ASTM E2652-09a

(Terminology)Standard Test Method for Behavior of Materials in a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750°C

Standard Test Method for Behavior of Materials in a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750<span class='unicode'>°</span>C

SIGNIFICANCE AND USE

While actual building fire exposure conditions are not duplicated, this test method will assist in indicating those materials which do not act to aid combustion or add appreciable heat to an ambient fire.

This test method does not apply to laminated or coated materials.

This test method is technically equivalent to ISO 1182.

SCOPE

1.1 This fire-test-response test method covers the determination under specified laboratory conditions of combustion characteristics of building materials.

1.2 Limitations of this fire-test response test method are shown below.

1.2.1 This test method does not apply to laminated or coated materials.

1.2.2 This test method is not suitable or satisfactory for materials that soften, flow, melt, intumesce or otherwise separate from the meeasuring thermocouple.

1.2.3 This test method does not provide a measure of an intrinsic property.

1.2.4 This test method does not provide a quantitative measure of heat generation or combustibility; it simply serves as a test method with selected (end point) measures of combustibility.

1.2.5 This test method does not measure the self-heating tendencies of materials.

1.2.6 In this test method materials are not being tested in the nature and form used in building aplications. The test specimen consists of a small, specified volume that is either (1) cut from a thick sheet; (2) assembled from multiple thicknesses of thin sheets; or (3) placed in a container if composed of grarnular powder or loose fiber materials.

1.2.7 Results from this test method apply to the specific test apparatus and test conditions and are likely to vary when changes are made to one or more of the following: (1) the size, shape, and arrangement of the specimen; (2) the distribution of organice content; (3) the exposure temperature; (4) the air supply; (5) the location of thermocouples.

1.3 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this test method.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This test method is technically equivalent to ISO 1182.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.7 FIre testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E2652 – 09a

Standard Test Method for

Behavior of Materials in a Tube Furnace with a Cone-shaped

1

Airflow Stabilizer, at 750°C

This standard is issued under the fixed designation E2652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

1.1 This fire-test-response test method covers the determi-

only.

nation under specified laboratory conditions of combustion

1.5 This test method is technically equivalent to ISO 1182.

characteristics of building materials.

1.6 This standard is used to measure and describe the

1.2 Limitations of this fire-test response test method are

response of materials, products, or assemblies to heat and

shown below.

flame under controlled conditions, but does not by itself

1.2.1 Thistestmethoddoesnotapplytolaminatedorcoated

incorporate all factors required for fire-hazard or fire-risk

materials.

assessment of the materials, products, or assemblies under

1.2.2 This test method is not suitable or satisfactory for

actual fire conditions.

materials that soften, flow, melt, intumesce or otherwise

1.7 FIre testing is inherently hazardous. Adequate safe-

separate from the meeasuring thermocouple.

guards for personnel and property shall be employed in

1.2.3 This test method does not provide a measure of an

conducting these tests.

intrinsic property.

1.8 This standard does not purport to address all of the

1.2.4 This test method does not provide a quantitative

safety concerns, if any, associated with its use. It is the

measure of heat generation or combustibility; it simply serves

responsibility of the user of this standard to establish appro-

as a test method with selected (end point) measures of

priate safety and health practices and determine the applica-

combustibility.

bility of regulatory limitations prior to use.

1.2.5 This test method does not measure the self-heating

tendencies of materials.

2. Referenced Documents

1.2.6 Inthistestmethodmaterialsarenotbeingtestedinthe

2

2.1 ASTM Standards:

natureandformusedinbuildingaplications.Thetestspecimen

E136 Test Method for Behavior of Materials in a Vertical

consists of a small, specified volume that is either (1) cut from

Tube Furnace at 750°C

a thick sheet; (2) assembled from multiple thicknesses of thin

E176 Terminology of Fire Standards

sheets; or (3) placed in a container if composed of grarnular

3

2.2 ISO Standards:

powder or loose fiber materials.

ISO 1182 Reaction to Fire Tests for Building Products –

1.2.7 Results from this test method apply to the specific test

Non-combustibility Test

apparatus and test conditions and are likely to vary when

ISO 13943 Fire Safety — Vocabulary

changes are made to one or more of the following: (1) the size,

ISO 5725-2:1994 Accuracy (trueness and precision) of

shape, and arrangement of the specimen; (2) the distribution of

MeasuredMethodsandResults–Part2:BasicMethodfor

organice content; (3) the exposure temperature; (4) the air

the Determination of Repeatability and Reproducibility of

supply; (5) the location of thermocouples.

a Standard Measurement Method

1.3 This test method references notes and footnotes that

4

2.3 Other Standards:

provide explanatory information. These notes and footnotes,

excludingthoseintablesandfigures,shallnotbeconsideredas

requirements of this test method.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire Standards volume information, refer to the standard’s Document Summary page on

Standards and is the direct responsibility of Subcommittee E05.23 on Combustibil- the ASTM website.

3

ity. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Dec. 15, 2009. Published January 2010. Originally 4th Floor, New York, NY 10036, http://www.ansi.org.

´1 4

approved in 2009. Last previous edition approved in 2009 as E2652–09 . DOI: Available from International Maritime Origanization, 55 Victoria St., London,

10.1520/E2652-09A. SWIH0EU, United Kingdom, http://www.imo.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

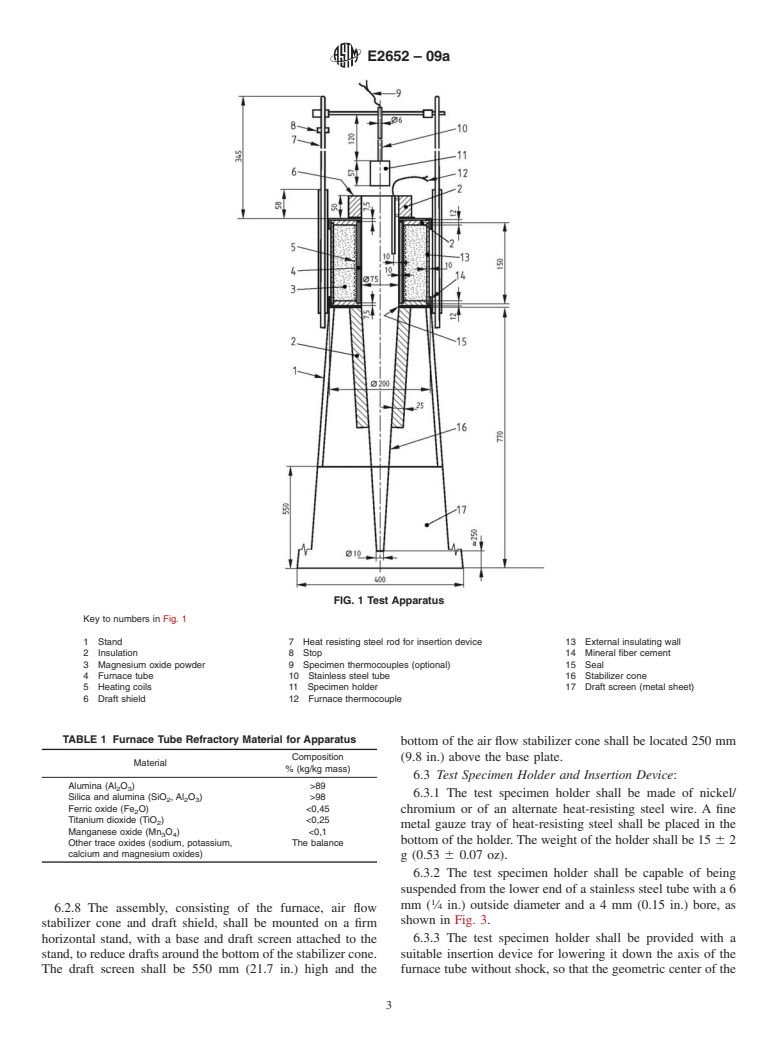

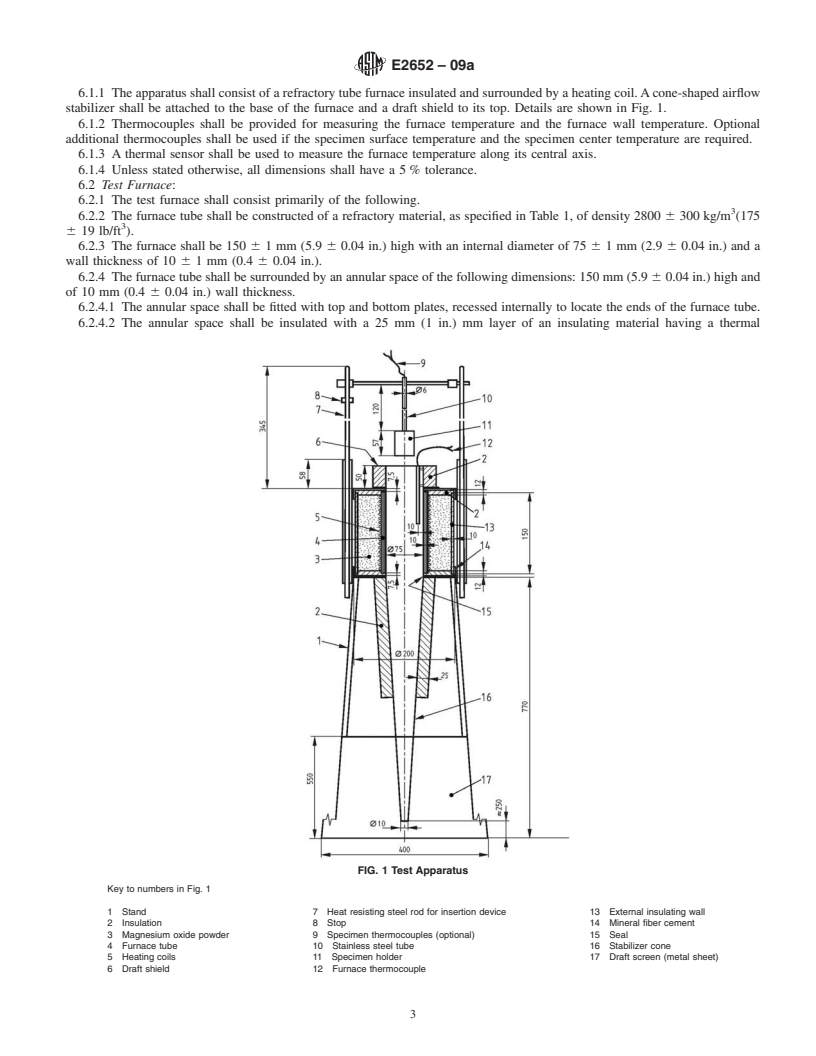

E2652 – 09a

IMO Fire Test Procedures Code 6.2.2 The furnace tube shall be constructed of a refractory

material, as specified in Table 1, of density 2800 6 300

3 3

3. Termino

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:E2652–09 Designation: E2652 – 09a

Standard Test Method for

Behavior of Materials in a Tube Furnace with a Cone-shaped

1

Airflow Stabilizer, at 750°C

This standard is issued under the fixed designation E2652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Figure 3 was corrected editorially in October 2009.

1. Scope

1.1This fire-test-response test method covers the determination under specified laboratory conditions of combustion

characteristics of building materials. It does not apply to laminated or coated materials.

1.2This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding

those in tables and figures, shall not be considered as requirements of this test method.

1.3Limitations of the test method are discussed in 1.1 and Annex A1

1.1 This fire-test-response test method covers the determination under specified laboratory conditions of combustion

characteristics of building materials.

1.2 Limitations of this fire-test response test method are shown below.

1.2.1 This test method does not apply to laminated or coated materials.

1.2.2 This test method is not suitable or satisfactory for materials that soften, flow, melt, intumesce or otherwise separate from

the meeasuring thermocouple.

1.2.3 This test method does not provide a measure of an intrinsic property.

1.2.4 This test method does not provide a quantitative measure of heat generation or combustibility; it simply serves as a test

method with selected (end point) measures of combustibility.

1.2.5 This test method does not measure the self-heating tendencies of materials.

1.2.6 In this test method materials are not being tested in the nature and form used in building aplications. The test specimen

consistsofasmall,specifiedvolumethatiseither (1)cutfromathicksheet; (2)assembledfrommultiplethicknessesofthinsheets;

or (3) placed in a container if composed of grarnular powder or loose fiber materials.

1.2.7 Results from this test method apply to the specific test apparatus and test conditions and are likely to vary when changes

are made to one or more of the following: (1) the size, shape, and arrangement of the specimen; (2) the distribution of organice

content; (3) the exposure temperature; (4) the air supply; (5) the location of thermocouples.

1.3 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding

those in tables and figures, shall not be considered as requirements of this test method.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This test method is technically equivalent to ISO 1182.

1.4This test method is technically equivalent to ISO 1182.

1.5The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.7 FIre testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.23 on Combustibility.

Current edition approved Aug. 1, 2009. Published August 2009. DOI: 10.1520/E2652-09E01.

´1

Current edition approved Dec. 15, 2009. Published January 2010. Originally approved in 2009. Last previous edition approved in 2009 as E2652–09 . DOI:

10.1520/E2652-09A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2652 – 09a

2. Referenced Documents

2

2.1 ASTM Stand

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.