ASTM F3136-22

(Test Method)Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting using a Dynamic Accumulation Method

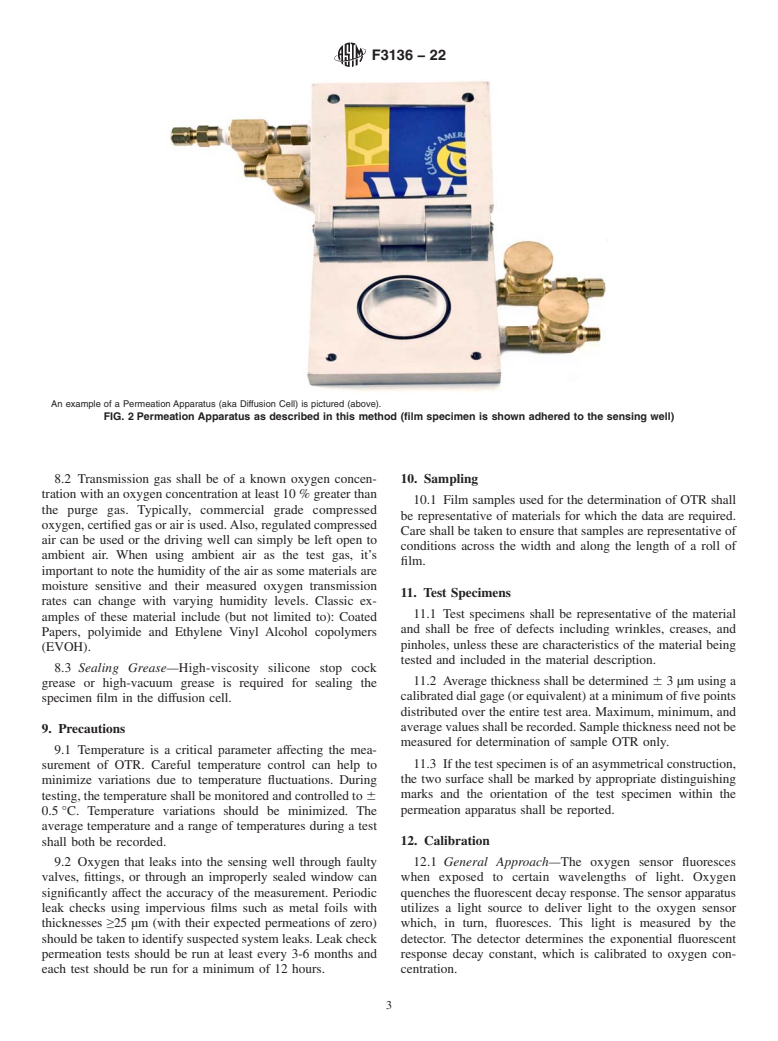

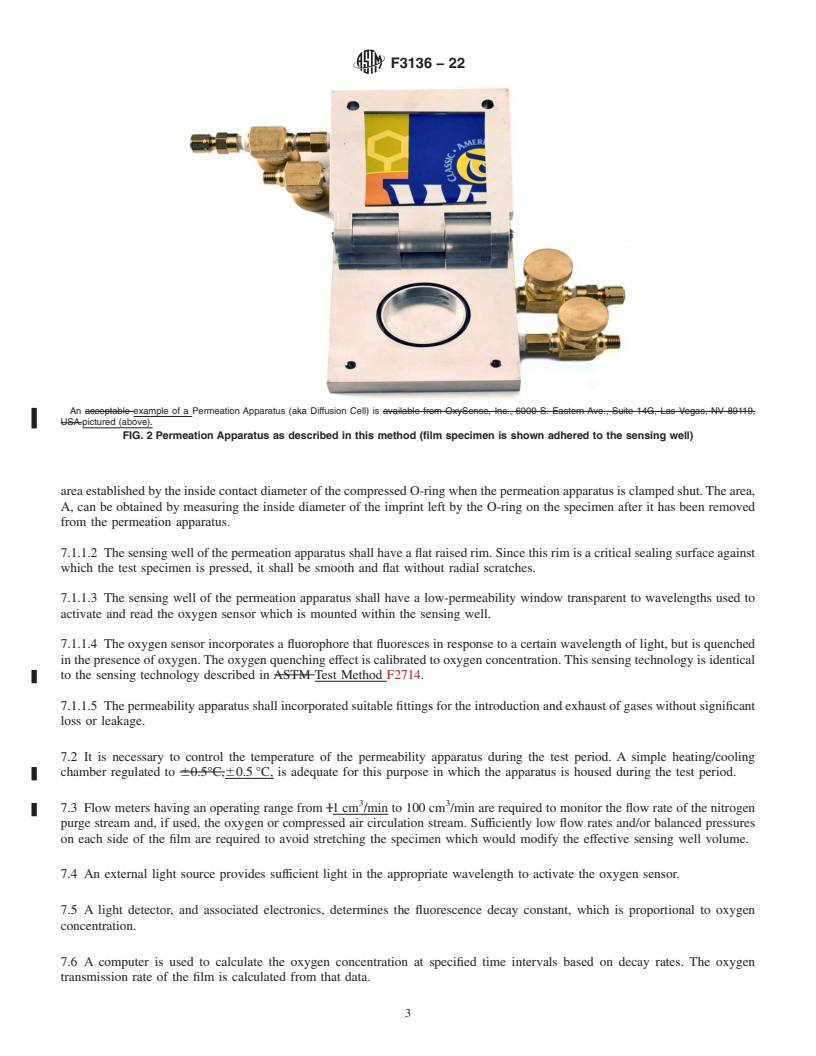

Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting using a Dynamic Accumulation Method

SIGNIFICANCE AND USE

5.1 The Oxygen Transmission Rate is an important determinant of packaging functionality afforded by packaging materials for a wide variety of packaged products including food, pharmaceuticals and medical devices. In some applications, sufficient oxygen must be allowed to permeate into the package. In others, the oxygen ingress must be minimized to maintain product quality.

5.2 Other ASTM Standard Methods to measure the oxygen transmission rate are described in Test Method D3985 and Test Method F2622.

SCOPE

1.1 This test method covers a procedure for determination of the transmission rate of oxygen gas through plastics in the form of film, sheeting, laminates, coextrusions, coated or uncoated papers or fabrics.

1.2 This test method is not the only method for measurement of the oxygen transmission rate (OTR). There are other methods of OTR determination that use other oxygen sensors and procedures.

1.3 The values stated in SI units are to be regarded as standard. Commonly used metric units used to report Oxygen Transmission Rate are included in Terminology, Procedure, Precision and Bias sections and in the Calculation section of the Appendix.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3136 − 22

Standard Test Method for

Oxygen Gas Transmission Rate through Plastic Film and

1

Sheeting using a Dynamic Accumulation Method

This standard is issued under the fixed designation F3136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers a procedure for determination

E691Practice for Conducting an Interlaboratory Study to

of the transmission rate of oxygen gas through plastics in the

Determine the Precision of a Test Method

form of film, sheeting, laminates, coextrusions, coated or

F2622Test Method for Oxygen Gas Transmission Rate

uncoated papers or fabrics.

Through Plastic Film and Sheeting UsingVarious Sensors

1.2 This test method is not the only method for measure-

F2714Test Method for Oxygen Headspace Analysis of

ment of the oxygen transmission rate (OTR). There are other

Packages Using Fluorescent Decay

methods of OTR determination that use other oxygen sensors

and procedures.

3. Terminology

1.3 The values stated in SI units are to be regarded as

3.1 Definitions:

standard. Commonly used metric units used to report Oxygen

3.1.1 Oxygen Transmission Rate (OTR), n—the quantity of

Transmission Rate are included in Terminology, Procedure,

oxygen gas passing through a unit area of the parallel surfaces

Precision and Bias sections and in the Calculation section of

of a plastic film per unit time under the conditions of test. The

the Appendix.

2

SI unit of transmission rate is the mol/(m ·s). The test condi-

1.4 This standard does not purport to address all of the

tions including temperature, relative humidity and oxygen

safety concerns, if any, associated with its use. It is the

partial pressure on both sides of the film must be stated in the

responsibility of the user of this standard to establish appro-

report.

priate safety, health, and environmental practices and deter-

3.1.1.1 Discussion—A commonly used unit of OTR is the

mine the applicability of regulatory limitations prior to use.

3 2

cm (STP)/(m ·day) at one atmosphere pressure difference

1.5 This international standard was developed in accor-

3

where 1 cm (STP) is 44.62 µmol, 1 atmosphere is 0.1013

dance with internationally recognized principles on standard-

3

MPa, and one day is 86.4 × 10 s. The OTR in SI units is

ization established in the Decision on Principles for the

obtained by multiplying the value in commonly used units by

Development of International Standards, Guides and Recom-

-10

5.160 × 10 .

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

2. Referenced Documents

4.1 The specimen is mounted as a sealed semi-barrier

2

2.1 ASTM Standards:

between two chambers, which together make up the perme-

D3985Test Method for Oxygen Gas Transmission Rate

ation apparatus. The sensing well which contains the oxygen

Through Plastic Film and Sheeting Using a Coulometric

sensor is slowly purged by a stream of pure nitrogen or other

Sensor

oxygen deficient gas mixture until the oxygen concentration

represents that of the purge gas. A commercial grade of

compressed nitrogen containing less than 0.05% oxygen is

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF02onPrimary recommended.Agasofknownoxygenconcentration,typically

Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

air or pure oxygen, is directed into the opposite chamber, the

Permeation.

driving well. Oxygen concentration in the sensing well con-

Current edition approved Dec. 1, 2022. Published December 2022. Originally

taining the oxygen sensor is measured periodically and the

approved in 2015. Last previous edition approved in 2015 as F3136–15. DOI:

10.1520/F3136-22.

accumulating oxygen concentration recorded. The Oxygen

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Transmission Rate (OTR) parameter is determined from the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

slope of the logarithm of accumulated oxygen concentration in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the sensing well versus time as described in 14.2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3136 − 22

5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3136 − 15 F3136 − 22

Standard Test Method for

Oxygen Gas Transmission Rate through Plastic Film and

1

Sheeting using a Dynamic Accumulation Method

This standard is issued under the fixed designation F3136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determination of the transmission rate of oxygen gas through plastics in the form of

film, sheeting, laminates, coextrusions, coated or uncoated papers or fabrics.

1.2 This test method is not the only method for measurement of the oxygen transmission rate (OTR). There are other methods of

OTR determination that use other oxygen sensors and procedures.

1.3 The values stated in SI units are to be regarded as standard. Commonly used metric units used to report Oxygen Transmission

Rate are included in Terminology, Procedure, Precision and Bias sections and in the Calculation section of the Appendix.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D3985 Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F2622 Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using Various Sensors

F2714 Test Method for Oxygen Headspace Analysis of Packages Using Fluorescent Decay

3. Terminology

3.1 Definitions:

3.1.1 Oxygen Transmission Rate (OTR)—(OTR), n—the quantity of oxygen gas passing through a unit area of the parallel surfaces

1

This test method is under the jurisdiction of ASTM Committee F02 on FlexiblePrimary Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

Permeation.

Current edition approved April 1, 2015Dec. 1, 2022. Published April 2015December 2022. Originally approved in 2015. Last previous edition approved in 2015 as

F3136 – 15. DOI: 10.1520/F3136-15.10.1520/F3136-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3136 − 22

2

of a plastic film per unit time under the conditions of test. The SI unit of transmission rate is the mol/(m —s). The test conditions

including temperature, relative humidity and oxygen partial pressure on both sides of the film must be stated in the report.

3.1.1.1 Discussion—

3 2 3

A commonly used unit of OTR is the cm (STP)/(m —day) at one atmosphere pressure difference where 1 cm (STP) is 44.62 μmol,

3

1 atmosphere is 0.1013 MPa, and one day is 86.4 × 10 s. The OTR in SI units is obtained by multiplying the value in commonly

-10

used units by 5.160 × 10 .

4. Summary of Test Method

4.1 The specimen is mounted as a sealed semi-barrier between two chambers, which together make up the permeation apparatus.

The sensing well which contains the oxygen sensor is slowly purged by a stream of pure nitrogen or other oxygen deficient gas

mixture until the oxygen concentration represents that of the purge gas. A commercial grade of compressed nitrogen containing

less than 0.05%0.05 % oxygen is recommended. A gas of known oxygen concentration, typically air or pure oxygen, is directed

into the opposite chamber, the driving well. Oxygen concentration in the sensing well containing the oxygen sensor is measured

periodically and the accumul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.