ASTM D3985-05(2010)e1

(Test Method)Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor

Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor

SIGNIFICANCE AND USE

The OTR is an important determinant of the packaging protection afforded by barrier materials. It is not, however, the sole determinant, and additional tests, based on experience, must be used to correlate packaging performance with OTR. It is suitable as a referee method of testing, provided that the purchaser and the seller have agreed on sampling procedures, standardization procedures, test conditions, and acceptance criteria.

Limited statistical data on correlations with Test Method D1434 methods are available ; however, the oxygen transmission rate of a standard reference material (see 12.1) as determined manometrically by NIST, is in good agreement with the values obtained in the coulometric interlaboratory test using material from the same manufacturing lot. Thus, this test method may be used as a referee method.

SCOPE

1.1 This test method covers a procedure for determination of the steady-state rate of transmission of oxygen gas through plastics in the form of film, sheeting, laminates, coextrusions, or plastic-coated papers or fabrics. It provides for the determination of (1) oxygen gas transmission rate (OTR), (2) the permeance of the film to oxygen gas (PO2), and (3) oxygen permeability coefficient (P'O2) in the case of homogeneous materials.

1.2 This test method does not purport to be the only method for measurement of OTR. There may be other methods of OTR determination that use other oxygen sensors and procedures.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D3985 − 05 (Reapproved 2010)

Standard Test Method for

Oxygen Gas Transmission Rate Through Plastic Film and

Sheeting Using a Coulometric Sensor

This standard is issued under the fixed designation D3985; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in November 2010.

1. Scope F1927TestMethodforDeterminationofOxygenGasTrans-

mission Rate, Permeability and Permeance at Controlled

1.1 This test method covers a procedure for determination

Relative Humidity Through Barrier Materials Using a

of the steady-state rate of transmission of oxygen gas through

Coulometric Detector

plastics in the form of film, sheeting, laminates, coextrusions,

or plastic-coated papers or fabrics. It provides for the determi-

3. Terminology

nation of (1) oxygen gas transmission rate (OTR), (2) the

3.1 Definitions:

permeance of the film to oxygen gas (PO ), and (3) oxygen

3.1.1 oxygen permeability coeffıcient (P'O )—the product of

permeability coefficient (P'O ) in the case of homogeneous

the permeance and the thickness of film. The permeability is

materials.

meaningfulonlyforhomogeneousmaterials,inwhichcaseitis

1.2 Thistestmethoddoesnotpurporttobetheonlymethod

a property characteristic of the bulk material. This quantity

formeasurementofOTR.TheremaybeothermethodsofOTR

should not be used, unless the relationship between thickness

determination that use other oxygen sensors and procedures.

andpermeancehasbeenverifiedontestsusingseveraldifferent

thicknessesofthematerial.TheSIunitofoxygenpermeability

1.3 The values stated in SI units are to be regarded as

is the mol/(m·s·Pa). The test conditions (see 3.1.3) must be

standard. No other units of measurement are included in this

stated.

standard.

3.1.2 oxygen permeance (PO )—the ratio of the OTR to the

1.4 This standard does not purport to address all of the

difference between the partial pressure of O on the two sides

safety problems, if any, associated with its use. It is the

of the film.The SI unit of permeance is the mol/(m ·s·Pa).The

responsibility of the user of this standard to establish appro-

test conditions (see 5.1) must be stated.

priate safety and health practices and determine the applica-

3.1.3 oxygen transmission rate (OTR)—the quantity of

bility of regulatory limitations prior to use.

oxygen gas passing through a unit area of the parallel surfaces

of a plastic film per unit time under the conditions of test. The

2. Referenced Documents

SI unit of transmission rate is the mol/(m ·s). The test

2.1 ASTM Standards:

conditions, including temperature and oxygen partial pressure

D1434TestMethodforDeterminingGasPermeabilityChar-

on both sides of the film must be stated.

acteristics of Plastic Film and Sheeting 3

3.1.3.1 A commonly used unit of OTR is the cm (STP)/

D1898Practice for Sampling of Plastics (Withdrawn 1998) 2 3

(m ·d) at one atmosphere pressure difference where 1 cm

E691Practice for Conducting an Interlaboratory Study to

(STP) is 44.62 µmol, 1 atm is 0.1013 MPa, and one day is

Determine the Precision of a Test Method 3

86.4×10 s.TheOTRinSIunitsisobtainedbymultiplyingthe

−10

value in inch-pound units by 5.160×10 .

4. Summary of Test Method

ThistestmethodisunderthejurisdictionofASTMCommitteeF02onFlexible

Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

4.1 Theoxygengastransmissionrateisdeterminedafterthe

Permeation.

sample has equilibrated in a dry test environment. In this

Current edition approved Oct. 1, 2010. Published November 2010. Originally

ε1

approved in 1981. Last previous edition approved in 2005 as D3985–05 . DOI:

context, a “dry” environment is considered to be one in which

10.1520/D3985-05R10E01.

the relative humidity is less than 1%.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 The specimen is mounted as a sealed semi-barrier

Standards volume information, refer to the standard’s Document Summary page on

between two chambers at ambient atmospheric pressure. One

the ASTM website.

chamberisslowlypurgedbyastreamofnitrogenandtheother

The last approved version of this historical standard is referenced on

www.astm.org. chamber contains oxygen. As oxygen gas permeates through

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D3985 − 05 (2010)

FIG. 1 A Practical Arrangement of Components for the Measurement of Oxygen Transmission Rate Using the Coulometric Method

the film into the nitrogen carrier gas, it is transported to the and some strong oxidizing agents. Exposure to carbon dioxide

coulometric detector where it produces an electrical current, should also be minimized to avoid damage to the sensor

the magnitude of which is proportional to the amount of through reaction with the potassium hydroxide electrolyte.

oxygen flowing into the detector per unit time.

7. Apparatus

5. Significance and Use

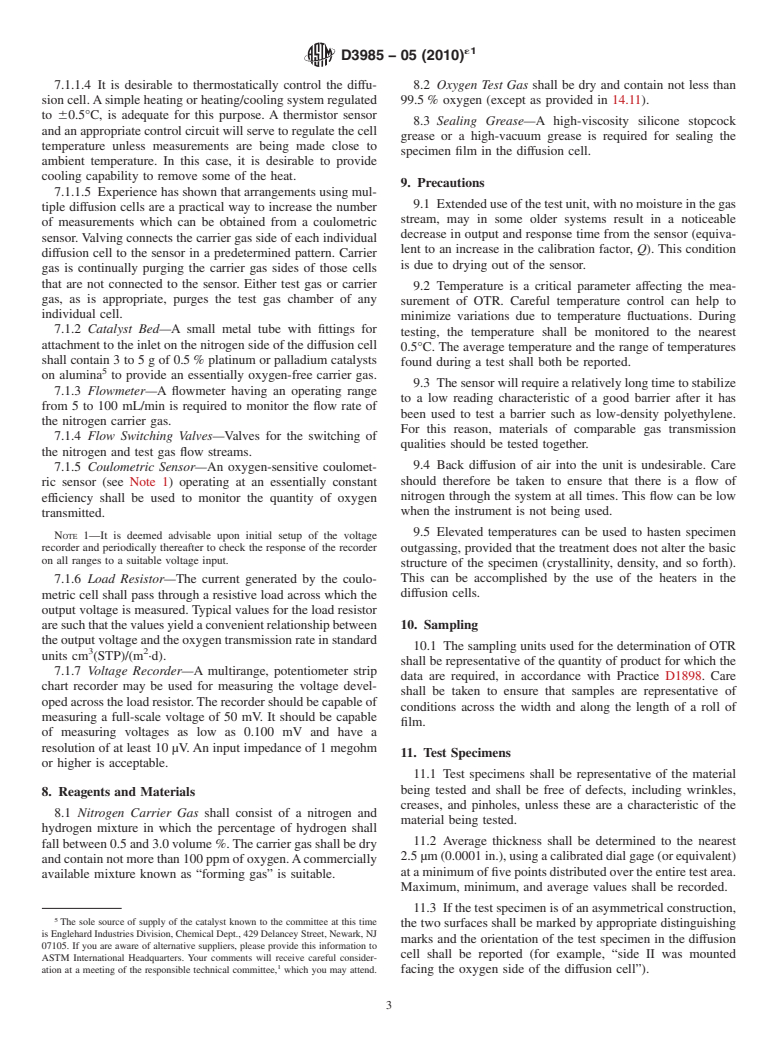

7.1 Oxygen Gas Transmission Apparatus,asdiagrammedin

5.1 The OTR is an important determinant of the packaging

Fig. 1 with the following:

protection afforded by barrier materials. It is not, however, the

7.1.1 Diffusion Cell shall consist of two metal halves,

sole determinant, and additional tests, based on experience,

which, when closed upon the test specimen, will accurately

must be used to correlate packaging performance with OTR. It

define a circular area. The volume enclosed by each cell half,

is suitable as a referee method of testing, provided that the

when clamped, is not critical; it should be small enough to

purchaser and the seller have agreed on sampling procedures,

allow for rapid gas exchange, but not so small that an

standardization procedures, test conditions, and acceptance

unsupported film which happens to sag or bulge will contact

criteria.

the top or bottom of the cell. The diffusion cell shall be

5.2 LimitedstatisticaldataoncorrelationswithTestMethod provided with a thermometer well for measuring temperature.

D1434 methods are available ; however, the oxygen transmis-

7.1.1.1 O-Ring—An appropriately sized groove, machined

sion rate of a standard reference material (see 12.1)as

into the oxygen (or test gas) side of the diffusion cell, retains a

determined manometrically by NIST, is in good agreement

neoprene O-ring. The test area is considered to be that area

with the values obtained in the coulometric interlaboratory test

established by the inside contact diameter of the compressed

using material from the same manufacturing lot.Thus, this test

O-ring when the diffusion cell is clamped shut against the test

method may be used as a referee method.

specimen.Thearea, A,canbeobtainedbymeasuringtheinside

diameteroftheimprintleftbytheO-ringonthespecimenafter

6. Interferences

it has been removed from the diffusion cell.

6.1 The presence of certain interfering substances in the

7.1.1.2 Thenitrogen(orcarriergas)sideofthediffusioncell

carrier gas stream may give rise to unwanted electrical outputs

shall have a flat raised rim. Since this rim is a critical sealing

and error factors. Interfering substances include free chlorine

surface against which the test specimen is pressed, it shall be

smooth and flat, without radial scratches.

7.1.1.3 Diffusion Cell Pneumatic Fittings—The diffusion

Supporting data have been filed atASTM International Headquarters and may

cell shall incorporate suitable fittings for the introduction and

beobtainedbyrequestingResearchReportRR:D20-1085.ContactASTMCustomer

Service at service@astm.org. exhaust of gases without significant loss or leakage.

´1

D3985 − 05 (2010)

7.1.1.4 It is desirable to thermostatically control the diffu- 8.2 Oxygen Test Gas shall be dry and contain not less than

sioncell.Asimpleheatingorheating/coolingsystemregulated 99.5% oxygen (except as provided in 14.11).

to 60.5°C, is adequate for this purpose. A thermistor sensor

8.3 Sealing Grease—A high-viscosity silicone stopcock

andanappropriatecontrolcircuitwillservetoregulatethecell

grease or a high-vacuum grease is required for sealing the

temperature unless measurements are being made close to

specimen film in the diffusion cell.

ambient temperature. In this case, it is desirable to provide

cooling capability to remove some of the heat.

9. Precautions

7.1.1.5 Experience has shown that arrangements using mul-

9.1 Extendeduseofthetestunit,withnomoistureinthegas

tiple diffusion cells are a practical way to increase the number

stream, may in some older systems result in a noticeable

of measurements which can be obtained from a coulometric

decrease in output and response time from the sensor (equiva-

sensor.Valving connects the carrier gas side of each individual

lent to an increase in the calibration factor, Q). This condition

diffusion cell to the sensor in a predetermined pattern. Carrier

is due to drying out of the sensor.

gas is continually purging the carrier gas sides of those cells

that are not connected to the sensor. Either test gas or carrier

9.2 Temperature is a critical parameter affecting the mea-

gas, as is appropriate, purges the test gas chamber of any

surement of OTR. Careful temperature control can help to

individual cell.

minimize variations due to temperature fluctuations. During

7.1.2 Catalyst Bed—A small metal tube with fittings for

testing, the temperature shall be monitored to the nearest

attachmenttotheinletonthenitrogensideofthediffusioncell

0.5°C. The average temperature and the range of temperatures

shall contain 3 to5gof0.5% platinum or palladium catalysts

found during a test shall both be reported.

on alumina to provide an essentially oxygen-free carrier gas.

9.3 Thesensorwillrequirearelativelylongtimetostabilize

7.1.3 Flowmeter—A flowmeter having an operating range

to a low reading characteristic of a good barrier after it has

from 5 to 100 mL/min is required to monitor the flow rate of

been used to test a barrier such as low-density polyethylene.

the nitrogen carrier gas.

For this reason, materials of comparable gas transmission

7.1.4 Flow Switching Valves—Valves for the switching of

qualities should be tested together.

the nitrogen and test gas flow streams.

9.4 Back diffusion of air into the unit is undesirable. Care

7.1.5 Coulometric Sensor—An oxygen-sensitive coulomet-

should therefore be taken to ensure that there is a flow of

ric sensor (see Note 1) operating at an essentially constant

nitrogen through the system at all times. This flow can be low

efficiency shall be used to monitor the quantity of oxygen

when the instrument is not being used.

transmitted.

9.5 Elevated temperatures can be used to hasten specimen

NOTE 1—It is deemed advisable upon initial setup of the voltage

recorder and periodically thereafter to check the response of the recorder outgassing, provided that the treatment does not alter the basic

on all ranges to a suitable voltage input.

structure of the specimen (crystallinity, density, and so forth).

This can be accomplished by the use of the heaters in the

7.1.6 Load Resistor—The current generated by the coulo-

diffusion cells.

metric cell shall pass through a resistive load across which the

output voltage is measured.Typical values for the load resistor

10. Sampling

aresuchthatthevaluesyieldaconvenientrelationshipbetween

theoutputvoltageandtheoxygentransmissionrateinstandard

10.1 The sampling units used for the determination of OTR

3 2

units cm (STP)/(m ·d).

shall be representative of the quantity of product for which the

7.1.7 Voltage Recorder—A multirange, potentiometer strip

data are required, in accordance with Practice D1898. Care

chart recorder may be used for measuring the voltage devel-

shall be taken to ensure that samples are representative of

opedacrosstheloadresistor.Therecordershouldbecapableof

conditions across the width and along the length of a roll of

measuring a full-scale voltage of 50 mV. It should be capable

film.

of measuring voltages as low as 0.100 mV and have a

resolution of at least 10 µV.An input impedance of 1 megohm

11. Test Specimens

or higher is acceptable.

11.1 Test specimens shall be representative of the material

being tested and shall be free of defects, including wrinkles,

8. Reagents and Materials

creases, and pinholes, unless these are a characteristic of the

8.1 Nitrogen Carrier Gas shall consist of a nitrogen and

material being tested.

hydrogen mixture in which the percentage of hydrogen shall

11.2 Average thickness shall be determined to the nearest

fallbetween0.5and3.0volume%.Thecarriergasshallbedry

2.5µm(0.0001in.),usingacalibrateddialgage(orequivalent)

andcontainnotmorethan100ppmofoxygen.Acommercially

ataminimumoffivepointsdistributedovertheentiretestarea.

available mixture known as “forming gas” is suitable.

Maximum, minimum, and average values shall be recorded.

11.3 Ifthetestspecimenisofanasymmetricalconstruction,

The sole source of supply of the catalyst known to the committee at this time

the two surfaces shall be marked by appropriate distinguishing

isEnglehardIndustriesDivision,ChemicalDept.,429DelanceyStreet,Newark,NJ

marks and the orientation of the test specimen in the diffusion

07105. If you are aware of alternative suppliers, please provide this information to

cell shall be reported (for example, “side II was mounted

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee, which you may attend. facing the oxygen side of the diffusion cell”).

´1

D3985 − 05 (2010)

12. Calibration materials to a condition where their measured OTRs will be

reproducible. Previous experience should serve as the primary

12.1 General Approach—The oxygen sensor used in this

guide to the suitability of a given conditioning regimen. If a

test method is a coulometric device that yields a linear output

material is being tested with which the user has no previous

as predicted by Faraday’s Law. In principle, four electrons are

experience, the effect of conditioning time should be investi-

producedbythesensorforeachmoleculeofoxygenthatpasses

gated and a regimen selected such that there is no significant

into it. Considering that the sensor is known to have a basic

effect due to conditioning time. In any case, the conditioning

efficiency of 95 to 98 %, it may be considered an “intrinsic”

procedure used should be included in the report section.

standard that does not r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.