ASTM F2805-09

(Specification)Standard Specification for Multilayer Thermoplastic And Flexible Steel Pipe And Connections

Standard Specification for Multilayer Thermoplastic And Flexible Steel Pipe And Connections

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, markings for factory manufactured multilayer flexible steel pipe with thermoplastic inner and outer layers and end connections (Fig. 1). It covers nominal sizes 2 in. through 8 in. (50 mm through 200 mm). Flexible steel pipes are multilayered pipe products manufactured in long continuous lengths and reeled for storage, transport and installation. The multilayer thermoplastic and flexible steel pipe governed by this standard are intended for use for the transport of crude oil, natural gas, hazardous chemicals, industrial chemicals and water.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2805 – 09

Standard Specification for

Multilayer Thermoplastic And Flexible Steel Pipe And

Connections

This standard is issued under the fixed designation F2805; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This specification covers requirements and test methods

D1505 Test Method for Density of Plastics by the Density-

for materials, dimensions, workmanship, markings for factory

Gradient Technique

manufactured multilayer flexible steel pipe with thermoplastic

D1600 Terminology for Abbreviated Terms Relating to

inner and outer layers and end connections (Fig. 1). It covers

Plastics

nominal sizes 2 in. through 8 in. (50 mm through 200 mm).

D2122 Test Method for Determining Dimensions of Ther-

Flexible steel pipes are multilayered pipe products manufac-

moplastic Pipe and Fittings

tured in long continuous lengths and reeled for storage,

D2321 Practice for Underground Installation of Thermo-

transport and installation. The multilayer thermoplastic and

plastic Pipe for Sewers and Other Gravity-Flow Applica-

flexible steel pipe governed by this standard are intended for

tions

use for the transport of crude oil, natural gas, hazardous

D2765 Test Methods for Determination of Gel Content and

chemicals, industrial chemicals and water.

Swell Ratio of Crosslinked Ethylene Plastics

1.2 The values stated in inch-pound units are to be regarded

F412 Terminology Relating to Plastic Piping Systems

as standard. The values given in parentheses are mathematical

2.2 ANSI Standard:

conversions to SI units that are provided for information only

B 16.5 Pipe, Flanges, and Flanged Fittings

and are not considered standard.

2.3 API Standards:

1.3 This standard does not purport to address all of the

17B Recommended Practice for Flexible Pipe

safety concerns, if any, associated with its use. It is the

17J Specification for Unbonded Flexible Pipe

responsibility of the user of this standard to establish appro-

2.4 ISO Standards:

priate safety and health practices and determine the applica-

ISO 9080 Plastics Piping and Ducting Systems Determi-

bility of regulatory limitations prior to use.

nation of the Long-Term Hydrostatic Strength of Thermo-

2. Referenced Documents plastics Materials in Pipe Form by Extrapolation

2.5 PPI Standards:

2.1 ASTM Standards:

TR-4 PPI Listing of Hydrostatic Design Basis (HDB),

A109/A109M Specification for Steel, Strip, Carbon (0.25

Strength Design Basis (SDB), Pressure Design Basis

Maximum Percent), Cold-Rolled

(PDB), and Minimum Required Strength (MRS) Ratings

A312/A312M Specification for Seamless, Welded, and

for Thermoplastic Piping Materials or Pipe

Heavily Cold Worked Austenitic Stainless Steel Pipes

TR-19 Thermoplastics Piping for the Transport of Chemi-

A333/A333M Specification for Seamless and Welded Steel

cals

Pipe for Low-Temperature Service

2.6 BSI Standards:

A506 Specification for Alloy and Structural Alloy Steel,

EN 10210 Hot Finished Structural Hollow Sections of

Sheet and Strip, Hot-Rolled and Cold-Rolled

Non-Alloy and Fine Grain Steels

A519 Specification for Seamless Carbon and Alloy Steel

Mechanical Tubing

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

1 4

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Available from American Petroleum Institute (API), 1220 L. St., NW, Wash-

Piping Systems and is the direct responsibility of Subcommittee F17.11 on ington, DC 20005-4070, http://www.api.org.

Composite. Available from International Organization for Standardization (ISO), 1, ch. de

CurrenteditionapprovedDec.15,2009.PublishedFebruary2010.DOI:10.1520/ la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

F2805–09. www.iso.ch.

2 6

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Irving, TX 75062, http://www.plasticpipe.org.

Standards volume information, refer to the standard’s Document Summary page on Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

the ASTM website. London W4 4AL, U.K., http://www.bsi-global.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2805 – 09

FIG. 1 Cutaway of Flexible Steel Pipe

EN 10297 Seamless Circular Steel Tubes for Mechanical 4.2.1 Density—When determined in accordance with Test

and General Engineering Purposes Method D1505 or D792, the crosslinked polyethylene material

3 3

shall have a minimum density of 0.033 lb/in (0.926 g/cm ).

3. Terminology

4.2.2 Degree of Crosslinking —When tested in accordance

3.1 Definitions—Definitions are in accordance with Termi- withTestMethodD2765,MethodB,thedegreeofcrosslinking

nology F412 and abbreviations are accordance with Terminol- for the PEX material shall be within the range of 65% to 89%

ogy D1600, unless otherwise specified. inclusive.

3.2 Definitions of Terms Specific to This Standard: 4.3 Long Term Hydrostatic Strength —Polyethylene and

3.3 inner sheath layer, n—pipe lining made from extruded crosslinked polyethylene compounds used in the manufacture

thermoplastic compound. of these products shall have Hydrostatic Design Basis (HDB)

3.4 tensile armor layer, n—hoop and structural reinforce- listings in PPI TR-4.

ment helically wrapped over the inner sheath layer. The steel 4.4 Rework materials—Reground or reprocessed thermo-

layers are not bonded. plastic materials are not permitted to be used.

3.5 outer sheath layer, n—external extruded thermoplastic 4.5 Steel Materials:

coating applied to resist mechanical damage and to provide the 4.5.1 Steel tensile armor layers shall consist of steel strip

underlying layers of the pipe protection from the environment. manufactured in accordance with SpecificationA506 or Speci-

3.6 end connection, n—connects the pipe ends with adja- fication A109/A109M with a number 3 edge and number 1 or

cent pipe or other parts of the system. 2 finish.

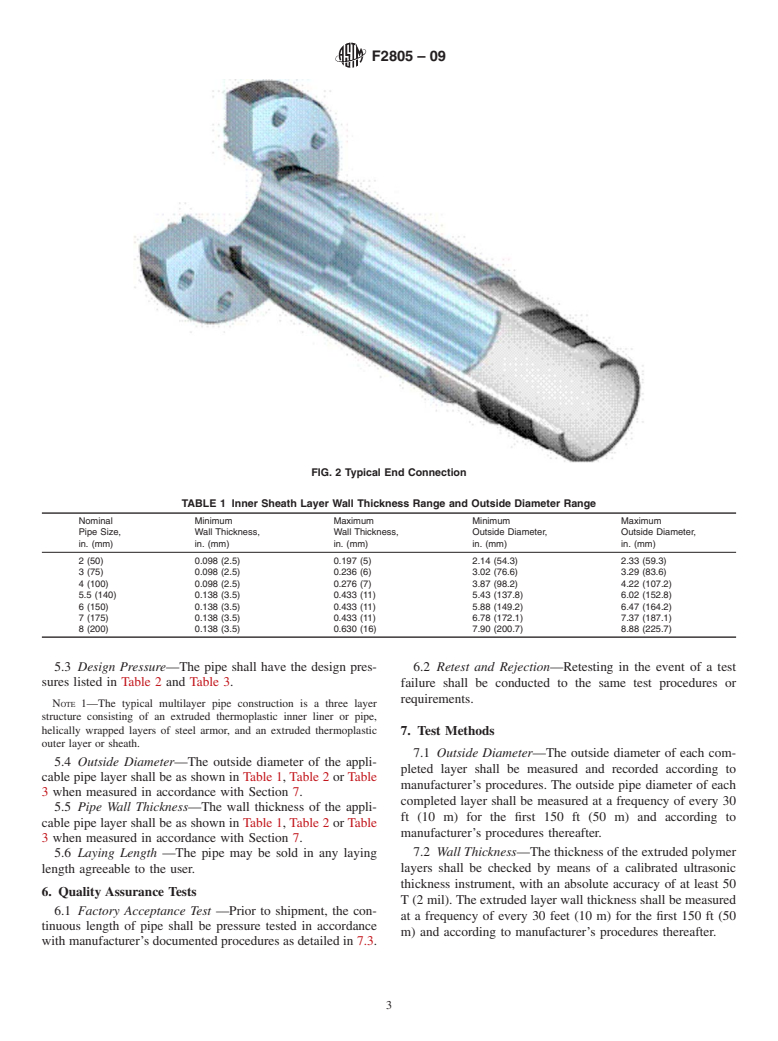

4.5.2 Steel in end connections shall meet the requirements

4. Materials

of Specification A312/A312M, Specification A333/A333M,

4.1 Polyethylene Materials—Polyethylene compounds used SpecificationA519,EN 10210,orEN 10297(Fig.2).Specialty

inthemanufactureoftheseproductsshallhaveaminimumcell steel grades requested by the purchaser must meet the same

classification of 444474 in accordance with Specification minimum performance requirements.

D2321 (PE4710 as defined in PPI TR-4) or PE100 in accor-

5. Requirements

dance with ISO 9080. Addition of pigments or stabilizers to

natural polyethylene compounds during extrusion is permitted. 5.1 Workmanship- The inside and outside surfaces of the

4.2 Crosslinked Polyethylene Materials—Crosslinked poly- pipe shall be semi-matte or glossy in appearance and free of

ethylene compounds used in the manufacture of these products chalking, sticky or tacky materials. The pipe surfaces shall be

shall be made from polyethylene compounds which have been free of cracks, holes, blisters, voids, foreign inclusions or other

crosslinked by peroxides, azo compounds or silane compounds defects that are visible to the naked eye.

in extrusion or by other means such that the inner sheath layer 5.2 Multilayer Pipe Dimensions—Pipe Dimensions shall

and/or the outer sheath layer meets the following performance comply with Table 1, Table 2 and Table 3, when measured in

requirements: accordance with Test Method D2122.

F2805 – 09

FIG. 2 Typical End Connection

TABLE 1 Inner Sheath Layer Wall Thickness Range and Outside Diameter Range

Nominal Minimum Maximum Minimum Maximum

Pipe Size, Wall Thickness, Wall Thickness, Outside Diameter, Outside Diameter,

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

2 (50) 0.098 (2.5) 0.197 (5) 2.14 (54.3) 2.33 (59.3)

3 (75) 0.098 (2.5) 0.236 (6) 3.02 (76.6) 3.29 (83.6)

4 (100) 0.098 (2.5) 0.276 (7) 3.87 (98.2) 4.22 (107.2)

5.5 (140) 0.138 (3.5) 0.433 (11) 5.43 (137.8) 6.02 (152.8)

6 (150) 0.138 (3.5) 0.433 (11) 5.88 (149.2) 6.47 (164.2)

7 (175) 0.138 (3.5) 0.433 (11) 6.78 (172.1) 7.37 (187.1)

8 (200) 0.138 (3.5) 0.630 (16) 7.90 (200.7) 8.88 (225.7)

5.3 Design Pressure—The pipe shall have the design pres- 6.2 Retest and Rejection—Retesting in the event of a test

sures listed in Table 2 and Table 3. failure shall be conducted to the same test procedures or

requirements.

NOTE 1—The typical multilayer pipe construction is a three layer

structure consisting of an extruded thermoplastic inner liner or pipe,

helically wrapped layers of steel armor, and an extruded thermoplastic

7. Test Methods

outer layer or sheath.

7.1 Outside Diameter—The outside diameter of each com-

5.4 Outside Diameter—The outside diameter of the appli-

pleted layer shall be measured and recorded according to

cable pipe layer shall be as shown in Table 1, Table 2 or Table

manufacturer’s procedures. The outside pipe diameter of each

3 when measured in accordance with Section 7.

completed layer shall be measured at a frequency of every 30

5.5 Pipe Wall Thickness—The wall thickness of the appli-

ft (10 m) for the first 150 ft (50 m) and according to

cable pipe layer shall be as shown in Table 1, Table 2 or Table

manufacturer’s procedures thereafter.

3 when measured in accordance with Section 7.

7.2 Wall Thickness—The thickness of the extruded polymer

5.6 Laying Length —The pipe may be sold in any laying

layers shall be checked by means of a calibrated ultrasonic

length agreeable to the user.

thickness instrument, with an absolute accuracy of at least 50

6. Quality Assurance Tests

T (2 mil). The extruded layer wall thickness shall be measured

6.1 Factory Acceptance Test —Prior to shipment, the con-

at a frequency of every 30 feet (10 m) for the first 150 ft (50

tinuous length of pipe shall be pressure tested in accordance

m) and according to manufacturer’s procedures thereafter.

with manufacturer’s documented procedures as detailed in 7.3.

F2805 – 09

TABLE 2 Inner Sheath Layer Wall Thickness Range and Outside Diameter Range

Nominal Design Pressure, Minimum Maximum

Pipe Size, psi (kPa) Outside Diameter, Outside Diameter,

in. (mm) in. (mm) in. (mm)

2 (50) 750 (5,171) 2.18 (55.5) 2.41 (61.2)

2 (50) 1,000 (6,895) 2.22 (56.5) 2.46 (62.5)

2 (50) 1,500 (10,342) 2.23 (56.7) 2.49 (63.1)

2 (50) 2,250 (15,513) 2.28 (57.9) 2.54 (64.6)

2 (50) 3,000 (20,684) 2.31 (58.7) 2.59 (65.8)

3 (75) 750 (5,171) 3.09 (78.5) 3.40 (86.5)

3 (75) 1,000 (6,895) 3.11 (79.1) 3.44 (87.5)

3 (75) 1,500 (10,342) 3.16 (80.3) 3.50 (88.9)

3 (75) 2,250 (15,513) 3.21 (81.5) 3.58 (90.9)

3 (75) 3,000 (20,684) 3.25 (82.5) 3.62 (92.0)

4 (100) 750 (5,171) 3.96 (100.7) 4.37 (111.1)

4 (100) 1,000 (6,895) 3.99 (101.3) 4.41 (111.9)

4 (100) 1,500 (10,342) 4.02 (102.1) 4.49 (114.1)

4 (100) 2,250 (15,513) 4.13 (104.9) 4.61 (117.0)

4 (100) 3,000 (20,684) 4.15 (105.3) 4.65 (118.2)

5.5 (140) 750 (5,171) 5.55 (140.9) 6.23 (158.3)

5.5 (140) 1,000 (6,895) 5.57 (141.5) 6.28 (159.5)

5.5 (140) 1,500 (10,342) 5.62 (142.7) 6.34 (161.1)

5.5 (140) 2,250 (15,513) 5.66 (143.7) 6.45 (163.8)

6 (150) 750 (5,171) 6.00 (152.3) 6.67 (169.4)

6 (150) 1,000 (6,895) 6.03 (153.1) 6.73 (170.9)

6 (150) 1,500 (10,342) 6.13 (155.7) 6.85 (174.0)

6 (150) 2,250 (15,513) 6.18 (157.0) 6.91 (175.4)

7 (175) 750 (5,171) 6.90 (175.1) 7.57 (192.2)

7 (175) 1,000 (6,895) 6.93 (176.0) 7.65 (194.2)

7 (175) 1,500 (10,342) 7.03 (178.6) 7.76 (197.1)

7 (175) 2,250 (15,513) 7.08 (179.8) 7.81 (198.5)

8 (200) 750 (5,171) 8.02 (203.7) 9.16 (232.8)

8 (200) 1,000 (6,895) 8.05 (204.5) 9.28 (235.8)

8 (200) 1,500 (10,342) 8.16 (207.2) 9.35 (237.5)

8 (200) 2,250 (15,513) 8.20 (208.4) 9.44 (239.9)

TABLE 3 Outer Sheath Layer Wall Thickness Range and Outside Diameter Range

Nominal Design Pressure, Minimum Maximum Minimum Maximum

Pipe Size, psi (kPa) Wall Thickness, Wall Thickness, Outside Diameter, Outside Diameter,

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

2 (50) 750 (5,171) 0.098 (2.5) 0.276 (7.0) 2.38 (60.5) 2.96 (75.2)

2 (50) 1,000 (6,895) 0.098 (2.5) 0.276 (7.0) 2.42 (61.5) 3.01 (76.5)

2 (50) 1,500 (10,342) 0.098 (2.5) 0.276 (7.0) 2.43 (61.7) 3.04 (77.1)

2 (50) 2,250 (15,513) 0.098 (2.5) 0.276 (7.0) 2.48 (62.9) 3.09 (78.6)

2 (50) 3,000 (20,684) 0.098 (2.5) 0.276 (7.0) 2.51 (63.7) 3.14 (79.8)

3 (75) 750 (5,171) 0.098 (2.5) 0.276 (7.0) 3.29 (83.5) 3.96 (100.5)

3 (75) 1,000 (6,895) 0.098 (2.5) 0.276 (7.0) 3.31 (84.1) 4.00 (101.5)

3 (75) 1,500 (10,342) 0.098 (2.5) 0.276 (7.0) 3.36 (85.3) 4.05 (102.9)

3 (75) 2,250 (15,513) 0.098 (2.5) 0.276 (7.0) 3.41 (86.5) 4.13 (104.9)

3 (75) 3,000 (20,684) 0.098 (2.5) 0.276 (7.0) 3.45 (87.5) 4.17 (106.0)

4 (100) 750 (5,171) 0.098 (2.5) 0.276 (7.0) 4.16 (105.7) 4.92 (125.1)

4 (100) 1,000 (6,895) 0.098 (2.5) 0.276 (7.0) 4.18 (106.3) 4.96 (125.9)

4 (100) 1,500 (10,342) 0.098 (2.5) 0.276 (7.0) 4.22 (107.1) 5.04 (128.1)

4 (100) 2,250 (15,513) 0.098 (2.5) 0.276 (7.0) 4.33 (109.9) 5.16 (131.0)

4 (100) 3,000 (20,684) 0.098 (2.5) 0.276 (7.0) 4.34 (110.3) 5.20 (132.2)

5.5 (140) 750 (5,171) 0.098 (2.5) 0.276 (7.0) 5.74 (145.9) 6.78 (172.3)

5.5 (140) 1,000 (6,895) 0.098 (2.5) 0.276 (7.0) 5.77 (146.5) 6.83 (173.5)

5.5 (140) 1,500 (10,342) 0.098 (2.5) 0.276 (7.0) 5.81 (147.7) 6.90 (175.1)

5.5 (140) 2,250 (15,513) 0.098 (2.5) 0.276 (7.0) 5.85 (148.7) 7.00 (177.8)

6 (150) 750 (5,171) 0.098 (2.5) 0.295 (7.5) 6.19 (157.3) 7.25 (184.1)

6 (150) 1,000 (6,895) 0.098 (2.5) 0.295 (7.5) 6.22 (158.1) 7.32 (185.9)

6 (150) 1,500 (10,342) 0.098 (2.5) 0.295 (7.5) 6.33 (160.7) 7.44 (189.0)

6 (150) 2,250 (15,513) 0.098 (2.5) 0.344 (8.75) 6.38 (162.0) 7.60 (192.9)

7 (175) 750 (5,171) 0.098 (2.5) 0.295 (7.5) 7.09 (180.1) 8.16 (207.2)

7 (175) 1,000 (6,895) 0.098 (2.5) 0.295 (7.5) 7.12 (181.0) 8.24 (209.2)

7 (175) 1,500 (10,342) 0.098 (2.5) 0.295 (7.5) 7.23 (183.6) 8.35 (212.0)

7 (175) 2,250 (15,513) 0.098 (2.5) 0.344 (8.75) 7.28 (184.8) 8.50 (216.0)

8 (200) 750 (5,171) 0.098 (2.5) 0.354 (9.0) 8.22 (208.7) 9.75 (247.8)

8 (200) 1,000 (6,895) 0.098 (2.5) 0.354 (9.0) 8.25 (209.5) 9.87 (250.8)

8 (200) 1,500 (10,342) 0.098 (2.5) 0.354 (9.0) 8.35 (212.2) 9.94 (252.4)

8 (200) 2,250 (15,513) 0.098 (2.5) 0.354 (9.0) 8.40 (213.4) 10.15 (257.9)

F2805 – 09

7.3 Pressure Testing—Unless otherwise speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.