ASTM C1675-11(2015)

(Practice)Standard Practice for Installation of Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers

Standard Practice for Installation of Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers

SIGNIFICANCE AND USE

4.1 This practice is useful as a reference by an owner and the owner’s engineer in preparing project specifications.

SCOPE

1.1 This practice covers the installation of precast reinforced concrete box sections cast monolithically and intended to be used for the conveyance of storm water, industrial wastes and sewage, and for passageways.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1675 − 11 (Reapproved 2015)

Standard Practice for

Installation of Precast Reinforced Concrete Monolithic Box

Sections for Culverts, Storm Drains, and Sewers

This standard is issued under the fixed designation C1675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 AASHTO Standards:

AASHTO Standard Specifications for Highway Bridges ,

1.1 This practice covers the installation of precast rein-

Div. II, Section 27

forced concrete box sections cast monolithically and intended

AASHTO LRFD Bridge Construction Specifications , Sec-

to be used for the conveyance of storm water, industrial wastes

tion 27

and sewage, and for passageways.

AASHTO LRFD Bridge Design Specifications

1.2 The values stated in inch-pound units are to be regarded

AASHTO M145 Classification of Soils and Soil-Aggregate

as standard. The values given in parentheses are mathematical

Mixtures for Highway Construction Purposes

conversions to SI units that are provided for information only

and are not considered standard.

3. Terminology

3.1 For definitions of terms relating to precast box sections,

2. Referenced Documents

see Terminology C822.

2.1 ASTM Standards:

3.2 For terminology related to soil classifications, see Prac-

C822 Terminology Relating to Concrete Pipe and Related

tice D2487.

Products

3.3 For terminology and definitions of terms relating to

C1433 Specification for Precast Reinforced Concrete Mono-

structural design, see ASCE 26.

lithic Box Sections for Culverts, Storm Drains, and

Sewers

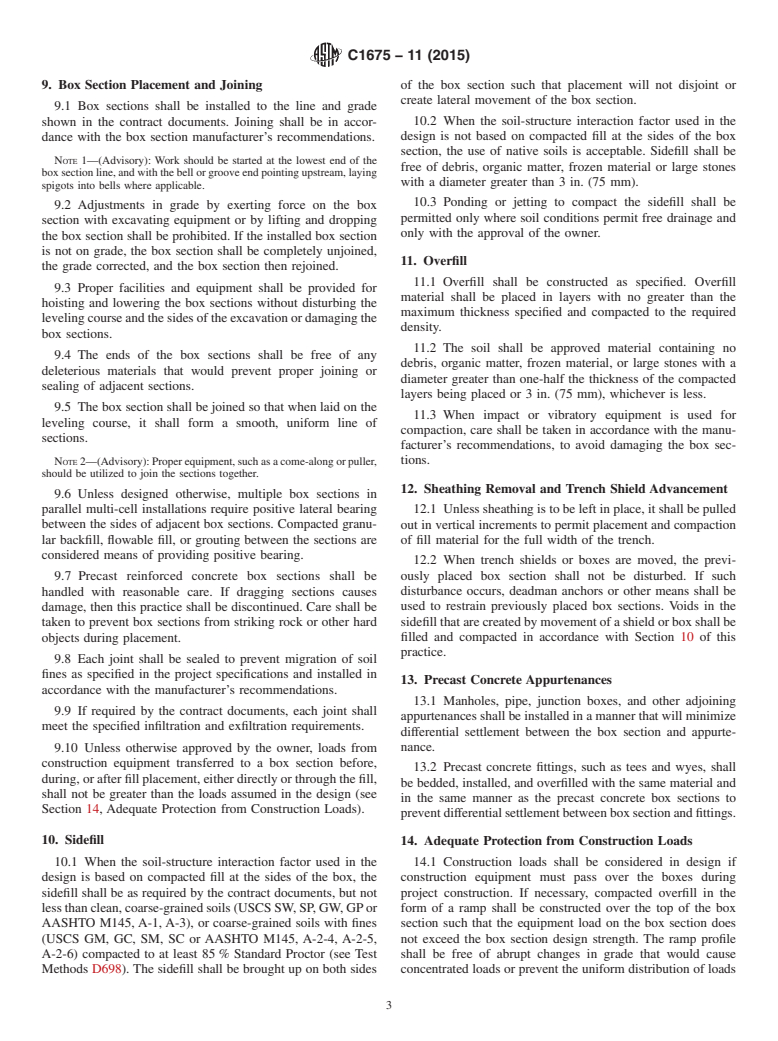

3.4 Fig. 1 illustrates the installation terminology.

C1433M Specification for Precast Reinforced Concrete

Monolithic Box Sections for Culverts, Storm Drains, and

4. Significance and Use

Sewers (Metric)

4.1 This practice is useful as a reference by an owner and

C1577 Specification for Precast Reinforced Concrete Mono-

the owner’s engineer in preparing project specifications.

lithic Box Sections for Culverts, Storm Drains, and

Sewers Designed According to AASHTO LRFD

5. General

D698 Test Methods for Laboratory Compaction Character-

5.1 The precast reinforced concrete box section/soil system

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

3 shall be constructed to conform to the dimensions and require-

kN-m/m ))

ments specified or shown on the plans and to this practice.

D2487 Practice for Classification of Soils for Engineering

Additionally, for highway projects, the precast reinforced

Purposes (Unified Soil Classification System)

concrete box section/soil system shall conform to requirements

2.2 ASCE Standard:

of Section 27 of AASHTO Standard Specifications for High-

ASCE 26 Standard Practice for the Direct Design of Buried

way Bridges or AASHTO LRFD Bridge Construction Speci-

Precast Concrete Box Sections

fications as appropriate. The owner is advised to provide or

require adequate inspection of the box section installation at

the construction site.

This practice is under the jurisdiction of ASTM Committee C13 on Concrete

Pipe and is the direct responsibility of Subcommittee C13.05 on Special Projects.

6. Excavation

Current edition approved Oct. 1, 2015. Published October 2015. Originally

approved in 2011. Last previous edition approved in 2011 as C1675 – 11. DOI:

6.1 Trenchesshallbeexcavatedtothedimensionsandgrade

10.1520/C1675–11R15.

specified on the plans or as ordered by the owner.The width of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from American Association of State Highway and Transportation

Available from American Society of Civil Engineers (ASCE), 1801 Alexander Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

Bell Dr., Reston, VA 20191, http://www.asce.org. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1675 − 11 (2015)

FIG. 1 Box Section/Installation Terminology

trenches shall be kept to the minimum required for installation 7.4 Box sections installed over an unyielding foundation,

of the box sections and proper compaction of the sidefill. including concrete, shall be cushioned so as to prevent non-

uniform bearing in accordance with Section 8.

6.2 When ledge rock, compacted rocky, or other unyielding

foundation material is encountered, it shall be removed to the

8. Leveling Course

requirements shown on the plans. Over-excavated areas shall

be backfilled with approved materials specified for the leveling

8.1 Aminimum 3 in. (75 mm) leveling course, as shown in

course.

Fig.1,shallbeconstructedofcleancoarsegrainedsoils:USCS

SW, SP, GW, GP or any soil beginning with one of those

6.3 Thecontractorshallmakesuchprovisionsasrequiredto

symbols and with 12 % or less passing a #200 (75 µm) sieve

ensure adequate drainage of the trench to protect the leveling

(AASHTOM145,A-1,A-3).Thenominalmaximumaggregate

courseduringtheconstructionoperations.Wheresurfacewater

size shall not be greater than 1 in. (25 mm) (#57 aggregate). In

or groundwater conditions exist, the site and trench shall be

the event that the leveling course consists of layers with the

dewatered.

upper layer being clean, uncompacted sand, that layer shall be

a maximum thickness of 2 in. (50 mm) to prevent non-uniform

7. Foundation

settlement from personnel and equipment during the installa-

7.1 The foundation shall be moderately firm to hard in situ

tion process.

material, stabilized soil, or compacted fill material.

8.2 In situ material that provide a suitable leveling course in

7.2 When unsuitable or unstable material is encountered,

accordance with this practice shall be acceptable.

thefoundationshallbestabilizedorremovedandreplacedwith

8.3 If rock strata or boulders are encountered under the box

firm and stable foundation material.

section within the limits of the required leveling course, the

7.3 Wheregroundwaterandsoilcharacteristicscontributeto

rock or boulders shall be removed and replaced with additional

the migration of soil fines into or out of the foundation,

leveling course material.

leveling course, or overfill materials, methods to prevent

migration shall be provided. 8.4 A concrete slab is not an appropriate leveling course.

C1675 − 11 (2015)

9. Box Section Placement and Joining of the box section such that placement will not disjoint or

create lateral movement of the box section.

9.1 Box sections shall be installed to the line and grade

10.2 When the soil-structure interaction factor used in the

shown in the contract documents. Joining shall be in accor-

dance with the box section manufacturer’s recommendations. design is not based on compacted fill at the sides of the box

section, the use of native soils is acceptable. Sidefill shall be

NOTE 1—(Advisory): Work should be started at the lowest end of the

free of debris, organic matter, frozen material or large stones

boxsectionline,andwiththebellorgrooveendpointingupstream,laying

with a diameter greater than 3 in. (75 mm).

spigots into bells where applicable.

10.3 Ponding or jetting to compact the sidefill shall be

9.2 Adjustments in grade by exerting force on the box

permitted only where soil conditions permit free drainage and

section with excavating equipment or by lifting and dropping

only with the approval of the owner.

the box section shall be prohibited.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1675 − 11 C1675 − 11 (Reapproved 2015)

Standard Practice for

Installation of Precast Reinforced Concrete Monolithic Box

Sections for Culverts, Storm Drains, and Sewers

This standard is issued under the fixed designation C1675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the installation of precast reinforced concrete box sections cast monolithically and intended to be used

for the conveyance of storm water, industrial wastes and sewage, and for passageways.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

C822 Terminology Relating to Concrete Pipe and Related Products

C1433 Specification for Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers

C1433M Specification for Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers

(Metric)

C1577 Specification for Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers Designed

According to AASHTO LRFD

3 3

D698 Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft (600 kN-m/m ))

D2487 Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)

2.2 ASCE Standard:

ASCE 26 Standard Practice for the Direct Design of Buried Precast Concrete Box Sections

2.3 AASHTO Standards:

AASHTO Standard Specifications for Highway Bridges , Div. II, Section 27

AASHTO LRFD Bridge Construction Specifications , Section 27

AASHTO LRFD Bridge Design Specifications

AASHTO M145 Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes

3. Terminology

3.1 For definitions of terms relating to precast box sections, see Terminology C822.

3.2 For terminology related to soil classifications, see Practice D2487.

3.3 For terminology and definitions of terms relating to structural design, see ASCE 26.

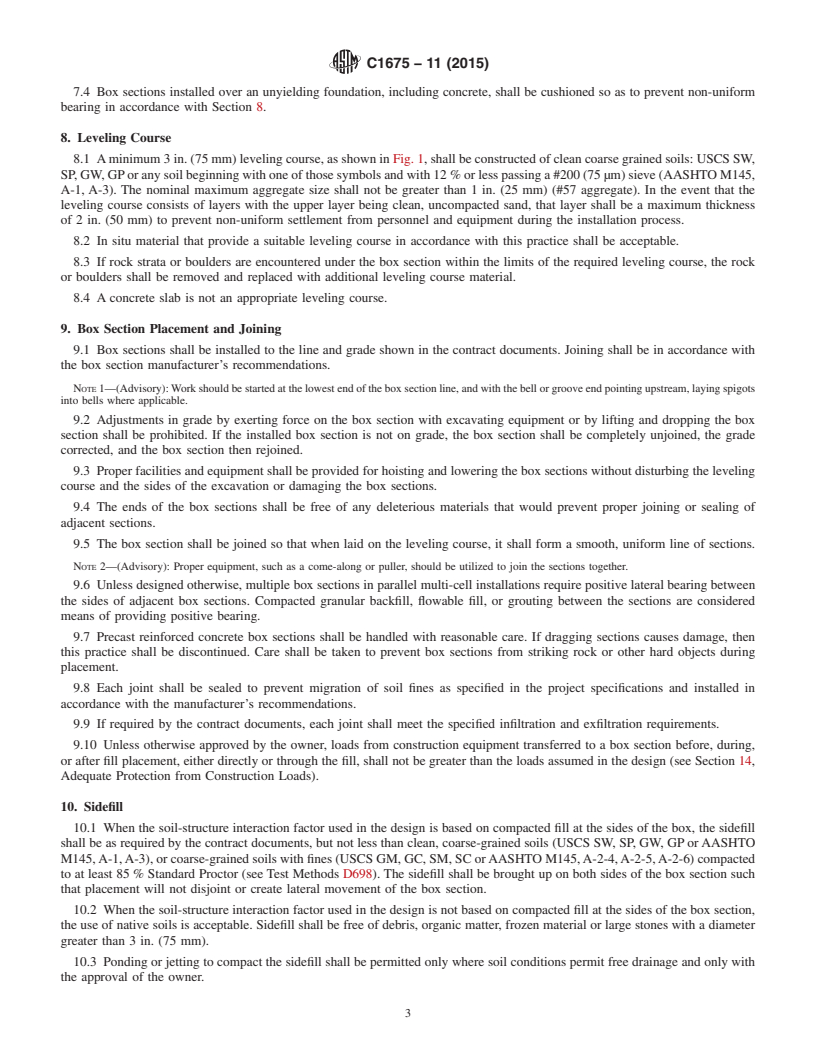

3.4 Fig. 1 illustrates the installation terminology.

4. Significance and Use

4.1 This practice is useful as a reference by an owner and the owner’s engineer in preparing project specifications.

This practice is under the jurisdiction of ASTM Committee C13 on Concrete Pipe and is the direct responsibility of Subcommittee C13.05 on Special Projects.

Current edition approved Oct. 15, 2011Oct. 1, 2015. Published November 2011October 2015. Originally approved in 2011. Last previous edition approved in 2011 as

C1675 – 11. DOI: 10.1520/C1675–11.10.1520/C1675–11R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Civil Engineers (ASCE), 1801 Alexander Bell Dr., Reston, VA 20191, http://www.asce.org.

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1675 − 11 (2015)

FIG. 1 Box Section/Installation Terminology

5. General

5.1 The precast reinforced concrete box section/soil system shall be constructed to conform to the dimensions and requirements

specified or shown on the plans and to this practice. Additionally, for highway projects, the precast reinforced concrete box

section/soil system shall conform to requirements of Section 27 of AASHTO Standard Specifications for Highway Bridges or

AASHTO LRFD Bridge Construction Specifications as appropriate. The owner is advised to provide or require adequate inspection

of the box section installation at the construction site.

6. Excavation

6.1 Trenches shall be excavated to the dimensions and grade specified on the plans or as ordered by the owner. The width of

trenches shall be kept to the minimum required for installation of the box sections and proper compaction of the sidefill.

6.2 When ledge rock, compacted rocky, or other unyielding foundation material is encountered, it shall be removed to the

requirements shown on the plans. Over-excavated areas shall be backfilled with approved materials specified for the leveling

course.

6.3 The contractor shall make such provisions as required to ensure adequate drainage of the trench to protect the leveling

course during the construction operations. Where surface water or groundwater conditions exist, the site and trench shall be

dewatered.

7. Foundation

7.1 The foundation shall be moderately firm to hard in situ material, stabilized soil, or compacted fill material.

7.2 When unsuitable or unstable material is encountered, the foundation shall be stabilized or removed and replaced with firm

and stable foundation material.

7.3 Where groundwater and soil characteristics contribute to the migration of soil fines into or out of the foundation, leveling

course, or overfill materials, methods to prevent migration shall be provided.

C1675 − 11 (2015)

7.4 Box sections installed over an unyielding foundation, including concrete, shall be cushioned so as to prevent non-uniform

bearing in accordance with Section 8.

8. Leveling Course

8.1 A minimum 3 in. (75 mm) leveling course, as shown in Fig. 1, shall be constructed of clean coarse grained soils: USCS SW,

SP, GW, GP or any soil beginning with one of those symbols and with 12 % or less passing a #200 (75 μm) sieve (AASHTO M145,

A-1, A-3). The nominal maximum aggregate size shall not be greater than 1 in. (25 mm) (#57 aggregate). In the event that the

leveling course consists of layers with the upper layer being clean, uncompacted sand, that layer shall be a maximum thickness

of 2 in. (50 mm) to prevent non-uniform settlement from personnel and equipment during the installation process.

8.2 In situ material that provide a suitable leveling course in accordance with this practice shall be acceptable.

8.3 If rock strata or boulders are encountered under the box section within the limits of the required leveling course, the rock

or boulders shall be removed and replaced with additional leveling course material.

8.4 A concrete slab is not an appropriate leveling course.

9. Box Section Placement and Joining

9.1 Box sections shall be installed to the line and grade shown in the contract documents. Joining shall be in accordance with

the box section manufacturer’s recommendations.

NOTE 1—(Advisory): Work should be started at the lowest end of the box section line, and with the bell or groove end pointing upstream, laying spigots

into bells where applicable.

9.2 Adjustments in grade by exerting force on the box section with excavating equipment or by lifting and dropping the box

section shall be prohibited. If the installed box section is not on grade, the box section shall be completely unjoined, the grade

corrected, and the box section then rejoined.

9.3 Proper facilities and equipment shall be provided for hoisting and lowering the box sections without disturbing the leveling

course and the sides of the excavation or damaging the box sections.

9.4 The ends of the box sections shall be free of any deleterious materials that would prevent p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.