ASTM D6208-07(2014)

(Test Method)Standard Test Method for Repassivation Potential of Aluminum and Its Alloys by Galvanostatic Measurement

Standard Test Method for Repassivation Potential of Aluminum and Its Alloys by Galvanostatic Measurement

SIGNIFICANCE AND USE

5.1 This test method is designed to measure the relative effectiveness of inhibitors to mitigate pitting corrosion of aluminum and its alloys, in particular AA3003-H14, rapidly and reproducibly. The measurements are not intended to correlate quantitatively with other test method values or with susceptibility to localized corrosion of aluminum observed in service. Qualitative correlation of the measurements and susceptibility in service has been established (1).

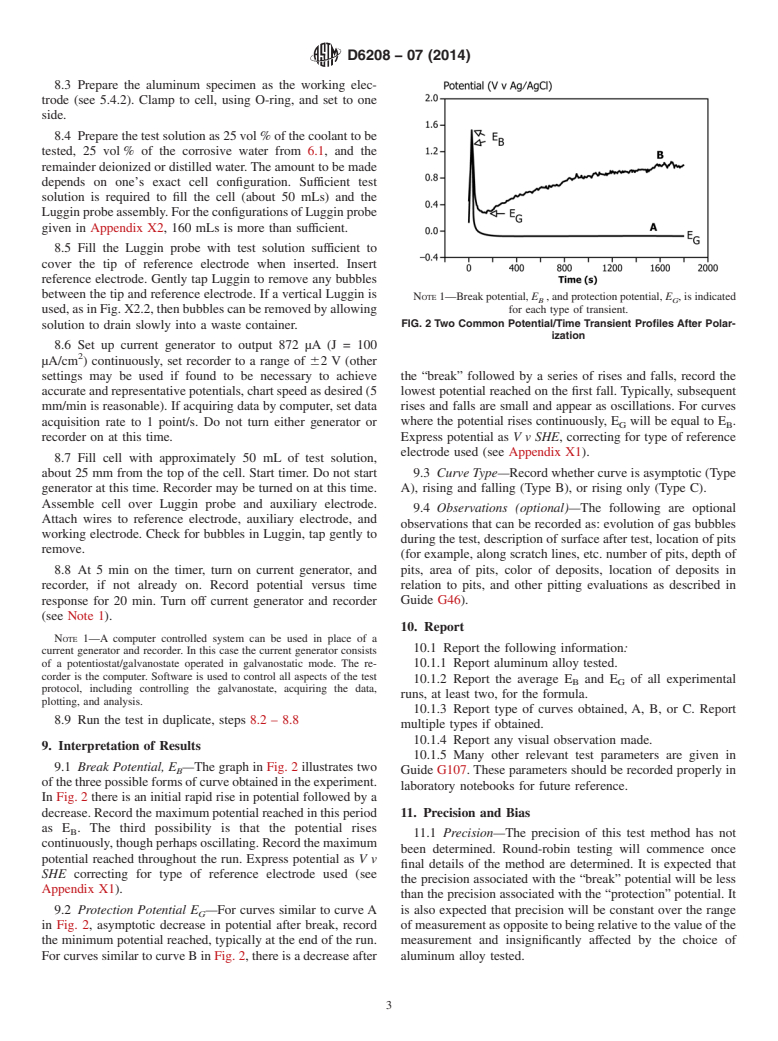

5.2 The maximum potential reached upon initial polarization, EB, is a measure of the resistance to breakdown of the aluminum oxide film. Lower susceptibility to initiation of pitting corrosion is indicated by a more noble potential (See Practice G3 and Terminology G15.) This potential, as measured in this test method, is not very sensitive to the inhibitors present.

5.3 The minimum potential, EG, following the maximum potential is a measure of the protection against continued pitting corrosion by the inhibitors. Again, a more noble potential indicates better protection. This potential is sensitive to the inhibitors present.

5.4 Visual examination of the specimens can provide information about subleties of the pitting and inhibition mechanisms. Number of pits, pit depth, amount of deposit, and surface discoloration are some examples of recordable observations, which can assist evaluation of inhibitor effectiveness.

5.5 The presence of chloride in the test solution is critical to observation of pitting corrosion. Also, a coolant/corrosive water solution in which gas bubbles evolve spontaneously on the aluminum (indicating general corrosion) is unlikely to have a significant amount of observable pitting corrosion.

SCOPE

1.1 A procedure to determine the repassivation potential of aluminum alloy 3003-H14 (UNS A93003) (1) 2 as a measure of relative susceptibility to pitting corrosion by conducting a galvanostatic polarization is described. A procedure that can be used to check experimental technique and instrumentation is described, as well.

1.2 The test method serves as a guide for similar measurement on other aluminum alloys and metals (2-5).

1.3 The values stated in SI units are to be regarded as the standard. Values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6208 − 07 (Reapproved 2014)

Standard Test Method for

Repassivation Potential of Aluminum and Its Alloys by

Galvanostatic Measurement

This standard is issued under the fixed designation D6208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G107Guide for Formats for Collection and Compilation of

Corrosion Data for Metals for Computerized Database

1.1 A procedure to determine the repassivation potential of

2 Input

aluminumalloy3003-H14(UNSA93003) (1) asameasureof

relative susceptibility to pitting corrosion by conducting a

3. Terminology

galvanostaticpolarizationisdescribed.Aprocedurethatcanbe

3.1 Definitions:Termsusedinthistestmethodcanbefound

used to check experimental technique and instrumentation is

in Practice G3 and Terminology G15.

described, as well.

3.2 Symbols:

1.2 The test method serves as a guide for similar measure-

3.2.1 E —break potential, potential at which the passive

ment on other aluminum alloys and metals (2-5).

B

aluminum oxide layer breaks down.

1.3 The values stated in SI units are to be regarded as the

3.2.2 E —protection potential as measured in this galvano-

G

standard.Values given in parentheses are for information only.

static method, potential at which oxide layer repassivates.

1.4 This standard does not purport to address all of the

3.2.3 J—current density, in A/m

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.1 The test method described is an adaptation of the

method described in FORD Motor Company standards (6).

2. Referenced Documents

4.2 An aluminum alloy specimen is polarized at fixed

2.1 ASTM Standards:

current density for 20 min. in a solution of coolant and

D1193Specification for Reagent Water

corrosivewatercontainingchloride.Thepotentialasafunction

D3585Specification forASTM Reference Fluid for Coolant

of time is recorded.

Tests

4.3 The maximum potential, E reached upon polarization

B

G3Practice for Conventions Applicable to Electrochemical

is determined, as is the minimum potential following the

Measurements in Corrosion Testing

maximum potential, E .

G

G15TerminologyRelatingtoCorrosionandCorrosionTest-

4.4 Visual examination of the specimen may be made using

ing (Withdrawn 2010)

Guide G46 as a guide after disassembly and rinsing.

G46Guide for Examination and Evaluation of Pitting Cor-

rosion

5. Significance and Use

5.1 This test method is designed to measure the relative

1 effectiveness of inhibitors to mitigate pitting corrosion of

This test method is under the jurisdiction ofASTM CommitteeD15 on Engine

CoolantsandRelatedFluidsandisthedirectresponsibilityofSubcommitteeD15.06

aluminum and its alloys, in particular AA3003-H14, rapidly

on Glassware Performance Tests.

and reproducibly. The measurements are not intended to

Current edition approved Feb. 1, 2014. Published March 2014. Originally

correlate quantitatively with other test method values or with

approved in 1997. Last previous edition approved in 2007 as D6208-07. DOI:

susceptibility to localized corrosion of aluminum observed in

10.1520/D6208-07R14.

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

service. Qualitative correlation of the measurements and sus-

this standard.

ceptibility in service has been established (1).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The maximum potential reached upon initial

Standards volume information, refer to the standard’s Document Summary page on

polarization,E isameasureoftheresistancetobreakdownof

B,

the ASTM website.

the aluminum oxide film. Lower susceptibility to initiation of

The last approved version of this historical standard is referenced on

www.astm.org. pitting corrosion is indicated by a more noble potential (See

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6208 − 07 (2014)

Practice G3 and Terminology G15.) This potential, as mea- current supply and mV strip chart recorder, and Fig. X2.1

sured in this test method, is not very sensitive to the inhibitors shows a schematic for using a computer and potentiostat/

present. galvanostat.

5.3 The minimum potential, E following the maximum 6.4 Electrodes:

G,

potential is a measure of the protection against continued

6.4.1 Working Electrode (WE)—Theworkingelectrode,alu-

pitting corrosion by the inhibitors. Again, a more noble minumtestcoupon,iscutas51×51mm(2in.×2in.)squares

potential indicates better protection. This potential is sensitive

from aluminum sheet 2 to 6 mm (1/16 in. to 1/4 in.) thick.The

to the inhibitors present. standard material is AA3003-H14 (UNS A93003), used to

developtheprecisionandbiasstatements.Thecouponisrinsed

5.4 Visual examination of the specimens can provide infor-

thoroughly (both sides) with methanol and placed in a low

mation about subleties of the pitting and inhibition mecha-

temperature drying oven. No additional surface preparation is

nisms. Number of pits, pit depth, amount of deposit, and

desirable. Prior to testing, a coupon is allowed to cool to room

surface discoloration are some examples of recordable

temperature. Then it is clamped to the bottom of the O-ring

observations,whichcanassistevaluationofinhibitoreffective-

joint using the matching O-ring (viton or silicone rubber) and

ness.

clamp. The clamping screw may be tightened to finger

5.5 Thepresenceofchlorideinthetestsolutioniscriticalto

tightness, if desired. Excessive tightening must be avoided.

observation of pitting corrosion. Also, a coolant/corrosive 2

This gives an area of 8.72 cm aluminum exposed to the

water solution in which gas bubbles evolve spontaneously on

solution.

thealuminum(indicatinggeneralcorrosion)isunlikelytohave

6.4.2 Auxiliary Electrode (AE)—Ultrafine grade graphite

a significant amount of observable pitting corrosion.

rod, 6-8 mm (1/4 in.) in diameter and at least 20 cm (8 in.)

long. Avoid coarse grades as they can adsorb inhibitors.

6. Apparatus

6.4.3 Reference Electrode (RE)—The reference electrode

6.1 General Description—The apparatus for the electro-

can be of any convenient type, for example saturated calomel

chemical test consists of a cell, current supply, recorder, and

(Hg/HgCl)orsilverchloride(Ag/AgCl).Theelectrodemustbe

three electrodes. Fig. 1 is a generalized schematic of the

in good working order and stable in the solution to be

arrangement. More specific requirements for each component

measured.ThereferenceelectrodeisplacedinLugginprobeto

are given below.

avoid solution impedance bias. Appendix X2 contains two

suggestions for easily constructed Luggin probes.

6.2 Cell—The cell consists of a No.25 O-ring borosilicate

glassjointheldverticallyusingstandardlaboratoryclampsand

6.5 Timer—Timer with 1 s resolution out to 30 min.

ring stand. The working electrode will be clamped to the

bottom using the matching O-ring clamp and viton or silicone

7. Preparation of Apparatus

rubber gasket.

7.1 Assembly—Prior to running tests, assemble the cell and

6.3 Current Supply and Recorder—A constant current sup-

electrodes, using an unpreparedAl specimen as the “working”

plycapableofgenerating872µAcontinuouslyisrequired.The

electrode using appropriate clamping. The auxiliary electrode

recorder must have a high input impedance (> 10 Ohms), be

is positioned so that the tip is from 5 to 10 mm from the

capableofrecordingpotentialsof 62VwithmVaccuracy,and

working electrode surface. The Luggin probe is positioned so

have a low gain. These capabilities are typical of commercial

that the tip is from 1 to 3 mm from the working electrode

potentiostat/galvanostat instruments connected to either a strip

surface. It is most convenient if the clamping arrangement is

chart recorder or computer, for experimental control and data

such that this electrode configuration is maintained easily. The

acquisition.TheschematicinFig.1showsconnectionsusinga

cell is then removed and Al specimen unclamped.

8. Procedure

8.1 A corrosive water containing chloride, sulfate, and

bicarbonateispreparedbydissolvingthefollowingamountsof

anhydrous salts in distilled or deionized water,ASTM Type II

(see Specification D1193):

Sodium sulfate 592 mg

Sodium chloride 660 mg

Sodium bicarbonate 552 mg

The solution is made up to a total weight of 1 kg with

distilled or deionized water at 20°C. A 4-kg batch size is

convenientifmanytestsaretoberun,multiplyamountsabove

byfour.Thiswillgiveasolution,whichis400ppminchloride,

sulfate, and bicarbonate.

8.2 Rinse cell, O-ring, Luggin probe (inside and out),

auxilliary electrode, and reference electrode thoroughly with

FIG. 1 Generalized Experimental Set-up Type II water.

D6208 − 07 (2014)

8.3 Prepare the aluminum specimen as the working elec-

trode (see 5.4.2). Clamp to cell, using O-ring, and set to one

side.

8.4 Preparethetestsolutionas25vol%ofthecoolanttobe

tested, 25 vol% of the corrosive water from 6.1, and the

remainder deionized or distilled water.The amount to be made

depends on one’s exact cell configuration. Sufficient test

solution is required to fill the cell (about 50 mLs) and the

Lugginprobeassembly.FortheconfigurationsofLugginprobe

given in Appendix X2, 160 mLs is more than sufficient.

8.5 Fill the Luggin probe with test solution sufficient to

cover the tip of reference electrode when inserted. Insert

reference electrode. Gently tap Luggin to remove any bubbles

between the tip and reference electrode. If a vertical Luggin is

NOTE1—Breakpotential, E ,andprotectionpotential, E ,isindicated

B G

used,asinFig.X2.2,thenbubblescanberemovedbyallowing for each type of transient.

FIG. 2 Two Common Potential/Time Transient Profiles After Polar-

solution to drain slowly into a waste container.

ization

8.6 Set up current generator to output 872 µA (J = 100

µA/cm ) continuously, set recorder to a range of 62 V (other

settings may be used if found to be necessary to achieve the “break” followed by a series of rises and falls, record the

accurateandrepresentativepotentials,chartspeedasdesired(5 lowest potential reached on the first fall. Typically, subsequent

mm/min is reasonable). If acquiring data by computer, set data rises and falls are small and appear as oscillations. For curves

acquisition rate to 1 point/s. Do not turn either generator or where the potential rises continuously, E will be equal to E .

G B

Express potential as V v SHE, correcting for type of reference

recorder on at this time.

electrode used (see Appendix X1).

8.7 Fill cell with approximately 50 mL of test solution,

9.3 Curve Type—Record whether curve is asymptotic (Type

about 25 mm from the top of the cell. Start timer. Do not start

generator at this time. Recorder may be turned on at this time. A), rising and falling (Type B), or rising only (Type C).

Assemble cell over Luggin probe and auxiliary electrode.

9.4 Observations (optional)—The following are optional

Attach wires to reference electrode, auxiliary electrode, and

observations that can be recorded as: evolution of gas bubbles

working electrode. Check for bubbles in Luggin, tap gently to

duringthetest,descriptionofsurfaceaftertest,locationofpits

remove.

(for example, along scratch lines, etc. number of pits, depth of

pits, area of pits, color of deposits, location of deposits in

8.8 At 5 min on the timer, turn on current generator, and

recorder, if not already on. Record potential versus time relation to pits, and other pitting evaluations as described in

response for 20 min. Turn off current generator and recorder Guide G46).

(see Note 1).

10. Report

NOTE 1—A computer controlled system can be used in place of a

10.1 Report the following information:

current generator and recorder. In this case the current generator consists

of a potentiostat/galvanostate operated in galvanostatic mode. The re- 10.1.1 Report aluminum alloy tested.

corder is the computer. Software is used to control all aspects of the test

10.1.2 Report the average E and E of all experimental

B G

protocol, including controlling the galvanostate, acquiring the data,

runs, at least two, for the formula.

plotting, and analysis.

10.1.3 Report type of curves obtained, A, B, or C. Report

8.9 Run the test in duplicate, steps 8.2 – 8.8

multiple types if obtained.

10.1.4 Report any visual observation made.

9. Interpretation of Results

10.1.5 Many other relevant test parameters are given in

9.1 Break Potential, E —The graph in Fig. 2 illustrates two

B

Guide G107. These parameters should be recorded properly in

ofthethreepossibleformsofcurveobtainedintheexperiment.

laboratory notebooks for future reference.

In Fig. 2 there is an initial rapid rise in potential followed by a

decrease.Recordthemaximumpotentialreachedinthisperiod 11. Precision and Bias

as E . The third possibility is that the potential rises

B

11.1 Precision—The precision of this test method has not

continuously,thoughperhapsoscillating.Recordthemaximum

been determined. Round-robin testing will commence once

potential reached throughout the run. Express potential asVv

final details of the method are determined. It is expected that

SHE correcting for type of reference electrode used (see

the precision associated with the “break” potential will be less

Appendix X1).

than the precision associated with the “protection” potential. It

9.2 Protection Potential E —For curves similar to curveA is also expected that precision will be constant over the range

G

in Fig. 2, asymptotic decrease in potential after break, record ofmeasurementasoppositetobeingrelativetothevalueofthe

the minimum potential reached, typically at the end of the run. measurement and insignificantly affected by the choice of

ForcurvessimilartocurveBinFig.2,thereisadecreaseafter aluminum alloy tested.

D6208 − 07 (2014)

11.2 Bias: specific reference electrode used. Potential always must be

11.2.1 Statement on Bias—This procedure has no bias expressedasrelativetoastandardhydrogenelectrode(SHE)at

because the values for the “break” and “protection” potentials the pH of use (see Appendix X1).

are defined only in terms of this test method.An apparent bias

11.2.2 Procedure to Determine Bias Due to Technique or

will exist if the user does not correct the potentials for the

Instrumentation—The following procedure u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.