ASTM D581-99

(Specification)Standard Specification for Glass Fiber Greige Braided Tubular Sleeving

Standard Specification for Glass Fiber Greige Braided Tubular Sleeving

SCOPE

1.1 This specification covers the requirements for continuous glass filament greige braided tubular sleeving and is suitable for use as electrical insulation and for structural and mechanical applications.

1.2 This specification is intended to assist ultimate users by designating the types of these products that are typical in the industry.

1.3 This specification shows the values in both inch-pound units and in SI units. "Inch-pound units" is the technically correct name for the customary units used in the United States. "SI" units is the technically correct name for the system of metric units known as the International System of Units. The values stated in inch-pound units are to be regarded as standard; the values in SI units are provided as information only.

1.4 The following precautionary statement pertains only to the test methods portions, Section 21 through 35 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-This specification is one of a series to provide a substitute for Military Specifications: MIL-Y-1140H Yarn, Cord, Sleeving, Cloth, and Tape-Glass MIL-C-9084C Cloth, Glass Finished for Resin Laminates

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 581 – 99

Standard Specification for

Glass Fiber Greige Braided Tubular Sleeving

This standard is issued under the fixed designation D 581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1907 Test Method for Yarn Number by the Skein

Method

1.1 This specification covers the requirements for continu-

D 3773 Test Methods for Length of Woven Fabric

ous glass filament greige braided tubular sleeving and is

D 3775 Test Method for Fabric Count of Woven Fabric

suitable for use as electrical insulation and for structural and

D 4963 Test Method for Ignition Loss of Glass Strands and

mechanical applications.

Fabrics

1.2 This specification is intended to assist ultimate users by

2.2 ANSI Standard:

designating the types of these products that are typical in the

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

industry.

Attributes

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

3.1 Definitions:

system shall be used independently of the other. Combining

3.1.1 braid, n—a narrow tubular or flat fabric produced by

values from the two systems may result in nonconformance

intertwining a single set of yarns according to a definite pattern

with the standard.

(Maypole process).

1.4 This standard does not purport to address all of the

3.1.2 carrier, n—in braiding machinery, that part of a

safety concerns, if any, associated with its use. It is the

braiding machine that holds the package of yarn, thread, or

responsibility of the user of this standard to establish appro-

cord, and carries the yarn when the machine is operated.

priate safety and health practices and determine the applica-

3.1.3 continuous filament yarn, n—a yarn made of filaments

bility of regulatory limitations prior to use.

that extend substantially throughout the length of the yarn.

2. Referenced Documents 3.1.4 greige goods—textile fabrics that have received no

bleaching, dyeing, or finishing treatment after being produced

2.1 ASTM Standards:

by any textile process.

D 76 Specification for Tensile Testing Machines for Tex-

2 3.1.5 sleeving—braided, knitted, or woven fabric of cylin-

tiles

drical form having a width less than 100 mm (4 in.) (circum-

D 123 Terminology Relating to Textiles

ference less than 200 mm (8 in.)).

D 350 Test Methods for Flexible Treated Sleeving Used for

3.1.6 tubing—braided, knitted, or woven fabric of cylindri-

Electrical Insulation

cal form having a width of 100 mm (4 in.) or more (circum-

D 374 Test Methods for Thickness of Solid Electrical Insu-

ference of 200 mm (8 in.) or more).

lation

2 3.1.7 For definitions of other textile terms used in this

D 578 Specification for Glass Fiber Strands

specification, refer to Terminology D 123.

D 579 Specification for Greige Woven Glass Fabrics

D 1059 Test Method for Yarn Number Based on Short-

CLASSIFICATION

Length Specimens

D 1423 Test Method for Twist in Yarns by the Direct-

4. Tubing Classifications

Counting Method

4.1 Glass fiber greige braided tubular sleeving is produced

D 1776 Practice for Conditioning Textiles for Testing

in one type and two styles within that type and uses yarns

designated as directed in Specification D 578. The standard

1 type and styles are:

This specification is under the jurisdiction of ASTM Committee D-13 on

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and

Its Products.

Current edition approved March 10, 1999. Published June 1999. Originally

published as D 581 – 40 T. Last previous edition D 581 – 94. Annual Book of ASTM Standards, Vol 07.02.

2 5

Annual Book of ASTM Standards, Vol 07.01. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 10.01. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 581

4.1.1 Type G—Glass fiber greige braided tubular sleeving. 10. Ends Per Carrier

4.1.2 Style A—Glass fiber greige braided tubular sleeving

10.1 Thenominalnumberofendspercarriershallbeagreed

having a nominal wall thickness of 0.20 mm (0.008 in.).

upon between the purchaser and the supplier. The observed

4.1.3 Style B—Glass fiber greige braided tubular sleeving

number of ends per carrier shall not exceed that specified.

having a nominal wall thickness of 0.15 mm (0.006 in.).

11. Number of Carriers

REQUIREMENTS

11.1 The nominal number of carriers shall be agreed upon

between the purchaser and the supplier. The observed number

5. Material

of carriers shall not be less than that specified.

5.1 All yarns for braided tubular sleeving shall be electrical

classification, continuous filament glass yarns, unless other-

12. Picks Per Unit Length

wise specified, have a “C” filament size designation which has

12.1 The nominal number of picks per centimetre (picks per

a filament average diameter range from 4.00 to 4.74 µm

inch) shall be agreed upon between the purchaser and the

(0.00016 to 0.000189 in.).

supplier.Theobservednumberofpicksperinchshallbewithin

5.1.1 The fiber shall be free of any free alkali metal oxides,

1 pick per centimetre (3 picks per inch) of the specified value.

such as soda or potash, and foreign particles, dirt, and other

impurities.

13. Inside Diameter

6. Yarn Number

13.1 For braided tubular sleeving listed in Table 2, the

6.1 The nominal yarn number of the yarns in the braided nominal inside diameter shall conform to the requirements of

tubular sleeving shall be agreed upon between the purchaser

Table 2. For sleeving not listed in Table 2, the nominal inside

and the supplier. The average yarn number shall fall within the diameter shall be agreed upon between the purchaser and the

interval: nominal yarn number6 10 % of the nominal yarn

supplier. The average inside diameter shall conform to the

number. requirements of Table 3 unless otherwise agreed upon between

the purchaser and the seller.

7. Strand Construction

14. Wall Thickness

7.1 The basis for specifying strand construction is given in

Specification D 578. The construction of the component

14.1 For braided tubular sleeving listed in Table 2, the

strands shall be agreed upon between the purchaser and the

nominal wall thickness shall conform to the requirements of

supplier.

Table 2. For sleeving not listed in Table 2, the nominal wall

thickness shall be agreed upon between the purchaser and the

8. Direction of Twist

supplier. The average wall thickness shall be within 0.03 mm

(0.001 in.) of the nominal value.

8.1 Unless otherwise agreed upon between the purchaser

and the supplier, the primary twist in the singles strands shall

15. Length Per Unit Mass

be “Z” twist and the final twist in the plied yarns shall be “S”

twist.

15.1 For braided tubular sleeving listed in Table 2, the

nominallengthperunitmassshallconformtotherequirements

9. Twist Level

of Table 2. For sleeving not listed in Table 2, the nominal

9.1 The nominal twist in the component strands and the

length per unit mass shall be agreed upon between the

finished yarns shall be agreed upon between the purchaser and

purchaser and the supplier. The average length per unit mass

the supplier. The tolerances for the primary twist and the final

shall be within the interval: nominal length per unit mass 6

twist shall conform to Table 1.

10 % of the nominal length per unit mass.

16. Length Per Package

TABLE 1 Twist Tolerances

16.1 Thenominallengthofbraidedtubularsleevingoneach

Tolerances

package, such as a spool or serving tube, shall be no more than

Turns per Centimetre:

108 m (120 yd) nor less than 72 m (80 yd) unless otherwise

From zero to 0.4, incl 60.1 turn per centimetre

agreed upon between the purchaser and the supplier.

Over 0.4 and up to and including 60.2 turn per centimetre

4.0

16.2 Unless otherwise agreed upon between the purchaser

Over 4 65.0 % of the specified average twist

and the supplier, no piece of braided tubular sleeving shall be

Turns per Metre:

less than 14 m (15 yd) long and there shall be no more than

From zero to 40, incl 610 turns per metre

Over 40 and up to and including 620 turns per metre

three pieces in a package.

16.3 None of the sample tubes or serving spools shall

Over 400 65.0 % of the specified average twist

Turns per Inch: contain more than the allowable pieces, and the combined

From zero to 1, incl 6 0.25 turn per inch

length of all of the sample tubes or serving spools shall not be

Over 1 and up to and including 10 60.5 turn per inch

less than the combined length of those tubes or serving spools

Over 10 6 5.0 % of the specified average twist

on the identification labels.

D 581

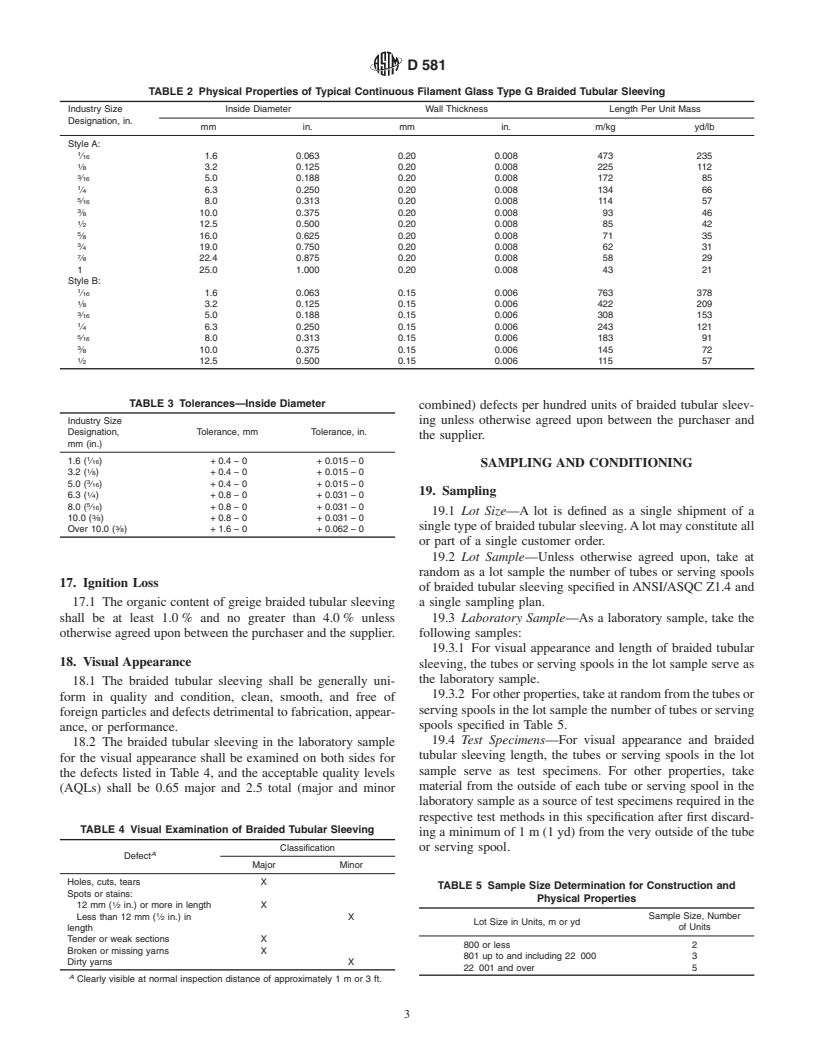

TABLE 2 Physical Properties of Typical Continuous Filament Glass Type G Braided Tubular Sleeving

Industry Size Inside Diameter Wall Thickness Length Per Unit Mass

Designation, in.

mm in. mm in. m/kg yd/lb

Style A:

⁄16 1.6 0.063 0.20 0.008 473 235

⁄8 3.2 0.125 0.20 0.008 225 112

⁄16 5.0 0.188 0.20 0.008 172 85

⁄4 6.3 0.250 0.20 0.008 134 66

⁄16 8.0 0.313 0.20 0.008 114 57

⁄8 10.0 0.375 0.20 0.008 93 46

⁄2 12.5 0.500 0.20 0.008 85 42

⁄8 16.0 0.625 0.20 0.008 71 35

⁄4 19.0 0.750 0.20 0.008 62 31

⁄8 22.4 0.875 0.20 0.008 58 29

1 25.0 1.000 0.20 0.008 43 21

Style B:

⁄16 1.6 0.063 0.15 0.006 763 378

⁄8 3.2 0.125 0.15 0.006 422 209

⁄16 5.0 0.188 0.15 0.006 308 153

⁄4 6.3 0.250 0.15 0.006 243 121

⁄16 8.0 0.313 0.15 0.006 183 91

⁄8 10.0 0.375 0.15 0.006 145 72

⁄2 12.5 0.500 0.15 0.006 115 57

TABLE 3 Tolerances—Inside Diameter

combined) defects per hundred units of braided tubular sleev-

Industry Size ing unless otherwise agreed upon between the purchaser and

Designation, Tolerance, mm Tolerance, in.

the supplier.

mm (in.)

1.6 ( ⁄16) +0.4−0 +0.015−0

SAMPLING AND CONDITIONING

3.2 ( ⁄8) +0.4−0 +0.015−0

5.0 ( ⁄16) +0.4−0 +0.015−0

1 19. Sampling

6.3 ( ⁄4) +0.8−0 +0.031−0

8.0 ( ⁄16) +0.8−0 +0.031−0

19.1 Lot Size—A lot is defined as a single shipment of a

10.0 ( ⁄8) +0.8−0 +0.031−0

3 single type of braided tubular sleeving.Alot may constitute all

Over 10.0 ( ⁄8) +1.6−0 +0.062−0

or part of a single customer order.

19.2 Lot Sample—Unless otherwise agreed upon, take at

random as a lot sample the number of tubes or serving spools

17. Ignition Loss

of braided tubular sleeving specified in ANSI/ASQC Z1.4 and

17.1 The organic content of greige braided tubular sleeving a single sampling plan.

shall be at least 1.0 % and no greater than 4.0 % unless 19.3 Laboratory Sample—As a laboratory sample, take the

otherwise agreed upon between the purchaser and the supplier. following samples:

19.3.1 For visual appearance and length of braided tubular

18. Visual Appearance

sleeving, the tubes or serving spools in the lot sample serve as

the laboratory sample.

18.1 The braided tubular sleeving shall be generally uni-

19.3.2 Forotherproperties,takeatrandomfromthetubesor

form in quality and condition, clean, smooth, and free of

serving spools in the lot sample the number of tubes or serving

foreign particles and defects detrimental to fabrication, appear-

spools specified in Table 5.

ance, or performance.

19.4 Test Specimens—For visual appearance and braided

18.2 The braided tubular sleeving in the laboratory sample

tubular sleeving length, the tubes or serving spools in the lot

for the visual appearance shall be examined on both sides for

sample serve as test specimens. For other properties, take

the defects listed in Table 4, and the acceptable quality levels

material from the outside of each tube or serving spool in the

(AQLs) shall be 0.65 major and 2.5 total (major and minor

laboratory sample as a source of test specimens required in the

respective test methods in this specification after first discard-

TABLE 4 Visual Examination of Braided Tubular Sleeving

ing a minimum of 1 m (1 yd) from the very outside of the tube

Classification

or serving spool.

A

Defect

Major Minor

Holes, cuts, tears X

TABLE 5 Sample Size Determination for Construction and

Spots or stains:

Physical Properties

12 mm ( ⁄2 in.) or more in length X

Less than 12 mm ( ⁄2 in.) in X Sample Size, Number

Lot Size in Units, m or yd

of Units

length

Tender or weak sections X

800 or less 2

Broken or missing yarns X

801 up to and including 22 000 3

Dirty yarns X

22 001 and over 5

A

Clearly visible at normal inspection distance of approximately1mor3ft.

D 581

20. Conditioning angles to the axis of the braided sleeving and then counting the

number of cut yarn ends observed in each weave of the braided

20.1 Condition the laboratory samples for a period of at

tubular sleeving.

least5hintheatmosphereasspecifiedinPracticeD 1776.Test

under the same conditions. Preconditioning is not required.

28. Number of Carriers

NOTE 1—Glass textiles are normally tested under either the atmosphere

28.1 Verify the number of carriers in the braided tubular

specified for textiles or for plastics depending on their end use.

sleeving for one test specimen from each of the selected tubes

TEST METHODS or serving spools in the laboratory sample. This is determined

while making ends per carrier determinations and counting the

21. Material total number of cut yarn ends observed and dividing by the

ends per carrier.

21.1 Accept the supplier certification that the material is of

the correct classification as specified in Specification D 578.

29. Picks Per Unit Length

Verify that the fiber is continuous filament, if not specified

29.1 Determine the picks per centimetre (picks per inch) of

otherwise, during testing for strand construction as directed in

the braided tubular sleeving as directed in Test Method D 3775

Section24.Determinethefreedomfromdetrimentalimpurities

using three test specimens from each of the selected tubes or

during the inspection for fabric appearances as directed in

serving spools in the laboratory sample except:

Section 35.

29.1.1 Measure the number of picks per centimetre (picks

per inch) over a 75-mm (3-in.) length after the braided tubular

22. Filament Diameter

sleeving has been placed snugly upon a mandrel having the

22.1 Determinethefilamentdiameterforthebraidedtubular

same diameter as the specified inside diameter of the sleeving.

sleeving yarns as directed in Specification D 578 by using 50

Use a standard pick counter in counting the number of picks

individual filaments from one yarn specimen from each of the

per centimetre (picks per inch). Take the average of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.