ASTM D3700-12

(Practice)Standard Practice for Obtaining LPG Samples Using a Floating Piston Cylinder

Standard Practice for Obtaining LPG Samples Using a Floating Piston Cylinder

SIGNIFICANCE AND USE

5.1 This practice allows the collection of a representative sample of LPG that may contain trace volatile dissolved components such as methane, ethane, and nitrogen. Sampling by Practice D1265 can result in a small, but predictable, loss of these lighter components. Practice D1265 is suitable for collecting samples for routine specification testing, as the small loss of light components is not significant under Specification D1835 specification requirements. Practice D3700 is recommended whenever highly accurate determination of light components is required. For example, compositions determined on samples collected according to Practice D3700 may be used to establish the product value of NGL mixtures (see Appendix X1).

SCOPE

1.1 This practice covers the equipment and procedures for obtaining a representative sample of specification liquefied petroleum gas (LPG), such as specified in ASTM Specification D1835, GPA 2140, and comparable international standards. It may also be used for other natural gas liquid (NGL) products that are normally single phase (for example, NGL mix, field butane, and so forth), defined in other industry specifications or contractual agreements.

1.2 This practice is not intended for non-specification products that contain significant quantities of undissolved gases (N2, CO2), free water or other separated phases, such as raw or unprocessed gas/liquids mixtures and related materials. The same equipment can be used for these purposes, but additional precautions are generally needed to obtain representative samples of multi-phase products (see Appendix X1).

1.3 This practice includes recommendations for the location of a sample point in a line or vessel. It is the responsibility of the user to ensure that the sampling point is located so as to obtain a representative sample.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3700 − 12

StandardPractice for

1

Obtaining LPG Samples Using a Floating Piston Cylinder

This standard is issued under the fixed designation D3700; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1835 Specification for Liquefied Petroleum (LP) Gases

3

2.2 GPA Standards:

1.1 This practice covers the equipment and procedures for

GPA 2174 Obtaining Liquid Hydrocarbon Samples for

obtaining a representative sample of specification liquefied

Analysis by Gas Chromatography

petroleum gas (LPG), such as specified inASTM Specification

GPA 2140 Liquefied Petroleum Gas Specifications and Test

D1835, GPA 2140, and comparable international standards. It

Methods

may also be used for other natural gas liquid (NGL) products

that are normally single phase (for example, NGL mix, field

3. Terminology

butane,andsoforth),definedinotherindustryspecificationsor

3.1 Definitions:

contractual agreements.

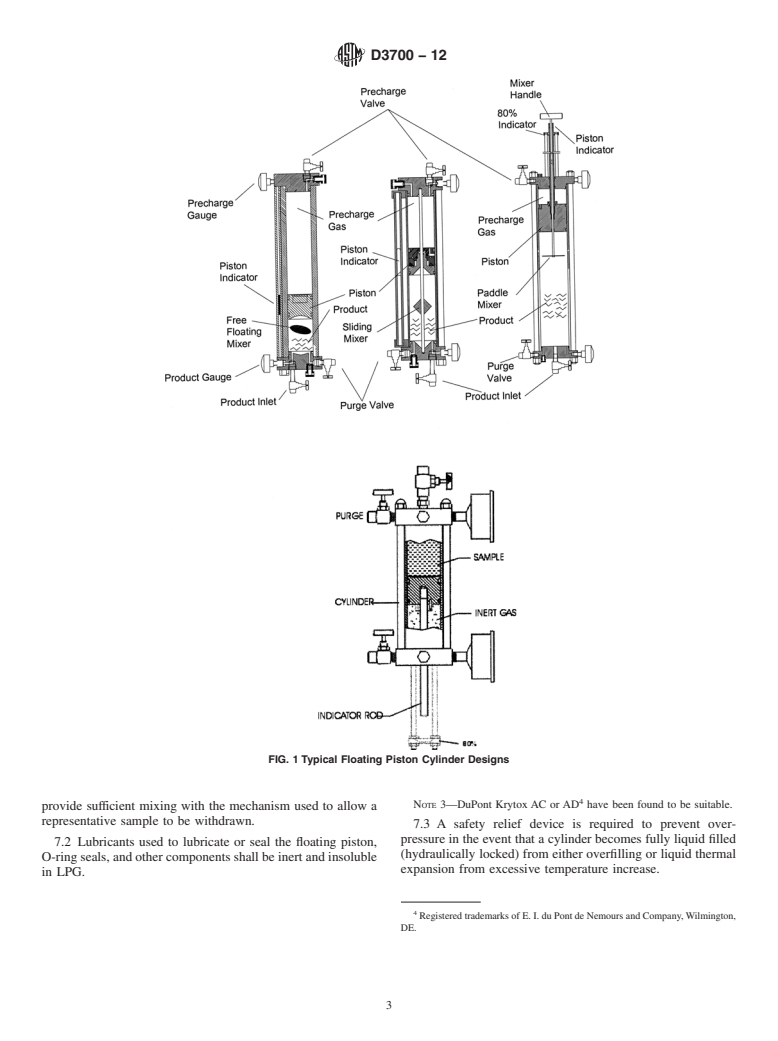

3.1.1 floating piston cylinder (FPC), n—a high pressure

1.2 This practice is not intended for non-specification prod-

sample container, with a free floating internal piston that

ucts that contain significant quantities of undissolved gases

effectively divides the container into two separate compart-

(N ,CO ), free water or other separated phases, such as raw or

2 2

ments.

unprocessed gas/liquids mixtures and related materials. The

3.1.1.1 Discussion—A floating piston cylinder is used to

same equipment can be used for these purposes, but additional

collect a sample of liquid under pressure without the formation

precautions are generally needed to obtain representative

of a gaseous phase which can result in changes in the

samples of multi-phase products (see Appendix X1).

composition of the liquid sample.

1.3 This practice includes recommendations for the location

3.1.2 maximum fill volume (reduced fill volume), n—the

of a sample point in a line or vessel. It is the responsibility of

volume of a container occupied by the sample, usually ex-

the user to ensure that the sampling point is located so as to

pressed as a percentage of the total capacity.

obtain a representative sample.

3.1.2.1 Discussion—Some regulatory agencies use the ex-

pressions “maximum fill density” and “reduced fill density.”

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

4. Summary of Practice

only.

4.1 Aliquid petroleum gas (LPG) sample is transferred as a

1.5 This standard does not purport to address all of the

liquid under pressure from a sample point to a floating piston

safety concerns, if any, associated with its use. It is the

cylinder. The floating piston cylinder (FPC) is designed to

responsibility of the user of this standard to establish appro-

collect liquid samples with no vaporization by displacing a

priate safety and health practices, and determine the applica-

pistonagainstapressurizingfluid(preferablyaninertgas).The

bility of regulatory limitations prior to use.

piston serves as a physical barrier between the sample and the

pressurizing fluid, at the sampling pressure.The position of the

2. Referenced Documents

piston at the end of sampling indicates the percent fill of the

2

2.1 ASTM Standards:

sample cylinder.

D1265 Practice for Sampling Liquefied Petroleum (LP)

4.2 It is the responsibility of the user of this practice to

Gases, Manual Method

locate the sample point at a suitable location and orientation

where the product being sampled is a representative, single

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

phase, homogeneous liquid.

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.H0on

Liquefied Petroleum Gas.

5. Significance and Use

Current edition approved Nov. 1, 2012. Published February 2013. Originally

approved in 1978. Last previous edition approved in 2007 as D3700–07. DOI: 5.1 This practice allows the collection of a representative

10.1520/D3700-12.

sample of LPG that may contain trace volatile dissolved

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Gas ProcessorsAssociation (GPA), 6526 E. 60th St.,Tulsa, OK

the ASTM website. 74145, www.gpaglobal.org

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3700 − 12

components such as meth

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3700 − 07 D3700 − 12

Standard Practice for

1

Obtaining LPG Samples Using a Floating Piston Cylinder

This standard is issued under the fixed designation D3700; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the equipment and procedures for obtaining a representative sample of specification liquefied petroleum

gas (LPG), such as specified in ASTM Specification D1835, GPA 2140, and comparable international standards. It may also be

used for other natural gas liquid (NGL) products that are normally single phase (NGL (for example, NGL mix, field butane, and

so forth), defined in other industry specifications or contractual agreements.

1.2 This practice is not intended for non-specification products that contain significant quantities of undissolved gases (N ,

2

CO ), free water or other separated phases, such as raw or unprocessed gas/liquids mixtures and related materials. The same

2

equipment can be used for these purposes, but additional precautions are generally needed to obtain representative samples of

multi-phase products (see Appendix X1).

1.3 This practice includes recommendations for the location of a sample point in a line or vessel. It is the responsibility of the

user to ensure that the sampling point is located so as to obtain a representative sample.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1265 Practice for Sampling Liquefied Petroleum (LP) Gases, Manual Method

D1835 Specification for Liquefied Petroleum (LP) Gases

3

2.2 GPA Standards:

GPA 2174 Obtaining Liquid Hydrocarbon Samples for Analysis by Gas Chromatography

GPA 2140 Liquefied Petroleum Gas Specifications and Test Methods

3. Terminology

3.1 Definitions:

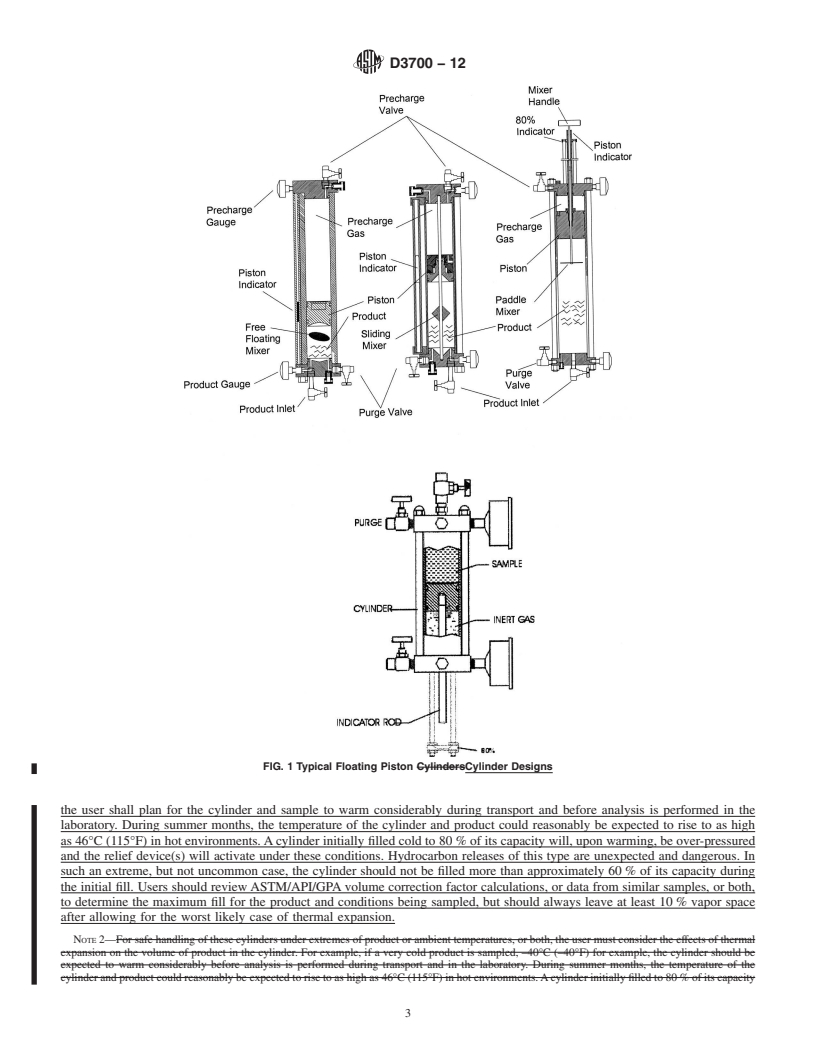

3.1.1 floating piston cylinder (FPC)—(FPC), n—a high pressure sample container, with a free floating internal piston that

effectively divides the container into two separate compartments.

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.H0 on

Liquefied Petroleum Gas.

Current edition approved Feb. 15, 2007Nov. 1, 2012. Published March 2007February 2013. Originally approved in 1978. Last previous edition approved in 20012007 as

D3700–01.–07. DOI: 10.1520/D3700-07.10.1520/D3700-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Gas Processors Association (GPA), 6526 E. 60th St., Tulsa, OK 74145.74145, www.gpaglobal.org

3.1.1.1 Discussion—

A floating piston cylinder is used to collect a sample of liquid under pressure without the formation of a gaseous phase which can

result in changes in the composition of the liquid sample.

3.1.2 maximum fill densityvolume (reduced fill density)—volume), n—the volume of a container occupied by the sample, usually

expressed as a percentage of the total capacity.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3700 − 12

3.1.2.1 Discussion—

Some regulatory agencies use the expressions “maximum fill density” and “reduced fill density.”

4. Summary of Practice

4.1 A liquid LPG petroleum gas (LPG) sample is transferred as a liquid under pressure from a sample point to a floating piston

cylinder. The floating piston cylinder (FPC) is designed to collect liquid samples with no vaporization by displacing a piston

against a pressurizing fluid (usually(preferably an inert gas). The piston serves as a physical barrier between the sample and the

pressurizing fluid, at the sampling pressure. The position of the piston at the end of sampling indicates the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.