ASTM F733-09(2014)

(Practice)Standard Practice for Optical Distortion and Deviation of Transparent Parts Using the Double-Exposure Method

Standard Practice for Optical Distortion and Deviation of Transparent Parts Using the Double-Exposure Method

SIGNIFICANCE AND USE

5.1 Transparent parts, such as aircraft windshields and windows, can be inspected using this practice, and the amount of optical distortion or deviation can be measured. The measurement can be checked for acceptability against the specification for the part. The photograph (digital file, print or negative) can be maintained as a permanent record of the optical quality of the part.

SCOPE

1.1 This photographic practice determines the optical distortion and deviation of a line of sight through a simple transparent part, such as a commercial aircraft windshield or a cabin window. This practice applies to essentially flat or nearly flat parts and may not be suitable for highly curved materials.

1.2 Test Method F801 addresses optical deviation (angluar deviation) and Test Method F2156 addresses optical distortion using grid line slope. These test methods should be used instead of Practice F733 whenever practical.

1.3 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F733 − 09 (Reapproved 2014)

Standard Practice for

Optical Distortion and Deviation of Transparent Parts Using

the Double-Exposure Method

ThisstandardisissuedunderthefixeddesignationF733;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 May also be expressed as the slope of the angle of

localized grid line bending, for example, 1 in 5 (see Fig. 1).

1.1 This photographic practice determines the optical dis-

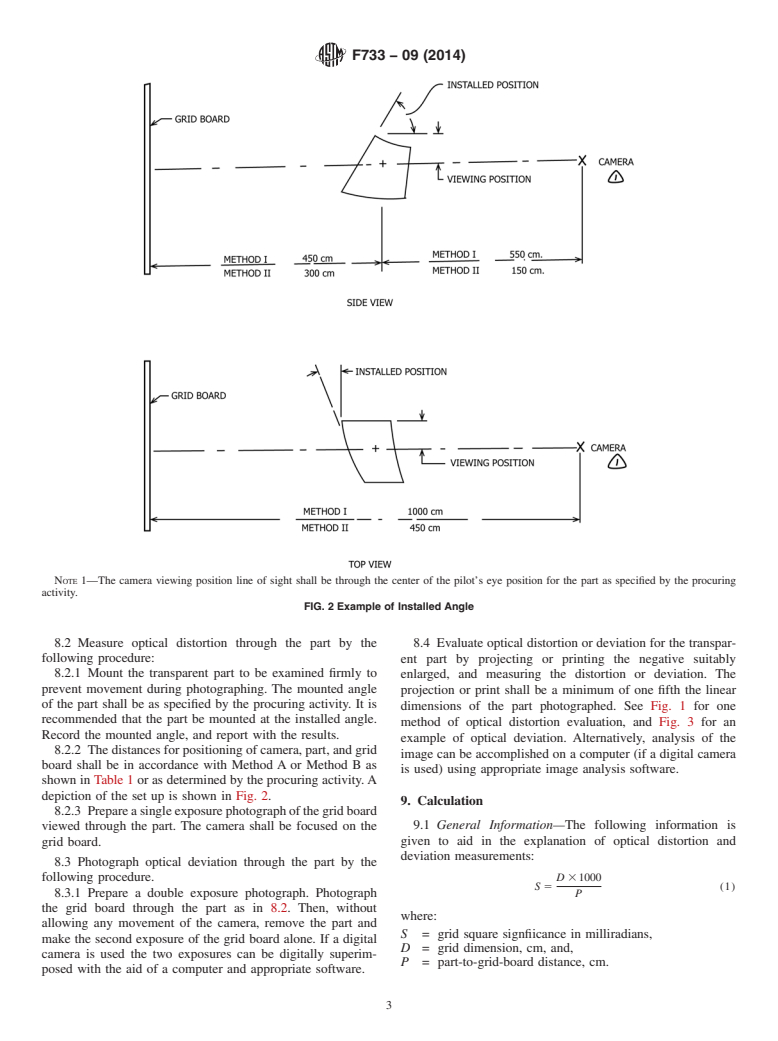

3.1.5 installed angle—the part attitude as installed in the

tortion and deviation of a line of sight through a simple

aircraft.Definedbytheanglebetweenahorizontallineandthe

transparent part, such as a commercial aircraft windshield or a

planeofthepart,andtheangleofsweepbackfromahorizontal

cabinwindow.Thispracticeappliestoessentiallyflatornearly

line normal to the center line of the aircraft. See Fig. 2 for an

flat parts and may not be suitable for highly curved materials.

example.

1.2 Test Method F801 addresses optical deviation (angluar

deviation) and Test Method F2156 addresses optical distortion

4. Summary of Practice

using grid line slope. These test methods should be used

4.1 The transparent part is placed a given distance from a

instead of Practice F733 whenever practical.

grid line pattern. A camera is placed so as to photograph the

1.3 This standard does not purport to address the safety

gridpatternasviewedthroughthepart.Thephotographisthen

concerns associated with its use. It is the responsibility of the

examined and optical distortion or deviation is measured.

user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

5. Significance and Use

tions prior to use.

5.1 Transparent parts, such as aircraft windshields and

2. Referenced Documents

windows, can be inspected using this practice, and the amount

of optical distortion or deviation can be measured. The

2.1 ASTM Standards:

measurement can be checked for acceptability against the

F801Test Method for Measuring OpticalAngular Deviation

specification for the part. The photograph (digital file, print or

of Transparent Parts

negative) can be maintained as a permanent record of the

F2156Test Method for Measuring Optical Distortion in

optical quality of the part.

Transparent Parts Using Grid Line Slope

6. Apparatus

3. Terminology

6.1 Test Room—The test room must be large enough to

3.1 Definitions:

properly locate the required testing equipment.

3.1.1 deviation—the displacement of a line or object when

6.1.1 MethodArequires a room approximately 12 m (40 ft)

viewed through the transparent part. Expressed as the angular

measurementofthedisplacedline,forexample,milliradiansof long.

angle. 6.1.2 Method B requires a room approximately 7 m (23 ft)

long.

3.1.2 distortion—the rate of change of deviation resulting

6.1.3 The walls, ceiling, and floor shall have low reflec-

from an irregularity in a transparent part.

tance. A flat black paint or coating is preferred.

3.1.3 Expressed as the angular bending of the light ray per

6.2 Grid Board—The grid board provides a defined pattern

unit of length of the part, for example, milliradians per

againstwhichthetransparentpartisexamined.Gridboardsare

centimetre.

of the following types.

6.2.1 Type 1—The grid board is composed of white strings

held taut, each spaced at a specific interval, with the strings

This practice is under the jurisdiction ofASTM Committee F07 on Aerospace

andAircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

stretched vertically and horizontally.The grid board frame and

Enclosures and Materials.

background shall have a flat black finish to reduce light

Current edition approved Dec. 1, 2014. Published December 2014. Originally

reflection. A bank of fluorescent lights at each side provides

approved in 1981. Last previous edition approved in 2009 as F733–09. DOI:

10.1520/F0733-09R14. illumination of the strings.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F733 − 09 (2014)

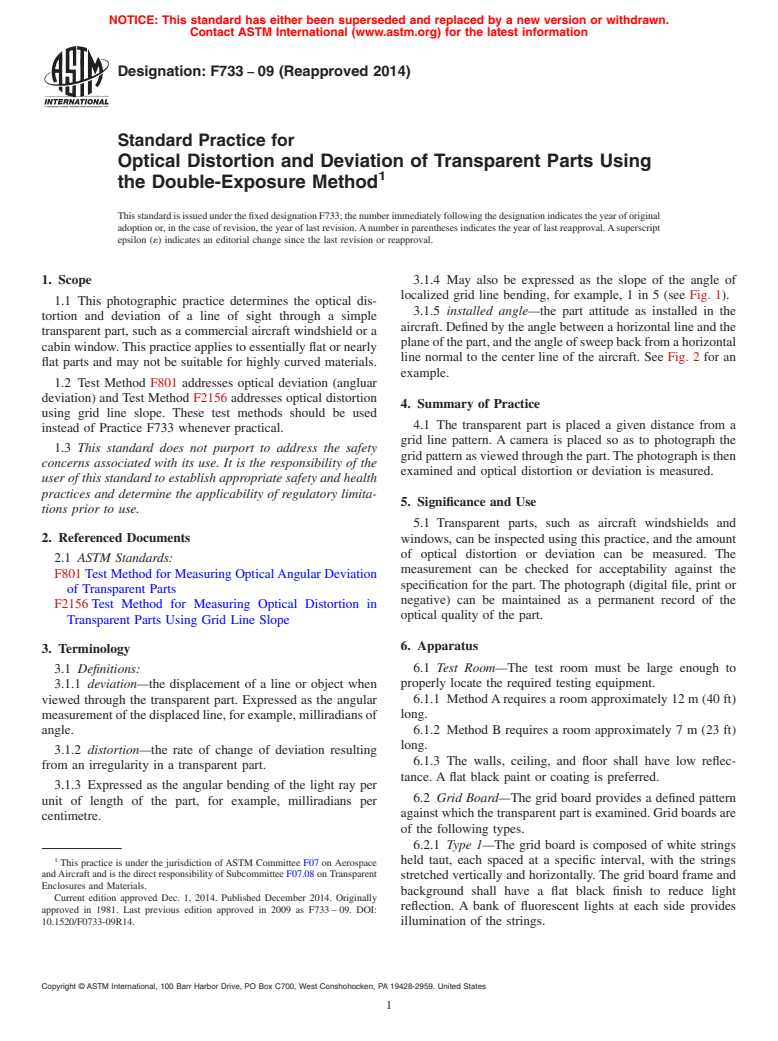

FIG. 1 Optical Distortion Represented by Tangent

6.2.2 Type 2—The grid board is a transparent sheet having 6.3 Camera—Unless otherwise specified, the camera shall

anopaque,flatblackoutersurfaceexceptforthegridlines.The utilizea4by 5-in. film size.The lens opening used shall be f8

grid lines are left transparent, and when lighted from behind or smaller. The camera shall be firmly mounted to prevent any

with fluorescent lights, provide a bright grid pattern with movement during the photographic exposure. Digital cameras

excellent photographic characteristics. are acceptable if they have sufficient resolution (pixel count)

for the size of part to be measured.

TABLE 1 Optical Inspection Distances

7. Test Specimen

Method A

Camera-to-grid-board distance 1000 cm (32 ft 10 in.)

7.1 The part to be checked shall be cleaned, using any

Camera-to-part distance 550 cm (18 ft 1 in.)

acceptable procedure, to remove any foreign material that

Part-to-grid board distance 450 cm (14 ft 9 in.)

Method B might cause localized optical distortion. No special

Camera-to-grid-board distance 450 cm (14 ft 9 in.)

conditioning, other than cleaning, is required.The part shall be

Camera-to-part distance 150 cm (4 ft 11 in.)

at ambient temperature.

Part-to-grid-board distance 300 cm (9 ft 10 in.)

8. Procedure

6.2.3 Type 3—The grid board is a rigid sheet of material 8.1 The procuring activity shall specify whether Method A

which has a grid pattern printed on the front surface. Details of or Method B (see Table 1) or some other set of distances shall

the grid lines, pattern, and lighting shall be as specified by the be used to measure optical distortion and deviation. If Method

procuring activity. Aor Method B are not used, the actual distances used shall be

6.2.4 The grid board shall have a width and height large reported. When the part is flat and mounted nearly vertical,

enough so that the area of the part to be photographed can be MethodAisamorestringenttestthanMethodB.Certainparts

superimposedwithintheperimeterofthegridboard.Detailsof may show substantial optical deviation by Method B simply

the grid square size shall be as specified by the procuring duetorefractionofthelightrays.Ifthepartisawindscreenthe

activity, but grids shall not have a line spacing less than 1.27 procuring activity may require the camera to be positioned at

cm ( ⁄2 in.), or more than 2.54 cm (1 in.). the pilot’s eye position.

F733 − 09 (2014)

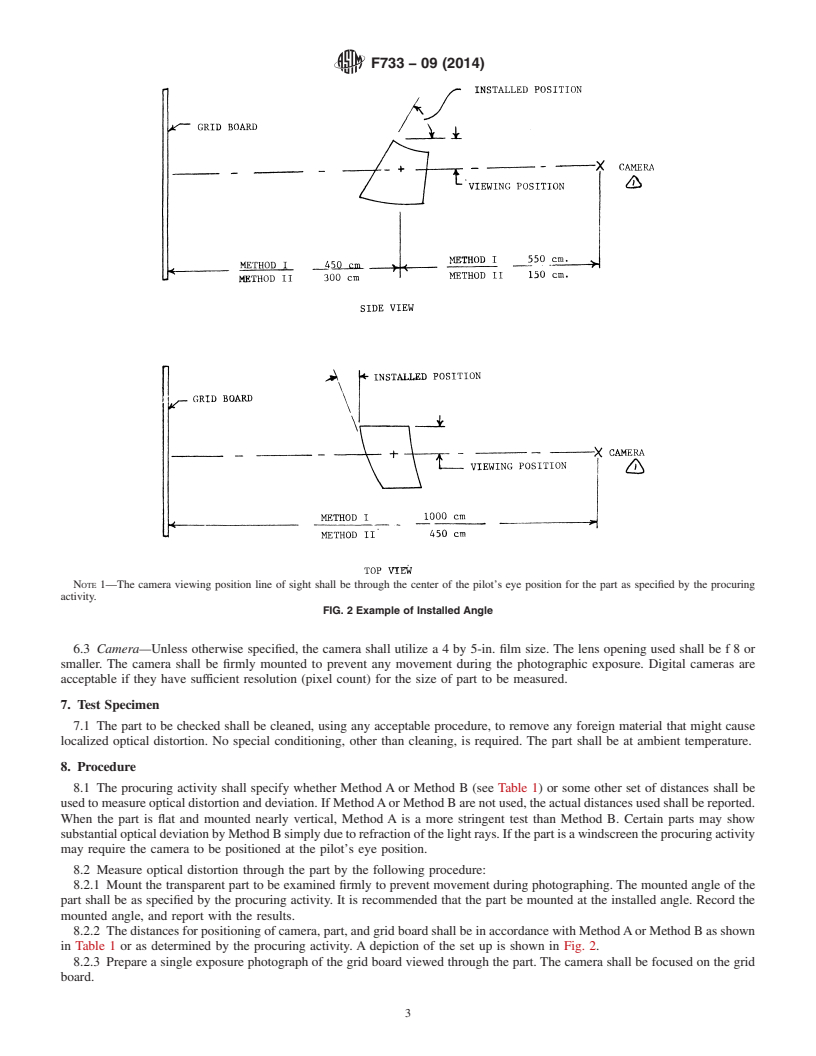

NOTE 1—The camera viewing position line of sight shall be through the center of the pilot’s eye position for the part as specified by the procuring

activity.

FIG. 2 Example of Installed Angle

8.2 Measure optical distortion through the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F733 − 09 F733 − 09 (Reapproved 2014)

Standard Practice for

Optical Distortion and Deviation of Transparent Parts Using

the Double-Exposure Method

This standard is issued under the fixed designation F733; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This photographic practice determines the optical distortion and deviation of a line of sight through a simple transparent

part, such as a commercial aircraft windshield or a cabin window. This practice applies to essentially flat or nearly flat parts and

may not be suitable for highly curved materials.

1.2 Test Method F801 addresses optical deviation (angluar deviation) and Test Method F2156 addresses optical distortion using

grid line slope. These test methods should be used instead of Practice F733 whenever practical.

1.3 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of

this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

F801 Test Method for Measuring Optical Angular Deviation of Transparent Parts

F2156 Test Method for Measuring Optical Distortion in Transparent Parts Using Grid Line Slope

3. Terminology

3.1 Definitions:

3.1.1 deviation—the displacement of a line or object when viewed through the transparent part. Expressed as the angular

measurement of the displaced line, for example, milliradians of angle.

3.1.2 distortion—the rate of change of deviation resulting from an irregularity in a transparent part.

3.1.3 Expressed as the angular bending of the light ray per unit of length of the part, for example, milliradians per centimetre.

3.1.4 May also be expressed as the slope of the angle of localized grid line bending, for example, 1 in 5 (see Fig. 1).

3.1.5 installed angle—the part attitude as installed in the aircraft. Defined by the angle between a horizontal line and the plane

of the part, and the angle of sweep back from a horizontal line normal to the center line of the aircraft. See Fig. 2 for an example.

4. Summary of Practice

4.1 The transparent part is placed a given distance from a grid line pattern. A camera is placed so as to photograph the grid

pattern as viewed through the part. The photograph is then examined and optical distortion or deviation is measured.

5. Significance and Use

5.1 Transparent parts, such as aircraft windshields and windows, can be inspected using this practice, and the amount of optical

distortion or deviation can be measured. The measurement can be checked for acceptability against the specification for the part.

The photograph (digital file, print or negative) can be maintained as a permanent record of the optical quality of the part.

6. Apparatus

6.1 Test Room—The test room must be large enough to properly locate the required testing equipment.

6.1.1 Method A requires a room approximately 12 m (40 ft) long.

This practice is under the jurisdiction of ASTM Committee F07 on Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

Enclosures and Materials.

Current edition approved May 15, 2009Dec. 1, 2014. Published June 2009December 2014. Originally approved in 1981. Last previous edition approved in 20032009 as

F733 – 90 (2003).F733 – 09. DOI: 10.1520/F0733-09.10.1520/F0733-09R14.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F733 − 09 (2014)

FIG. 1 Optical Distortion Represented by Tangent

6.1.2 Method B requires a room approximately 7 m (23 ft) long.

6.1.3 The walls, ceiling, and floor shall have low reflectance. A flat black paint or coating is preferred.

6.2 Grid Board—The grid board provides a defined pattern against which the transparent part is examined. Grid boards are of

the following types.

6.2.1 Type 1—The grid board is composed of white strings held taut, each spaced at a specific interval, with the strings stretched

vertically and horizontally. The grid board frame and background shall have a flat black finish to reduce light reflection. A bank

of fluorescent lights at each side provides illumination of the strings.

6.2.2 Type 2—The grid board is a transparent sheet having an opaque, flat black outer surface except for the grid lines. The grid

lines are left transparent, and when lighted from behind with fluorescent lights, provide a bright grid pattern with excellent

photographic characteristics.

TABLE 1 Optical Inspection Distances

Method A

Camera-to-grid-board distance 1000 cm (32 ft 10 in.)

Camera-to-part distance 550 cm (18 ft 1 in.)

Part-to-grid board distance 450 cm (14 ft 9 in.)

Method B

Camera-to-grid-board distance 450 cm (14 ft 9 in.)

Camera-to-part distance 150 cm (4 ft 11 in.)

Part-to-grid-board distance 300 cm (9 ft 10 in.)

6.2.3 Type 3—The grid board is a rigid sheet of material which has a grid pattern printed on the front surface. Details of the

grid lines, pattern, and lighting shall be as specified by the procuring activity.

6.2.4 The grid board shall have a width and height large enough so that the area of the part to be photographed can be

superimposed within the perimeter of the grid board. Details of the grid square size shall be as specified by the procuring activity,

but grids shall not have a line spacing less than 1.27 cm ( ⁄2 in.), or more than 2.54 cm (1 in.).

F733 − 09 (2014)

NOTE 1—The camera viewing position line of sight shall be through the center of the pilot’s eye position for the part as specified by the procuring

activity.

FIG. 2 Example of Installed Angle

6.3 Camera—Unless otherwise specified, the camera shall utilize a 4 by 5-in. film size. The lens opening used shall be f 8 or

smaller. The camera shall be firmly mounted to prevent any movement during the photographic exposure. Digital cameras are

acceptable if they have sufficient resolution (pixel count) for the size of part to be measured.

7. Test Specimen

7.1 The part to be checked shall be cleaned, using any acceptable procedure, to remove any foreign material that might cause

localized optical distortion. No special conditioning, other than cleaning, is required. The part shall be at ambient temperature.

8. Procedure

8.1 The procuring activity shall specify whether Method A or Method B (see Table 1) or some other set of distances shall be

used to measure optical distortion and deviation. If Method A or Method B are not used, the actual distances used shall be reported.

When the part is flat and mounted nearly vertical, Method A is a more stringent test than Method B. Certain parts may show

substantial optical deviation by Method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.