ASTM A266/A266M-11

(Specification)Standard Specification for Carbon Steel Forgings for Pressure Vessel Components

Standard Specification for Carbon Steel Forgings for Pressure Vessel Components

ABSTRACT

This specification covers four grades of carbon steel forgings for boiler and pressure vessel components, and associated equipment. Materials shall be manufactured by melting process and hot-worked forging. Heat and product analyses shall be performed wherein forgings shall conform to chemical requirements for carbon, manganese, phosphorus, sulphur, and silicon. Mechanical properties such as tensile strength, yield strength, elongation, and reduction of area shall be inspected as well. The requirements for annealed, normalized, or normalized and tempered steel forgings, and that for quenched and tempered steel forgings have been specified separately.

SCOPE

1.1 This specification covers four grades of carbon steel forgings for boilers, pressure vessels, and associated equipment.

Note 1—Designations have been changed as follows: Current

Formerly

Grade 1Class 1 Grade 2Class 2 Grade 3Class 3 Grade 4Class 4

1.2 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound units.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A266/A266M −11

StandardSpecification for

1

Carbon Steel Forgings for Pressure Vessel Components

This standard is issued under the fixed designationA266/A266M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A1058 Test Methods for Mechanical Testing of Steel

2 Products—Metric

1.1 This specification covers four grades of carbon steel

E112 Test Methods for Determining Average Grain Size

forgings for boilers, pressure vessels, and associated equip-

E165 Practice for Liquid Penetrant Examination for General

ment.

Industry

NOTE 1—Designations have been changed as follows:

E381 Method of Macroetch Testing Steel Bars, Billets,

Current Formerly

Blooms, and Forgings

Grade 1 Class 1

2.2 Other Standard:

Grade 2 Class 2

Grade 3 Class 3 ASME Boiler and Pressure Vessel Code, Section IX, Weld-

4

Grade 4 Class 4

ing Qualifications

1.2 Supplementary requirements are provided for use when

3. Ordering Information and General Requirements

additional testing or inspection is desired. These shall apply

only when specified individually by the purchaser in the order.

3.1 In addition to the ordering information required by

Specification A788/A788M, the purchaser shall include with

1.3 The values stated in either SI units or inch-pound units

the inquiry and order a detailed drawing, sketch, or written

are to be regarded separately as standard. The values stated in

description of the forging.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3.2 Material supplied to this specification shall conform to

values from the two systems may result in non-conformance

the requirements of Specification A788/A788M, which out-

with the standard.

lines additional ordering information, manufacturing

requirements, testing and retesting methods and procedures,

1.4 Unless the order specifies the applicable “M” specifica-

marking, certification, product analysis variations, and addi-

tion designation, the material shall be furnished to the inch-

tional supplementary requirements.

pound units.

3.3 If the requirements of this specification are in conflict

2. Referenced Documents

with the requirements of Specification A788/A788M, the

3

2.1 ASTM Standards: requirements of this specification shall prevail.

A275/A275M Practice for Magnetic Particle Examination of

3.4 For hubbed flanges and tube sheets ordered for ASME

Steel Forgings

Boiler and Pressure Vessel Code application, Supplementary

A370 Test Methods and Definitions for Mechanical Testing

Requirement S12 of Specification A788/A788M shall be

of Steel Products

specified in addition to Supplementary Requirement S8 of this

A788/A788M Specification for Steel Forgings, General Re-

specification.

quirements

4. Materials and Manufacture

1

4.1 The steel shall be made in accordance with the Melting

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

Process Section of Specification A788/A788M. A sufficient

A01.06 on Steel Forgings and Billets.

discard shall be made to secure freedom from injurious pipe

Current edition approved Oct. 1, 2011. Published October 2011. Originally

and undue segregation.

approved in 1943. Last previous edition approved in 2008 as A266/A266M – 03a

(2008). DOI: 10.1520/A0266_A0266M-11.

4.2 The material shall be forged as close as practical to the

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

specified shape and size.

cation SA–266/ SA–266M in Section II of that code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from the American Society of Mechanical Engineers, 345 East 47th

the ASTM website. St., New York, NY 10017.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A266/A266M−11

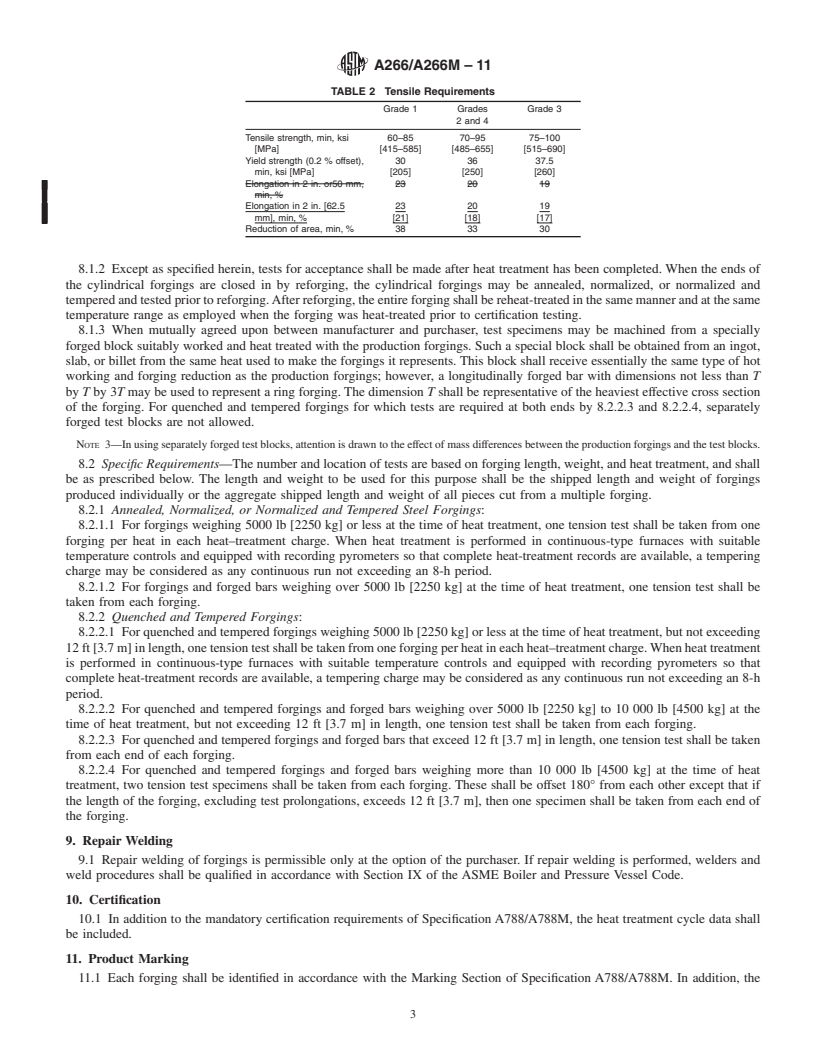

4.3 The finished product shall be a hot-worked forging as propertiesprescribedinTable2whentestedinaccordancewith

defined by Specification A788/A788M. the latest issue of Test Methods and Definitions A370 or Test

MethodsA1058whentheMsuffixstandardhasbeenspecified.

5. Machining

ThelargestobtainabletensiontestspecimenasspecifiedinTest

Methods and Definit

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A266/A266M–03a (Reapproved 2008) Designation: A266/A266M – 11

Standard Specification for

1

Carbon Steel Forgings for Pressure Vessel Components

This standard is issued under the fixed designationA266/A266M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification covers four grades of carbon steel forgings for boilers, pressure vessels, and associated equipment.

NOTE 1—Designations have been changed as follows:

Current Formerly

Grade 1 Class 1

Grade 2 Class 2

Grade 3 Class 3

Grade 4 Class 4

1.2 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only

when specified individually by the purchaser in the order.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound

units.

2. Referenced Documents

3

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A788/A788M Specification for Steel Forgings, General Requirements

A1058 Test Methods for Mechanical Testing of Steel ProductsMetric

E112 Test Methods for Determining Average Grain Size

E165 Practice for Liquid Penetrant Examination for General Industry

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

2.2 Other Standard:

4

ASME Boiler and Pressure Vessel Code, Section IX, Welding Qualifications

3. Ordering Information and General Requirements

3.1 In addition to the ordering information required by SpecificationA788/A788M, the purchaser shall include with the inquiry

and order a detailed drawing, sketch, or written description of the forging.

3.2 Material supplied to this specification shall conform to the requirements of Specification A788/A788M, which outlines

additional ordering information, manufacturing requirements, testing and retesting methods and procedures, marking, certification,

product analysis variations, and additional supplementary requirements.

3.3 IftherequirementsofthisspecificationareinconflictwiththerequirementsofSpecificationA788/A788M,therequirements

of this specification shall prevail.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.06

on Steel Forgings and Billets.

Current edition approved March 1, 2008. Published April 2008. Originally approved in 1943. Last previous edition approved in 2003 as A266/A266M–03a. DOI:

10.1520/A0266_A0266M-03AR08.

Current edition approved Oct. 1, 2011. Published October 2011. Originally approved in 1943. Last previous edition approved in 2008 asA266/A266M – 03a (2008). DOI:

10.1520/A0266_A0266M-11.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA–266/ SA–266M in Section II of that code.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from the American Society of Mechanical Engineers, 345 East 47th St., New York, NY 10017.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A266/A266M – 11

3.4 For hubbed flanges and tube sheets ordered for ASME Boiler and Pressure Vessel Code application, Supplementary

Requirement S12 of Specification A788/A788M shall be specified in addition to Supplementary Requirement S8 of this

specification.

4. Materials and Manufacture

4.1 The steel shall be made in accordance with the Melting Process Section of SpecificationA788/A788M.Asufficient discard

shall be made to secure freedom from injurious pipe an

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A266/A266M–03a (Reapproved 2008) Designation: A266/A266M – 11

Standard Specification for

1

Carbon Steel Forgings for Pressure Vessel Components

This standard is issued under the fixed designationA266/A266M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification covers four grades of carbon steel forgings for boilers, pressure vessels, and associated equipment.

NOTE 1—Designations have been changed as follows:

Current Formerly

Grade 1 Class 1

Grade 2 Class 2

Grade 3 Class 3

Grade 4 Class 4

1.2 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only

when specified individually by the purchaser in the order.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound

units.

2. Referenced Documents

3

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A788/A788M Specification for Steel Forgings, General Requirements

A1058 Test Methods for Mechanical Testing of Steel ProductsMetric

E112 Test Methods for Determining Average Grain Size

E165 Practice for Liquid Penetrant Examination for General Industry

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

2.2 Other Standard:

4

ASME Boiler and Pressure Vessel Code, Section IX, Welding Qualifications

3. Ordering Information and General Requirements

3.1 In addition to the ordering information required by SpecificationA788/A788M, the purchaser shall include with the inquiry

and order a detailed drawing, sketch, or written description of the forging.

3.2 Material supplied to this specification shall conform to the requirements of Specification A788/A788M, which outlines

additional ordering information, manufacturing requirements, testing and retesting methods and procedures, marking, certification,

product analysis variations, and additional supplementary requirements.

3.3 IftherequirementsofthisspecificationareinconflictwiththerequirementsofSpecificationA788/A788M,therequirements

of this specification shall prevail.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.06

on Steel Forgings and Billets.

Current edition approved March 1, 2008. Published April 2008. Originally approved in 1943. Last previous edition approved in 2003 as A266/A266M–03a. DOI:

10.1520/A0266_A0266M-03AR08.

Current edition approved Oct. 1, 2011. Published October 2011. Originally approved in 1943. Last previous edition approved in 2008 asA266/A266M – 03a (2008). DOI:

10.1520/A0266_A0266M-11.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA–266/ SA–266M in Section II of that code.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from the American Society of Mechanical Engineers, 345 East 47th St., New York, NY 10017.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A266/A266M – 11

3.4 For hubbed flanges and tube sheets ordered for ASME Boiler and Pressure Vessel Code application, Supplementary

Requirement S12 of Specification A788/A788M shall be specified in addition to Supplementary Requirement S8 of this

specification.

4. Materials and Manufacture

4.1 The steel shall be made in accordance with the Melting Process Section of SpecificationA788/A788M.Asufficient discard

shall be made to secure freedom from injurious pipe an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.