ASTM C1693-09e1

(Specification)Standard Specification for Autoclaved Aerated Concrete (AAC)

Standard Specification for Autoclaved Aerated Concrete (AAC)

SCOPE

1.1 This specification covers autoclaved aerated concrete (AAC), a cementitious product based on calcium silicate hydrates in which low density is attained by the inclusion of an agent resulting in macroscopic voids, and in which curing is carried out using high-pressure steam.

1.2 The raw materials used in the production of autoclaved aerated concrete are portland cement or blended cements, quartz sand, water, lime, gypsum or anhydrite, and an agent resulting in macroscopic voids. The quartz sand used as a raw material may be replaced by a siliceous fine aggregate other than sand, and usually is ground to a fine powder before use. Fly ash may be used as a sand replacement. The batched raw materials are mixed thoroughly together to form a slurry. The slurry is cast into steel molds. Due to the chemical reactions that take place within the slurry, the volume expands. After setting, and before hardening, the mass is machine cut into units of various sizes. The units then are steam-cured under pressure in autoclaves where the material is transformed into a hard calcium silicate.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 6, 7, and 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C1693 – 09

Standard Specification for

1

Autoclaved Aerated Concrete (AAC)

This standard is issued under the fixed designation C1693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Subsection 3.1 was editorially corrected in December 2009.

1. Scope C33 Specification for Concrete Aggregates

C39/C39M Test Method for Compressive Strength of Cy-

1.1 This specification covers autoclaved aerated concrete

lindrical Concrete Specimens

(AAC), a cementitious product based on calcium silicate

C144 Specification for Aggregate for Masonry Mortar

hydrates in which low density is attained by the inclusion of an

C150 Specification for Portland Cement

agent resulting in macroscopic voids, and in which curing is

C332 Specification for Lightweight Aggregates for Insulat-

carried out using high-pressure steam.

ing Concrete

1.2 The raw materials used in the production of autoclaved

C595/C595M Specification for Blended Hydraulic Cements

aerated concrete are portland cement or blended cements,

C618 Specification for Coal Fly Ash and Raw or Calcined

quartz sand, water, lime, gypsum or anhydrite, and an agent

Natural Pozzolan for Use in Concrete

resulting in macroscopic voids. The quartz sand used as a raw

C1692 Practice for Construction and Testing ofAutoclaved

material may be replaced by a siliceous fine aggregate other

Aerated Concrete (AAC) Masonry

than sand, and usually is ground to a fine powder before use.

E4 Practices for Force Verification of Testing Machines

Fly ash may be used as a sand replacement. The batched raw

E575 Practice for Reporting Data from Structural Tests of

materials are mixed thoroughly together to form a slurry. The

Building Constructions, Elements, Connections, and As-

slurry is cast into steel molds. Due to the chemical reactions

semblies

that take place within the slurry, the volume expands. After

setting, and before hardening, the mass is machine cut into

3. Classification

units of various sizes. The units then are steam-cured under

3.1 AAC units manufactured in accordance with this speci-

pressure in autoclaves where the material is transformed into a

fication are classified according to their strength class.

hard calcium silicate.

1.3 The values stated in inch-pound units are to be regarded

4. Materials and Manufacture

as standard. The values given in parentheses are mathematical

4.1 Raw Materials—Materials shall conform to the follow-

conversions to SI units that are provided for information only

ing applicable specifications:

and are not considered standard.

4.1.1 Portland Cement, Specification C150.

1.4 This standard does not purport to address all of the

4.1.2 Blended Cements, Specification C595/C595M.

safety concerns, if any, associated with its use. It is the

4.1.3 Pozzolan, Specification C618.

responsibility of the user of this standard to establish appro-

4.1.4 Gypsum, Specification C22/C22M.

priate safety and health practices and determine the applica-

4.1.5 Aggregates, Specifications C33, C144,or C332.

bility of regulatory limitations prior to use. See Section 6, 7,

and 8.

5. Physical Requirements

5.1 Compressive Strength—The compressive strength shall

2. Referenced Documents

2 be determined according to Section 6 and shall conform to the

2.1 ASTM Standards:

requirements of Table 1.

C22/C22M Specification for Gypsum

5.2 Dry Bulk Density—The dry bulk density shall be deter-

mined according to Section 7 and shall conform to the

1

This specification is under the jurisdiction ofASTM Committee C27 on Precast

requirements of Table 1.

Concrete Products and is the direct responsibility of Subcommittee C27.60 on

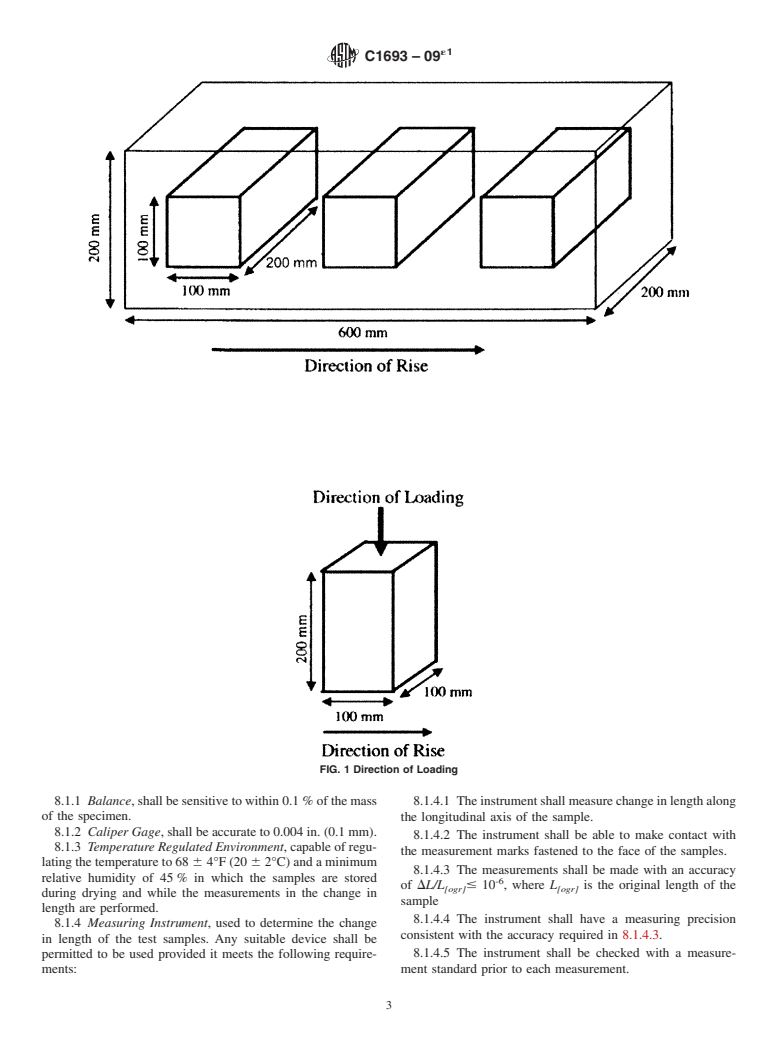

5.3 Drying Shrinkage—The drying shrinkage shall be de-

Precast Autoclaved Aerated Concrete.

termined in accordance with Section 8, and shall conform to

Current edition approved Oct. 1, 2009. Published November 2009. DOI:

10.1520/C1693-09E01. the requirements of Table 1.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4 Modulus of Elasticity—If required, the modulus of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

elasticity shall be determined in accordance with Section 9.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

C1693 – 09

TABLE 1 Physical Requirements

Strength Class Compressive Strength, Nominal Dry Density Limits, Average Drying

3 3

psi (MPa) Bulk Density, lb/ft (kg/m ) Shrinkage, %

3 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.