ASTM F1567-94(2006)

(Specification)Standard Specification for Fabricated or Cast Automatic Self-Cleaning, Fuel Oil and Lubricating Oil Strainers

Standard Specification for Fabricated or Cast Automatic Self-Cleaning, Fuel Oil and Lubricating Oil Strainers

ABSTRACT

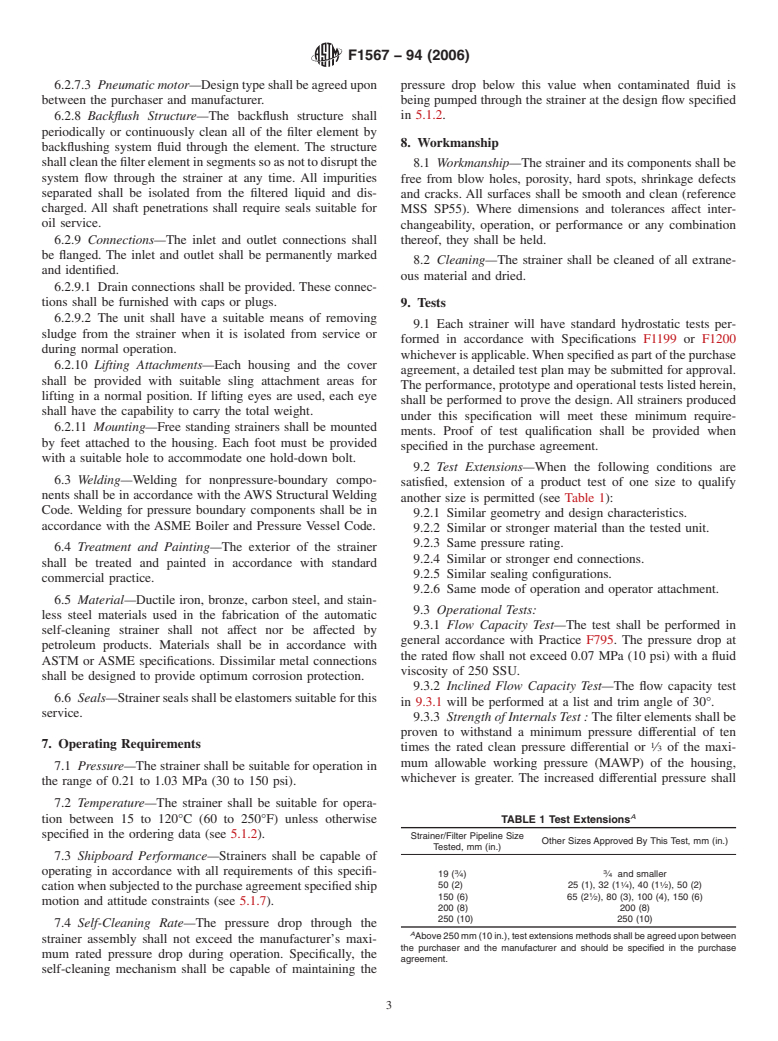

This specification covers the material, operating, and testing requirements for automatic or continuously self-cleaning strainers, or both, for use in fuel oil and lubricating oil systems and in any marine environment. The strainer may be either hydraulic, electric, or pneumatic operated, and is designed to operate under positive pressure, that is, on the discharge side of the pump. The strainers should operate at specified pressures, temperatures, shipboard environments, and self-cleaning rates. They shall also undergo flow capacity test, inclined flow capacity test, strength of internals test, and self-cleaning and filtration efficiency test.

SCOPE

1.1 This specification covers automatic or continuously self-cleaning automatic strainers, or both, for use in fuel and lubrication oil systems. The strainer is designed to operate under positive pressure (discharge side of the pump). Strainers manufactured to this specification are suitable for use in any marine environment.

1.2 It is not the intent of this document to redefine existing filtration standards. The intent is to provide sound guidelines for purchasers and designers of lube oil and fuel oil systems. Nominal micron requirements and filter efficiencies shall be as agreed upon by the purchaser and manufacturer and stated in the purchase order document.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1567 −94(Reapproved 2006) An American National Standard

Standard Specification for

Fabricated or Cast Automatic Self-Cleaning, Fuel Oil and

1

Lubricating Oil Strainers

This standard is issued under the fixed designation F1567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ASME Boiler and Pressure Vessel Code: Section IX, Weld-

ing and Brazing Procedures

1.1 This specification covers automatic or continuously

B16.5 Steel Pipe Flanges and Flanged Fittings (Including

self-cleaning automatic strainers, or both, for use in fuel and

Ratings for Class 150, 300, 400, 600, 900, 1500, and

lubrication oil systems. The strainer is designed to operate

2500)

under positive pressure (discharge side of the pump). Strainers

B16.42 Ductile Iron Pipe Flanges and Flanged Fittings Class

manufactured to this specification are suitable for use in any

150 and 300

marine environment.

Y14.5 Dimensioning and Tolerancing

1.2 It is not the intent of this document to redefine existing 5

2.3 American Welding Society Standard:

filtration standards. The intent is to provide sound guidelines

AWS D1.3 Structural Welding Code

for purchasers and designers of lube oil and fuel oil systems.

6

2.4 MSS Standards:

Nominal micron requirements and filter efficiencies shall be as

SP25 Standard Marking Systems for Valves and Fittings

agreed upon by the purchaser and manufacturer and stated in

SP55 Quality Standards for Valve, Flanges and Fittings and

the purchase order document.

Other Piping Components (Visual Method)

7

2.5 Federal Specification:

2. Referenced Documents

PPP-F-320 Fiberboard: Corrugate and Solid Sheet Stock

2

2.1 ASTM Standards:

(Container Grade) and Cut Shapes

8

D3951 Practice for Commercial Packaging

2.6 Military Specifications:

F795 Practice for Determining the Performance of a Filter

MIL-P-116 Preservation, Methods of

Medium Employing a Single-Pass, Constant-Rate, Liquid

MIL-B-121 Barrier Material, Greaseproofed,Water Proofed,

3

Test (Withdrawn 2002)

Flexible

F1199 Specification for Cast (All Temperatures and Pres-

MIL-S-901 Shock Tests, H.I. (High Impact): Shipboard

sures) and Welded Pipe Line Strainers (150 psig and

Machinery, Equipment and Systems, Requirements for

150°F Maximum)

MIL-P-15024 Plates, Tags and Bands for Identification of

F1200 Specification for Fabricated (Welded) Pipe Line

Equipment

Strainers (Above 150 psig and 150°F)

MIL-P-15024/5 Plates, Identification

4

8

2.2 ASME/ANSI Standards:

2.7 Military Standards:

ASME Boiler and Pressure Vessel Code: Section VIII

MIL-STD-167-1 Mechanical Vibrations of Shipboard

Division 1,Pressure Vessels

Equipment(TypeI—EnvironmentalandTypeIIInternally

Induced)

MIL-STD-740 Airborne and Structureborne Noise Measure-

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

ment and Acceptance Criteria of Shipboard Equipment

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

MIL-STD-2073-1 MaterialProceduresforDevelopmentand

Machinery and Piping Systems.

Application of Packaging Requirements

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approved in 1994. Last previous edition approved in 2001 as F1567 – 94 (2001).

DOI: 10.1520/F1567-94R06.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Miami, FL 33126, http://www.aws.org.

6

Standards volume information, refer to the standard’s Document Summary page on AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

the ASTM website. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

3

The last approved version of this historical standard is referenced on hq.com.

7

www.astm.org. Available from Superintendent of Documents, U.S. Government Printing

4

Available from American Society of Mechanical Engineers (ASME), ASME Office, Washington, DC 20402.

8

International Headquarters, Three Park Ave., New York, NY 10016-5990, http:// AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

www.asme.org. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1567 − 94 (2006)

3. Terminology filter/straining element(s), self-cleaning mechanism(s), con-

trols, and a differential pressure gauge. The strainer unit shall

3.1 Definitions of Terms Specific to This Standard:

have suitab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.