ASTM D3787-07

(Test Method)Standard Test Method for Bursting Strength of Textiles-Constant-Rate-of-Traverse (CRT) Ball Burst Test

Standard Test Method for Bursting Strength of Textiles-Constant-Rate-of-Traverse (CRT) Ball Burst Test

SIGNIFICANCE AND USE

This test method for the determination of ball bursting strength of textiles is being used by the textile industry for the evaluation of a wide variety of fabrics.

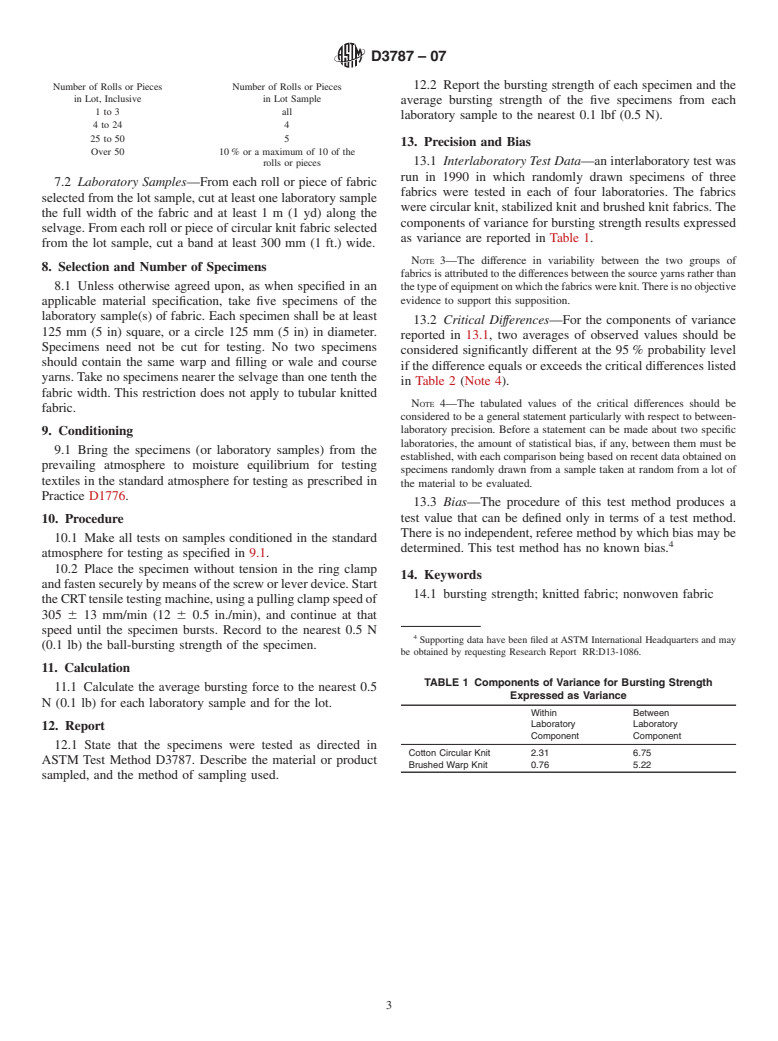

Test results obtained using the procedures in Test Method D 3787 have not been correlated with actual performance. Test Method D 3787 is considered satisfactory for acceptance testing of commercial shipments of textiles fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In cases of disagreement arising from differences in values reported by the purchaser and the seller when using Test Method D 3787 for acceptance testing, the statistical bias, if any, between the laboratory of the purchaser and the laboratory of the seller should be determined with comparison based on testing specimens randomly drawn from one sample of material of the type being evaluated.

Note 2—The kind force transfer and strength that occur when knitted goods are worn is prevented by clamping them as directed in this test method.

5.2.1 If there are differences of practical significance between reported test results for two (or more) laboratories, comparative tests should be performed to determine if there is a statistical bias between them. The test samples used should be: as homogeneous as possible, drawn from the material from which the disparate test results were obtained, and randomly assigned in equal numbers to the laboratories for testing. Other materials with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data at a probability level chosen prior to the testing series. If a bias is found, either the cause must be determined and corrected or future test results must be adjusted in consideration of known bias.

SCOPE

1.1 This test method describes the measurement for bursting strength with a ball burst strength tester of textiles or garments that exhibit a high degree of ultimate elongation.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the test, the inch-pound units are shown in parenthesis. The values stated in each system are not exact equivalents; therefore, each system may be used independently of the other. Combining values from the two systems may result in nonconformance within the specification.Note 1

For the measurement of bursting strength with a hydraulic testing machine, refer to Test Method D 3786.

This standard may involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3787–07

Standard Test Method for

Bursting Strength of Textiles—Constant-Rate-of-Traverse

1

(CRT) Ball Burst Test

This standard is issued under the fixed designation D3787; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D3786 Test Method for Bursting Strength of Textile

Fabrics—Diaphragm Bursting Strength Tester Method

1.1 Thistestmethoddescribesthemeasurementforbursting

D4850 Terminology Relating to Fabrics and Fabric Test

strength with a ball burst strength tester of textiles or garments

Methods

that exhibit a high degree of ultimate elongation.

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard.

3.1 For all terminology relating to D13.59, Fabric Test

1.3 The values stated in either SI units or inch-pound units

Methods, General, refer to Terminology D4850.

are to be regarded separately as the standard. Within the test,

3.1.1 The following terms are relevant to this standard:

the inch-pound units are shown in parenthesis. The values

bursting strength, constant–rate-of-traverse (CRT) tensile test-

stated in each system are not exact equivalents; therefore, each

ing machine, fabric, knitted, fabric, nonwoven.

system may be used independently of the other. Combining

3.2 For all other terminology related to textiles, refer to

values from the two systems may result in nonconformance

Terminology D123.

within the specification.

NOTE 1—For the measurement of bursting strength with a hydraulic 4. Summary of Test Method

testing machine, refer to Test Method D3786.

4.1 A specimen is securely clamped without tension be-

1.4 This standard may involve hazardous materials, opera-

tween grooved, circular plates of the ball burst attachment

tionsandequipment.Thisstandarddoesnotpurporttoaddress secured to the pulling (movable) jaw for the constant-rate-of-

all of the safety concerns, if any, associated with its use. It is traverse (CRT) testing machine. A force is exerted against the

the responsibility of the user of this standard to establish

specimen by a polished, hardened steel ball that is attached to

appropriate safety and health practices and determine the the pendulum-actuating (fixed) clamp of the machine, until

applicability of regulatory limitations prior to use.

rupture occurs.

2. Referenced Documents 5. Significance and Use

2

2.1 ASTM Standards:

5.1 This test method for the determination of ball bursting

D76 Specification for Tensile Testing Machines for Textiles strength of textiles is being used by the textile industry for the

D123 Terminology Relating to Textiles

evaluation of a wide variety of fabrics.

D1776 Practice for Conditioning and Testing Textiles 5.2 Test results obtained using the procedures in Test

Method D3787 have not been correlated with actual perfor-

mance. Test Method D3787 is considered satisfactory for

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

acceptance testing of commercial shipments of textiles fabrics

and is the direct responsibility of D13.59 on Fabric Test Methods, General.

for bursting strength since the method has been used exten-

Current edition approved July 1, 2007. Published August 2007. Originally

sively in the trade for acceptance testing. In cases of disagree-

approved in 2001. Last previous edition approved in 2001 as D3787–01. DOI:

10.1520/D3787-07.

ment arising from differences in values reported by the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

purchaser and the seller when using Test Method D3787 for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

acceptance testing, the statistical bias, if any, between the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. laboratory of the purchaser and the laboratory of the seller

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3787–07

should be determined with comparison based on testing speci- 6. Apparatus

mens randomly drawn from one sample of material of the type

6.1 Constant-Rate-of-Traverse (CRT) Tensile Testing Ma-

being evaluated.

chine (CRT), as specified in Specification D76, with a ball-

burst attachment replacing the clamp assembly.

NOTE 2—The kind force transfer and strength that occur when knitted

3

6.2 Ball-Burst Attachment, consisting of an attachment

goods are worn is prevented by clamping them as directed in this

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.