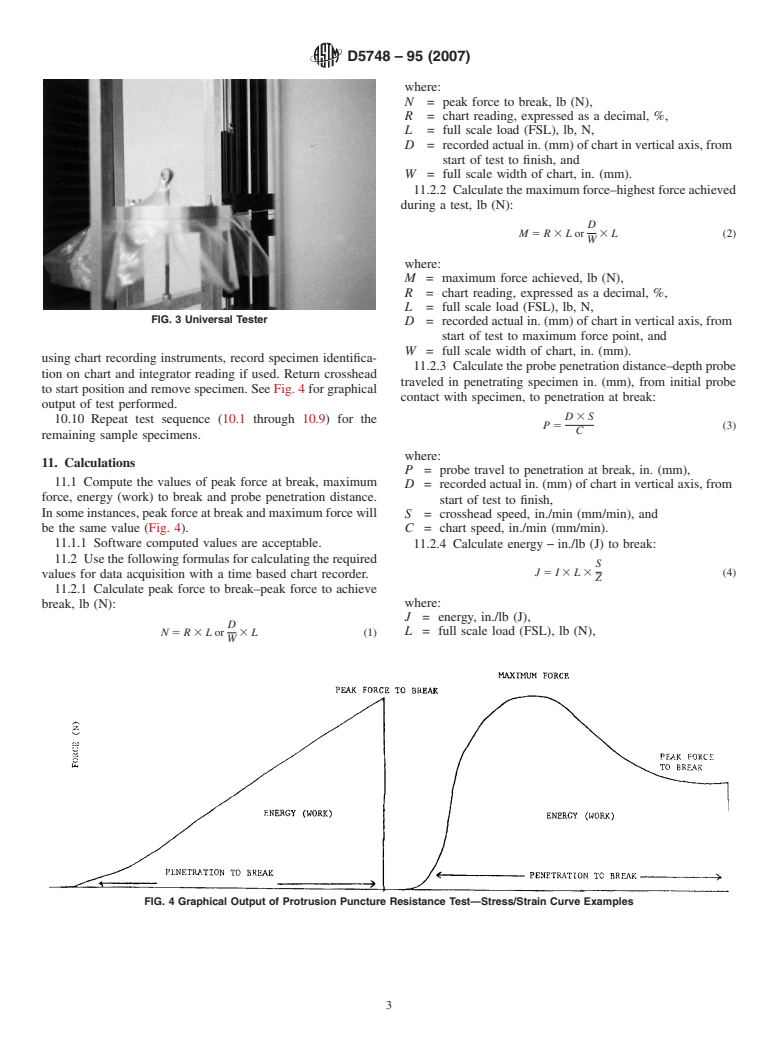

D5748–95 (2007)

NOTE 1—Measurements are in inches (millimetres).

FIG. 1 Probe

6. Sampling

6.1 Acceptance Sampling—Samplingshallbeinaccordance

with Practice D1898.

6.2 Sampling for Other Purposes—The sampling and the

numberoftestspecimensdependonthepurposeofthetesting.

Practice E122 is recommended.Test specimens are taken from

several rolls of film, and where possible, from several produc-

tion runs of film. Strong conclusions about a specific property

of a film cannot be based on a single roll of film.

7. Number of Test Specimens

7.1 Test a minimum of five specimens for each sample.

NOTE 1—Measurements are in inches (millimetres).

FIG. 2 Clamp

8. Preparation of Apparatus

8.1 For specific instruction in setting up and operating the

apparatus, consult the operations manual.

10.3 Using the template and specimen cutter, prepare a

8.2 Install probe apparatus (Fig. 2).

minimum of five specimens from each sample.

8.3 Center the probe (Fig. 1) over the specimen clamping

10.4 Measure the caliper (average of three readings) in the

fixture (Fig. 2).

center of each specimen and record the average.

10.5 Set universal tester crosshead speed at 10 in./min (250

9. Conditioning

mm/min)andchartrecorderspeedat10in./min(250mm/min).

9.1 Condition the test specimens at 73.4 6 3.6°F (23 6 If using an integrator instead of a data acquisition system, set

2°C) and 50 6 5% relative humidity for not less than 40 h

the counters to zero.

prior to testing in accordance with Procedure A of Practice 10.6 Clamp the specimen in the holder. Lower the probe as

D618.

close as possible to the specimen without actually touching.

9.2 Conduct tests in the standard laboratory atmosphere of 10.7 Set the appropriate stops and returns on the universal

23 6 2°C (73.4 6 3.6°F) and 50 6 5% relative humidity

tester. Reset data collection devices if applicable.

unless otherwise specified in the test method. 10.8 Activate the universal tester. Stop the crosshead when

the puncture probe passes completely through the film. Where

10. Procedure

holes occur other than at the probe point, the specimen test

10.1 With

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.