ASTM F1567-94(2019)

(Specification)Standard Specification for Fabricated or Cast Automatic Self-Cleaning, Fuel Oil and Lubricating Oil Strainers

Standard Specification for Fabricated or Cast Automatic Self-Cleaning, Fuel Oil and Lubricating Oil Strainers

ABSTRACT

This specification covers the material, operating, and testing requirements for automatic or continuously self-cleaning strainers, or both, for use in fuel oil and lubricating oil systems and in any marine environment. The strainer may be either hydraulic, electric, or pneumatic operated, and is designed to operate under positive pressure, that is, on the discharge side of the pump. The strainers should operate at specified pressures, temperatures, shipboard environments, and self-cleaning rates. They shall also undergo flow capacity test, inclined flow capacity test, strength of internals test, and self-cleaning and filtration efficiency test.

SCOPE

1.1 This specification covers automatic or continuously self-cleaning automatic strainers, or both, for use in fuel and lubrication oil systems. The strainer is designed to operate under positive pressure (discharge side of the pump). Strainers manufactured to this specification are suitable for use in any marine environment.

1.2 It is not the intent of this document to redefine existing filtration standards. The intent is to provide sound guidelines for purchasers and designers of lube oil and fuel oil systems. Nominal micron requirements and filter efficiencies shall be as agreed upon by the purchaser and manufacturer and stated in the purchase order document.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1567 −94 (Reapproved 2019) An American National Standard

Standard Specification for

Fabricated or Cast Automatic Self-Cleaning, Fuel Oil and

Lubricating Oil Strainers

This standard is issued under the fixed designation F1567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASME Standards:

ASME Boiler and Pressure Vessel Code: Section VIII Divi-

1.1 This specification covers automatic or continuously

sion 1, Pressure Vessels

self-cleaning automatic strainers, or both, for use in fuel and

ASMEBoilerandPressureVesselCode:SectionIX Welding

lubrication oil systems. The strainer is designed to operate

and Brazing Procedures

under positive pressure (discharge side of the pump). Strainers

B16.5 Pipe Flanges and Flanged Fittings (Including Ratings

manufactured to this specification are suitable for use in any

for Class 150, 300, 400, 600, 900, 1500, and 2500)

marine environment.

B16.42 Ductile Iron Pipe Flanges and Flanged Fittings:

1.2 It is not the intent of this document to redefine existing

Classes 150 and 300

filtration standards. The intent is to provide sound guidelines

Y14.5 Dimensioning and Tolerancing

for purchasers and designers of lube oil and fuel oil systems. 5

2.3 American Welding Society Standard:

Nominal micron requirements and filter efficiencies shall be as

AWS D1.3 Structural Welding Code

agreed upon by the purchaser and manufacturer and stated in 6

2.4 MSS Standards:

the purchase order document.

SP25 Standard Marking Systems for Valves and Fittings

1.3 This international standard was developed in accor-

SP55 Quality Standards for Valve, Flanges and Fittings and

dance with internationally recognized principles on standard- Other Piping Components (Visual Method)

ization established in the Decision on Principles for the

2.5 Federal Specification:

Development of International Standards, Guides and Recom- PPP-F-320 Fiberboard: Corrugate and Solid Sheet Stock

mendations issued by the World Trade Organization Technical

(Container Grade) and Cut Shapes

Barriers to Trade (TBT) Committee. 2.6 Military Specifications:

MIL-P-116 Preservation, Methods of

2. Referenced Documents

MIL-B-121 Barrier Material, Greaseproofed,Water Proofed,

2.1 ASTM Standards: Flexible

D3951 Practice for Commercial Packaging MIL-S-901 Shock Tests, H.I. (High Impact): Shipboard

F795 Practice for Determining the Performance of a Filter Machinery, Equipment and Systems, Requirements for

Medium Employing a Single-Pass, Constant-Rate, Liquid MIL-P-15024 Plates, Tags and Bands for Identification of

Test (Withdrawn 2002)

Equipment

F1199 Specification for Cast (All Temperatures and Pres- MIL-P-15024/5 Plates, Identification

sures) and Welded Pipe Line Strainers (150 psig and

2.7 Military Standards:

150°F Maximum) MIL-STD-167-1 Mechanical Vibrations of Shipboard

F1200 Specification for Fabricated (Welded) Pipe Line

Equipment(TypeI—EnvironmentalandTypeIIInternally

Strainers (Above 150 psig and 150°F) Induced)

1 4

This specification is under the jurisdiction of ASTM Committee F25 on Ships Available from American Society of Mechanical Engineers (ASME), ASME

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Machinery and Piping Systems. www.asme.org.

Current edition approved May 1, 2019. Published June 2019. Originally Available from American Welding Society (AWS), 8669 NW 36 St., #130,

approved in 1994. Last previous edition approved in 2013 as F1567 – 94 (2013). Miami, FL 33166-6672, http://www.aws.org.

DOI: 10.1520/F1567-94R19. AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Industry (MSS), 127 Park St., NE,Vienna,VA22180-4602, http://www.mss-hq.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from U.S. Government Printing Office, Superintendent of

Standards volume information, refer to the standard’s Document Summary page on Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http://

the ASTM website. www.access.gpo.gov.

3 8

The last approved version of this historical standard is referenced on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

www.astm.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1567 − 94 (2019)

MIL-STD-740 Airborne and Structureborne Noise Measure- the filter element in segments such that the contaminating

ment and Acceptance Criteria of Shipboard Equipment particlesareflushedfreeofthefilterelement.Theself-cleaning

MIL-STD-2073-1 MaterialProceduresforDevelopmentand action of each unit shall be driven by a motor (electric,

Application of Packaging Requirements pneumatic, or hydraulic).

6.2 Components—Each strainer assembly shall consist of a

3. Terminology

housing with a removable cover, inlet and outlet connections,

3.1 Definitions of Terms Specific to This Standard:

filter/straining element(s), self-cleaning mechanism(s),

3.1.1 filter, or straining element, n—the replaceable compo-

controls, and a differential pressure gauge. The strainer unit

nent in a strainer that performs the barrier separation of solid

shall have suitable supports. The cross-sectional flow area

particles from flowing fluid. It shall be removable for cleaning

throughout the unit shall be equal to or greater than that of the

and servicing.

piping to which the strainer is connected.

3.1.2 maximum allowable working pressure (MAWP), 6.2.1 Housing—The strainer housing, cover, flanges, and

n—the highest internal pressure that the strainer can be other items which form the pressure boundary shall conform to

the requirements of the ASME Boiler and Pressure Vessel

subjected to in service. The maximum non-shock working

pressure for which a strainer is rated by the manufacturer on its Code: Section VIII, Division 1, Pressure Vessels. Cast grey

iron pressure retaining components shall not be used. Units

nameplate.

requiring ASME stamp shall have it specified in the purchase

3.1.3 maximum design temperature, n—the maximum tem-

agreement. The dirty oil inlet shall be located at the lower part

perature for which a strainer is rated by the manufacturer.

of the body and arranged to help prevent contamination of the

3.1.4 strainer, n—a device which, when installed in a

clean outlet side of the strainer during disassembly.

pipeline, provides a mechanical means of removing suspended

6.2.2 Cover—The removable cover shall be secured to the

solids from flowing liquid.

housing by threaded fasteners. Removal of the cover shall

3.1.5 straining element open area, n—the net effective open

provide access to all internal components and shall not require

area of the clean element through which the fluid can pass.

unbolting the inlet and outlet strainer piping connections.

Coverliftingdeviceswithintegralsupportsorliftingeyesshall

4. Classification

be required for covers weighing more than 30 lb.

4.1 Strainers shall be furnished as Type I fuel oil or Type II

6.2.2.1 Antispray feature—Thestrainercovershallcontaina

lubricating oil. The strainers may be either hydraulic, electric,

device to deflect fluid spray downward in the event of gasket

or pneumatic operated.

failure. The spray deflector shall remain in position at all times

when the cover is connected to the housing.

5. Ordering Information

6.2.3 Gasket—The gasket or o-ring shall be capable of

5.1 Ordersforstrainersunderthisspecificationshallinclude providing a positive seal under service and test conditions.The

gasket shall be installed between the cover and strainer

the following:

5.1.1 This specification number, housing. This gasket shall be in place during the hydrostatic

pressure test.

5.1.2 Operating and design requirements for flow rate,

pressure, temperature, nominal micron rating, fluid type, and 6.2.4 Pipe and Flange Dimensions—The inlet and outlet

viscosity.ASME Section VIII Division 1 Code Stamp require- flanges shall be sized and drilled to conform withANSI B16.5,

ments. Class 150 or 300, or as specified in the ordering data (see 5.1.3

5.1.3 Flanged end connections class and type drilling, that and ANSI B 16.42).

is, ANSI, DIN, and so forth.

6.2.5 Element Support—The filter element support shall not

5.1.4 Orientation of inlet and outlet connections (see 6.2.9). permanently deform when the assembly of the filter element

5.1.5 Repair spare parts package (see 14.1).

andelementsupportissubjectedtothestrengthofinternalstest

5.1.6 Quality criteria and test plan requirements. (see 9.3.3). The element support shall be designed to facilitate

5.1.7 Additionaltestorsupplementaryrequirements(thatis,

easy removal of the filter element and element support as one

ship motions and attitude constraints, see 7.3 and S1). assembly. The element support must satisfy the flow area

5.1.8 Strainer element open area if greater than require-

requirements of 6.2.6.

ments in 6.2.6.

6.2.6 Filter Element—The filter element may be furnished

5.1.9 Any special seal requirements.

in any corrosion resistant material compatible with the fluid in

5.1.10 Any special control requirements, that is, differential

service. The filter element shall be attached to the element

pressure gauges, valves, control panels, motors and so forth.

support in such a manner that it can be easily removed and

5.1.11 Certified drawing requirements showing mainte-

replaced from the element support. The straining element open

nance envelope and mounting details.

area shall be at least two to four times larger than the area of

the strainer discharge connection.

6. Materials and Manufacture

6.2.7 Motor—The self-cleaning action of each unit shall be

operated by a motor included as a part of the strainer. This

6.1 The strainer shall be designed to remove contaminating

motor can be hydraulic, electric or pneumatic.

or unwanted solid particles, or both, from fuel oil and lube oil.

The self-cleaning action shall be automatic, and shall have the 6.2.7.1 Hydraulicmotor—Amotorexhaustconnectionsized

ability to backwash, when required, the filtered fluid through to meet the strainer hydraulic motor shall be provided. This

F1567 − 94 (2019)

motor exhaust connection shall also be suitable for venting air cationwhensubjectedtothepurchaseagreementspecifiedship

during the initial fill and pressurization. motion and attitude constraints (see 5.1.7).

6.2.7.2 Electric motor—Electric motors shall be fractional

7.4 Self-Cleaning Rate—The pressure drop through the

horsepower, TEFC, NEMA design B, with a continuous rated

strainer assembly shall not exceed the manufacturer’s maxi-

1.15 service factor or equivalent. Voltage, phase and cycle

mum rated pressure drop during operation. Specifically, the

rating shall be stated in the purchase document.

self-cleaning mechanism shall be capable of maintaining the

6.2.7.3 Pneumatic motor—Designtypeshallbeagreedupon

pressure drop below this value when contaminated fluid is

between the purchaser and manufacturer.

being pumped through the strainer at the design flow specified

6.2.8 Backflush Structure—The backflush structure shall

in 5.1.2.

periodically or continuously clean all of the filter element by

8. Workmanship

backflushing system fluid through the element. The structure

shallcleanthefilterelementinsegmentssoasnottodisruptthe

8.1 Workmanship—The strainer and its components shall be

system flow through the strainer at any time. All impurities

free from blow holes, porosity, hard spots, shrinkage defects

separated shall be isolated from the filtered liquid and dis-

and cracks. All surfaces shall be smooth and clean (reference

charged. All shaft penetrations shall require seals suitable for

MSS SP55). Where dimensions and tolerances affect

oil service.

interchangeability, operation, or performance or any combina-

6.2.9 Connections—The inlet and outlet connections shall

tion thereof, they shall be held.

be flanged. The inlet and outlet shall be permanently marked

8.2 Cleaning—The strainer shall be cleaned of all extrane-

and identified.

ous material and dried.

6.2.9.1 Drain connections shall be provided. These connec-

tions shall be furnished with caps or plugs.

9. Tests

6.2.9.2 The unit shall have a suitable means of removing

9.1 Each strainer will have standard hydrostatic tests per-

sludge from the strainer when it is isolated from service or

formed in accordance with Specifications F1199 or F1200

during normal operation.

whicheverisapplicable.Whenspecifiedaspartofthepurchase

6.2.10 Lifting Attachments—Each housing and the cover

agreement, a detailed test plan may be submitted for approval.

shall be provided with suitable sling attachment areas for

The performance, prototype and operational tests listed herein,

lifting in a normal position. If lifting eyes are used, each eye

shall be performed to prove the design. All strainers produced

shall have the capability to carry the total weight.

under this specification will meet these minimum require-

6.2.11 Mounting—Free standing strainers shall be mounted

ments. Proof of test qualification shall be provided when

by feet attached to the housing. Each foot must be provided

specified in the purchase agreement.

with a suitable hole to accommodate one hold-down bolt.

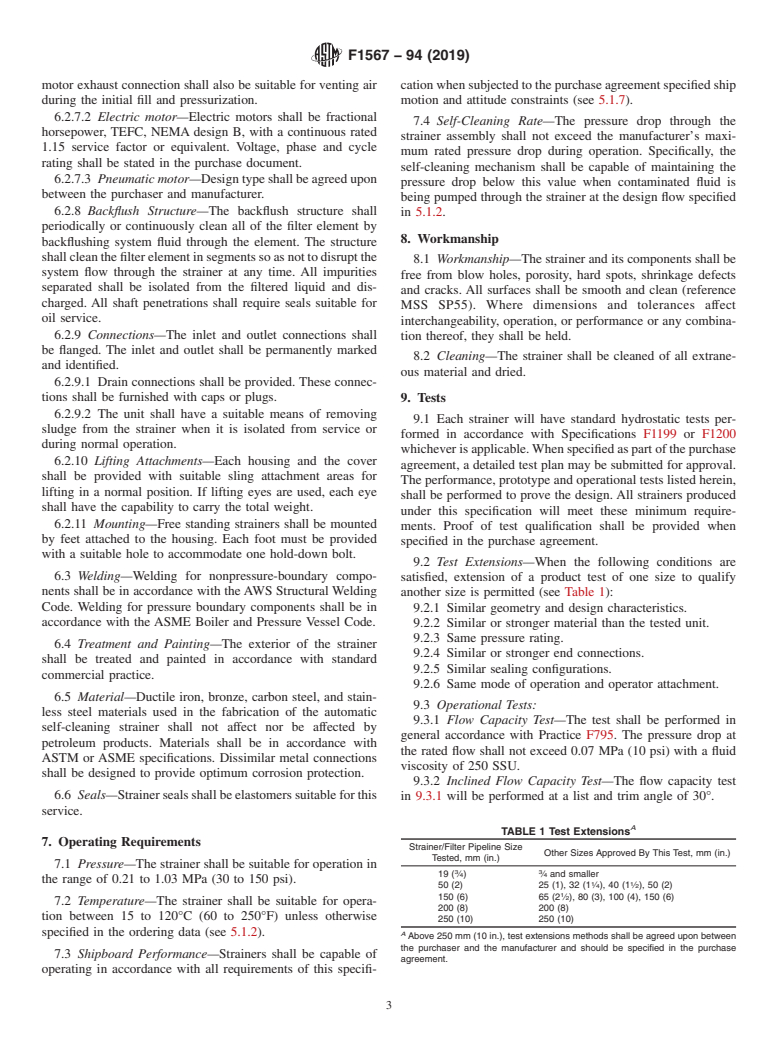

9.2 Test Extensions—When the following conditions are

6.3 Welding—Welding for nonpressure-boundary compo-

satisfied, extension of a product test of one size to qualify

nents shall be in accordance with theAWS Structural Welding another size is permitted (see Table 1):

Code. Welding for pressure boundary components shall be in

9.2.1 Similar geometry and design characteristics.

accordance with the ASME Boiler and Pressure Vessel Code. 9.2.2 Similar or stronger material than the tested unit.

9.2.3 Same pressure rating.

6.4 Treatment and Painting—The exterior of the strainer

9.2.4 Similar or stronger end connections.

shall be treated and painted in accordance with standard

9.2.5 Similar sealing configurations.

commercial practice.

9.2.6 Same mode of operation and operator attachment.

6.5 Material—Ductile iron, bronze, carbon steel, and stain-

9.3 Operational Tests:

less steel materials used in the fabrication of the automatic

9.3.1 Flow Capacity Test—The test shall be performed in

self-cleaning strainer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.