ASTM D5424-99

(Test Method)Standard Test Method for Smoke Obscuration of Insulating Materials Contained in Electrical or Optical Fiber Cables When Burning in a Vertical Cable Tray Configuration

Standard Test Method for Smoke Obscuration of Insulating Materials Contained in Electrical or Optical Fiber Cables When Burning in a Vertical Cable Tray Configuration

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method provides a means to measure the smoke obscuration resulting from burning electrical insulating materials contained in electrical or optical fiber cables when the cable specimens, excluding accessories, are subjected to a specified flaming ignition source and burn freely under well ventilated conditions.

1.3 This standard provides two different protocols for exposing the materials, when made into cable specimens, to an ignition source (approximately 20 kW), for a 20 min test duration. Use it to determine the flame propagation and smoke release characteristics of the materials contained in single and multiconductor electrical or optical fiber cables designed for use in cable trays.

1.4 This test method does not provide information on the fire performance of electrical or optical fiber cables in fire conditions other than the ones specifically used in this standard nor does it measure the contribution of the cables to a developing fire condition.

1.5 Data describing the burning behavior from ignition to the end of the test are obtained.

1.6 The production of light obscuring smoke is measured.

1.7 The burning behavior is documented visually, by photographic or video recordings, or both.

1.8 The test equipment is suitable for making other, optional, measurements, including the rate of heat release of the burning specimen, by an oxygen consumption technique and weight loss.

1.9 Another set of optional measurements are the concentrations of certain toxic gas species in the combustion gases.

1.10 The values stated in SI units are to be regarded as the standard (see Practice E380).

1.11 This standard should be used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire-hazard or fire-risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard or fire risk of a particular end use.

1.12 Fire testing of products and materials is inherently hazardous. Employ adequate safeguards for personnel and property in conducting these tests.

1.13 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5424 – 99

Standard Test Method for

Smoke Obscuration of Insulating Materials Contained in

Electrical or Optical Fiber Cables When Burning in a Vertical

Cable Tray Configuration

This standard is issued under the fixed designation D5424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope factors required for fire hazard or fire risk assessment of the

materials, products or assemblies under actual fire conditions.

1.1 This is a fire-test-response standard.

1.12 Fire testing of products and materials is inherently

1.2 This test method provides a means to measure the

hazardous. Employ adequate safeguards for personnel and

smoke obscuration resulting from burning electrical insulating

property in conducting these tests.

materials contained in electrical or optical fiber cables when

1.13 This standard does not purport to address all of the

the cable specimens, excluding accessories, are subjected to a

safety concerns, if any, associated with its use. It is the

specified flaming ignition source and burn freely under well

responsibility of the user of this standard to establish appro-

ventilated conditions.

priate safety and health practices and determine the applica-

1.3 This test method provides two different protocols for

bility of regulatory limitations prior to use.

exposing the materials, when made into cable specimens, to an

ignition source (approximately 20 kW), for a 20 min test

2. Referenced Documents

duration. Use it to determine the flame propagation and smoke

2.1 ASTM Standards:

release characteristics of the materials contained in single and

D1835 Specification for Liquefied Petroleum (LP) Gases

multiconductor electrical or optical fiber cables designed for

E84 Test Method for Surface Burning Characteristics of

use in cable trays.

Building Materials

1.4 This test method does not provide information on the

E176 Terminology of Fire Standards

fire performance of electrical or optical fiber cables in fire

E800 Guide for Measurement of Gases Present or Gener-

conditions other than the ones specifically used in this test

ated During Fires

method nor does it measure the contribution of the cables to a

E1354 Test Method for Heat and Visible Smoke Release

developing fire condition.

Rates for Materials and Products Using an Oxygen Con-

1.5 Data describing the burning behavior from ignition to

sumption Calorimeter

the end of the test are obtained.

IEEE/ASTM SI 10 Standard for Use of the International

1.6 The production of light obscuring smoke is measured.

System of Units (SI): The Modern Metric System

1.7 The burning behavior is documented visually, by pho-

2.2 NFPA Standard:

tographic or video recordings, or both.

ANSI/NFPA70-1990, NationalElectricalCode—1990,Na-

1.8 The test equipment is suitable for making other, op-

tional Fire Protection Association

tional, measurements, including the rate of heat release of the

2.3 Underwriters Laboratories Standards:

burning specimen, by an oxygen consumption technique and

UL 1056: Fire Test of Upholstered Furniture, Underwriters

weight loss.

Laboratories, 1989

1.9 Another set of optional measurements are the concen-

UL 1581: Reference Standard for Electrical Wires, Cables,

trations of certain toxic gas species in the combustion gases.

and Flexible Cords, March 6, 1987, Underwriters Labo-

1.10 The values stated in SI units are to be regarded as the

ratories, Inc., ANSI/UL 1581-1985

standard (see IEEE/ASTM SI 10).

UL 1685: Standard Vertical Tray Fire Propagation and

1.11 This standard measures and describes the response of

materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 04.07.

1 4

This test method is under the jurisdiction of ASTM Committee D-9 on Annual Book of ASTM Standards, Vol 14.02.

Electrical and Electronic Insulating Materials and is the direct responsibility of Available from National Fire Protection Association, Batterymarch Park,

Subcommittee D09.21 on Fire Performance Standards. Quincy, MA 02269.

Current edition approved Oct. 10, 1999. Published December 1999. Originally AvailablefromUnderwritersLaboratories,Inc.,333PfingstenRd.,Northbrook,

published as D5424–93. Last previous edition D5424–98. IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5424–99

Smoke Release Test for Electrical and Optical Fiber 5. Significance and Use

Cables, Underwriters Laboratories, Inc., January 27, 1992

5.1 This test method provides a means to measure a variety

2.4 Canadian Standards Association Standards:

of fire-test-response characteristics associated with smoke

CSA Standard FT-4, Vertical Flame Tests: Cables in Cable

obscurationandresultingfromburningtheelectricalinsulating

Trays, Section 4.11.4 in C22.2 No. 0.3-M1985, Test

materials contained in electrical or optical fiber cables. The

Methods for Electrical Wires and Cables

specimens are allowed to burn freely under well ventilated

2.5 IEEE Standards:

conditions after ignition by means of a propane gas burner.

IEEE 1202-1991: Standard for Flame Testing of Cables for

5.2 Smoke obscuration quantifies the visibility in fires.

Use in Cable Tray in Industrial and Commercial Occu-

5.3 This test method is also suitable for measuring the rate

pancies, May 29, 1991.

of heat release as an optional measurement. The rate of heat

2.6 Other Standards:

release often serves as an indication of the intensity of the fire

CATechnicalBulletin133, FlammabilityTestProcedurefor

generated.

Seating Furniture for Use in Public Occupancies, January,

5.4 Other optional fire-test-response characteristics that are

measurablebythistestmethodareusefultomakedecisionson

Nordtest Method NT Fire 032, Upholstered Furniture:

fire safety. The most important gaseous components of smoke

Burning Behavior—Full Scale Test

are the carbon oxides, present in all fires. They are major

indicators of the toxicity of the atmosphere and of the

3. Terminology

completeness of combustion and are often used as part of fire

3.1 For definitions of terms used in this test method and

hazard assessment calculations and to improve the accuracy of

associated with fire issues, refer to Terminology E176.

heat release measurements. Other toxic gases, which are

3.2 Definitions of Terms Specific to This Standard:

specific to certain materials, are less crucial for determining

3.2.1 sample, n—an amount of the cable type and construc-

combustion completeness.

tiontobetested,whichisrepresentativeoftheproductfortest.

5.5 Test Limitations:

3.2.2 specimen, n—the individual length of cable, or cable

5.5.1 The fire-test-response characteristics measured in this

bundle, to be placed in the cable tray, which is representative

test method are a representation of the manner in which the

of the product to be tested.

specimens tested behave under certain specific conditions. Do

4. Summary of Test Method not assume they are representative of a generic fire perfor-

mance of the materials tested when made into cables of the

4.1 This fire-test-response standard determines a number of

construction under consideration.

fire-test-response characteristics associated with smoke obscu-

5.5.2 In particular, it is unlikely that this test method is an

rationresultingfromburningthematerialsinsulatingfull-scale

adequate representation of the fire behavior of cables in

specimens of electrical or optical fiber cables located in a

confined spaces, without abundant circulation of air.

vertical cable tray and ignited with a propane gas burner. This

5.5.3 This is an intermediate-scale test, and the predictabil-

test method is also suitable for making other, optional mea-

ity of its results to large scale fires has not been determined.

surements,includingratesofheatrelease,totalamountsofheat

Some information exists to suggest that it has been validated

released, rates and concentrations of carbon oxides released

against some large-scale scenarios.

and rates and amounts of mass of the specimen lost (see

Appendix X2). Further optional measurements are also pos-

6. Apparatus

sible.

4.2 Theverticalcabletraythatholdsthespecimenislocated

6.1 Enclosure:

in an enclosure of specified dimensions.

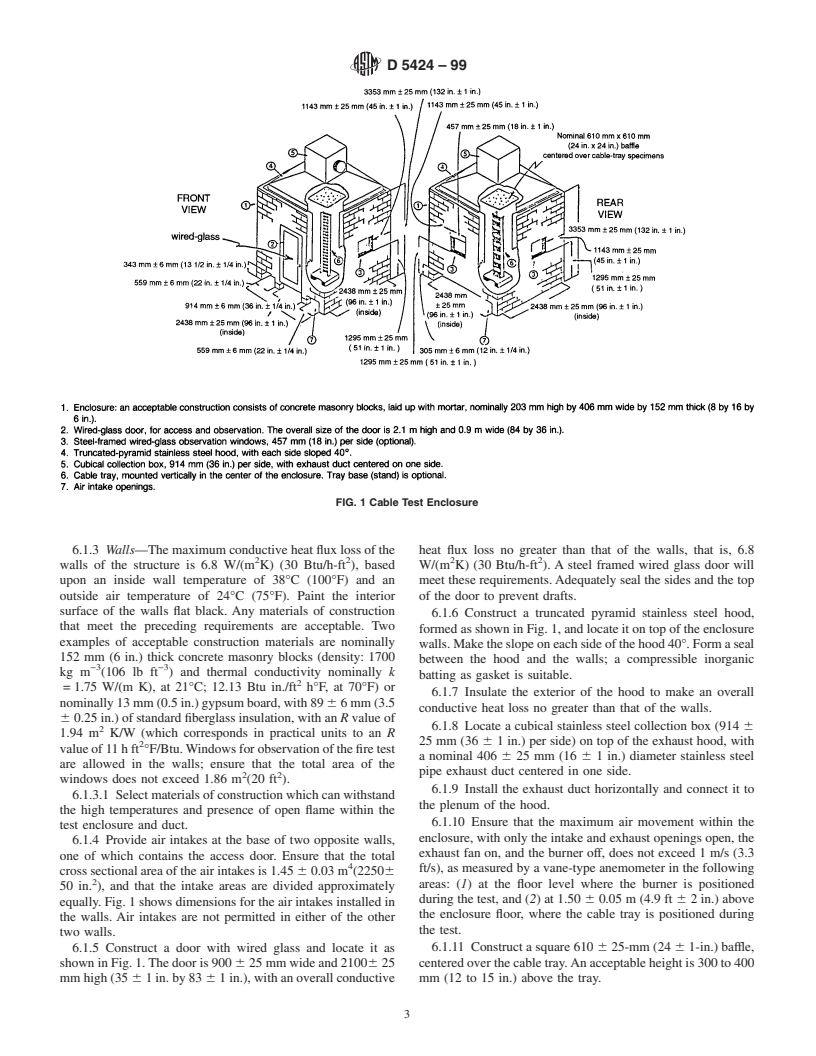

6.1.1 The enclosure in which the specimen is tested is

4.3 A hood, connected to a duct, is located above the fire

shown in Fig. 1.

enclosure.Smokereleaseinstrumentationisplacedintheduct.

6.1.2 The enclosure has a floor area of 2.44 m 6 25 mm by

Heatandgasanalysisreleaseinstrumentation(optional)isalso

2.44 m 6 25 mm, with a height of 3.35 m 6 25 mm (8 ft 6

placed in the duct.

1 in. by 8 ft 6 1 in. by 11 ft 6 1 in. high). On top of the walls

4.4 Two different test procedures are specified, which differ

there is a pyramidal collection hood with a collection box.

in the burner used and in the electrical or optical fiber cable

6.1.2.1 Otherenclosuresizes,suchas2.4by2.4by2.4m(8

loading.Thesereflectdetailsofthreeexistingtestmethods:UL

by 8 by 8 ft) or the 3 m cube are permitted, provided that the

1581 (protocol A) and CSA Standard FT-4 in C22.2 No.

internal volume of the enclosure, exclusive of the pyramidal

0.3-M1985 or IEEE 1202 (protocol B) and UL 1685 (both 3 3 3 3

hood,rangesbetween14.5m (512ft )and36m (1272ft ),the

2 2 2 2

protocols).

floorarearangesbetween6m (64ft )and9m (97ft ),andthe

maximum air movement within the enclosure complies with

6.1.10 (Note 1).

Available from Canadian Standards Association, 178 Rexdale Blvd., Rexdale,

Ontario, Canada, M9W 1R3.

8 NOTE 1—Thereis,asyet,notenoughinformationastotheequivalence

Available from Institute of Electrical and Electronic Engineers, 345 East 47th

on smoke release between the various facilities. Further work needs to be

St., New York, NY 10017.

done to confirm this.

Available from Bureau of Home Furnishings and Thermal Insulation, State of

California, Department of Consumer Affairs, 3485 Orange Grove Ave., North

6.1.2.2 In case of disputes, the referee method are the tests

Highlands, CA 95660-5595.

Available from Nordtest, P.O. Box 22, SF-00341, Helsingfore, Finland, 1987. conducted using the enclosure in 6.1.2.

D5424–99

FIG. 1 Cable Test Enclosure

6.1.3 Walls—Themaximumconductiveheatfluxlossofthe heat flux loss no greater than that of the walls, that is, 6.8

2 2 2 2

walls of the structure is 6.8 W/(m K) (30 Btu/h-ft ), based W/(m K) (30 Btu/h-ft ). A steel framed wired glass door will

upon an inside wall temperature of 38°C (100°F) and an meet these requirements.Adequately seal the sides and the top

outside air temperature of 24°C (75°F). Paint the interior of the door to prevent drafts.

surface of the walls flat black. Any materials of construction

6.1.6 Construct a truncated pyramid stainless steel hood,

that meet the preceding requirements are acceptable. Two

formedasshowninFig.1,andlocateitontopoftheenclosure

examples of acceptable construction materials are nominally

walls.Maketheslopeoneachsideofthehood40°.Formaseal

152 mm (6 in.) thick concrete masonry blocks (density: 1700

between the hood and the walls; a compressible inorganic

−3 −3

kg m (106 lb ft ) and thermal conductivity nominally k

batting as gasket is suitable.

=1.75 W/(m K), at 21°C; 12.13 Btu in./ft h°F, at 70°F) or

6.1.7 Insulate the exterior of the hood to make an overall

nominally13mm(0.5in.)gypsumboard,with89 66mm(3.5

conductive heat loss no greater than that of the walls.

60.25in.)ofstandardfiberglassinsulation,withan Rvalueof

6.1.8 Locate a cubical stainless steel collection box (914 6

1.94 m K/W (which corresponds in practical units to an R

25 mm (36 6 1 in.) per side) on top of the exhaust hood, with

valueof11hft °F/Btu.Windowsforobservationofthefiretest

a nominal 406 6 25 mm (16 6 1 in.) diameter stainless steel

are allowed in the walls; ensure that the total area of the

pipe exhaust duct centered in one side.

2 2

windows does not exceed 1.86 m (20 ft ).

6.1.9 Install the exhaust duct horizontally and connect it to

6.1.3.1 Selectmaterialsofconstructionwhichcanwithstand

the plenum of the hood.

the high temperatures and presence of open flame within the

6.1.10 Ensure that the maximum air movement within the

test enclosure and duct.

enclosure, with only the intake and exhaust openings open, the

6.1.4 Provide air intakes at the base of two opposite walls,

exhaust fan on, and the burner off, does not exceed 1 m/s (3.3

one of which contains the access door. Ensure that the total

ft/s), as measured by a vane-type anemometer in the following

crosssectionalareaoftheairintakesis1.45 60.03m (22506

areas: (1) at the floor level where the burner is positioned

50 in. ), and that the intake areas are divided approximately

during the test, and (2) at 1.50 6 0.05 m (4.9 ft 6 2 in.) above

equally.Fig.1showsdimensionsfortheairintakesinstalledin

the enclosure floor, where the cable tray is positioned during

the walls. Air intakes are not permitted in either of the other

the test.

two walls.

6.1.5 Construct a door with wired glass and locate it as 6.1.11 Constructasquare610 625-mm(24 61-in.)baffle,

showninFig.1.Thedooris900 625mmwideand2100625 centeredoverthecabletray.Anacceptableheightis300to400

mmhigh(35 61in.by83 61in.),withanoverallconductive mm (12 to 15 in.) above the tray.

D5424–99

FIG. 2 Bidirectional Probe

FIG. 3 Optical System

6.1.12 Constructacollection-exhaustsystemconsistingofa bendandtheprobeisatleast8timestheinsidediameterofthe

blower, steel hood, duct, bidirectional probe, thermocouple(s), duct. If the system is positioned at a different location,

oxygen measurement system (optional), smoke obscuration demonstrate the achievement of equivalent results.

measurement system, and gas analysis system (optional). 6.3.4 Build the probe of a short stainless steel cylinder

Ensure that the system for collecting the combustion products

44-mm (1.75-in.) long and 22-mm (0.875-in.) inside diameter

has the capacity and is designed in such a way that all of the with a solid diaphragm in the center. The pressure taps on

combustion products leaving the burning specimen are col-

either side of the diaphragm are also the support for the probe.

3 −1

lected. Make the exhaust system capacity at least 2.7 m s at Position the axis of the probe along the centerline of the duct.

normal pressure and at a temperature of 25 6 2°C. Construct

Connect the taps to a pressure transducer able to resolve

the co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.