ASTM E826-08

(Practice)Standard Practice for Testing Homogeneity of a Metal Lot or Batch in Solid Form by Spark Atomic Emission Spectrometry

Standard Practice for Testing Homogeneity of a Metal Lot or Batch in Solid Form by Spark Atomic Emission Spectrometry

SIGNIFICANCE AND USE

The purpose of this practice is to evaluate the homogeneity of a lot of material selected as a candidate for development as a reference material or certified reference material, or for a L/B selected for some other purpose (see Appendix X1-Appendix X4 for examples).

This practice is applicable to the testing of samples taken at various stages during production. For example, continuous cast materials, ingots, rolled bars, wire, etc., could be sampled at various stages during the production process and tested.

SCOPE

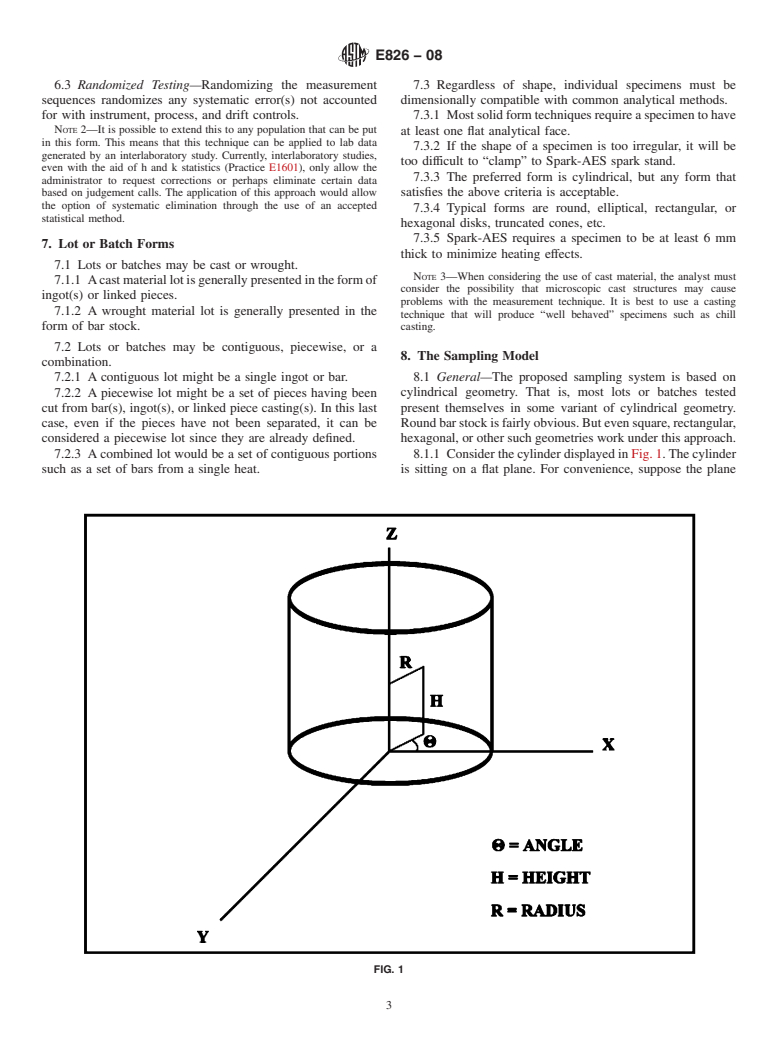

1.1 This practice is suitable for testing the homogeneity of a metal lot or batch (L/B) in solid form by spark atomic emission spectrometry (Spark-AES). It is compliant with ISO Guide 35—Certification of Reference Materials: General and Statistical Principles. It is primarily intended for use in the development of reference materials but may be used in any other application where a L/B is to be tested for homogeneity. It is designed to provide a combined study of within-unit and between-unit homogeneity of such a L/B.

1.2 This practice is designed primarily to test for elemental homogeneity of a metal L/B by Spark-AES. However, it can be adapted for use with other instrumental techniques such as X-ray fluorescence spectrometry (XRF) or atomic absorption spectrometry (AAS).

Note 1—This practice is not limited to elemental analysis or techniques. This practice can be applied to any property that can be measured, for example, the property of hardness as measured by the Rockwell technique.

1.3 The criteria for acceptance of the test specimens must be previously determined. That is, the maximum acceptable level of heterogeneity must be determined on the basis of the intended use of the L/B.

1.4 It is assumed that the analyst is trained in Spark-AES techniques including the specimen preparation procedures needed to make specimens ready for measurements. It is further assumed that the analyst is versed in and has access to computer-based data capture and analysis. The methodology of this practice is best utilized in a computer based spreadsheet.

1.5 This practice can be applied to one or more elements in a specimen provided the signal-to-background ratio is not a limiting factor.

1.6 This practice includes methods to correct for systematic drift of the instrument with time. (Warning—If drift occurs, erroneous conclusions will be obtained from the data analysis.)

1.7 This practice also includes methods to refine estimates of composition and uncertainty through the use of a type standard or multiple calibrants.

1.8 It further provides a means of reducing a nonhomogeneous set to a homogeneous subset.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E826 − 08

StandardPractice for

Testing Homogeneity of a Metal Lot or Batch in Solid Form

1

by Spark Atomic Emission Spectrometry

This standard is issued under the fixed designation E826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This practice also includes methods to refine estimates

of composition and uncertainty through the use of a type

1.1 Thispracticeissuitablefortestingthehomogeneityofa

standard or multiple calibrants.

metallotorbatch(L/B)insolidformbysparkatomicemission

spectrometry (Spark-AES). It is compliant with ISO Guide

1.8 It further provides a means of reducing a nonhomoge-

35—Certification of Reference Materials: General and Statis-

neous set to a homogeneous subset.

tical Principles. It is primarily intended for use in the devel-

1.9 This standard does not purport to address all of the

opment of reference materials but may be used in any other

safety concerns, if any, associated with its use. It is the

application where a L/B is to be tested for homogeneity. It is

responsibility of the user of this standard to establish appro-

designed to provide a combined study of within-unit and

priate safety and health practices and determine the applica-

between-unit homogeneity of such a L/B.

bility of regulatory limitations prior to use.

1.2 This practice is designed primarily to test for elemental

homogeneityofametalL/BbySpark-AES.However,itcanbe

2. Referenced Documents

adapted for use with other instrumental techniques such as

2

X-ray fluorescence spectrometry (XRF) or atomic absorption

2.1 ASTM Standards:

spectrometry (AAS).

E135Terminology Relating to Analytical Chemistry for

NOTE 1—This practice is not limited to elemental analysis or tech-

Metals, Ores, and Related Materials

niques.Thispracticecanbeappliedtoanypropertythatcanbemeasured,

E177Practice for Use of the Terms Precision and Bias in

for example, the property of hardness as measured by the Rockwell

technique. ASTM Test Methods

E178Practice for Dealing With Outlying Observations

1.3 Thecriteriaforacceptanceofthetestspecimensmustbe

E634Practice for Sampling of Zinc and Zinc Alloys by

previously determined. That is, the maximum acceptable level

Spark Atomic Emission Spectrometry

of heterogeneity must be determined on the basis of the

E716Practices for Sampling and Sample Preparation of

intended use of the L/B.

Aluminum and Aluminum Alloys for Determination of

1.4 It is assumed that the analyst is trained in Spark-AES

Chemical Composition by Spectrochemical Analysis

techniques including the specimen preparation procedures

E1329PracticeforVerificationandUseofControlChartsin

needed to make specimens ready for measurements. It is

Spectrochemical Analysis

further assumed that the analyst is versed in and has access to

E1601Practice for Conducting an Interlaboratory Study to

computer-baseddatacaptureandanalysis.Themethodologyof

Evaluate the Performance of an Analytical Method

this practice is best utilized in a computer based spreadsheet.

E1806Practice for Sampling Steel and Iron for Determina-

1.5 This practice can be applied to one or more elements in

tion of Chemical Composition

a specimen provided the signal-to-background ratio is not a

3

2.2 ISO Standard:

limiting factor.

ISO Guide 35Certification of Reference Materials: General

1.6 This practice includes methods to correct for systematic

and Statistical Principles

drift of the instrument with time. (Warning—If drift occurs,

erroneousconclusionswillbeobtainedfromthedataanalysis.)

1 2

This practice is under the jurisdiction ofASTM Committee E01 on Analytical For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ChemistryforMetals,Ores,andRelatedMaterialsandisthedirectresponsibilityof contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee E01.22 on Laboratory Quality. Standardsvolumeinformation,refertothestandard’sDocumentSummarypageon

Current edition approved May 1, 2008. Published June 2008. Originally the ASTM website.

ϵ1 3

approved in 1981. Last previous edition approved in 1996 as E826–81(1996) , Available from International Organization for Standardization (ISO), 1, ch. de

whichwaswithdrawnApril2004andreinstatedinMay2008.DOI:10.1520/E0826- la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

08. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E826 − 08

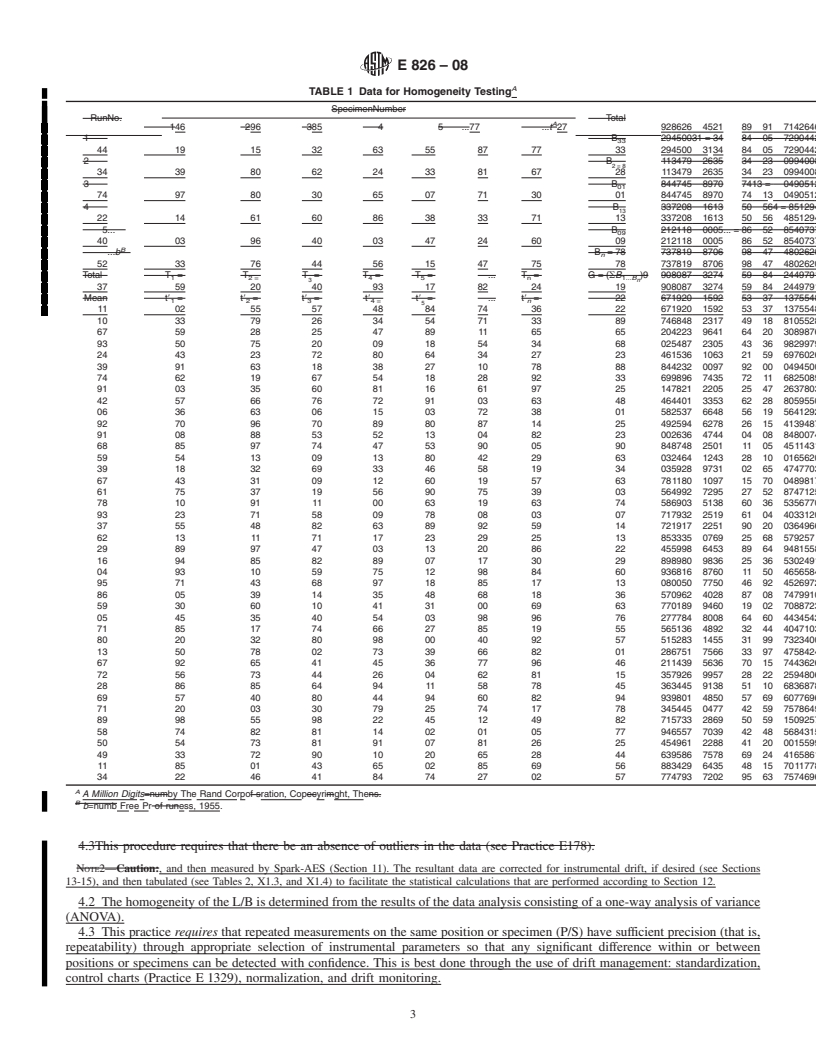

3. Terminology 4.4 This practice requires that there be an absence of

outliers in the data (Pra

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:E826–85 (Reapproved 1996) Designation: E 826 – 08

Standard Practice for

Testing Homogeneity of Materials for Development of

Reference MaterialsTesting Homogeneity of a Metal Lot or

Batch in Solid Form by Spark Atomic Emission

1

Spectrometry

This standard is issued under the fixed designation E826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Section 12 was added editorially in June 1996.

1. Scope

1.1This practice is suitable for testing the homogeneity of metals, either in solid or powdered form, and finely ground oxide

materials that are intended for use as reference materials in X-ray emission, or optical emission spectroscopy, or both.The criteria

for acceptance of the test specimens as reference materials, however, must be previously determined by the user for meeting his

specific requirements.

1.2TheprocedureisdesignedprimarilyfortestingspecimensbyX-rayemissionspectrometryoropticalemissionspectroscopy,

or both. However, the practice could be easily adapted for use with other instrumental techniques such as atomic absorption

spectrophotometry.

1.3Thisprocedurecanbeappliedtooneormoreelementsinaspecimenprovidedthesignal-to-backgroundratioisnotalimiting

factor.

1.4This practice includes one method, if desired, to correct for systematic or periodic (sinusoidal) drift in the instrument with

time through the use of a control reference material.

1.1 This practice is suitable for testing the homogeneity of a metal lot or batch (L/B) in solid form by spark atomic emission

spectrometry (Spark-AES). It is compliant with ISO Guide 35—Certification of Reference Materials: General and Statistical

Principles.Itisprimarilyintendedforuseinthedevelopmentofreferencematerialsbutmaybeusedinanyotherapplicationwhere

a L/B is to be tested for homogeneity. It is designed to provide a combined study of within-unit and between-unit homogeneity

of such a L/B.

1.2 This practice is designed primarily to test for elemental homogeneity of a metal L/B by Spark-AES. However, it can be

adapted for use with other instrumental techniques such as X-ray fluorescence spectrometry (XRF) or atomic absorption

spectrometry (AAS).

NOTE1—Caution: If serious drift occurs (for example, unstable power supply, X-ray tube, etc.) erroneous conclusions may be obtained from the data

analysis.

1.5 1—This practice is not limited to elemental analysis or techniques. This practice can be applied to any property that can

be measured, for example, the property of hardness as measured by the Rockwell technique.

1.3 The criteria for acceptance of the test specimens must be previously determined. That is, the maximum acceptable level of

heterogeneity must be determined on the basis of the intended use of the L/B.

1.4 It is assumed that the analyst is trained in Spark-AES techniques including the specimen preparation procedures needed to

make specimens ready for measurements. It is further assumed that the analyst is versed in and has access to computer-based data

capture and analysis. The methodology of this practice is best utilized in a computer based spreadsheet.

1.5 Thispracticecanbeappliedtooneormoreelementsinaspecimenprovidedthesignal-to-backgroundratioisnotalimiting

factor.

1.6 This practice includes methods to correct for systematic drift of the instrument with time. (Warning—If drift occurs,

erroneous conclusions will be obtained from the data analysis.)

1

This practice is under the jurisdiction of ASTM Committee E-1 on Analytical Chemistry for Metals, Ores and Related Materials and is the direct responsibility of

Subcommittee E01.22 on Statistics and Quality Control.

Current edition approved June 28, 1985. Published October 1985. Originally published as E826–81. Last previous edition E826–81.

1

This practice is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores and Related Materials and is the direct responsibility of

Subcommittee E01.22 on Laboratory Quality.

´1

Current edition approved May 1, 2008. Published June 2008. Originally approved in 1981. Last previous edition approved in 1996 as E826–81(1996) , which was

withdrawn April 2004 and reinstated in May 2008.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.