ASTM D6208-07(2014)

(Test Method)Standard Test Method for Repassivation Potential of Aluminum and Its Alloys by Galvanostatic Measurement

Standard Test Method for Repassivation Potential of Aluminum and Its Alloys by Galvanostatic Measurement

SIGNIFICANCE AND USE

5.1 This test method is designed to measure the relative effectiveness of inhibitors to mitigate pitting corrosion of aluminum and its alloys, in particular AA3003-H14, rapidly and reproducibly. The measurements are not intended to correlate quantitatively with other test method values or with susceptibility to localized corrosion of aluminum observed in service. Qualitative correlation of the measurements and susceptibility in service has been established (1).

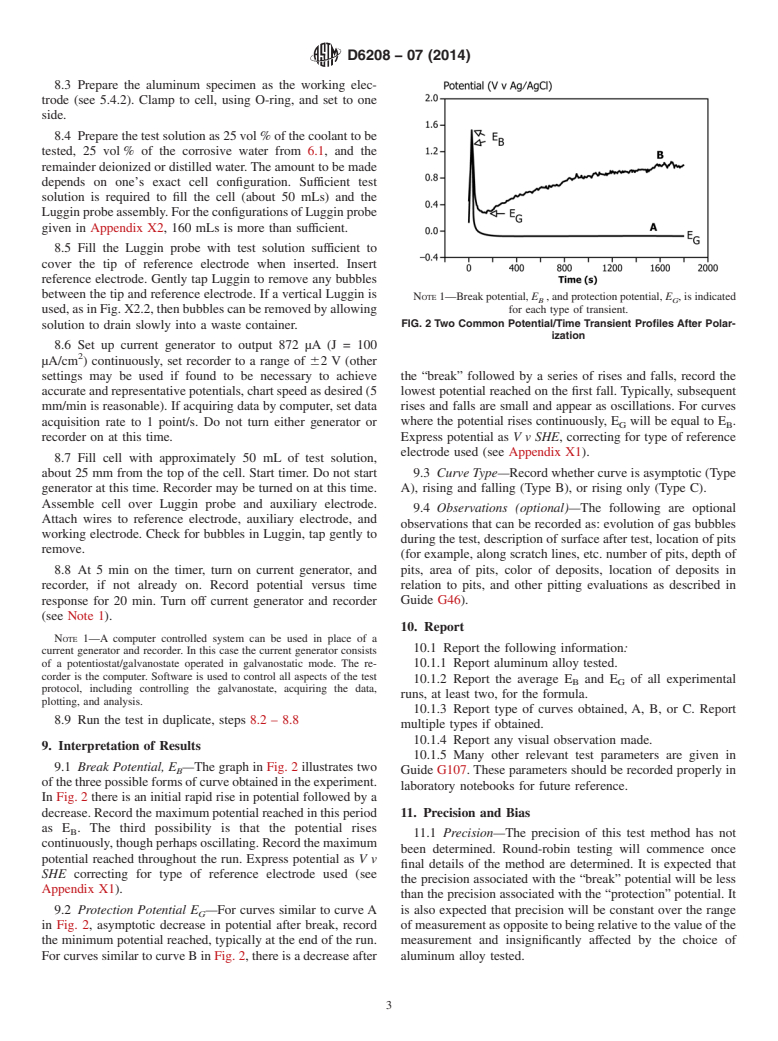

5.2 The maximum potential reached upon initial polarization, EB, is a measure of the resistance to breakdown of the aluminum oxide film. Lower susceptibility to initiation of pitting corrosion is indicated by a more noble potential (See Practice G3 and Terminology G15.) This potential, as measured in this test method, is not very sensitive to the inhibitors present.

5.3 The minimum potential, EG, following the maximum potential is a measure of the protection against continued pitting corrosion by the inhibitors. Again, a more noble potential indicates better protection. This potential is sensitive to the inhibitors present.

5.4 Visual examination of the specimens can provide information about subleties of the pitting and inhibition mechanisms. Number of pits, pit depth, amount of deposit, and surface discoloration are some examples of recordable observations, which can assist evaluation of inhibitor effectiveness.

5.5 The presence of chloride in the test solution is critical to observation of pitting corrosion. Also, a coolant/corrosive water solution in which gas bubbles evolve spontaneously on the aluminum (indicating general corrosion) is unlikely to have a significant amount of observable pitting corrosion.

SCOPE

1.1 A procedure to determine the repassivation potential of aluminum alloy 3003-H14 (UNS A93003) (1) 2 as a measure of relative susceptibility to pitting corrosion by conducting a galvanostatic polarization is described. A procedure that can be used to check experimental technique and instrumentation is described, as well.

1.2 The test method serves as a guide for similar measurement on other aluminum alloys and metals (2-5).

1.3 The values stated in SI units are to be regarded as the standard. Values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6208 − 07 (Reapproved 2014)

Standard Test Method for

Repassivation Potential of Aluminum and Its Alloys by

1

Galvanostatic Measurement

This standard is issued under the fixed designation D6208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G107Guide for Formats for Collection and Compilation of

Corrosion Data for Metals for Computerized Database

1.1 A procedure to determine the repassivation potential of

2 Input

aluminumalloy3003-H14(UNSA93003) (1) asameasureof

relative susceptibility to pitting corrosion by conducting a

3. Terminology

galvanostaticpolarizationisdescribed.Aprocedurethatcanbe

3.1 Definitions:Termsusedinthistestmethodcanbefound

used to check experimental technique and instrumentation is

in Practice G3 and Terminology G15.

described, as well.

3.2 Symbols:

1.2 The test method serves as a guide for similar measure-

3.2.1 E —break potential, potential at which the passive

ment on other aluminum alloys and metals (2-5).

B

aluminum oxide layer breaks down.

1.3 The values stated in SI units are to be regarded as the

3.2.2 E —protection potential as measured in this galvano-

G

standard.Values given in parentheses are for information only.

static method, potential at which oxide layer repassivates.

1.4 This standard does not purport to address all of the

2

3.2.3 J—current density, in A/m

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.1 The test method described is an adaptation of the

method described in FORD Motor Company standards (6).

2. Referenced Documents

4.2 An aluminum alloy specimen is polarized at fixed

3

2.1 ASTM Standards:

current density for 20 min. in a solution of coolant and

D1193Specification for Reagent Water

corrosivewatercontainingchloride.Thepotentialasafunction

D3585Specification forASTM Reference Fluid for Coolant

of time is recorded.

Tests

4.3 The maximum potential, E reached upon polarization

B

G3Practice for Conventions Applicable to Electrochemical

is determined, as is the minimum potential following the

Measurements in Corrosion Testing

maximum potential, E .

G

G15TerminologyRelatingtoCorrosionandCorrosionTest-

4

4.4 Visual examination of the specimen may be made using

ing (Withdrawn 2010)

Guide G46 as a guide after disassembly and rinsing.

G46Guide for Examination and Evaluation of Pitting Cor-

rosion

5. Significance and Use

5.1 This test method is designed to measure the relative

1 effectiveness of inhibitors to mitigate pitting corrosion of

This test method is under the jurisdiction ofASTM CommitteeD15 on Engine

CoolantsandRelatedFluidsandisthedirectresponsibilityofSubcommitteeD15.06

aluminum and its alloys, in particular AA3003-H14, rapidly

on Glassware Performance Tests.

and reproducibly. The measurements are not intended to

Current edition approved Feb. 1, 2014. Published March 2014. Originally

correlate quantitatively with other test method values or with

approved in 1997. Last previous edition approved in 2007 as D6208-07. DOI:

susceptibility to localized corrosion of aluminum observed in

10.1520/D6208-07R14.

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

service. Qualitative correlation of the measurements and sus-

this standard.

ceptibility in service has been established (1).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The maximum potential reached upon initial

Standards volume information, refer to the standard’s Document Summary page on

polarization,E isameasureoftheresistancetobreakdownof

B,

the ASTM website.

4

the aluminum oxide film. Lower susceptibility to initiation of

The last approved version of this historical standard is referenced on

www.astm.org. pitting corrosion is indicated by a more noble potential (See

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6208 − 07 (2014)

Practice G3 and Terminology G15.) This potential, as mea- current supply and mV strip chart recorder, and Fig. X2.1

sured in this test method, is not very sensitive to the inhibitors shows a schematic for using a computer and potentiostat/

present. galvanostat.

5.3 The minimum potential, E following the maximum 6.4 Electrodes:

G,

potential is a measure of the protection against continued

6.4.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.