ASTM E2652-09e1

(Terminology)Standard Test Method for Behavior of Materials in a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750°C

Standard Test Method for Behavior of Materials in a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750<span class='unicode'>°</span>C

SIGNIFICANCE AND USE

While actual building fire exposure conditions are not duplicated, this test method will assist in indicating those materials which do not act to aid combustion or add appreciable heat to an ambient fire.

This test method does not apply to laminated or coated materials.

This test method is technically equivalent to ISO 1182.

SCOPE

1.1 This fire-test-response test method covers the determination under specified laboratory conditions of combustion characteristics of building materials. It does not apply to laminated or coated materials.

1.2 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this test method.

1.3 Limitations of the test method are discussed in 1.1 and Annex A1.

1.4 This test method is technically equivalent to ISO 1182.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

´1

Designation: E2652 – 09

Standard Test Method for

Behavior of Materials in a Tube Furnace with a Cone-shaped

1

Airflow Stabilizer, at 750°C

This standard is issued under the fixed designation E2652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Figure 3 was corrected editorially in October 2009.

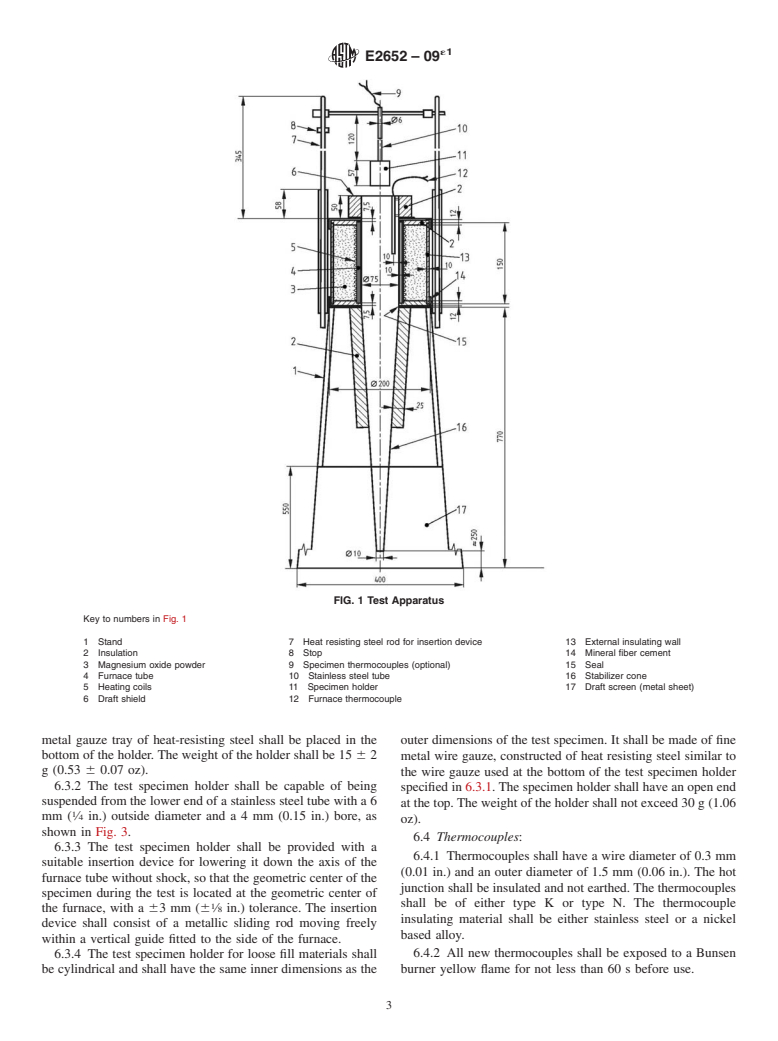

3

1. Scope 2.2 ISO Standards:

ISO 1182 Reaction to Fire Tests for Building Products –

1.1 This fire-test-response test method covers the determi-

Non-combustibility Test

nation under specified laboratory conditions of combustion

ISO 13943 Fire Safety — Vocabulary

characteristics of building materials. It does not apply to

ISO 5725-2:1994 Accuracy (trueness and precision) of

laminated or coated materials.

MeasuredMethodsandResults–Part2:BasicMethodfor

1.2 This test method references notes and footnotes that

the Determination of Repeatability and Reproducibility of

provide explanatory information. These notes and footnotes,

a Standard Measurement Method

excludingthoseintablesandfigures,shallnotbeconsideredas

4

2.3 Other Standards:

requirements of this test method.

IMO Fire Test Procedures Code

1.3 Limitations of the test method are discussed in 1.1 and

Annex A1.

3. Terminology

1.4 This test method is technically equivalent to ISO 1182.

3.1 Definitions—For definitions of terms found in this test

1.5 The values stated in SI units are to be regarded as

method, refer to Terminology E176 and ISO 13943. In case of

standard. The values given in parentheses are for information

conflict, the definitions given in Terminology E176 shall

only.

prevail.

1.6 This standard is used to measure and describe the

3.2 Definitions of Terms Specific to This Standard:

response of materials, products, or assemblies to heat and

3.2.1 homogeneous product, n—a product with nominally

flame under controlled conditions, but does not by itself

uniform density and composition.

incorporate all factors required for fire-hazard or fire-risk

3.2.2 non-homogeneous product, n—a product that does not

assessment of the materials, products, or assemblies under

satisfy the requirements of a homogeneous product.

actual fire conditions.

3.2.2.1 Discussion—Non-homogeneous products are often

1.7 This standard does not purport to address all of the

composed of more than one component.

safety concerns, if any, associated with its use. It is the

3.2.3 substantial component, n—a material that constitutes

responsibility of the user of this standard to establish appro-

a significant part of a non-homogeneous product that consists

priate safety and health practices and determine the applica-

of more than one component.

bility of regulatory limitations prior to use.

3.2.3.1 Discussion—A layer with a weight/unit area larger

2 2

2. Referenced Documents than 1.0 kg/m (0.2 lb/ft ) or a thickness larger than 1 mm (0.04

2

in.) is often considered to be a substantial component. A layer

2.1 ASTM Standards:

2 2

with a weight per unit area smaller than 1.0 kg/m (0.2 lb/ft )

E136 Test Method for Behavior of Materials in a Vertical

and a thickness less than 1 mm (0.04 in.) is not considered to

Tube Furnace at 750°C

be a substantial component.

E176 Terminology of Fire Standards

3.2.4 sustained flaming (for testing at 750°C), n—sustained

flaming for testing at 750°C (1382°F) is the persistence of a

flameonoroveranypartofthevisiblepartofthetestspecimen

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire

lasting5sor longer.

Standards and is the direct responsibility of Subcommittee E05.23 on Combustibil-

ity.

Current edition approved Aug. 1, 2009. Published August 2009. DOI: 10.1520/

E2652-09E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from International Maritime Origanization, 55 Victoria St., London,

the ASTM website. SWIH0EU, United Kingdom, http://www.imo.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

E2652 – 09

TABLE 1 Furnace Tube Refractory Material for Apparatus

6.2.4.1 Theannularspaceshallbefittedwithtopandbottom

Composition plates, recessed internally to locate the ends of the furnace

Material

% (kg/kg mass)

tube.

Alumina (Al O ) >89

2 3 6.2.4.2 The annular space

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.