ASTM E136-99e1

(Test Method)Standard Test Method for Behavior of Materials in a Vertical Tube Furnace at 750oC

Standard Test Method for Behavior of Materials in a Vertical Tube Furnace at 750<sub>o</sub>C

SCOPE

1.1 This fire-test-response standard covers the determination under specified laboratory conditions of combustion characteristics of building materials. It is not intended to apply to laminated or coated materials.

1.2 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this test method.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: E 136 – 99

Standard Test Method for

Behavior of Materials in a Vertical Tube Furnace at 750°C

This standard is issued under the fixed designation E 136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—An editorial correction was made in July 2000.

1. Scope E 176 Terminology of Fire Standards

2.2 ISO Standard:

1.1 This fire-test-response test method covers the determi-

ISO 1182 Noncombustibility Test for Building Materials

nation under specified laboratory conditions of combustion

2.3 Other Standard:

characteristics of building materials. It is not intended to apply

BS 476 Combustibility Test of Materials

to laminated or coated materials.

1.2 This test method references notes and footnotes that

3. Terminology

provide explanatory information. These notes and footnotes,

3.1 Definitions—For definitions of terms found in this test

excluding those in tables and figures, shall not be considered as

method, refer to Terminology E 176.

requirements of this test method.

1.3 The values stated in SI units are to be regarded as the

4. Significance and Use

standard. The values given in parentheses are for information

4.1 While actual building fire exposure conditions are not

only.

duplicated, this test method will assist in indicating those

1.4 This standard is used to measure and describe the

materials which do not act to aid combustion or add appre-

response of materials, products, or assemblies to heat and

ciable heat to an ambient fire.

flame under controlled conditions, but does not by itself

4.2 Materials passing the test are permitted limited flaming

incorporate all factors required for fire-hazard or fire-risk

and other indications of combustion.

assessment of the materials, products, or assemblies under

actual fire conditions.

5. Apparatus

1.5 This standard does not purport to address all of the

5.1 The apparatus, as shown in Fig. 1,shall consist primarily

safety concerns, if any, associated with its use. It is the

of the following:

responsibility of the user of this standard to establish appro-

5.1.1 Refractory Tubes—Two concentric, refractory tubes,

priate safety and health practices and determine the applica-

76 and 102 mm (3 and 4 in.) in inside diameter and 210 to 250

bility of regulatory limitations prior to use.

mm (8 ⁄2 to 10 in.) in length, with axes vertical, and with heat

applied by electric heating coils outside of the larger tube. A

2. Referenced Documents

controlled flow of air is admitted tangentially near the top of

2.1 ASTM Standards:

2 the annular space between the tubes and passes to the bottom

D 1929 Test Method for Ignition Properties of Plastics

of the inner tube. The outer tube rests on a refractory bottom

D 3174 Test Method for Ash in the Analysis Sample of Coal

3 and the inner tube rests on three spacer blocks so as to afford

and Coke from Coal

a total opening under the inner tube equal to or greater than that

E 84 Test Method for Surface Burning Characteristics of

4 of the annular space. The refractory bottom plate has a

Building Materials

removable plug for cleaning.

5.1.2 Transparent Cover—A transparent cover of heat-

resistant glass or other transparent material shall be provided

This test method is under the jurisdiction of ASTM Committee E-5 on Fire

Standards and is the direct responsibility of Subcommittee E05.23 on Combustibil-

over the top of the inner tubes. The cover shall have a circular

ity.

1 1

opening 1 ⁄8 6 ⁄32 in. (28.7 6 0.8 mm) centered over the axis

Current edition approved Oct. 10, 1999. Published January 2000. Originally

e1

published as E 136 – 58 T. Last previous edition E 136 – 98 .

Annual Book of ASTM Standards, Vol 08.01.

3 5

Annual Book of ASTM Standards, Vol 05.05. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 04.07. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 136

NOTE—Inch-Pound Equivalents

in. 3 4 61010 ⁄4 1 in. No. 16 Awg

mm 76 102 152 254 273 6.4 cm 1.29

FIG. 1 Cross Section of Furnace Assembly

2 2

of the tubes. This opening has an area of 1.0 in. (645 mm ). outside dimensions conform to the specimen shape and maxi-

The cover shall be in two equally-sized, movable parts. mum size specified in 6.1. These vessels shall have walls of

5.1.3 Thermocouples and an automatically recording device either solid or mesh construction.

shall be provided. The thermocouples shall be located as 5.3 Specimen Location—During the test, the geometric

follows: center of the specimen shall be located at the geometric center

5.1.3.1 Thermocouple T is located in the center of the air 63mm(6 ⁄8 in.) of the 76-mm (3-in.) diameter tube.

space between the two concentric, refractory tubes; approxi-

6. Test Specimens

mately 204 mm (8 in.) down from the top of the 102-mm

(4-in.) diameter tube (Note 1).

6.1 All test specimens shall be 38 by 38 by 51 6 2.5 mm

5.1.3.2 Thermocouple T is located at the approximate

(1.5 by 1.5 by 2.0 6 0.1 in.). The specimens shall be dried at

geometric center of the specimen.

60 6 3°C (140 6 5°F) for not less than 24 h but no more than

5.1.3.3 Thermocouple T is located on the surface, in

48 h. Specimens shall then be placed in a desiccator to cool at

contact with the specimen; in the same horizontal plane as T .

3 least 1 h before testing.

5.1.3.4 Thermocouples T,T and T shall have a time

6.2 Not less than four identical specimens shall be tested.

1 3 4

constant (time to reach 63.2 % of the furnace air temperature of

750°C (1382°F)) of 5 to 10 s (Note 2).

7. Procedure

7.1 Furnace Preparation:

NOTE 1—Thermocouple T is used for better regulation of the tempera-

ture of the air in the furnace space. 7.1.1 Conduct the test at room conditions of 21 6 3°C

NOTE 2—Ungrounded, metallic-sheathed thermocouples of 1-mm di-

(70 6 5°F).

ameter have been found to meet the time constant requirements.

7.1.2 Air Flow—Provide an external air source to supply

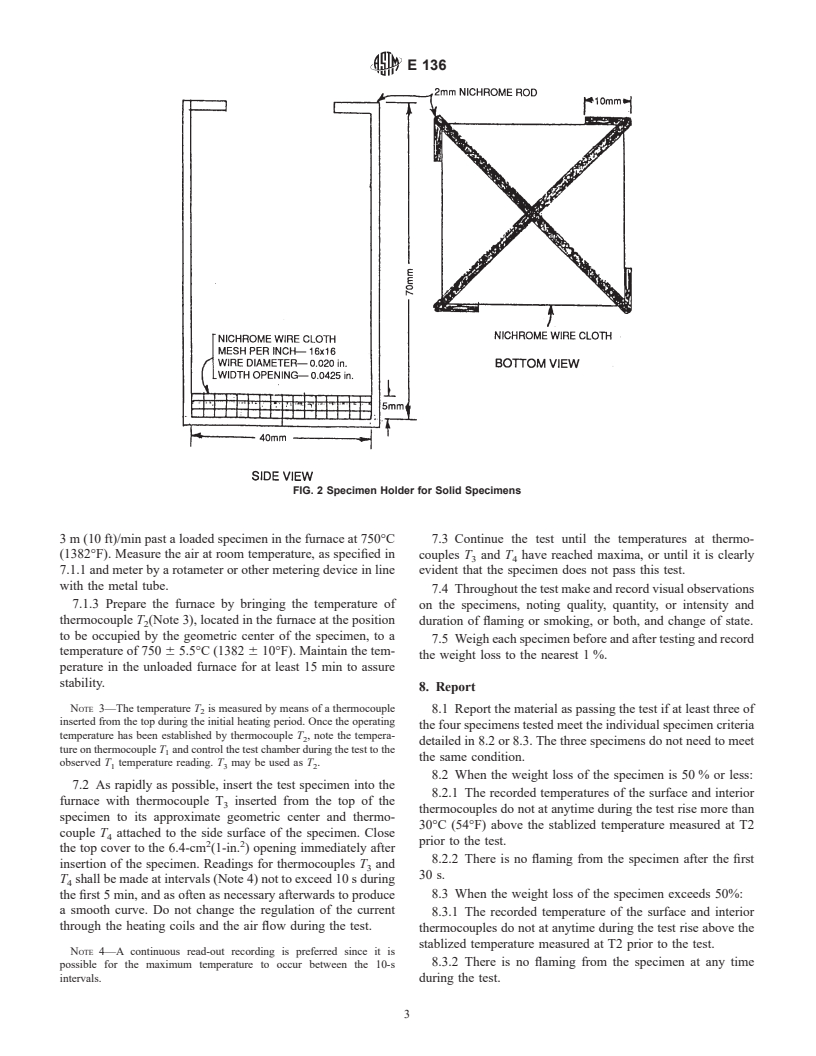

5.2 Specimen Holder—The specimen holder for solid speci- clean air through a metal tube located near the furnace top,

mens shall be as shown in Fig. 2. tangentially between the annular spaced ceramic tubes. The air

5.2.1 Specimens in granular or powder form shall be con- shall be supplied at a steady and controllable rate of 0.0027

3 3

tained in thin-wall, open-top vessels of inert materials whose m /min (0.10 ft /min) 6 20 %, which will give an air flow of

E 136

FIG. 2 Specimen Holder for Solid Specimens

3 m (10 ft)/min past a loaded specimen in the furnace at 750°C 7.3 Continue the test until the temperatures at thermo-

(1382°F). Measure the air at room temperature, as specified in couples T and T have reached maxima, or until it is clearly

3 4

7.1.1 and meter by a rotameter or other metering device in line evident that the specimen does not pass this test.

with the metal tube.

7.4 Throughout the test make and record visual observations

7.1.3 Prepare the furnace by bringing the temperature of on the specimens, noting quality, quantity, or intensity and

thermocouple T (Note 3), located in the furnace at the position

duration of flaming or smoking, or both, and change of state.

to be occupied by the geometric center of the specimen, to a

7.5 Weigh each specimen before and after testing and record

temperature of 750 6 5.5°C (1382 6 10°F). Maintain the tem-

the weight loss to the nearest 1 %.

perature in the unloaded furnace for at least 15 min to assure

stability.

8. Report

NOTE 3—The temperature T is measured by means of a thermocouple

8.1 Report the material as passing the test if at least three of

inserted from the top during the initial heating period. Once the operating

the four specimens tested meet the individual specimen criteria

temperature has been established by thermocouple T , note the tempera-

detailed in 8.2 or 8.3. The three specimens do not need to meet

ture on thermocouple T and control the test chamber during the test to the

the same condition.

observed T temperature reading. T may be used as T .

1 3 2

8.2 When the weight loss of the specimen is 50 % or less:

7.2 As rapidly as possible, insert the test specimen into the

8.2.1 The recorded temperatures of the surface and interior

furnace with thermocouple T inserted from the top of the

thermocouples do not at anytime during the test rise more than

specimen to its approximate geometric center and thermo-

30°C (54°F) above the stablized temperature measured at T2

couple T attached to the side surface of the specimen. Close

prior to the test.

2 2

the top cover to the 6.4-cm (1-in. ) opening immediately after

8.2.2 There is no flaming from the specimen after the first

insertion of the specimen. Readings for thermocouples T and

30 s.

T shall be made at intervals (Note 4) not to exceed 10 s during

8.3 When the weight loss of the specimen exceeds 50%:

the first 5 min, and as often as necessary afterwards to produce

a smooth curve. Do not change the regulation of the current

8.3.1 The recorded temperature of the surface and interior

through the heating coils and the air flow during the test.

thermocouples do not at anytime during the test rise above the

stablized temperature measured at T2 prior to the test.

NOTE 4—A continuous read-out recording is preferred since it is

8.3.2 There is no flaming from the specimen at any time

possible for the maximum temperature to occur between the 10-s

intervals. during the test.

E 136

9. Precision and Bias 10. Keywords

9.1 No information is presented about the precision and bias

10.1 building materials; combustion; heated tube; limited

of this test method for measuring combustion characteristics

combustion; Setchkin furnace; vertical tube furnace

since the test results are nonquantitative. (See X1.7.)

APPENDIX

(Nonmandatory Information)

X1. COMMENTARY

X1.1 Introduction ture. No material shall be classed as noncombustible which is

subject to increase in combustibility or flame spread rating

X1.1.1 The difference in fire risk between a combustible

beyond the limits herein established, through the effects of age,

building material and a noncombustible (or incombustible) one

moisture or other atmospheric condition. Flame spread rating

is generally obvious. However, some materials may contain

as used herein refers to ratings obtained in accordance with

only a limited amount of combustible content and may not

Test Method E 84.

contribute appreciably to an ambient fire. The term noncom-

a) Materials no part of which will ignite and burn when

bustible, while in recognized use as indicating a material that

subjected to fire. Any material that liberates flammable gas

will not ignite or burn, is indefinite in its application unless

when heated to a temperature of 750°C (1382°F), for 5 min

referenced to a well defined testing procedure.

shall not be considered noncombustible within the meaning of

this paragraph.

X1.2 Definition

b) Materials having a structural base of noncombustible

X1.2.1 Most dictionaries have defined noncombustible in

material, as defined in (a), with a surfacing not over ⁄8-in. thick

simple terms, such as that used in the 1920 edition of the

that has a flame spread rating not higher than 50.

National Building Code promulgated by the National Board of

c) Materials, other than as described in (a) or (b), having a

Fire Underwriters (NBFU): Incombustible materials or con-

surface flame spread rating not higher than 25 without evidence

struction are those that “will not ignite or burn when subjected

of continued progressive combustion and of such composition

to fire.” In 1943 the same code redefined incombustible

that surfaces that would be exposed by cutting through the

construction as “assemblies which do not involve materials of

material in any way would not have a flame spread rating

such kind or quantity or so contained as to burn during

higher than 25 without evidence of continued progressive

exposure in a test fire or continue flaming or ignite after the

combustion.

furnace is shut off.”

X1.2.4 In adopting this definition, NBFU stated that it was

X1.2.2 About this same time Committee C-5 (now E-5) and

based on a determination of which materials “could be properly

the New York City Building Code suggested adding a reference

classed as noncombustible and then fixing the qualifying

of 649°C (1200°F) as the fire exposure temperature. By 1949

conditions in the definition to include these materials.” The

the term incombustible was changed to noncombustible in the

definition was considered to apply to materials used for the

National Building Code without definition. The first edition of

walls, roofs, or other structural parts of buildings, but not to

the BOCA Basic Building Code (1950) defined a noncombus-

surface finish materials and not to the determination of whether

tible material as “any material which will neither ignite or

a material is noncombustible from the standpoint of clearances

actively support combustion in air at a temperature of 649°C

to heating appliances, flues, or other sources of high tempera-

(1200°F) during an exposure of five minutes in a vented tube

ture.

or vented crucible furnace.”

X1.2.5 After Test Method E 136 was promulgated, (initially

X1.2.3 The 1955 edition of the NBFU National Building

as a tentative in 1958, then as a full standard in 1965), many

Code established a definition for noncombustible material (1)

building codes replaced either part (a) of the NBFU definition

that was subsequently adopted by other model codes, the Life

or the entire definition with the specification that materials

Safety Code (2), and most local codes. The adopted definition

shall have been successfully tested in accordance with Test

was as follows:

Method E 136. In 1973, the American Insurance Association

Noncombustible as applied to a building construction mate-

(successor to NBFU) introduced a definition of a limited-

rial means a material that, in the form in which it is used, falls

combustible material and redefined a noncombustible material

in one of the following groups (a) through (c). It does not apply

as one that, in the form in which it is used and under the

to surface finish materials nor to the determination of whether

conditions anticipated, will not ignite, burn, support combus-

a material is noncombustible from the standpoint o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.