ASTM D1055-97

(Specification)Standard Specifications for Flexible Cellular Materials-Latex Foam

Standard Specifications for Flexible Cellular Materials-Latex Foam

SCOPE

1.1 These specifications, including test methods, apply to flexible cellular rubber products known as latex foam rubbers but do not apply to sponge and expanded rubbers. The base material used in their manufacture may be natural rubber, reclaimed rubber, synthetic rubber, or rubber-like materials, alone or in combination.

1.2 In case of conflict between the provisions of these general specifications and those of detailed specifications or test methods for a particular product, the latter shall take precedence. Reference to methods for testing cellular rubber products should specifically state the particular test or tests desired.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test methods portions, Sections 8, 16, 18, 23, 26, 29, and 31, of these specifications: This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Used in USDOE-NE Standards

Designation: D 1055 – 97

Standard Specifications for

Flexible Cellular Materials—Latex Foam

This standard is issued under the fixed designation D1055; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * D573 Test Method for Rubber—Deterioration in an Air

2 Oven

1.1 These specifications, including test methods, apply to

D 1056 Specification for Flexible Cellular Materials—

flexible cellular rubber products known as latex foam rubbers

Sponge or Expanded Rubber

but do not apply to sponge and expanded rubbers. The base

D3182 Practice for Rubber—Materials, Equipment, and

material used in their manufacture may be natural rubber,

Procedures for Mixing Standard Compounds and Prepar-

reclaimed rubber, synthetic rubber, or rubber-like materials,

ing Standard Vulcanized Sheets

alone or in combination.

D3183 Practice for Rubber—Preparation of Pieces forTest

1.2 In case of conflict between the provisions of these

Purposes from Products

general specifications and those of detailed specifications or

test methods for a particular product, the latter shall take

3. Terminology

precedence. Reference to methods for testing cellular rubber

3.1 Definitions of Terms Specific to This Standard:

products should specifically state the particular test or tests

3.1.1 flexible cellular rubber—a cellular organic polymeric

desired.

material that will not rupture within 60 s when a specimen 200

1.3 The values stated in SI units are to be regarded as the

by 25 by 25 mm is bent around a 25-mm diameter mandrel at

standard. The values in parentheses are for information only.

a uniform rate to produce 1 lap in5sinthe form of a helix at

1.4 The following precautionary caveat pertains only to the

a temperature between 18 and 29°C.

testmethodsportions,Sections8,16,18,23,26,29,and31,of

3.1.2 rubber—the term rubber is used to include both

these specifications: This standard may involve hazardous

natural and synthetic types.

materials, operations, and equipment. This standard does not

3.1.3 skin—the smooth surface of the latex foam rubber

purport to address all of the safety concerns, if any, associated

product, formed by contact with the mold or cover plates, is

with its use. It is the responsibility of the user of this standard

defined as a natural skin.

to establish appropriate safety and health practices and

determine the applicability of regulatory limitations prior to

4. Materials and Manufacture

use.

4.1 Latex Foam Rubbers—The structure of latex foam

2. Referenced Documents rubbers consists of a network of open or interconnecting cells.

Latex foam rubbers are made from rubber latices or liquid

2.1 ASTM Standards:

rubbers. They are manufactured in sheet, strip, molded, or

D395 Test Methods for Rubber Property—Compression

3 specific shapes. Latex foam rubbers shall have a vulcanized

Set

cellular structure with a porous surface. The cells shall be

D454 Test Method for Rubber—Deterioration by Heat and

3 interconnectingandofauniformcharacter.Latexfoamrubbers

Air Pressure

may be either cored or solid. Size, shape, and distribution of

D572 Test Method for Rubber—Deterioration by Heat and

3 coring shall be at the producer’s option but subject to the

Oxygen

approval of the purchaser.

5. Grades of Latex Foam Rubbers

These specifications are under the jurisdiction of ASTM Committee D-20 on

Plastics and are the direct responsibility of Subcommittee D20.22 on Cellular

5.1 Latex foam rubbers shall have their grade numbers

Plastics.

designated by two letters which identify the kind of latex foam

Current edition approved Nov. 10, 1997. Published April 1998. Originally

published as D1055–69. Last previous edition D1055–90.

rubber as follows:

These specifications together with Specification D1056 replace the former

RC—Latex foam rubbers, cored, and

Tentative Methods of Testing Cellular Rubber Products (D552 – 46a T) and the

Tentative Specifications for Cellular Rubber Products (D798 – 46a T), which were

accordingly discontinued in 1949.

3 4

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 09.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1055–97

RU—Latex foam rubbers, uncored. 6. Physical Properties

Digits following the letters are used to indicate the degree of

6.1 The various grades of latex foam rubber shall conform

firmness, the softer grades being identified with the lower

to the requirements as to physical properties prescribed in

numbers and the firmer grades with the higher numbers (see

Table 1, together with any additional requirements indicated.

Table 1).

6.2 When subjected to the static fatigue test the latex foam

5.2 Suffıx Letters may be added singly or in combination

specimen shall show no cracking at the folded edge.

after any grade number to indicate additional requirements

beyond those specified in Table 1 as basic requirements. The 7. Tolerances on Dimensions

significance of the approved suffix letters is as follows:

7.1 Tolerancesondimensionsoflatexfoamrubberproducts

SIGNIFICANCE OF SUFFIX LETTERS

are given in Table 2 and Table 3.

Suffix Letters

A

C—Weather Resistance

8. Workmanship, Finish, and Appearance

A

D—Load Deflection

A 8.1 Latex foam rubbers furnished under these specifications

E—Oil Resistance Note that there are no requirements for oil resistance in

these specifications.

shallbemanufacturedfromnaturalrubber,syntheticrubber,or

F1—Low-Temperature Brittleness at − 40°C (−40°F) Required with values

rubber-likematerials,togetherwithaddedcompoundingingre-

as specified in Table 1

A

dients of such nature and quality that the finished product

F2—Low-Temperature Brittleness at − 55°C (−67°F)

A

G—Tear Resistance

complies with the specification requirements. In permitting

H—Flex Resistance Test required with values specified in Table 1

choice in use of those materials by the producer, it is not

A

J—Abrasion Resistance

A

intended to imply that the different rubber materials are

K—Adhesion Resistance

A

L—Water Resistance

equivalent in respect to all physical properties. Any special

A

M—Flammability Resistance

characteristics other than those prescribed in these specifica-

A

P—Non-Staining

A

tions which may be desired for specific applications shall be

R—Resilience

A

Z—Special Requirements

specified in the products specifications, as they may influence

the choice of the type of rubber materials or other ingredients

A

Test method and values to be arranged between the purchaser and the

supplier. used. All materials and workmanship shall be in accordance

with good commercial practice, and the resulting cellular

NOTE 1—Example: Grade RC 20 F1H denotes soft, cored latex foam

rubber shall be free of defects affecting serviceability.

rubber made from natural, reclaim synthetic, or a blend with a load

8.2 Due to manufacturing conditions, material may have to

deflectionvalueof89 618N(20 64lbf)andrequiringinadditiontothe

basic tests a low-temperature test at−40°C (−40°F) and a flexing test. be altered or repaired. This repaired or altered material will be

TABLE 1 Physical Requirements of Latex Foam Rubbers

Requirements Added by Suffix

Basic Requirements

Letters

Suffix F Suffix H

Constant Deflection

Air Oven Aged 22 h

Indentation Value on 325 cm

Low

Compression Set 22 h at

2 at 100°C (212°F)

Flexing Test

(50 in. ), 25 % Deflection

Temperature

70°C (158°F), 50 %

Grade Change from Original

Compression Set,

(Limits)

Test, Change

Deflection, max, %

Number Load-Deflection or

max, %

from Original

Indentation Value

Deflection,

(Limits), %

A A A A

Nlbf C C C C

h d h d

max, %

Latex Foam Rubbers (Cored)

RC 5 22613 563 620 10 20 75 5 10

RC 10 44613 1063 620 10 20 75 5 10

RC 15 67618 1564 620 10 20 75 5 10

RC 20 89618 2064 620 10 20 75 5 10

RC 25 111622 2565 620 10 20 75 5 10

RC 30 133627 3066 620 10 20 75 5 10

RC 40 178631 4067 620 10 20 75 5 10

RC 50 222636 5068 620 10 20 75 5 10

RC 60 267640 6069 620 10 20 75 5 10

RC 70 311653 70612 620 10 20 75 5 10

RC 90 400662 90614 620 10 20 75 5 10

Latex Foam Rubbers (Uncored)

RU 11 49618 1164 620 10 20 75 5 10

RU 20 89622 2065 620 10 20 75 5 10

RU 35 156644 35610 620 10 20 75 5 10

RU 55 245644 55610 620 10 20 75 5 10

RU 80 356667 80615 620 10 20 75 5 10

RU 150 6676245 150655 620 10 20 75 5 10

A

As defined in Section 19.

D1055–97

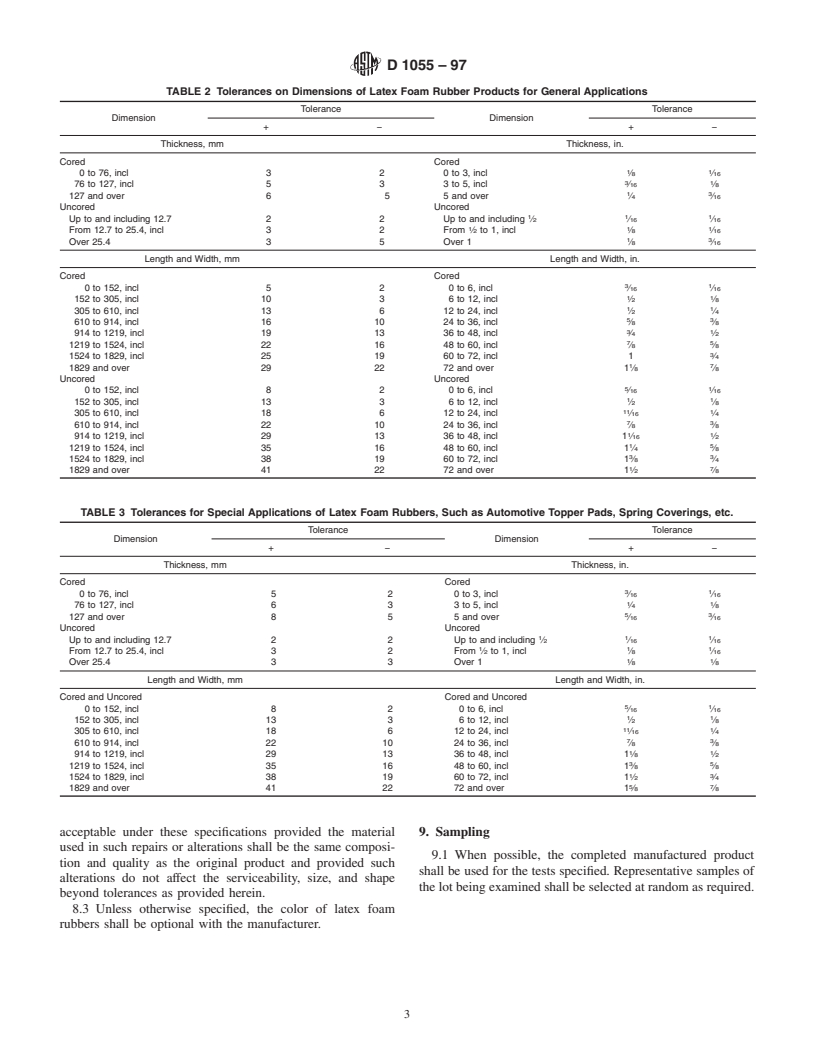

TABLE 2 Tolerances on Dimensions of Latex Foam Rubber Products for General Applications

Tolerance Tolerance

Dimension Dimension

+− + −

Thickness, mm Thickness, in.

Cored Cored

1 1

0 to 76, incl 3 2 0 to 3, incl ⁄8 ⁄16

3 1

76 to 127, incl 5 3 3 to 5, incl ⁄16 ⁄8

1 3

127 and over 6 5 5 and over ⁄4 ⁄16

Uncored Uncored

1 1 1

Up to and including 12.7 2 2 Up to and including ⁄2 ⁄16 ⁄16

1 1 1

From 12.7 to 25.4, incl 3 2 From ⁄2 to 1, incl ⁄8 ⁄16

1 3

Over 25.4 3 5 Over 1 ⁄8 ⁄16

Length and Width, mm Length and Width, in.

Cored Cored

3 1

0 to 152, incl 5 2 0 to 6, incl ⁄16 ⁄16

1 1

152 to 305, incl 10 3 6 to 12, incl ⁄2 ⁄8

1 1

305 to 610, incl 13 6 12 to 24, incl ⁄2 ⁄4

5 3

610 to 914, incl 16 10 24 to 36, incl ⁄8 ⁄8

3 1

914 to 1219, incl 19 13 36 to 48, incl ⁄4 ⁄2

7 5

1219 to 1524, incl 22 16 48 to 60, incl ⁄8 ⁄8

1524 to 1829, incl 25 19 60 to 72, incl 1 ⁄4

1 7

1829 and over 29 22 72 and over 1 ⁄8 ⁄8

Uncored Uncored

5 1

0 to 152, incl 8 2 0 to 6, incl ⁄16 ⁄16

1 1

152 to 305, incl 13 3 6 to 12, incl ⁄2 ⁄8

11 1

305 to 610, incl 18 6 12 to 24, incl ⁄16 ⁄4

7 3

610 to 914, incl 22 10 24 to 36, incl ⁄8 ⁄8

1 1

914 to 1219, incl 29 13 36 to 48, incl 1 ⁄16 ⁄2

1 5

1219 to 1524, incl 35 16 48 to 60, incl 1 ⁄4 ⁄8

3 3

1524 to 1829, incl 38 19 60 to 72, incl 1 ⁄8 ⁄4

1 7

1829 and over 41 22 72 and over 1 ⁄2 ⁄8

TABLE 3 Tolerances for Special Applications of Latex Foam Rubbers, Such as Automotive Topper Pads, Spring Coverings, etc.

Tolerance Tolerance

Dimension Dimension

+− + −

Thickness, mm Thickness, in.

Cored Cored

3 1

0 to 76, incl 5 2 0 to 3, incl ⁄16 ⁄16

1 1

76 to 127, incl 6 3 3 to 5, incl ⁄4 ⁄8

5 3

127 and over 8 5 5 and over ⁄16 ⁄16

Uncored Uncored

1 1 1

Up to and including 12.7 2 2 Up to and including ⁄2 ⁄16 ⁄16

1 1 1

From 12.7 to 25.4, incl 3 2 From ⁄2 to 1, incl ⁄8 ⁄16

1 1

Over 25.4 3 3 Over 1 ⁄8 ⁄8

Length and Width, mm Length and Width, in.

Cored and Uncored Cored and Uncored

5 1

0 to 152, incl 8 2 0 to 6, incl ⁄16 ⁄16

1 1

152 to 305, incl 13 3 6 to 12, incl ⁄2 ⁄8

11 1

305 to 610, incl 18 6 12 to 24, incl ⁄16 ⁄4

7 3

610 to 914, incl 22 10 24 to 36, incl ⁄8 ⁄8

1 1

914 to 1219, incl 29 13 36 to 48, incl 1 ⁄8 ⁄2

3 5

1219 to 1524, incl 35 16 48 to 60, incl 1 ⁄8 ⁄8

1 3

1524 to 1829, incl 38 19 60 to 72, incl 1 ⁄2 ⁄4

5 7

1829 and over 41 22 72 and over 1 ⁄8 ⁄8

acceptable under these specifications provided the material 9. Sampling

used in such repairs or alterations shall be the same composi-

9.1 When possible, the completed manufactured product

tion and quality as the original product and provided such

shall be used for the tests specified. Representative samples of

alterations do not affect the serviceability, size, and shape

thelotbeingexaminedshallbeselectedatrandomasrequired.

beyond tolerances as provided herein.

8.3 Unless otherwise specified, the color of latex foam

rubbers shall be optional with the manufacturer.

D1055–97

9.2 When it is necessary or advisable to obtain test speci- 12.2 Thicknessesuptoandincluding25mm(1in.)shallbe

mensfromthearticle,asinthosecaseswheretheentiresample measuredusingadial-typegage havingafoot32mm(1 ⁄4in.)

is not required or adaptable for testing, the method of cutting in diameter, taking care not to compress the sample. Thick-

and the exact position from which specimens are to be taken nesses over 25 mm shall be measured using a sliding caliper

shall be specified. The apparent density and the state of cure gage or as specified in 12.1. When a sliding caliper gage is

may vary in different parts of the finished product, more employed, the gage setting shall be made with the gage out of

especially if the article is of complicated shape or of varying contact with the latex foam rubber.The sample shall be passed

thickness and these factors affect the physical properties of the through the previously set gage and the proper setting shall be

specimens.Also,theapparentdensityisaffectedbythenumber the one when the measured faces of the gage contact the

of cut surfaces as opposed to the number of skin-covered surfaces of the article without compressing it.

surfaces on the test specimen. 12.3 Thesteelscaleortapeusedtomeasurelengthorwidth

shall be graduated to 1 mm ( ⁄32 in.). The dial gage for

9.3 When the finished product does not lend itself to testing

measuringthicknessshallbegraduatedto0.02mm(0.001in.).

ortothetakingoftestspecimensbecauseofcomplicatedshape

Thecalipersusedformeasuringthicknessshallbegraduatedto

or other reasons, the manufacturer and the purchaser shall

0.1 mm (0.005 in.).

agree on the preparation of a suitable test specimen. When

12.4 Results reported shall be the average of a minimum of

differences due to the difficulty in obtaining suitable test

three measurements.

specimens from the finished part arise, the manufacturer and

the purchaser may agree on acceptable deviations. This can be

13. Inspection and Rejection

donebycomparingresultsofstandardtestspecimensandthose

13.1 All tests and inspection shall be made at the place of

obtained on actual parts.

manufacture prior to shipment unless otherwise specified. The

manufacturershallaffordtheinspectorallreasonablefacilities,

10. Test Methods

without charge, for tests and inspection.

10.1 Unless specifically stated otherwise all tests shall be

13.2 The purchaser may make the tests and inspection to

made in accordance with the methods specified in Sections

govern acceptance or rejection of the material at his own

15-31, which include test procedures for the following:

laboratory or elsewhere. Such tests and inspection shall be

Procedures Sections

made not later than 15 days after receipt of the material.

Basic tests:

Air oven test 15 and 16 13.3 All samples for testing, provided as specified in Sec-

Constant deflection compression set 17-19

tion 9., shall be visually inspected to determine compliance

Indentation load deflection test 20-23

with the material, workmanship, and color requirements.

Suffix tests:

13.4 Any material which fails in one or more of the test

H—Flexing test 24-26

F—Low-temperature te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.