ASTM D3914-02

(Test Method)Standard Test Method for In-Plane Shear Strength of Pultruded Glass-Reinforced Plastic Rod

Standard Test Method for In-Plane Shear Strength of Pultruded Glass-Reinforced Plastic Rod

SIGNIFICANCE AND USE

Shear tests of various kinds are widely used in the reinforced plastics industry to assess the strength of the reinforcement-to-resin bond in polyester-, vinyl ester-, and epoxy-resin composites. In addition to their importance for the generation of data for research and development, quality control, and specification purposes, such tests are of fundamental value to the fibrous reinforcement industry, since they can be used to determine the potential of new sizing systems for the surface treatment of glass fibers.

The in-plane shear strength of pultruded cylindrical composites is an important property from an engineering standpoint, since pultruded rod, as such, is used in many structural applications.

SCOPE

1.1 This test method covers the determination of the in-plane shear strength of pultruded, glass-fiber reinforced, thermosetting plastic rod of diameters ranging from 19 to 32 mm (¾ to 1¼ in.).

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 2 and Note 3.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3914 – 02

Standard Test Method for

In-Plane Shear Strength of Pultruded Glass-Reinforced

1

Plastic Rod

This standard is issued under the fixed designation D 3914; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope compression tool, such as those shown in Fig. 1 and Fig. 2 of

Test Method D 695. Failure of the specimen occurs in shear

1.1 This test method covers the determination of the in-

between two centrally located notches, diametrically opposed

plane shear strength of pultruded, glass-fiber reinforced, ther-

and machined halfway through its diameter at a fixed distance

mosetting plastic rod of diameters ranging from 19 to 32 mm

3 1 apart. The notches are accurately machined in the specimen

( ⁄4 to 1 ⁄4in.).

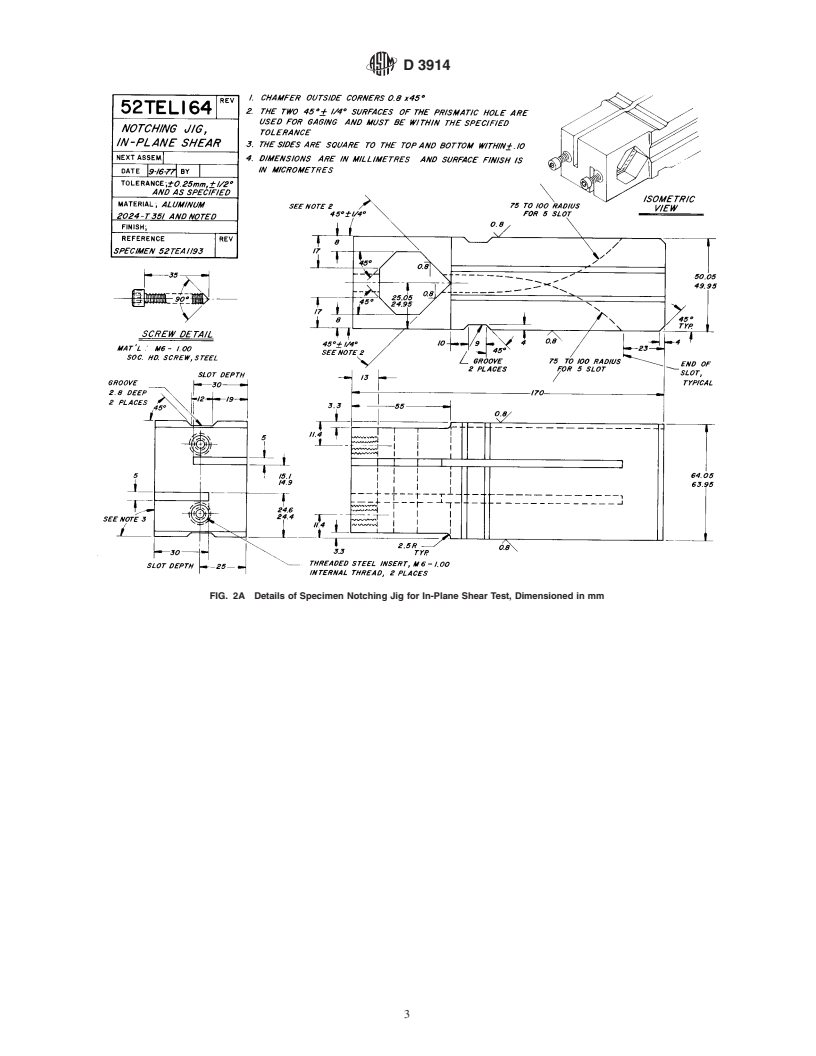

with maximum reproducibility by means of a special notching

1.2 The values stated in SI units are to be regarded as the

jig (Fig. 2a and Fig. 2b) designed specifically for this purpose.

standard.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Shear tests of various kinds are widely used in the

responsibility of the user of this standard to establish appro-

reinforced plastics industry to assess the strength of the

priate safety and health practices and determine the applica-

reinforcement-to-resin bond in polyester-, vinyl ester-, and

bility of regulatory limitations prior to use. Specific precau-

epoxy-resin composites. In addition to their importance for the

tionary statements are given in Note 2 and Note 3.

generation of data for research and development, quality

NOTE 1—There is no similar or equivalent ISO standard.

control,andspecificationpurposes,suchtestsareoffundamen-

tal value to the fibrous reinforcement industry, since they can

2. Referenced Documents

beusedtodeterminethepotentialofnewsizingsystemsforthe

2.1 ASTM Standards:

surface treatment of glass fibers.

2

D 618 Practice for Conditioning Plastics for Testing

5.2 The in-plane shear strength of pultruded cylindrical

D 695 Test Method for Compressive Properties of Rigid

composites is an important property from an engineering

2

Plastics

standpoint, since pultruded rod, as such, is used in many

3

E 4 Practices for Force Verification of Testing Machines

structural applications.

3. Terminology

6. Apparatus

3.1 Definition:

6.1 Testing Machine—Any suitable testing machine capable

3.1.1 in-plane shear strength—the shear strength at maxi-

of control of constant-rate-of-crosshead movement and com-

mum load in which the plane of fracture is centrally located

prising essentially the following:

along the longitudinal axis of the specimen between two

6.1.1 Drive Mechanism—A drive mechanism for imparting

diametrically opposed notches machined halfway through its

to the movable member a uniform, controlled velocity with

diameter.

respect to the stationary member, as required in 10.3.

6.1.2 Load Indicator—A load-indicating mechanism ca-

4. Summary of Test Method

pable of showing the total compressive load carried by the test

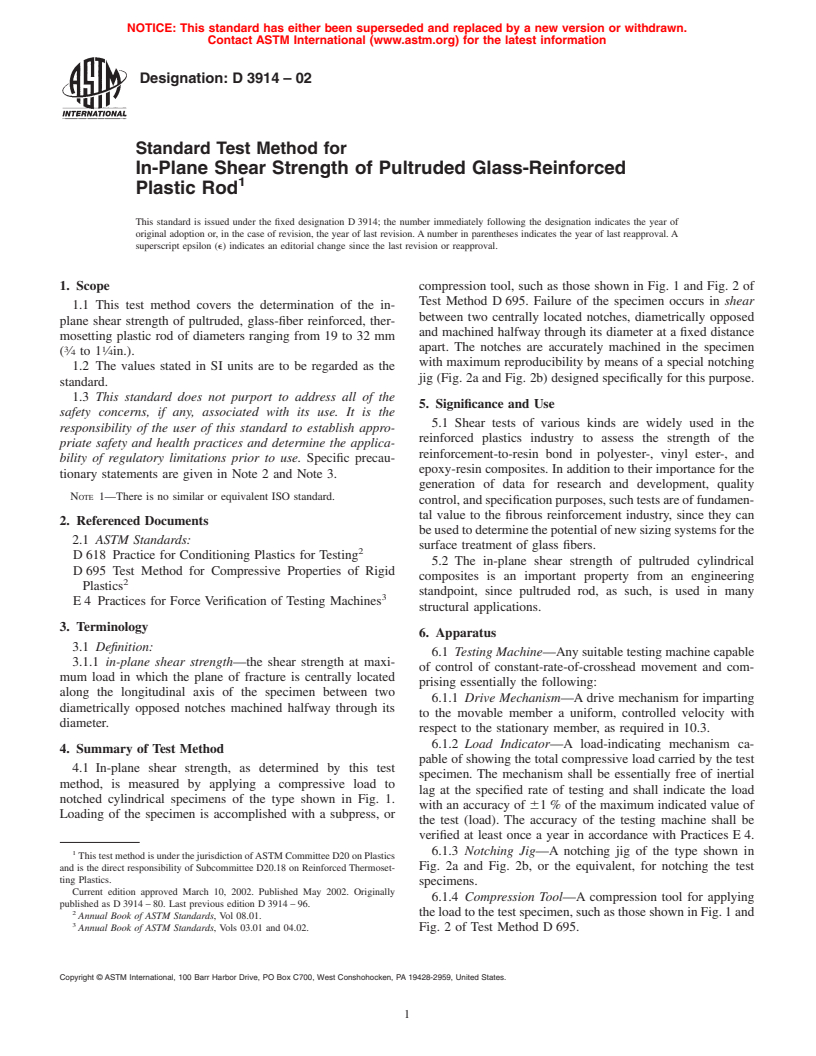

4.1 In-plane shear strength, as determined by this test

specimen. The mechanism shall be essentially free of inertial

method, is measured by applying a compressive load to

lag at the specified rate of testing and shall indicate the load

notched cylindrical specimens of the type shown in Fig. 1.

with an accuracy of 61 % of the maximum indicated value of

Loading of the specimen is accomplished with a subpress, or

the test (load). The accuracy of the testing machine shall be

verified at least once a year in accordance with Practices E 4.

1 6.1.3 Notching Jig—A notching jig of the type shown in

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

Fig. 2a and Fig. 2b, or the equivalent, for notching the test

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

ting Plastics.

specimens.

Current edition approved March 10, 2002. Published May 2002. Originally

6.1.4 Compression Tool—A compression tool for applying

published as D 3914 – 80. Last previous edition D 3914 – 96.

2 the load to the test specimen, such as those shown in Fig. 1 and

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vols 03.01 and 04.02. Fig. 2 of Test Method D 695.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3914

FIG. 1 Notched Rod In-Plane Shear Specimen; Dimensions: Top, mm; Bottom, in.

6.1.5 Micrometers—Suitable micrometers, reading to 0.025 the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.