ASTM D859-00

(Test Method)Standard Test Method for Silica in Water

Standard Test Method for Silica in Water

SCOPE

1.1 This test method covers the determination of silica in water and waste water; however, the analyst should recognize that the precision and accuracy statements for reagent water solutions may not apply to waters of different matrices.

1.2 This test method is a colorimetric method that determines molybdate-reactive silica. It is applicable to most waters, but some waters may require filtration and dilution to remove interferences from color and turbidity. This test method is useful for concentrations as low as 20 [u]g/L.

1.3 This test method covers the photometric determination of molybdate-reactive silica in water. Due to the complexity of silica chemistry, the form of silica measured is defined by the analytical method as molybdate-reactive silica. Those forms of silica that are molybdate-reactive include dissolved simple silicates, monomeric silica and silicic acid, and an undetermined fraction of polymeric silica.

1.4 The useful range of this test method is from 20 to 1000 [u]g/L at the higher wavelength (815 nm) and 0.1 to 5 mg/L at the lower wavelength (640 nm). It is particularly applicable to treated industrial waters. It may be applied to natural waters and wastewaters following filtration or dilution, or both. For seawater or brines, this test method is applicable only if matched matrix standards or standard addition techniques are employed.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1--For many natural waters, a measurement of molybdate-reactive silica by this test method provides a close approximation of total silica, and, in practice, the colorimetric method is frequently substituted for other more time-consuming techniques. This is acceptable when, as frequently occurs, the molybdate-reactive silica is in the milligram per liter concentration range while the nonmolybdate-reactive silica, if present at all, is in the microgram per liter concentration range.

1.6 Former Test Method A (Gravimetric--Total Silica) was discontinued. Refer to Appendix X1 for historical information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D 859–00

Standard Test Method for

Silica in Water

This standard is issued under the fixed designation D 859; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.6 Former Test Method A (Gravimetric—Total Silica) was

discontinued. Refer toAppendix X1 for historical information.

1.1 This test method covers the determination of silica in

water and waste water; however, the analyst should recognize

2. Referenced Documents

that the precision and accuracy statements for reagent water

2.1 ASTM Standards:

solutions may not apply to waters of different matrices.

D 1066 Practice for Sampling Steam

1.2 This test method is a colorimetric method that deter-

D 1129 Terminology Relating to Water

minesmolybdate-reactivesilica.Itisapplicabletomostwaters,

D 1193 Specification for Reagent Water

but some waters may require filtration and dilution to remove

D 2777 Practice for Determination of Precision and Bias of

interferences from color and turbidity. This test method is

Applicable Methods of Committee D-19 on Water

useful for concentrations as low as 20 µg/L.

D 3370 Practices for Sampling Water from Closed Con-

1.3 This test method covers the photometric determination

duits

of molybdate-reactive silica in water. Due to the complexity of

D 4841 Practice for Estimation of Holding Time for Water

silica chemistry, the form of silica measured is defined by the

Samples Containing Organic and Inorganic Constituents

analytical method as molybdate-reactive silica. Those forms of

D 5810 StandardGuideforSpikingintoAqueousSamples

silica that are molybdate-reactive include dissolved simple

D 5847 Standard Practice for the Writing Quality Control

silicates, monomeric silica and silicic acid, and an undeter-

Specifications for StandardTest Methods forWaterAnaly-

mined fraction of polymeric silica.

sis

1.4 The useful range of this test method is from 20 to 1000

E 60 Practice for Photometric and Spectrophotometric

µg/L at the higher wavelength (815 nm) and 0.1 to 5 mg/L at

Methods for Chemical Analysis of Metals

the lower wavelength (640 nm). It is particularly applicable to

E 275 Practice for Describing and Measuring Performance

treated industrial waters. It may be applied to natural waters

of Ultraviolet, Visible, and Near Infrared Spectrophotom-

and wastewaters following filtration or dilution, or both. For

eters

seawater or brines, this test method is applicable only if

matched matrix standards or standard addition techniques are

3. Terminology

employed.

3.1 Definitions—For definitions of terms used in this test

1.5 This standard does not purport to address all of the

method, refer to Terminology D 1129.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 This test method is based on the reaction of the soluble

bility of regulatory limitations prior to use.

silica with molybdate ion to form a greenish-yellow complex,

NOTE 1—For many natural waters, a measurement of molybdate-

which in turn is converted to a blue complex by reduction with

reactive silica by this test method provides a close approximation of total

1-amino-2-naphthol-1-sulfonic acid.

silica, and, in practice, the colorimetric method is frequently substituted

for other more time-consuming techniques. This is acceptable when, as

5. Significance and Use

frequently occurs, the molybdate-reactive silica is in the milligram per

5.1 Silicon comprises about 28 % of the lithosphere and is,

litreconcentrationrangewhilethenonmolybdate-reactivesilica,ifpresent

next to oxygen, the most abundant element. It is found as the

at all, is in the microgram per litre concentration range.

oxide in crystalline forms, as in quartz; combined with other

oxides and metals in a variety of silicates; and in amorphous

forms. Silicon is the most abundant element in igneous rocks

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.05 on Inorganic Constituents

in Water.

Current edition approved June 10, 2000. Published September 2000. Originally Annual Book of ASTM Standards, Vol 11.01.

published as D 859 – 45 T. Last previous edition D 859 – 94. Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D859–00

and is the characteristic element of all important rocks except 8. Reagents and Materials

the carbonates. It is the skeletal material of diatoms but is not

NOTE 3—Store all reagents to be used in this test method in polyeth-

known to play a significant role in the structure of processes of

ylene or other suitable plastic bottles.

higher life forms.

8.1 Purity of Reagents—Reagent grade chemicals shall be

5.2 Silica is only slightly soluble in water. The presence of

used in all tests. Unless otherwise indicated, it is intended that

most silica in natural waters comes from the gradual degrada-

all reagents shall conform to the specifications of the Commit-

tion of silica-containing minerals.The type and composition of

tee onAnalytical Reagents of theAmerican Chemical Society,

the silica-containing minerals in contact with the water and the

where such specifications are available. Other grades may be

pH of the water are the primary factors controlling both the

used, provided it is first ascertained that the reagent is of

solubility and the form of silica in the resulting solution. Silica

sufficiently high purity to permit its use without lessening the

may exist in suspended particles, as a colloid, or in solution. It

accuracy of the determination.

may be monomeric or polymeric. In solution it can exist as

8.2 Purity of Water— Unless otherwise indicated, refer-

silicic acid or silicate ion, depending upon pH. The silica

ences to water shall be understood to mean reagent water

content of natural waters is commonly in the 5 to 25 mg/L

conforming to Specification D 1193, Type II. In addition, the

range, although concentrations over 100 mg/L occur in some

water shall be made silica-free by distillation or demineraliza-

areas.

tion and determined as such in accordance with the method of

5.3 Silica concentration is an important consideration in

test being used. The collecting apparatus and storage contain-

some industrial installations such as steam generation and

ers for the reagent water must be polyethylene or other suitable

cooling water systems. Under certain conditions, silica forms

plastic.

troublesome silica and silicate scales, particularly on high-

8.3 Amino-Naphthol-Sulfonic Acid-Solution—Dissolve 0.5

pressure steam turbine blades. In cooling water systems, silica

g of 1-amino-2-naphthol-4-sulfonic acid in 50 mLof a solution

forms deposits when solubility limits are exceeded. In contrast,

containing 1 g of sodium sulfite (Na SO ). After dissolving,

2 3

silica may be added as a treatment chemical in some systems,

add the solution to 100 mL of a solution containing 30 g of

for example, in corrosion control. Silica removal is commonly

sodium hydrogen sulfite (NaHSO ). Make up to 200 mL and

accomplished by ion exchange, distillation, reverse osmosis, or

store in a dark, plastic bottle. Shelf life of this reagent may be

by precipitation, usually with magnesium compounds in a hot

extended by refrigeration. Solution should be adjusted to room

or cold lime softening process.

temperature, 25 6 5°C, before use. Discard when the color

darkens or a precipitate forms.

6. Interferences

8.4 Ammonium Molybdate Solution (75 g/L) (Note 4)—

6.1 Color and turbidity will interfere if not removed by

Dissolve 7.5 g of ammonium molybdate ((NH ) Mo -

4 6 7

filtration or dilution.

O ·4H O) in 100 mL of water.

24 2

6.2 The only specific substance known to interfere in the

NOTE 4—Batch to batch variations in ammonium molybdate have been

color reaction is phosphate. Phosphate interference is elimi-

found to affect results at low concentrations (below 0.1 mg/L). High

nated by the addition of oxalic acid.

blanks, nonlinear calibration curves, and poor reproducibility have been

6.3 Ahighdissolvedsaltsconcentration,suchasinseawater

observed with some batches of this compound. When working with low

or brine samples, can affect color development. This can be

concentrations of silica, a batch of ammonium molybdate known to

compensated for by preparing standards in a matrix similar to

produce reasonable blanks, linearity, and reproducibility should be set

that of samples or by using a standard additions technique.

aside for this purpose.

6.4 Strong oxidizing and reducing agents that may be found

8.5 Hydrochloric Acid (1 + 1)—Mix 1 volume of concen-

in some industrial waste waters may interfere in the reduction

trated hydrochloric acid (HCl, sp gr 1.19) with 1 volume of

step of the reaction. Such waste waters may also contain

water.

organic compounds that may interfere in the color formation.

8.6 OxalicAcid Solution(100g/L)—Dissolve10gofoxalic

acid (H C O ·2H O) in 100 mL of water.

2 2 4 2

7. Apparatus

8.7 Silica Solution, Standard (1 mL = 0.1 mg SiO )—

7.1 Spectrophotometer or Filter Photometer (see Note 2)—

Dissolve 0.473 g of sodium metasilicate (Na SiO ·9H O) in

2 3 2

To obtain maximum sensitivity and reproducibility, a spectro-

water and dilute to 1 L. Check the concentration of this

photometer suitable for measurements at 815 nm is required.

solution gravimetrically.

Measurements may be made at 640 nm with a spectrophotom-

NOTE 5—This solution may require filtration to remove fine particulate

eter,or640to700nmwithafilterphotometeriflesssensitivity

matter containing silica. This filtration, if needed, should precede stan-

is preferred. Precision and bias information on this test method

dardization gravimetrically. This step was not included as a requirement

(see Section 14) is based on data obtained at 815 nm.

NOTE 2—Photometers and photometric practices shall conform to

Reagent Chemicals, American Chemical Society Specifications, American

Practice E 60. Spectrophotometers shall conform to Practice E 275.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

7.2 Sample Cells— The cell size to be used depends on the

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

range covered and the particular instrument used. The higher

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

concentration range should be attainable with 10-mm path

MD.

length cells. Longer path length cells (40 to 50 mm) are

RefertoformerTestMethodA(Gravimetric—TotalSilica)lastpublishedinthe

recommended for concentrations below 0.1 mg/L. 1988 Annual Book of ASTM Standards for complete description of procedure.

D859–00

in the collaborative tests from which precision and bias determined.

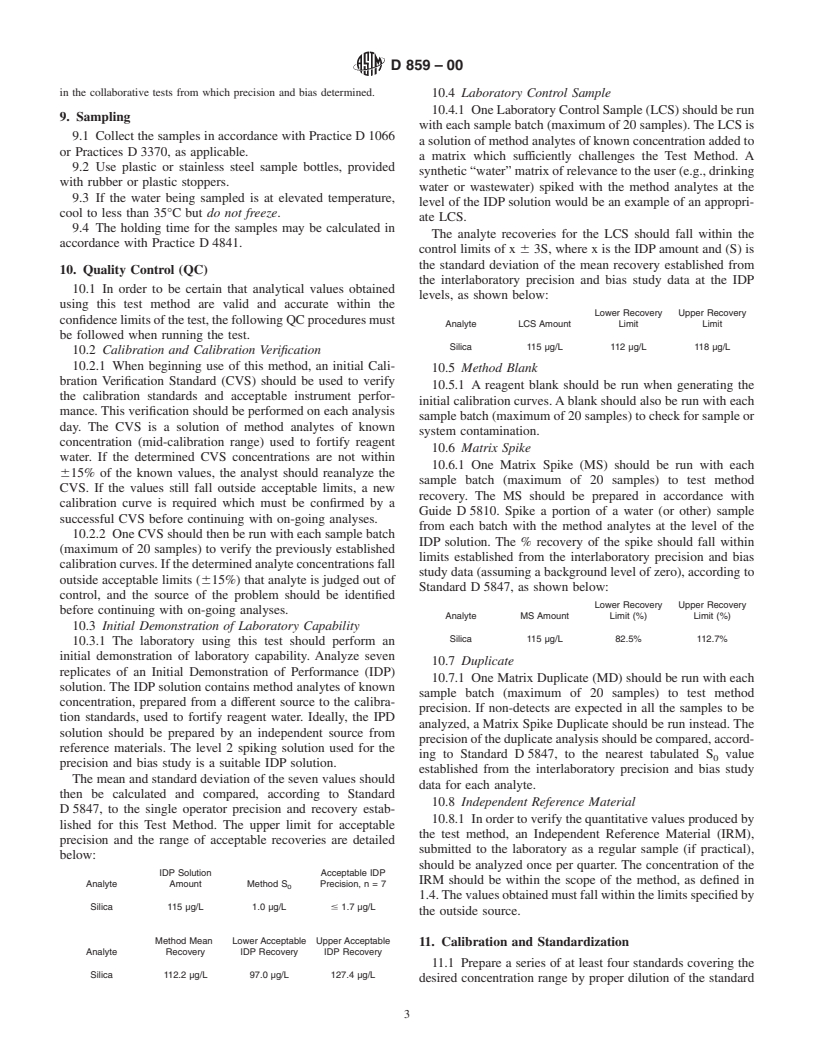

10.4 Laboratory Control Sample

10.4.1 OneLaboratoryControlSample(LCS)shouldberun

9. Sampling

with each sample batch (maximum of 20 samples).The LCS is

9.1 Collect the samples in accordance with Practice D 1066

a solution of method analytes of known concentration added to

or Practices D 3370, as applicable.

a matrix which sufficiently challenges the Test Method. A

9.2 Use plastic or stainless steel sample bottles, provided

synthetic“water”matrixofrelevancetotheuser(e.g.,drinking

with rubber or plastic stoppers.

water or wastewater) spiked with the method analytes at the

9.3 If the water being sampled is at elevated temperature,

level of the IDP solution would be an example of an appropri-

cool to less than 35°C but do not freeze.

ate LCS.

9.4 The holding time for the samples may be calculated in

The analyte recoveries for the LCS should fall within the

accordance with Practice D 4841.

control limits of x 6 3S, where x is the IDP amount and (S) is

the standard deviation of the mean recovery established from

10. Quality Control (QC)

the interlaboratory precision and bias study data at the IDP

10.1 In order to be certain that analytical values obtained

levels, as shown below:

using this test method are valid and accurate within the

Lower Recovery Upper Recovery

confidencelimitsofthetest,thefollowingQCproceduresmust

Analyte LCS Amount Limit Limit

be followed when running the test.

Silica 115 µg/L 112 µg/L 118 µg/L

10.2 Calibration and Calibration Verification

10.2.1 When beginning use of this method, an initial Cali-

10.5 Method Blank

bration Verification Standard (CVS) should be used to verify

10.5.1 A reagent blank should be run when generating the

the calibration standards and acceptable instrument perfor-

initial calibration curves.Ablank should also be run with each

mance. This verification should be performed on each analysis

sample batch (maximum of 20 samples) to check for sample or

day. The CVS is a solution of method analytes of known

system contamination.

concentration (mid-calibration range) used to fortify reagent

10.6 Matrix Spike

water. If the determined CVS concentrations are not within

10.6.1 One Matrix Spike (MS) should be run with each

615% of the known values, the analyst should reanalyze the

sample batch (maximum of 20 samples) to test method

CVS. If the values still fall outside acceptable limits, a new

recovery. The MS should be prepared in accordance with

calibration curve is required which must be confirmed by a

Guide D 5810. Spike a portion of a water (or other) sample

successful CVS before continuing with on-going analyses.

from each batch with the method analytes at the level of the

10.2.2 One CVS should then be run with each sample batch

IDP solution. The % recovery of the spike should fall within

(maximum of 20 samples) to verify the previously established

limits established from the interlaboratory precision and bias

calibrationcurves.Ifthedeterminedanalyteconcentrationsfall

study data (assuming a background level of zero), according to

outside acceptable limits (615%) that analyte is judged out of

Standard D 5847, as shown below:

control, and the source of the problem should be identified

Lower Recovery Upper Recovery

before continuing with on-going analyses.

Analyte MS Amount Limit (%) Limit (%)

10.3 Initial Demonstration of Laboratory Capability

Silica 115 µg/L 82.5% 112.7%

10.3.1 The laboratory using

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.