ASTM C1694-09(2017)

(Specification)Standard Specification for Reinforced Autoclaved Aerated Concrete (AAC) Elements

Standard Specification for Reinforced Autoclaved Aerated Concrete (AAC) Elements

SCOPE

1.1 This specification covers reinforced solid elements manufactured from autoclaved aerated concrete (AAC), a cementitious product addressed by Specification C1693. The specification addresses dimensional tolerances, maximum limits for drying shrinkage, requirements for steel reinforcement, and shipping and handling.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1694 −09 (Reapproved 2017)

Standard Specification for

Reinforced Autoclaved Aerated Concrete (AAC) Elements

This standard is issued under the fixed designation C1694; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Classification

3.1 Reinforced AAC elements manufactured in accordance

1.1 This specification covers reinforced solid elements

with this specification shall be classified according to their

manufactured from autoclaved aerated concrete (AAC), a

strength class.

cementitious product addressed by Specification C1693. The

specification addresses dimensional tolerances, maximum lim-

4. Materials and Manufacture

its for drying shrinkage, requirements for steel reinforcement,

and shipping and handling. 4.1 Reinforced AAC elements manufactured in accordance

with this specification shall be composed entirely of AAC

1.2 The values stated in inch-pound units are to be regarded

material conforming to Specification C1693.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

5. Physical Requirements

and are not considered standard.

5.1 Compressive Strength—The compressive strength of the

1.3 This standard does not purport to address all of the

elements shall be determined according to Specification

safety concerns, if any, associated with its use. It is the

C1693, and shall conform to the requirements of Specification

responsibility of the user of this standard to establish appro-

C1693 for the strength class in which the elements are

priate safety and health practices and determine the applica-

classified.

bility of regulatory limitations prior to use.

5.2 Dry Bulk Density—The dry bulk density shall be deter-

1.4 This international standard was developed in accor-

mined according to Specification C1693, and shall conform to

dance with internationally recognized principles on standard-

the requirements of Specification C1693 for the strength class

ization established in the Decision on Principles for the

in which the elements are classified.

Development of International Standards, Guides and Recom-

5.3 Drying Shrinkage—The drying shrinkage shall be deter-

mendations issued by the World Trade Organization Technical

mined in accordance with Specification C1693, and the aver-

Barriers to Trade (TBT) Committee.

age drying shrinkage shall conform to the requirements of

Specification C1693 for the strength class in which the

2. Referenced Documents

elements are specified.

2.1 ASTM Standards:

5.4 Steel Reinforcemen—The properties of the steel rein-

A82/A82M Specification for Steel Wire, Plain, for Concrete

forcementshallbedeterminedinaccordancewithSpecification

Reinforcement (Withdrawn 2013)

A82/A82M and shall conform to the requirements of Table 1.

C1693 Specification for Autoclaved Aerated Concrete

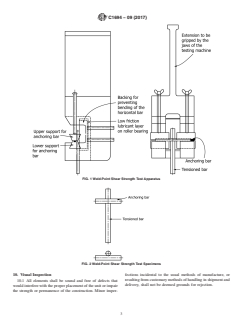

5.5 Weld-Point Shear Strength—The weld-point shear

(AAC)

strengthinthereinforcementshallbedeterminedinaccordance

with Section 8 and shall conform to the requirements of Table

2.

This specification is under the jurisdiction ofASTM Committee C27 on Precast

5.6 Concrete Cover of Steel Reinforcement—The minimum

Concrete Products and is the direct responsibility of Subcommittee C27.60 on

Precast Autoclaved Aerated Concrete. concrete cover over the steel reinforcement shall be 0.375 in.

CurrenteditionapprovedJune1,2017.PublishedJuly2017.Originallyapproved

(10 mm). The reinforcing steel shall receive a corrosion-

in 2009. Last previous edition approved in 2009 as C1694 – 09. DOI: 10.1520/

resistant coating before casting.

C1694-09R17.

2 NOTE1—Acovergreaterthan0.375in.(10mm)mayberequiredinfire

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

resistant applications.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.7 Effectiveness of Corrosion Protection of Steel

the ASTM website.

Reinforcement—The effectiveness of the corrosion protection

The last approved version of this historical standard is referenced on

www.astm.org. for the steel reinforcement shall be determined according to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1694 − 09 (2017)

TABLE 1 Properties of Steel Reinforcement

conditionsasthereferencespecimens.Aftercompletingtheten

Property Minimum Value testing cycles, allow the specimens to air dry for 4 h.

Characteristic

7.3.3 Inspection for Rust—After completing the testing

Yield strength, min, ksi (MPa) 70 (485)

procedure, remove the autoclaved aerated concrete around the

Tensile strength, min, ksi (MPa) 80 (550)

A

Reduction of area, min, % 30

steel reinforcement in the reference specimen and the test

A

specimens. By visual inspection, determine the area of rust

For material testing over 100 ksi (690 MPa) tensile strength, the reduction of area

shall be not less than 25 %.

covering the steel and express that area as a percentage of the

total area of the specimen, using the following calculation:

A 5 πn d l 1πn d l ~mm ! (1)

TABLE 2 Weld-Point Shear Strength for Steel Reinforcement t 1 1 1 2 2 2

Diameter of the Minimum Shear Strength

A 5 w l mm (2)

~ !

r ( i i

Longitudinal Reinforcement, in. (mm) of the Joint, lbf (kN)

P 5 100 ~A /A ! (3)

0.16 (4.0) 495 (2.20)

r r t

0.18 (4.5) 598 (2.66)

where:

0.20 (5.0) 771 (3.43)

0.24 (6.0) 1113 (4.95)

A = total surface of reinforcement present in the specimen

t

0.28 (7.0) 1513 (6.73)

(mm )

0.32 (8.0) 1987 (8.84)

0.35 (9.0) 2502 (11.13) n = number of longitudinal reinforcing rods,

0.40 (10.0) 3091 (13.75)

d = diameter of the longitudinal reinforcing rods (mm),

0.43 (11.0) 3741 (16.64)

l = length of the longitudinal reinforcing rods (mm),

0.47 (12.0) 5339 (19.79)

n = number of transverse reinforcing rods,

d = diameter of transverse reinforcing rods (mm),

l = length of the transverse reinforcing rods (mm),

A = area of rusted surface,

Secti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.