ASTM D1140-00(2006)

(Test Method)Standard Test Methods for Amount of Material in Soils Finer than No. 200 (75-μm) Sieve

Standard Test Methods for Amount of Material in Soils Finer than No. 200 (75-μm) Sieve

SIGNIFICANCE AND USE

Material finer than the 75-μm (No. 200) sieve can be separated from larger particles much more efficiently and completely by wet sieving than with dry sieving. Therefore, when accurate determinations of material finer than 75-μm sieve in soil are desired, this test method is used on the test specimen prior to dry sieving. Usually the additional amount of material finer than 75-μm sieve obtained in the dry sieving process is a small amount. If it is large, the efficiency of the washing operation should be checked, as it could be an indication of degradation of the soil.

With some soils, particularly clayey soils, in order to keep the finer material from adhering to the larger particles, it will be necessary to soak the soil prior to washing it through the sieve. A deflocculating agent (dispersing agent) should be added to the soil when it is soaked.

Note 1—The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These test methods cover determination of the amount of material finer than a 75-m (No. 200) sieve by washing.

1.2 Two methods for determining the amount of material finer than the No. 200 sieve are provided. The method to be used shall be specified by the requesting authority. If no method is specified, the choice should be based on the guidance given in 4.2 and 7.3

1.2.1 Method A-Test specimen is not dispersed prior to wash sieving.

1.2.2 Method B-Test specimen is dispersed by soaking in water containing a deflocculating agent prior to wash sieving.

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1140 − 00(Reapproved 2006)

Standard Test Methods for

Amount of Material in Soils Finer than No. 200 (75-µm)

Sieve

This standard is issued under the fixed designation D1140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D3740Practice for Minimum Requirements for Agencies

Engaged in Testing and/or Inspection of Soil and Rock as

1.1 These test methods cover determination of the amount

Used in Engineering Design and Construction

of material finer than a 75-µm (No. 200) sieve by washing.

D4753Guide for Evaluating, Selecting, and Specifying Bal-

1.2 Two methods for determining the amount of material

ances and Standard Masses for Use in Soil, Rock, and

finer than the No. 200 sieve are provided. The method to be

Construction Materials Testing

used shall be specified by the requesting authority. If no

D6026Practice for Using Significant Digits in Geotechnical

method is specified, the choice should be based on the

Data

guidance given in 4.2 and 7.3

E11Specification forWovenWireTest Sieve Cloth andTest

1.2.1 Method A—Test specimen is not dispersed prior to

Sieves

wash sieving.

E145Specification for Gravity-Convection and Forced-

1.2.2 Method B—Test specimen is dispersed by soaking in

Ventilation Ovens

water containing a deflocculating agent prior to wash sieving.

E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.3 The values stated in SI units are to be regarded as the

standard. E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1 Aspecimenofthesoiliswashedovera75-µm(No.200)

bility of regulatory limitations prior to use.

sieve. Clay and other particles that are dispersed by the wash

water,aswellaswater-solublematerials,areremovedfromthe

2. Referenced Documents

soil during the test. The loss in mass resulting from the wash

2.1 ASTM Standards: treatment is calculated as mass percent of the original sample

C702PracticeforReducingSamplesofAggregatetoTesting andisreportedasthepercentageofmaterialfinerthana75-µm

Size (No. 200) sieve by washing.

D75Practice for Sampling Aggregates

D422Test Method for Particle-Size Analysis of Soils 4. Significance and Use

D2216Test Methods for Laboratory Determination ofWater

4.1 Material finer than the 75-µm (No. 200) sieve can be

(Moisture) Content of Soil and Rock by Mass

separated from larger particles much more efficiently and

D2487Practice for Classification of Soils for Engineering

completely by wet sieving than with dry sieving. Therefore,

Purposes (Unified Soil Classification System)

when accurate determinations of material finer than 75-µm

sieve in soil are desired, this test method is used on the test

specimenpriortodrysieving.Usuallytheadditionalamountof

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD18onSoil

material finer than 75-µm sieve obtained in the dry sieving

and Rock and is the direct responsibility of Subcommittee D18.03 on Texture,

Plasticity and Density Characteristics of Soils. process is a small amount. If it is large, the efficiency of the

Current edition approved Nov. 15, 2006. Published January 2007. Originally

washing operation should be checked, as it could be an

approved in 1950. Last previous edition approved in 2000 as D1140–00. DOI:

indication of degradation of the soil.

10.1520/D1140-00R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 With some soils, particularly clayey soils, in order to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

keep the finer material from adhering to the larger particles, it

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. will be necessary to soak the soil prior to washing it through

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

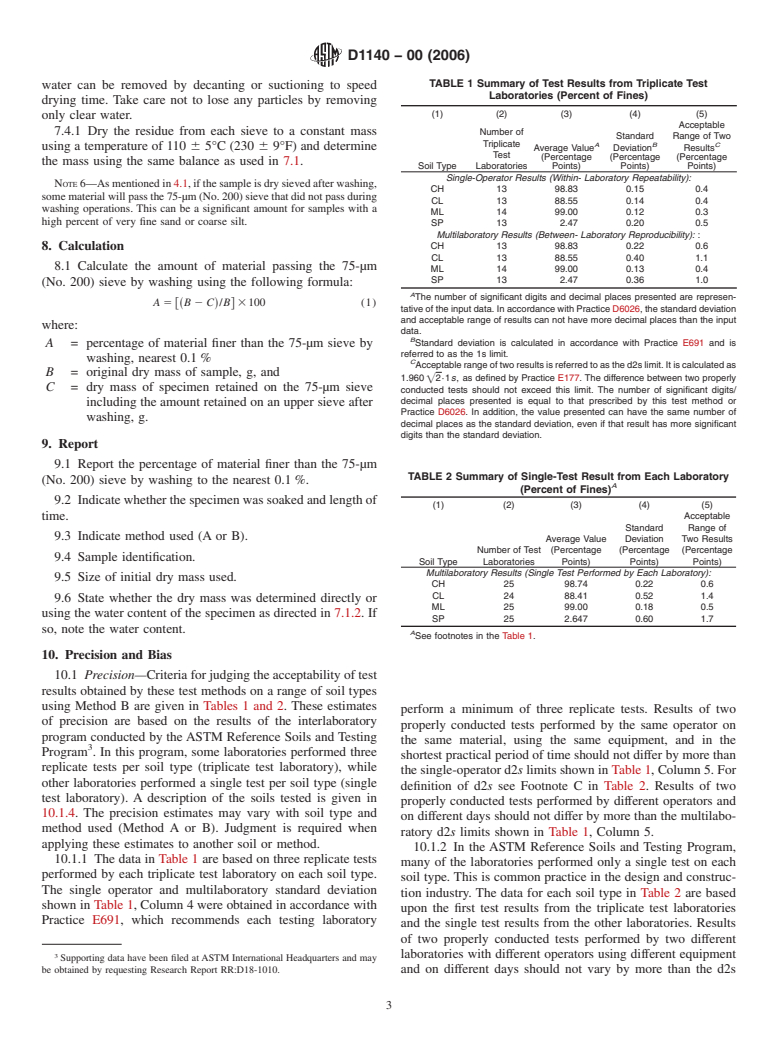

D1140 − 00 (2006)

the sieve. A deflocculating agent (dispersing agent) should be 7. Procedure

added to the soil when it is soaked.

7.1 Dry the test specimen to a constant mass at a tempera-

ture of 110 6 5°C (230 6 9°F) and determine its mass to the

NOTE 1—The quality of the result produced by this standard is

dependent on the competence of the personnel performing it, and the

nearest 0.1 g. To determine the balance needed, multiply the

suitability of the equipment and facilities used. Agencies that meet the

mass by 0.001, check the resultant number with Table1 of

criteria of Practice D3740 are generally considered capable of competent

Specification D4753 for the required balance.

and objective testing/sampling/inspection/etc. Users of this standard are

7.1.1 For example: Minimum readability = 276 g (mass) ×

cautioned that compliance with Practice D3740 does not in itself assure

0.001 = 0.3 g. A GP-2 with a readability of 0.1 g would be

reliable results. Reliable results depend on many factors; Practice D3740

provides a means of evaluating some of those factors.

suitable. A more sensitive balance could also be used.

7.1.2 As an alternative, select an auxiliary water content

5. Apparatus

specimen and determine the water content (nearest 0.1%) in

accordance with Test Method D2216. Calculate the oven-dry

5.1 Balance—Abalance or scale conforming to the require-

mass of the test specimen from the moist mass (nearest 0.1%

mentsofSpecificationD4753,readable(withnoestimation)to

of its mass, or better (see 5.1)) and the water content.

0.1% of the test mass, or better. To determine the balance

needed, multiply your test mass by 0.001 and checkTable1 of

7.2 Method A:

Specification D4753 for the class of balance readable to the

7.2.1 After preparing the specimen in accordance with 7.1,

number observed.

placethespecimenonontheuppermost(coarsest)sieve.Wash

thespecimen(material)onthesieve(s)bymeansofastreamof

5.2 Sieves—Aminimumnestoftwosievesisrecommended,

water from a faucet (Note 3). The material may be lightly

the lower must be a 75-µm (No. 200) sieve and the upper may

manipulated by hand, to facilitate the washing process, taking

be a 425-µm (No. 40) or larger sieve. Chose a sieve with a

care not to lose any of the retained material. No downward

diameter sufficient to handle the size of specimen required by

pressure should be exerted on the retained material or sieve to

6.2.The75-µmsieveshouldhaveabackingtopreventdamage.

avoid the forcing of particles through the sieve or damage to

The sieves shall conform to the requirements of Specification

thesieve.Continuethewashinguntilthewatercomingthrough

E11. Stainless sieve mesh is preferred, as it is less prone to

the sieve(s) is clear (Note 4).

damage or wear.

NOTE 3—Aspray nozzle or a piece of rubber tubing attached to a water

5.3 Oven—An oven of sufficient size, capable of maintain-

faucetmaybeusedforthewashing.Thevelocityofthewater,whichmay

ing a uniform temperature of 100 6 5°C (230 6 9°F) and

be increased by pinching the tubing, shall not cause any splashing of the

which meets the criteria of Specification E145.

material over the sides of the sieve. The water temperature should not

exceed 32°C (90°F) to avoid expanding the sieve fabric.

5.4 Deflocculating Agent—AsolutionofSodiumHexameta-

NOTE4—Careshouldbetakennottoletwateraccumulateonthe75-µm

phosphate of any concentration sufficient to cause particle

(No. 200) sieve due to clogging of the screen. The clogging can cause

separationcanbeused.Acommonamountis40gper1000mL

overflow of the sieve and loss of material. Lightly hand tapping the sides

of water.

of the sieve or the bottom of the screen with a fingertip(s) should prevent

clogging. Directing a stream of water up from below the screen is another

methodtounplugthesievewithoutphysicallydamagingit.Becarefulnot

6. Sampling

to overload the screen by sieving too large a specimen, or portion of a

specimen, at any one time.

6.1 Sample the soil in accordance with Practice D75.

7.3 Method B:

6.2 Thoroughly mix the soil sample and reduce the quantity

7.3.1 As an alternative, particularly for very cohesive soils;

to an amount suitable for testing using the applicable method

after preparing the specimen in accordance with 7.1, place the

described in Practice C702.The test specimen shall be the end

specimen in a container, cover with water containing a defloc-

result of the reduction. Reduction to an exact predetermined

culating agent, and soak for a minimum of 2 h (preferably

mass is not permitted. The mass of the test specimen, after

overnight) (Note 5). The specimen should be periodically

drying,shallconformwiththefollowingexceptasnoted(6.2.1

agitated manually or by mechanical means to facilitate the

and Note 2):

complete separation of the particles.

Recommen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.