ASTM E826-85(1996)e1

(Practice)Standard Practice for Testing Homogeneity of Materials for Development of Reference Materials (Withdrawn 2005)

Standard Practice for Testing Homogeneity of Materials for Development of Reference Materials (Withdrawn 2005)

SCOPE

1.1 This practice is suitable for testing the homogeneity of metals, either in solid or powdered form, and finely ground oxide materials that are intended for use as reference materials in X-ray emission, or optical emission spectroscopy, or both. The criteria for acceptance of the test specimens as reference materials, however, must be previously determined by the user for meeting his specific requirements.

1.2 The procedure is designed primarily for testing specimens by X-ray emission spectrometry or optical emission spectroscopy, or both. However, the practice could be easily adapted for use with other instrumental techniques such as atomic absorption spectrophotometry.

1.3 This procedure can be applied to one or more elements in a specimen provided the signal-to-background ratio is not a limiting factor.

1.4 This practice includes one method, if desired, to correct for systematic or periodic (sinusoidal) drift in the instrument with time through the use of a control reference material. Note 1-Caution: If serious drift occurs (for example, unstable power supply, X-ray tube, etc.) erroneous conclusions may be obtained from the data analysis.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice is suitable for testing the homogeneity of metals, either in solid or powdered form, and finely ground oxide materials that are intended for use as reference materials in X-ray emission, or optical emission spectroscopy, or both. The criteria for acceptance of the test specimens as reference materials, however, must be previously determined by the user for meeting his specific requirements.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, this practice was withdrawn in May 2005 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 826 – 85 (Reapproved 1996)

Standard Practice for

Testing Homogeneity of Materials for Development of

Reference Materials

This standard is issued under the fixed designation E826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 12 was added editorially in June 1996.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This practice is suitable for testing the homogeneity of

E178 Practice for Dealing with Outlying Observations

metals, either in solid or powdered form, and finely ground

E876 Practice for Use of Statistics in the Evaluation of

oxide materials that are intended for use as reference materials

Spectrometric Data

in X-ray emission, or optical emission spectroscopy, or both.

The criteria for acceptance of the test specimens as reference

3. Terminology

materials, however, must be previously determined by the user

3.1 Definitions—For definitions of terms used in this prac-

for meeting his specific requirements.

tice, refer to Terminology E135, and Practices E177 and

1.2 The procedure is designed primarily for testing speci-

E178.

mens by X-ray emission spectrometry or optical emission

3.2 Definitions of Terms Specific to This Standard:

spectroscopy, or both. However, the practice could be easily

3.2.1 drift—a gradual systematic or sinusoidal change in

adapted for use with other instrumental techniques such as

instrument readings with time.

atomic absorption spectrophotometry.

3.2.2 homogeneity—as defined in this practice, is statisti-

1.3 This procedure can be applied to one or more elements

cally acceptable differences among means of specimens in the

in a specimen provided the signal-to-background ratio is not a

test.

limiting factor.

1.4 This practice includes one method, if desired, to correct

4. Summary of Practice

for systematic or periodic (sinusoidal) drift in the instrument

4.1 This procedure, which is based on statistical methods (

with time through the use of a control reference material.

1-6), consistsofstepwiseinstructionsfortestinghomogeneity

NOTE 1—Caution: Ifseriousdriftoccurs(forexample,unstablepower

of candidate reference materials. The candidate materials are

supply, X-ray tube, etc.) erroneous conclusions may be obtained from the

selectedasdescribedinSection6,andthenmeasuredbyeither

data analysis.

X-ray emission or optical emission spectroscopy (see Sections

1.5 This standard does not purport to address all of the

7and8).Theresultantdataarecorrectedforinstrumentaldrift,

safety concerns, if any, associated with its use. It is the

if desired (see Section 10), and then tabulated (see Table 1,

responsibility of the user of this standard to establish appro-

Table X1.3, and Table X1.4) to facilitate the statistical calcu-

priate safety and health practices and determine the applica-

lations that are performed according to Section 9. The homo-

bility of regulatory limitations prior to use.

geneity of the material is determined from the results of the

data analysis.

2. Referenced Documents

4.2 This procedure requires that repeated measurements on

2.1 ASTM Standards:

the same specimen have sufficient precision (that is, repeat-

E135 Terminology Relating to Analytical Chemistry for

ability) through appropriate selection of instrumental param-

Metals, Ores, and Related Materials

eterssothatanysignificantdifferenceamongspecimenscanbe

detected with confidence.

This practice is under the jurisdiction of ASTM Committee E-1 on Analytical

Chemistry for Metals, Ores and Related Materials and is the direct responsibility of

Subcommittee E01.22 on Statistics and Quality Control. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved June 28, 1985. Published October 1985. Originally Annual Book of ASTM Standards, Vol 03.06.

published as E826–81. Last previous edition E826–81. The boldface numerals in parentheses refer to the list of references at the end

Annual Book of ASTM Standards, Vol 03.05. of this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 826

TABLE 1 Data for Homogeneity Testing

Specimen Number

Run No. Total

A

1 2 3 4 5 . .t

1 B 5

2 B 5

3 B 5

4 B 5

5. B 5

5.

B

...b B 5

n

Total T 5 T 5 T 5 T 5 T 5 . T 5 G 5 ((B .B )

1 2 3 4 5 n 1 n

Mean t8 5 t8 5 t8 5 t8 5 t8 5 . t8 5

1 2 3 4 5 n

A

t 5 number of specimens.

B

b 5 number of runs.

4.3 This procedure requires that there be an absence of 7.4 If correction of instrumental drift is desired, a control

outliers in the data (see Practice E178). referencematerialshallbemeasuredalongwiththespecimens.

7.5 Examine the data and discard any values which have

NOTE 2—Caution:The use of Practice E178 dealing with outliers

been determined to be outliers according to Practice E178. In

should be done with extreme care to ensure that values are not discarded

Table 1, enter either the raw or normalized values for each

that may be valid for the analysis.

element, or values corrected for drift.

5. Significance and Use

7.6 If any outliers occur, repeat the complete test, as

provision is not made for missing data in the mathematical

5.1 The purpose of this practice is to ensure the quality of

treatment.

materials selected in order that they can serve as a supplement

to primary standard reference materials.

8. Optical Emission Spectroscopy Test Procedure

5.2 This procedure is applicable to the testing of samples

8.1 Select optimum instrumental conditions to obtain ad-

taken at various stages during production. For example, con-

equate sensitivity for each element to be tested in the speci-

tinuous cast materials, ingots, rolled bars, wire, etc., could be

mens.

sampled at various stages during the production process and

8.2 Use excitation conditions appropriate for the element(s)

tested.

of interest. Select a spectral line(s) that has a minimum of

interferences from other elements in the specimen.

6. Selection of Test Specimens from a Large Batch

8.3 Measure the element(s) of interest in the specimens

6.1 If the candidate material consists of 15 specimens or

selected in Section 6. Repeat the measurements until a mini-

less, then all specimens should be tested.

mum of four sets have been made. For each set, take the

6.2 If the candidate material is in a form or quantity that

specimens in random order.

prohibitstestingallspecimens,thenaminimumof8%butnot

8.4 If correction of instrumental drift is desired, measure a

less than 15 specimens shall be tested according to the random

control reference material along with the specimens. The

sample selection scheme described in 6.3.

control reference material shall be homogeneous with respect

6.3 Label all specimens consecutively (that is, 01, 02, 03,···

to the element(s) being determined, in the specimens.

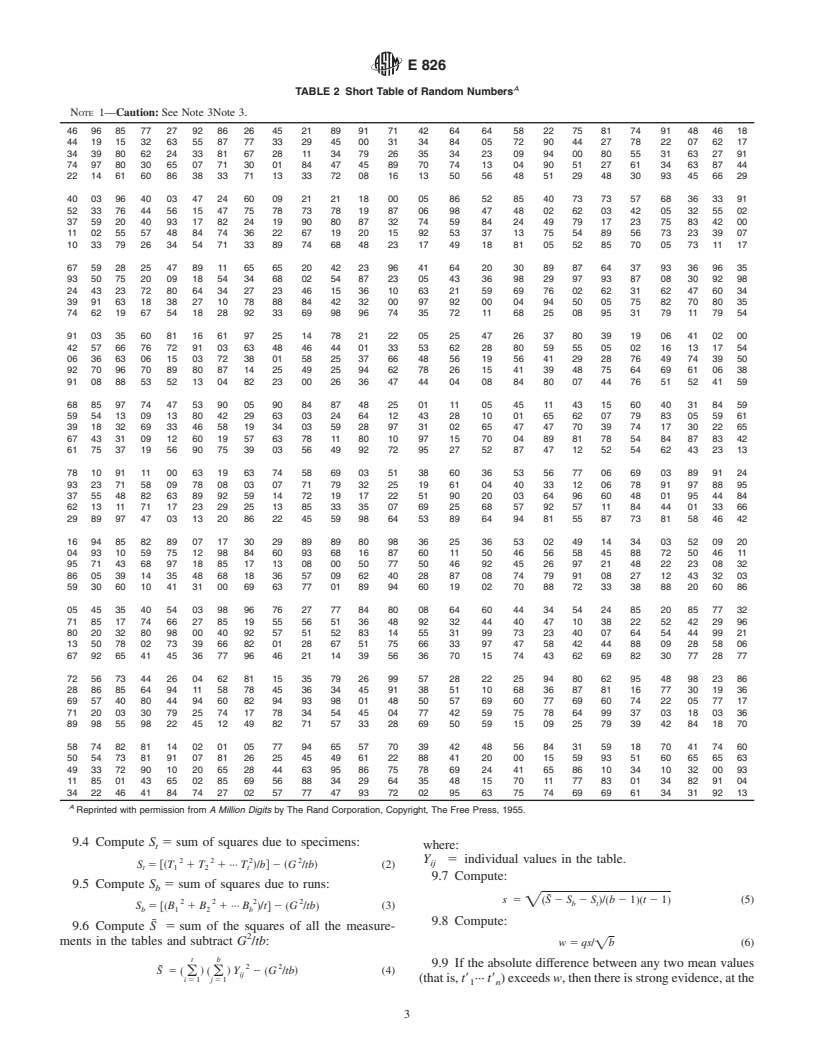

). From a table of random numbers (3) (see Table 2 and Note

8.5 Examine the data and discard any values that have been

3), pick an arbitrary starting place and select any direction for

determined to be outliers according to Practice E178. InTable

readingthenumbers,providedthedirectionisfixedinadvance

1,entereithertherawornormalizedvaluesforeachelementor

and is independent of the numbers occurring. Select those

values corrected for drift.

specimens for testing which match the numbers read from the

8.6 If any outliers occur, repeat the complete test, as

tables.

provision is not made for missing data in the mathematical

NOTE 3—Caution:Table 2 included herein is for example, only. Use

treatment.

the more complete tables in (3) when actually using this test procedure.

9. Calculations to Determine Homogeneity

7. X-Ray Emission Spectroscopy Test Procedure

9.1 Compute T, B, t8, and G, (see Table 1), where: T 5sum

7.1 Select optimum instrumental conditions to assure ad-

of each column; B 5sum of each row; t8 5mean of each

equate count rates from each element to be tested in the

column; and G 5sum of B ··· B ; b 5number of replicate

1 n

specimens.

measurements (that is, runs); and t 5number of specimens.

7.2 Select a counting time that is long enough to minimize

9.2 Choose a significance level (a) for the test.

the random error due to counting. Also, avoid counting rates

NOTE 4—A95%significancelevelisrecommendedforthisprocedure.

greater than 70 000 c/s to minimize dead-time corrections in

See (1) for more extensive tables containing values at other significance

the detection system.

levels.

7.3 Measure the element(s) of interest on the specimens

9.3 From Table 3, obtain the q value that corresponds to t

selected in Section 6. Repeat the measurements of X-ray

and n, where: n5the number of degrees of freedom:

intensity until a minimum of four sets have been made. For

each set, the specimens shall be taken in random order. n5 ~b 21! 3 ~t 21! (1)

E 826

A

TABLE 2 Short Table of Random Numbers

NOTE 1—Caution:See Note 3Note 3.

46 96 85 77 27 92 86 26 45 21 89 91 71 42 64 64 58 22 75 81 74 91 48 46 18

44 19 15 32 63 55 87 77 33 29 45 00 31 34 84 05 72 90 44 27 78 22 07 62 17

34 39 80 62 24 33 81 67 28 11 34 79 26 35 34 23 09 94 00 80 55 31 63 27 91

74 97 80 30 65 07 71 30 01 84 47 45 89 70 74 13 04 90 51 27 61 34 63 87 44

22 14 61 60 86 38 33 71 13 33 72 08 16 13 50 56 48 51 29 48 30 93 45 66 29

40 03 96 40 03 47 24 60 09 21 21 18 00 05 86 52 85 40 73 73 57 68 36 33 91

52 33 76 44 56 15 47 75 78 73 78 19 87 06 98 47 48 02 62 03 42 05 32 55 02

37 59 20 40 93 17 82 24 19 90 80 87 32 74 59 84 24 49 79 17 23 75 83 42 00

11 02 55 57 48 84 74 36 22 67 19 20 15 92 53 37 13 75 54 89 56 73 23 39 07

10 33 79 26 34 54 71 33 89 74 68 48 23 17 49 18 81 05 52 85 70 05 73 11 17

67 59 28 25 47 89 11 65 65 20 42 23 96 41 64 20 30 89 87 64 37 93 36 96 35

93 50 75 20 09 18 54 34 68 02 54 87 23 05 43 36 98 29 97 93 87 08 30 92 98

24 43 23 72 80 64 34 27 23 46 15 36 10 63 21 59 69 76 02 62 31 62 47 60 34

39 91 63 18 38 27 10 78 88 84 42 32 00 97 92 00 04 94 50 05 75 82 70 80 35

74 62 19 67 54 18 28 92 33 69 98 96 74 35 72 11 68 25 08 95 31 79 11 79 54

91 03 35 60 81 16 61 97 25 14 78 21 22 05 25 47 26 37 80 39 19 06 41 02 00

42 57 66 76 72 91 03 63 48 46 44 01 33 53 62 28 80 59 55 05 02 16 13 17 54

06 36 63 06 15 03 72 38 01 58 25 37 66 48 56 19 56 41 29 28 76 49 74 39 50

92 70 96 70 89 80 87 14 25 49 25 94 62 78 26 15 41 39 48 75 64 69 61 06 38

91 08 88 53 52 13 04 82 23 00 26 36 47 44 04 08 84 80 07 44 76 51 52 41 59

68 85 97 74 47 53 90 05 90 84 87 48 25 01 11 05 45 11 43 15 60 40 31 84 59

59 54 13 09 13 80 42 29 63 03 24 64 12 43 28 10 01 65 62 07 79 83 05 59 61

39 18 32 69 33 46 58 19 34 03 59 28 97 31 02 65 47 47 70 39 74 17 30 22 65

67 43 31 09 12 60 19 57 63 78 11 80 10 97 15 70 04 89 81 78 54 84 87 83 42

61 75 37 19 56 90 75 39 03 56 49 92 72 95 27 52 87 47 12 52 54 62 43 23 13

78 10 91 11 00 63 19 63 74 58 69 03 51 38 60 36 53 56 77 06 69 03 89 91 24

93 23 71 58 09 78 08 03 07 71 79 32 25 19 61 04 40 33 12 06 78 91 97 88 95

37 55 48 82 63 89 92 59 14 72 19 17 22 51 90 20 03 64 96 60 48 01 95 44 84

62 13 11 71 17 23 29 25 13 85 33 35 07 69 25 68 57 92 57 11 84 44 01 33 66

29 89 97 47 03 13 20 86 22 45 59 98 64 53 89 64 94 81 55 87 73 81 58 46 42

16 94 85 82 89 07 17 30 29 89 89 80 98 36 25 36 53 02 49 14 34 03 52 09 20

04 93 10 59 75 12 98 84 60 93 68 16 87 60 11 50 46 56 58 45 88 72 50 46 11

95 71 43 68 97 18 85 17 13 08 00 50 77 50 46 92 45 26 97 21 48 22 23 08 32

86 05 39 14 35 48 68 18 36 57 09 62 40 28 87 08 74 79 91 08 27 12 43 32 03

59 30 60 10 41 31 00 69 63 77 01 89 94 60 19 02 70 88 72 33 38 88 20 60 86

05 45 35 40 54 03 98 96 76 27 77 84 80 08 64 60 44 34 54 24 85 20 85 77 32

71 85 17 74 66 27 85 19 55 56 51 36 48 92 32 44 40 47 10 38 22 52 42 29 96

80 20 32 80 98 00 40 92 57 51 52 83 14 55 31 99 73 23 40 07 64 54 44 99 21

13 50 78 02 73 39 66 82 01 28 67 51 75 66 33 97 47 58 42 44 88 09 28 58 06

67 92 65 41 45 36 77 96 46 21 14 39 56 36 70 15 74 43 62 69 82 30 77 28 77

72 56 73 44 26 04 62 81 15 35 79 26 99 57 28 22 25 94 80 62 95 48 98 23 86

28 86 85 64 94 11 58 78 45 36 34 45 91 38 51 10 68 36 87 81 16 77 30 19 36

69 57 40 80 44 94 60 82 94 93 98 01 48 50 57 69 60 77 69 60 74 22 05 77 17

71 20 03 30 79 25 74 17 78 34 54 45 04 77 42 59 75 78 64 99 37 03 18 03 36

89 98 55 98 22 45 12 49 82 71 57 33 28 69 50 59 15 09 25 79 39 42 84 18 70

58 74 82 81 14 02 01 05 77 94 65 57 70 39 42 48 56 84 31 59 18 70 41 74 60

50 54 73 81 91 07 81 26 25 45 49 61 22 88 41 20 00 15 59 93 51 60 65 65 63

49 33 72 90 10 20 65 28 44 63 95 86 75 78 69 24 41 65 86 10 34 10 32 00 93

11 85 01 43 65 02 85 69 56 88 34 29 64 35 48 15 70 11 77 83 01 34 82 91 04

34 22 46 41 84 74 27 02 57 77 47 93 72 02 95 63 75 74 69 69 61 34 31 92 13

A

Reprinted with permission from A Million Digits by The Rand Corporation, Copyright, The Free Press, 1955.

9.4 Compute S 5sum of squares due to specimens:

t where:

2 2 2 2

Y 5 individual values in the table.

ij

S 5 @~T 1 T 1··· T !/b# 2 ~G /tb! (2)

t 1 2 t

9.7 Compute:

9.5 Compute S 5sum of squares due to runs:

b

¯

s 5=~S 2 S 2 S !/~b 21!~t 21! (5)

2 2 2 2

b t

S 5 @~B 1 B 1··· B !/t# 2 ~G /tb! (3)

b 1 2 b

9.8 Compute:

¯

9.6 Compute S 5sum of the squares of all the measure-

ments in the tables and subtract G /tb:

w 5 qs/ b (6)

=

t b

9.9 If the absolute difference between any two mean values

2 2

¯

S 5 ~ ! ~ !Y 2 ~G /tb! (4)

( ( ij

i 51 j 51 (thatis,t8 ···t8 )exceedsw,thenthereisstrongevidence,atthe

1 n

E 826

TABLE 3 Values of q for Various Combinations of t and n at 95 % Significance Level (1)

n

t→ 23456789 10

↓

1 17.97 26.98 32.82 37.08 40.41 43.12 45.40 47.36 49.07

2 6.08 8.33 9.80 10.88 11.74 12.44 13.03 13.54 13.99

3 4.50 5.91 6.82 7.50 8.04 8.48 8.85 9.18 9.46

4 3.93 5.04 5.76 6.29 6.71 7.05 7.35 7.60 7.83

5 3.64 4.60 5.22 5.67 6.03 6.33 6.58 6.80 6.99

6 3.46 4.34 4.90 5.30 5.63 5.90 6.12 6.32 6.49

7 3.34 4.16 4.68 5.06 5.36 5.61 5.82 6.00 6.16

8 3.26 4.04 4.53 4.89 5.17 5.40 5.60 5.77 5.92

9 3.20 3.95 4.41 4.76 5.02 5.24 5.43 5.59 5.74

10 3.15 3.88 4.33 4.65 4.91 5.12 5.30 5.46 5.60

11 3.11 3.82 4.26 4.57 4.82 5.03 5.20 5.35 5.49

12 3.08 3.77 4.20 4.51 4.75 4.95 5.12 5.27 5.39

13 3.06 3.73 4.15 4.45 4.69 4.88 5.05 5.19 5.32

14 3.03 3.70 4.11 4.41 4.64 4.83 4.99 5.13 5.25

15 3.01 3.67 4.08 4.37 4.59 4.78 4.94 5.08 5.20

16 3.00 3.65 4.05 4.33 4.56 4.74 4.90 5.03 5.15

17 2.98 3.63 4.02 4.30 4.52 4.70 4.86 4.99 5.11

18 2.97 3.61 4.00 4.28 4.49 4.67 4.82 4.96 5.07

19 2.96 3.59 3.98 4.25 4.47 4.65 4.79 4.92 5.04

20 2.95 3.58 3.96 4.23 4.45 4.62 4.77 4.90 5.01

24 2.92 3.53 3.90 4.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.