ASTM F1044-05

(Test Method)Standard Test Method for Shear Testing of Calcium Phosphate Coatings and Metallic Coatings

Standard Test Method for Shear Testing of Calcium Phosphate Coatings and Metallic Coatings

SIGNIFICANCE AND USE

The shear test method is recommended for shear testing of calcium phosphate and metallic/substrate combinations and can provide information on the adhesive or cohesive strength of coatings under a uniaxial shear stress.

The test method may be useful for comparative evaluation of adhesive or cohesive strengths of a variety of types of coatings. Information developed using this test method may be useful for certain quality control and design purposes.

The test method should not be considered to provide an intrinsic values for utilization directly in making calculations such as determining the ability of a coating to withstand specified environmental stresses.

Processing variables, such as substrate preparation prior to coating, surface texture, coating technique variables or post-coating heat treatment, or heat may introduce a significant effect on the results of the shear test. The specimen being evaluated must be representative of the actual end-use coating.

SCOPE

1.1 This test method covers shear testing of continuous calcium phosphate coatings and metallic coatings adhering to dense metal substrates at ambient temperatures. It assesses the degree of adhesion of coatings to substrates, or the internal cohesion of a coating in shear, parallel to the surface plane.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1044–05

Standard Test Method for

Shear Testing of Calcium Phosphate Coatings and Metallic

1

Coatings

This standard is issued under the fixed designation F1044; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope example, sintering or diffusion bonding) or may be bonded

together by use of a polymeric adhesive. The adhesive may be

1.1 This test method covers shear testing of continuous

in film form or bulk form, but it must have a minimum bulk

calcium phosphate coatings and metallic coatings adhering to

shear strength of 34.5 MPa (5000 psi) or as great as the

dense metal substrates at ambient temperatures. It assesses the

minimum required adhesion or cohesion strength of the coat-

degree of adhesion of coatings to substrates, or the internal

ing, whichever is greater.

cohesion of a coating in shear, parallel to the surface plane.

4.1.2 The shear load must be applied parallel to the plane of

1.2 The values stated in SI units are to be regarded as the

the coating utilizing a tensile machine, which is capable of

standard. The values given in parentheses are for information

determining the maximum strength of the coating or coating

only.

attachment to the substrate interface.

1.3 This standard may involve hazardous materials, opera-

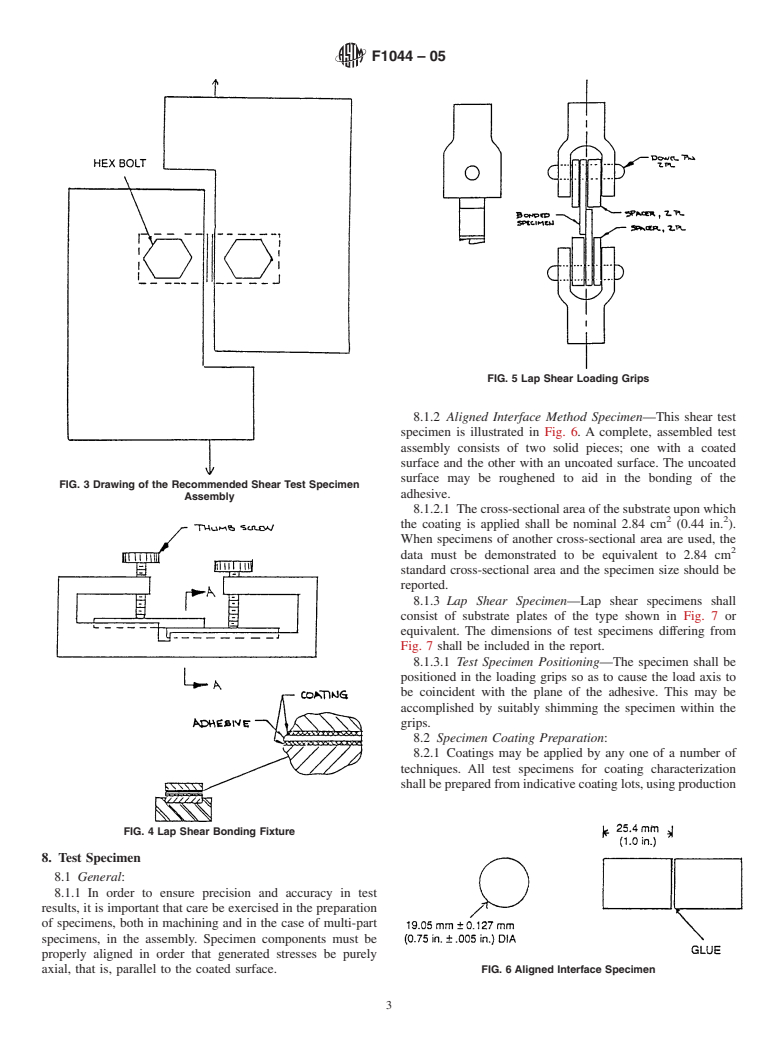

4.2 Shear Method for Metallic Coatings Only—The lap

tions, and equipment. This standard does not purport to

shear method consists of subjecting a porous coated area to

address all of the safety concerns, if any, associated with its

single shear loading, generally utilizing suitable polymeric

use. It is the responsibility of the user of this standard to

adhesive or bone cement adhesive and test jig in a tension

establish appropriate safety and health practices and deter-

machine, and determining the maximum shear stress required

mine the applicability of regulatory limitations prior to use.

to obtain separation (that is, the shear strength of the coating/

2. Referenced Documents

substrate bond or shear strength of the coating).

2

2.1 ASTM Standards:

5. Significance and Use

E4 Practices for Force Verification of Testing Machines

5.1 The shear test method is recommended for shear testing

E6 TerminologyRelatingtoMethodsofMechanicalTesting

of calcium phosphate and metallic/substrate combinations and

E8 Test Methods for Tension Testing of Metallic Materials

can provide information on the adhesive or cohesive strength

3. Terminology

of coatings under a uniaxial shear stress.

5.2 The test method may be useful for comparative evalu-

3.1 Definitions—Terminology E6 shall be considered as

ation of adhesive or cohesive strengths of a variety of types of

applying to the terms used in this test method.

coatings. Information developed using this test method may be

4. Summary of Test Method

useful for certain quality control and design purposes.

5.3 The test method should not be considered to provide an

4.1 Shear Method for Calcium Phosphate or Metallic Coat-

intrinsic values for utilization directly in making calculations

ings:

such as determining the ability of a coating to withstand

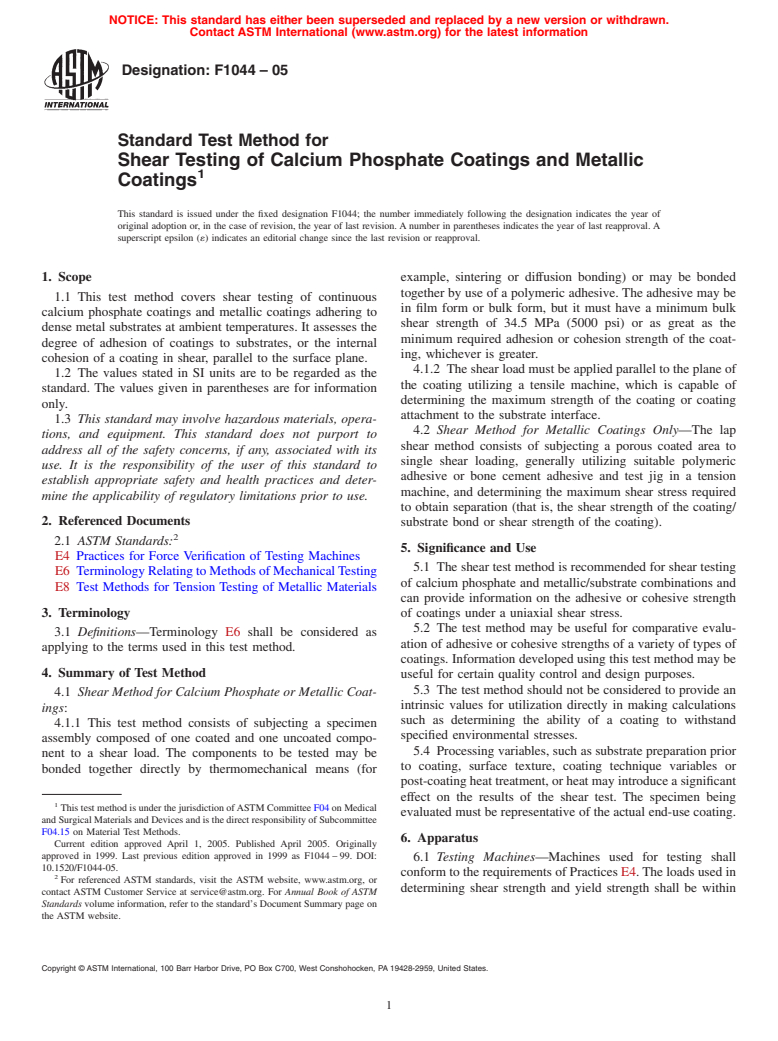

4.1.1 This test method consists of subjecting a specimen

specified environmental stresses.

assembly composed of one coated and one uncoated compo-

5.4 Processing variables, such as substrate preparation prior

nent to a shear load. The components to be tested may be

to coating, surface texture, coating technique variables or

bonded together directly by thermomechanical means (for

post-coating heat treatment, or heat may introduce a significant

effect on the results of the shear test. The specimen being

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

evaluated must be representative of the actual end-use coating.

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

6. Apparatus

Current edition approved April 1, 2005. Published April 2005. Originally

approved in 1999. Last previous edition approved in 1999 as F1044 – 99. DOI:

6.1 Testing Machines—Machines used for testing shall

10.1520/F1044-05.

conform to the requirements of Practices E4.The loads used in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

determining shear strength and yield strength shall be within

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 --

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.