ASTM D7650-10

(Test Method)Standard Test Method for Test Method for Sampling of Particulate Matter in High Pressure Hydrogen used as a Gaseous Fuel with an In-Stream Filter

Standard Test Method for Test Method for Sampling of Particulate Matter in High Pressure Hydrogen used as a Gaseous Fuel with an In-Stream Filter

SIGNIFICANCE AND USE

Fuel cells such as proton exchange membrane fuel cells require high purity hydrogen for maximum material performance and lifetime. Collection and measurement of particulate matter 0.2 µm or larger is necessary for assuring a feed gas of sufficient purity to satisfy fuel cell system needs. In addition, internal combustion engines using high pressure hydrogen fuel also require low particulate containing fuel. Specifically, particulate matter has been implicated in the premature failure of pneumatic control components, such as valves within vehicles. This sampling procedure is used to collect and measure samples containing particles 0.2 µm or larger in size as specified in ISO/CD 14687–2, SAE J2719, and other hydrogen fuel quality specifications.

Although not intended for application to gases other than hydrogen and related fuel cell supply gases, the techniques within this sampling procedure can be applied to other high pressure gaseous samples requiring particulate collection and measurement.

SCOPE

1.1 This test method is primarily for sampling particulates in hydrogen fuel used in hydrogen fuel cell vehicles or gaseous hydrogen powered internal combustion vehicle engines up to pressures of 35 MPa (350 Bars) using an in-stream filter. This test method describes sampling apparatus design, operating procedures, and quality control procedures required to obtain the stated levels of precision and accuracy.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 The values stated in Bars in 1.1, 7.1 and 10.1.1 are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7650 − 10

StandardTest Method for

Test Method for Sampling of Particulate Matter in High

Pressure Hydrogen used as a Gaseous Fuel with an In-

Stream Filter

This standard is issued under the fixed designation D7650; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 ISO Standard:

ISO/CD14687–2 Hydrogenfuel—ProductSpecification—

1.1 This test method is primarily for sampling particulates

Part 2: Proton exchange membrane (PEM) fuel cell

in hydrogen fuel used in hydrogen fuel cell vehicles or gaseous

applications for road vehicles.

hydrogen powered internal combustion vehicle engines up to

pressures of 35 MPa (350 Bars) using an in-stream filter. This

3. Terminology

test method describes sampling apparatus design, operating

3.1 Acronyms:

procedures, and quality control procedures required to obtain

3.1.1 FCV—Hydrogen Fuel Cell Vehicle.

the stated levels of precision and accuracy.

3.1.2 HQSA—Hydrogen quality sampling assembly for

1.2 The values stated in SI units are to be regarded as

sampling gaseous hydrogen fuel.

standard. No other units of measurement are included in this

3.1.3 PEM—Polymer Electrolyte Membrane also called a

standard.

Proton Exchange Membrane

1.2.1 The values stated in Bars in 1.1, 7.1 and 10.1.1 are for

3.1.4 PSA—Particulate sampling adapter for sampling par-

information only.

ticulate in hydrogen fuel.

1.3 This standard does not purport to address all of the

3.1.5 SAE—Society of Automotive Engineering

safety concerns, if any, associated with its use. It is the

3.2 Definitions:

responsibility of the user of this standard to establish appro-

3.2.1 pinhole—a small hole generated during sampling of

priate safety and health practices and determine the applica-

particulate in hydrogen that can be identified by microscope.

bility of regulatory limitations prior to use.

3.3 SAE J2719—Informational Report on the development

of a hydrogen quality guideline for fuel cell vehicles. This

2. Referenced Documents

report specifies PEM FCV hydrogen fuel quality from the

2.1 ASTM Standards:

fueling nozzle.

D7651 Test Method for Gravimetric Measurement of Par-

3.4 SAE J2600 Compressed Hydrogen Surface Vehicle

ticulate Concentration of Hydrogen Fuel

Refueling Connection Devices.—This document specifies the

2.2 SAE Standards:

design requirements for nozzles and receptacles used in high

SAE J2719 Information Report on the development of a

pressure hydrogen applications such as delivery from a fueling

hydrogen quality guideline for fuel cell vehicles.

station to a FCV

SAE J2600 Compressed Hydrogen Surface Vehicle Refuel-

4. Summary of Test Method

ing Connection Devices

4.1 This test method provides a procedure for the sampling

ofparticulatemattercontainedinhydrogenusedasaFCVfuel.

1 It is designed to collect all particulates 0.2 µm or larger

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

Fuels and is the direct responsibility of Subcommittee D03.14 on Hydrogen and

contained in a known amount of hydrogen at a station

Fuel Cells.

dispenser nozzle in a way that simulates a FCV or a gaseous

Current edition approved July 1, 2010. Published August 2010.DOI: 10.1520/

hydrogen powered internal combustion vehicle engine fueling

D7650–10.

event. The adapter used for sampling particulates in hydrogen

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

fuel is called a Particulate Sampling Adapter (PSA) and is

Standards volume information, refer to the standard’s Document Summary page on

described in 7. Great care should be taken to avoid contami-

the ASTM website.

nation and exposure of the PSA, filters, and other equipment

Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

PA 15096-0001, http://www.sae.org. with particles sized 10 µm or larger prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7650 − 10

5. Significance and Use minimize the particulates generated from the surface of this

area by fast flow and high pressure hydrogen

5.1 Fuel cells such as proton exchange membrane fuel cells

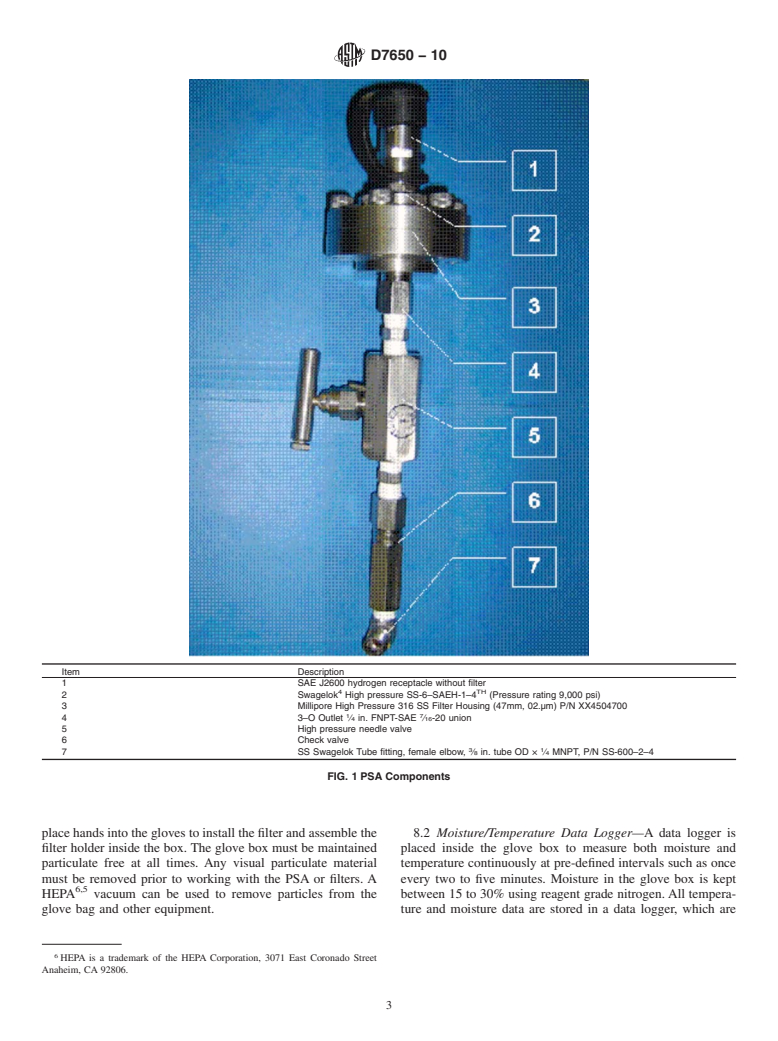

7.1.1 High Pressure Filter Holder—The high pressure filter

require high purity hydrogen for maximum material perfor-

holder is a 47 mm, stainless steel housing with maximum inlet

mance and lifetime. Collection and measurement of particulate

pressure 70 Mpa and a polytetrafluoroethylene (PTFE) inner

matter 0.2 µm or larger is necessary for assuring a feed gas of

47mm diameter PTFE-O ring. The filter holder must be

sufficient purity to satisfy fuel cell system needs. In addition,

equivalent,similarorexceedperformancecharacteristicsofthe

internal combustion engines using high pressure hydrogen fuel

filter holder shown in Fig. 1.

also require low particulate containing fuel. Specifically, par-

7.1.2 Filter—A polytetrafluoroethylene (PTFE) filter that

ticulate matter has been implicated in the premature failure of

tolerates flow rates of up to 38 g per s without damage and

pneumatic control components, such as valves within vehicles.

collects particulates with a minimum size of 0.2 µm.

This sampling procedure is used to collect and measure

samples containing particles 0.2 µm or larger in size as NOTE 2—Hydrogen back flow must be avoided since the backflow of

hydrogen can cause pinhole formation or other damage to filters. The

specified in ISO/CD 14687–2, SAE J2719, and other hydrogen

design of the apparatus and sampling procedures must prevent fuel

fuel quality specifications.

backflow, such as implementing the use of a check valve as shown in Fig.

1, Item 6.

5.2 Although not intended for application to gases other

than hydrogen and related fuel cell supply gases, the tech-

7.1.3 PSA Support—The mechanical PSA support must be

niques within this sampling procedure can be applied to other designed to securely hold the PSA and a station nozzle. The

high pressure gaseous samples requiring particulate collection

nozzle should be held firmly and not move or shake during

and measurement. particulate sampling.

7.1.4 PSA Design variations—The design of the PSAdown-

4,5

6. Interferences stream of the stainless steel Swagelok fitting (union 7 in Fig.

1) will vary with the sampling procedure. The procedure

6.1 Dust and other environmental particulate matter will

variations include:

interfere with the accurate measurement of particulates con-

(1) Sampling while the hydrogen is venting to atmosphere,

tained in FCV quality hydrogen; therefore, every measure

(2) Sampling while fueling a vehicle.

should be taken to avoid contamination of the apparatus and all

Sampling when fueling into a vehicle tank collects a sample

equipment, supplies and gases used in these procedures.

more representative of the particulates seen by vehicles in

service since the flow rate is much higher when fueling into a

7. Apparatus Design

vehicle tank than when venting to atmosphere. The following

NOTE 1—The use of trade names in this section are not intended as an

sections describes the post Swagelok fitting designs in detail.

endorsement for use.

7.1.4.1 PSA design for venting to atmosphere—For applica-

7.1 ThePSAisdesignedforpressuresatleastupto6000psi

tion to systems requiring venting hydrogen through the PSAto

(420 Bar) with appropriate safety factors built in and is

atmosphere, a ventilation assembly containsa3m long SS

designedforaflowrateof38gpersecondofhydrogenwithout

braidedtubingconnectsItem7ofFig.1inoneendandanother

damage to the filter or leakage from the PSA. The PSA

to a dual 2.4 m long 1.27cm OD SS tubing vertical to the

possesses a receptacle as per SAE J2600 which is connected

ground. During sampling, the hydrogen fuel flows through

directly to the filter housing.Ahigh pressure needle valve with

PSA, then the ventilation assembly, before venting to air at 8ft

working pressure at 42 Mpa is attached downstream of the

above ground.

filter holder to stop the hydrogen flow when leak testing the

7.1.4.2 PSA design for flowing hydrogen to gaseous hydro-

PSA. Downstream of the needle valve, a check valve is

gen vehicle tank—The configuration is the same as 7.1.4.1,

attachedtopreventthebackflowofhydrogenduringsampling.

except the downstream of the PSA at the elbow of the PSA

In summary, the configuration of the PSA, as shown in Fig. 1,

(Item 7, Fig. 1) connects the inlet hose of a 2nd nozzle

is:

assembly. The 2nd SAE J2600 nozzle is then attached to the

ASAEJ2600compliantReceptacle→FilterHolderwithFilter

receptacle on a vehicle. While sampling, the hydrogen fuel

→Needle Valve→ Check Valve.

flows from station SAE J2600 nozzle (1st nozzle)→ PSA→

Fig. 1 illustrates a PSA design that has been successfully

inlet hose of a 2nd SAE J2600 nozzle assembly→ receptacle

usedtocollectparticulatesamplesfrom5075psi(350Bar)fuel

of FCV tank.

cell quality hydrogen. The PSA should be rated above the

8. Additional Equipment Needed

operating pressure, and all materials used must be rated for

high pressure hydrogen applications at a 1.5 times minimum

8.1 Glove box—A glove box is a sealed container that is

margin of safety at the maximum operating pressure. The

designed to assemble PSA without particulate contamination

recommended working pressure of the PSA and associated

from ambient air. Two gloves are built into the sides of the

materials is 42 Mpa. Contamination from polytetrafluoroeth-

glove box with entry arranged in such a way that the user can

ylene (PTFE) tape, lubrication or other sources must be

avoided and the apparatus must be cleaned prior to use using

appropriate cleaning techniques for high pressure hydrogen

Thementionoftradenamesinthistestmethoddoesnotconstituteendorsement

applications.The design of the PSAshould include minimizing

or recommendation. Other manufacturers of equipment or equipment models can be

the distance and surface area between the nozzle and filter to used.

D7650 − 10

Item Description

1 SAE J2600 hydrogen receptacle without filter

4 TH

2 Swagelok High pressure SS-6–SAEH-1–4 (Pressure rating 9,000 psi)

3 Millipore High Pressure 316 SS Filter Housing (47mm, 02.µm) P/N XX4504700

1 7

4 3–O Outlet ⁄4 in. FNPT-SAE ⁄16-20 union

5 High pressure needle valve

6 Check valve

3 1

7 SS Swagelok Tube fitting, female elbow, ⁄8 in. tube OD × ⁄4 MNPT, P/N SS-600–2–4

FIG. 1 PSA Components

place hands into the gloves to install the filter and assemble the 8.2 Moisture/Temperature Data Logger—A data logger is

filter holder inside the box. The glove box must be maintained placed inside the glove box to measure both moisture and

particulate free at all times. Any visual particulate material temperature continuously at pre-defined intervals such as once

must be removed prior to working with the PSA or filters. A every two to five minutes. Moisture in the glove box is kept

6,5

HEPA vacuum can be used to remove particles from the between 15 to 30% using reagent grade nitrogen.All tempera-

glove bag and other equipment. ture and moisture data are stored in a data logger, which are

HEPA is a trademark of the HEPA Corporation, 3071 East Coronado Street

Anaheim, CA 92806.

D7650 − 10

7,5

downloaded into a Microsoft Excel , or a similar program, 10.1.1 Hydrogen fuel pressure can approach 6000 psi (414

sheet after completion of measurements. Bar). All PSA components must be constructed from 316

stainless steel, or better, and rated for this application.

8.3 Mini-Clean Room—A small clean room with HEPA air

10.1.2 The total mass of hydrogen passing through the PSA

filtration must be used to store unused polytetrafluoroethylene

during a sampling event is approximately 2 kg. Smoking,

(PTFE) filters, filter holders, and sampled filters at moisture

camera flashes, or mobile phones usage are an ignition hazard

content less than 30%.

and are not allowed within 7.6 m from the both ventilation

8.4 Ultrasonic Cleaner—Either an ultrasonic bath or probe

tubing (7.1.4.1) and hydrogen fueling station itself. Additional

is used in lab to shake off particulates on parts of PSA into

safety precautions must be taken as necessary to prevent fire or

reagent grade water.

explosion.

8.5 Hydrogen Leak Detector—Ahydrogen leak detector is a

10.2 Static Charges—During particulate sampling, the ex-

required safety device needed to detect small hydrogen gas

tremely high speed of hydrogen flow may generate a static

leaks in particular when the PSA is pressurized prior to

charge on PSA components. The static charge is removed by

particulate collection. The diluted soap bubble should not be

grounding the PSA with a wire from hydrogen fueling station

used to detect hydrogen leak from PSA.

or other available grounding wire(s).

8.6 HEPA Filter Horizontal Flow Hood—A HEPA filter

10.3 Hydrogen Embrittlement—Highpressurehydrogencan

horizontal flow hood blows filtered air through a HEPA filter

cause embrittlement of contacting metal surfaces or may cause

horizontally, providing for an environment with minimal sus-

metal hydride formation on metal surfaces. This can lead to

pended particulates. The air velocity measured by an air flow

catastrophic PSA failure, hydrogen leaks or generation of

meter (8.8) within the hood should be over 100 ft/minute. If

pyrophoric particulates. The PSA and all equipment used

below this velocity, the air velocity meter should trigger an

according to this standard must be closely inspected for signs

alarm notifying the operator about a low air velocity.

of cracks, metal oxide dust from metal hydride oxidation or

8.7 Plastic tweezers—Used to manipulate filters without any other combination of signs of wear and damage.

contamination.

11. Sampling, Test Specimens, and Test Units

8.8 Air Flow Meter—A meter to measure the air velocity

11.1 Sampling—Samplingofparticulatematterinhighpres-

going through the HEPAFilter Horizontal Flow Hood. The air

flow meter can trigger alarm when the air flow rate is lower surehydrogenfuelisatthedeliverynozzlewithoutusingeither

a regulator or pressure reducing orifice to lower the pressure.

than 30 m/min.

The pressure usage range is generally from 14 Mpa to 42Mpa.

8.9 Clean Room Air Filter Fan—A fan that blows air

11.2 Test Specimens—Particulate matter 0.2 µm or larger.

through a HEPA filter to improve particulate removal effi-

ciency.

11.3 Test Units—µg/L or mg/kg.

8.10 HEPA Vacuum—A vacuum with a HEPA filter that is

used to remove dust from a glove box or general filters storage 12. Preparation of Apparatus

or wor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.