ASTM F1165-98

(Test Method)Standard Test Method for Measuring Angular Displacement of Multiple Images in Transparent Parts

Standard Test Method for Measuring Angular Displacement of Multiple Images in Transparent Parts

SCOPE

1.1 This test method covers measuring the angular separation of secondary images from their respective primary images as viewed from the design eye position of an aircraft transparency. Angular separation is measured at 49 points within a 20 by 20° field of view. This procedure may be performed on any aircraft transparency in a laboratory or in the field. However, the procedure is limited to a dark environment. Laboratory measurements are done in a darkened room and field measurements are done at night.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in acceptable metric units are to be regarded as the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1165 – 98

Standard Test Method for

Measuring Angular Displacement of Multiple Images in

Transparent Parts

This standard is issued under the fixed designation F 1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers measuring the angular separa-

tion of secondary images from their respective primary images

as viewed from the design eye position of an aircraft transpar-

ency. Angular separation is measured at 49 points within a 20

by 20° field of view. This procedure may be performed on any

aircraft transparency in a laboratory or in the field. However,

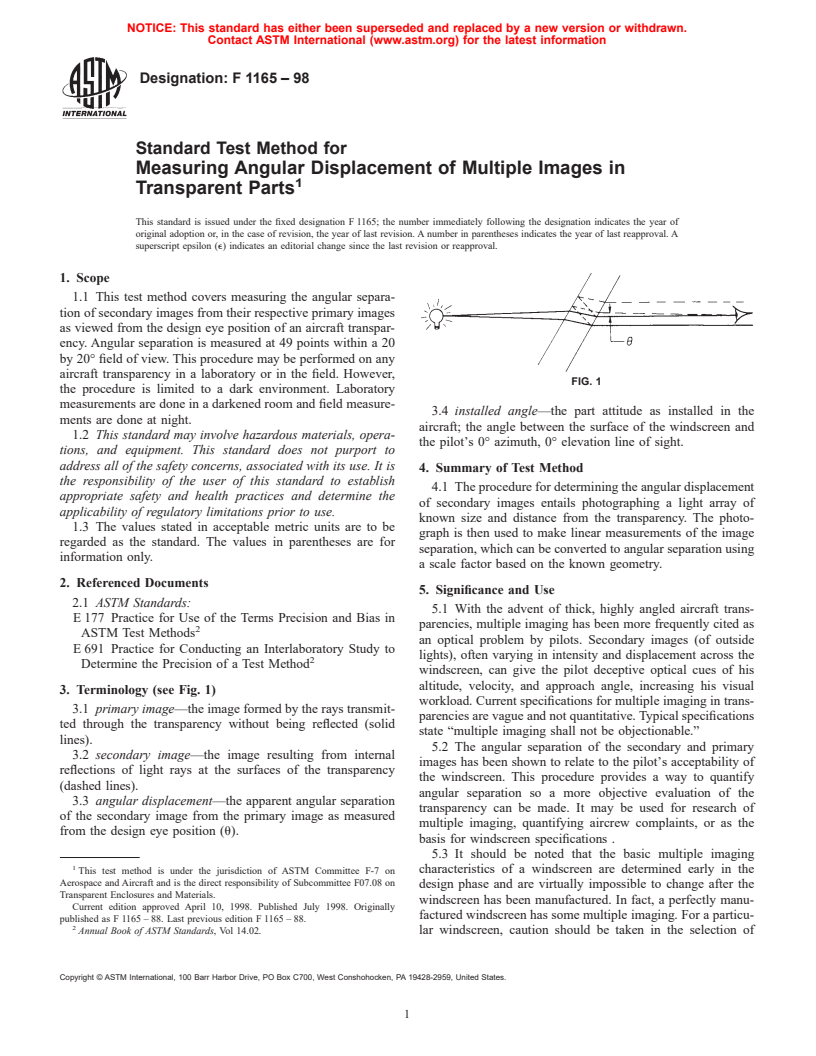

FIG. 1

the procedure is limited to a dark environment. Laboratory

measurements are done in a darkened room and field measure-

3.4 installed angle—the part attitude as installed in the

ments are done at night.

aircraft; the angle between the surface of the windscreen and

1.2 This standard may involve hazardous materials, opera-

the pilot’s 0° azimuth, 0° elevation line of sight.

tions, and equipment. This standard does not purport to

address all of the safety concerns, associated with its use. It is

4. Summary of Test Method

the responsibility of the user of this standard to establish

4.1 The procedure for determining the angular displacement

appropriate safety and health practices and determine the

of secondary images entails photographing a light array of

applicability of regulatory limitations prior to use.

known size and distance from the transparency. The photo-

1.3 The values stated in acceptable metric units are to be

graph is then used to make linear measurements of the image

regarded as the standard. The values in parentheses are for

separation, which can be converted to angular separation using

information only.

a scale factor based on the known geometry.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 With the advent of thick, highly angled aircraft trans-

E 177 Practice for Use of the Terms Precision and Bias in

parencies, multiple imaging has been more frequently cited as

ASTM Test Methods

an optical problem by pilots. Secondary images (of outside

E 691 Practice for Conducting an Interlaboratory Study to

lights), often varying in intensity and displacement across the

Determine the Precision of a Test Method

windscreen, can give the pilot deceptive optical cues of his

altitude, velocity, and approach angle, increasing his visual

3. Terminology (see Fig. 1)

workload. Current specifications for multiple imaging in trans-

3.1 primary image—the image formed by the rays transmit-

parencies are vague and not quantitative. Typical specifications

ted through the transparency without being reflected (solid

state “multiple imaging shall not be objectionable.”

lines).

5.2 The angular separation of the secondary and primary

3.2 secondary image—the image resulting from internal

images has been shown to relate to the pilot’s acceptability of

reflections of light rays at the surfaces of the transparency

the windscreen. This procedure provides a way to quantify

(dashed lines).

angular separation so a more objective evaluation of the

3.3 angular displacement—the apparent angular separation

transparency can be made. It may be used for research of

of the secondary image from the primary image as measured

multiple imaging, quantifying aircrew complaints, or as the

from the design eye position (u).

basis for windscreen specifications .

5.3 It should be noted that the basic multiple imaging

characteristics of a windscreen are determined early in the

This test method is under the jurisdiction of ASTM Committee F-7 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

design phase and are virtually impossible to change after the

Transparent Enclosures and Materials.

windscreen has been manufactured. In fact, a perfectly manu-

Current edition approved April 10, 1998. Published July 1998. Originally

factured windscreen has some multiple imaging. For a particu-

published as F 1165 – 88. Last previous edition F 1165 – 88.

Annual Book of ASTM Standards, Vol 14.02. lar windscreen, caution should be taken in the selection of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1165–98

aircraft when moving the elevated array. If wind conditions

present a hazard, do not attempt to measure.

8.3 Turn the array board on.

8.4 Place the camera in the design eye position and adjust

the camera such that the array is centered in the field of view;

focus the lens on the center light of the array.

8.5 Set the camera aperture to f/16 and the shutter speed to

an appropriate setting.

8.6 Take the picture(s) and develop 8 by 10 prints or a

suitable enlargement.

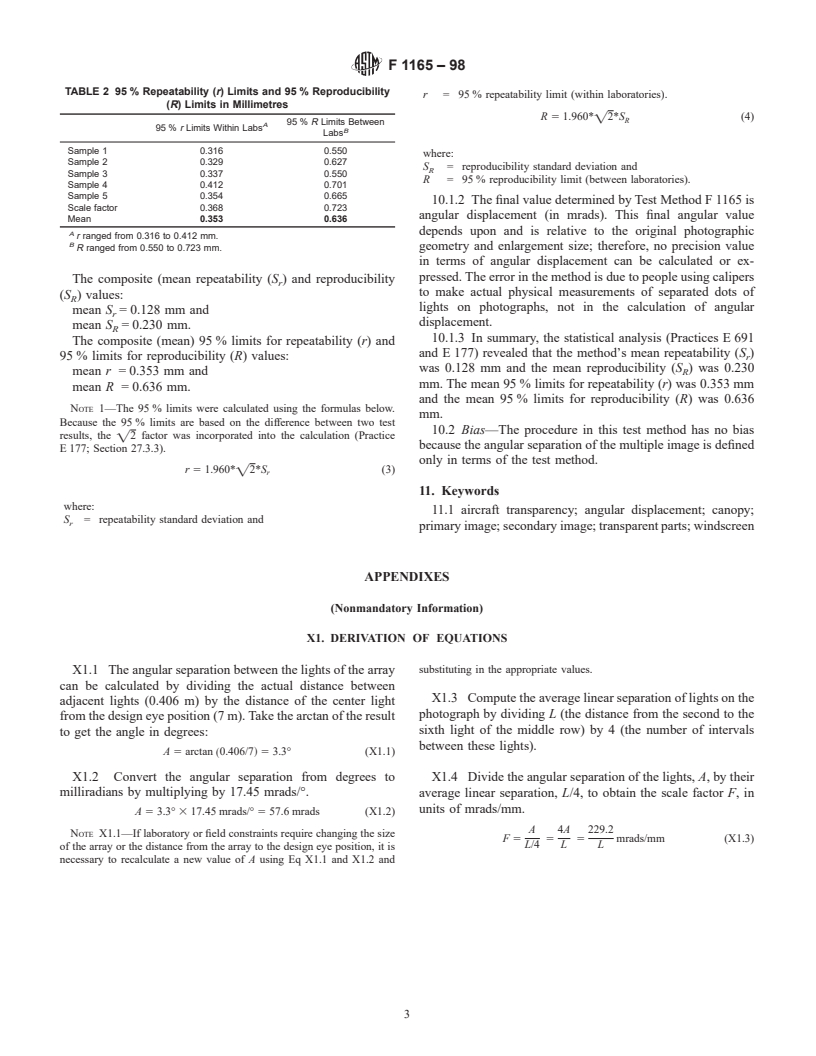

FIG. 2

8.7 On the photograph, measure the distance (L) from the

second light to the sixth light on the middle row. To ensure

specification criteria for multiple imaging, as the inherent

accuracy, use a precision measuring device, such as a digital

multiple imaging characteristics may vary significantly de-

caliper.

pending upon windscreen thickness, material, or installation

8.8 For each light in the 8 by 10 print, measure the linear

angle. Any tolerances that might be established should allow

separation (r) of the secondary image from the primary image

for inherent multiple imaging characteristics.

using the calipers. Measure from the center of both spots when

taking the measurement.

6. Apparatus

9. Calculation

6.1 Light Array—The light array isa7by7 matrix of small

incandescent lights (flashlight bulbs) mounted on a metal 9.1 To obtain the scale factor F, which relates the linear

frame. The separation of the lights is 406.4 mm (16 in.) on distances on the photograph to actual angular distances as

center making the overall dimensions of the array 2.44 by 2.44 measured from the design eye position, use the equation as

m (8 by 8 ft). A suitable power supply, such as a rechargable follows:

12-V d-c gel cell, is also required. A backdrop of nonreflective

229.2

F 5 mrads/mm (1)

material (such as black velvet) should be placed several inches

L

behind the array to block out background lights and prevent

reflections.

9.2 Compute the angular separation u for each light of the

6.2 Camera/film—No special camera or modification is

array using the equation:

needed for this process. The lens should have a focal length of

u5 r 3 F (2)

about 50 mm or as is necessary to permit the light array to fill

most of the field of view of the camera. The film should be

9.3 Enter the angular separation data intoa7by7 table so

black and white.

the rows and columns correspond to the location of lights on

7. Test Specimen

the array.

7.1 Position the part to be measured in the installed angle

10. Precision and Bias

(or installed in the aircraft for a field measurement) such that

10.1 Precision—An interlaboratory study (ASTM RR-

the camera is located in the pilot’s design eye position. No

F07 – 1003) was conducted to determine the precision of this

special conditioning other than cleaning is required.

standard. Twenty

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.