ASTM D1995-92(2017)

(Test Method)Standard Test Methods for Multi-Modal Strength Testing of Autohesives (Contact Adhesives)

Standard Test Methods for Multi-Modal Strength Testing of Autohesives (Contact Adhesives)

SIGNIFICANCE AND USE

5.1 The application procedures in these test methods yield films free of the irregularities, artifacts, and variations inherent in brushing, spraying, or trowelling. Accordingly, these test methods measure the strength of autohesive bonds between two autohesive films whose topography is characteristic of the autohesive itself rather than the artifacts of the application procedure. It is recommended that this information be considered in extrapolating results from these test methods.

5.2 The magnitude of the measured bond strengths also depends on other factors such as film thickness, the manner in which pressure is applied, the magnitude and duration of the application of pressure, and the temperature and humidity at various stages of the test. Accordingly, these parameters should be chosen in a manner consistent with the end use of the autohesive.

5.3 In case of a dispute arising from differences in reported results when using these test methods for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to diagnose the causes for lack of repeatability between their laboratories. Competent statistical assistance is recommended for the investigation of precision. As a minimum, the two parties should select a group of test specimens and visually examine their failure modes. The average results from the two laboratories should then be compared using Student’s t-test for unpaired data and an acceptable probability level should be chosen by the two parties before testing is begun.

FIG. 1 One Type of Knife Applicator

SCOPE

1.1 These test methods cover procedures by which autohesives can be tested in four commonly practiced stressing modes, namely: compression shear, cleavage, climbing drum peel, and T-peel, and in various combinations of rigid-to-rigid, flexible-to-rigid, and flexible-to-flexible adherends that include wood, aluminum, steel flakeboard, and plastic laminates. Quantitative test methods that involve bond formation by impact are also provided. Three pressure modes are provided: static, roller, and impact. Because there are many types of contact adhesives being used to bond many different materials under widely differing conditions, these test methods are designed to allow the user to select the test mode, coating thickness, temperature and relative humidity conditions, pressure magnitude and mode, open time, and bond-conditioning time.

1.1.1 The bond-formation process used with autohesives is unlike that of all other adhesives and in consequence, testing of autohesives requires methods that are unlike those provided by other ASTM standards. See Annex A1.

1.2 A choice of adherends is available in each test mode. The combination of adherends that can be bonded together is limited to those shown in Appendix X1.

1.3 Methods for application of pressure are available in each test mode. For a particular combination of substrates, the means available for application of pressure are limited to those shown in Appendix X2.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.5.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1995 − 92 (Reapproved 2017)

Standard Test Methods for

Multi-Modal Strength Testing of Autohesives (Contact

Adhesives)

This standard is issued under the fixed designation D1995; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mine the applicability of regulatory limitations prior to use.

Specific precautionary statements are given in 7.5.

1.1 These test methods cover procedures by which autohe-

1.6 This international standard was developed in accor-

sives can be tested in four commonly practiced stressing

dance with internationally recognized principles on standard-

modes, namely: compression shear, cleavage, climbing drum

ization established in the Decision on Principles for the

peel, and T-peel, and in various combinations of rigid-to-rigid,

Development of International Standards, Guides and Recom-

flexible-to-rigid, and flexible-to-flexible adherends that include

mendations issued by the World Trade Organization Technical

wood, aluminum, steel flakeboard, and plastic laminates.

Barriers to Trade (TBT) Committee.

Quantitative test methods that involve bond formation by

impact are also provided. Three pressure modes are provided:

2. Referenced Documents

static, roller, and impact. Because there are many types of

2.1 ASTM Standards:

contact adhesives being used to bond many different materials

D905 Test Method for Strength Properties of Adhesive

under widely differing conditions, these test methods are

Bonds in Shear by Compression Loading

designed to allow the user to select the test mode, coating

D907 Terminology of Adhesives

thickness, temperature and relative humidity conditions, pres-

D1062 Test Method for Cleavage Strength of Metal-to-

sure magnitude and mode, open time, and bond-conditioning

Metal Adhesive Bonds

time.

D1151 Practice for Effect of Moisture and Temperature on

1.1.1 The bond-formation process used with autohesives is

Adhesive Bonds

unlikethatofallotheradhesivesandinconsequence,testingof

D1781 Test Method for Climbing Drum Peel for Adhesives

autohesives requires methods that are unlike those provided by

D1876 Test Method for Peel Resistance of Adhesives (T-

other ASTM standards. See Annex A1.

Peel Test)

1.2 A choice of adherends is available in each test mode.

D2651 GuideforPreparationofMetalSurfacesforAdhesive

The combination of adherends that can be bonded together is

Bonding

limited to those shown in Appendix X1.

E4 Practices for Force Verification of Testing Machines

1.3 Methodsforapplicationofpressureareavailableineach

test mode. For a particular combination of substrates, the 3. Terminology

means available for application of pressure are limited to those

3.1 Definitions:

shown in Appendix X2.

3.1.1 Many terms in these test methods are defined in

Terminology D907.

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3.1.2 autohesion, n—adhesion developed by interdiffusion

of the molecules of two solid surfaces of the same material and

conversions to SI units that are provided for information only

and are not considered standard. consequent obliteration of the interface between them.

3.1.3 autohesive, n—an adhesive possessing the property of

1.5 This standard does not purport to address all of the

autohesion. (Also called contact-bond adhesive and dry-bond

safety concerns, if any, associated with its use. It is the

adhesive.)

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.1.4 shear strength, n—in adhesive joint, the maximum

average stress when a force is applied parallel to the joint.

These test methods are under the jurisdiction of ASTM Committee D14 on

Adhesives and are the direct responsibility of Subcommittee D14.70 on Construc-

tion Adhesives. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2017. Published November 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2011 as D1995 – 92 (2011). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D1995-92R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1995 − 92 (2017)

3.1.4.1 Discussion—In most adhesive test methods, the acceptable probability level should be chosen by the two

shearstrengthisactuallythemaximumaveragestressatfailure parties before testing is begun.

ofthespecimen,notnecessarilythetruemaximumstressinthe

material.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 autohesive (contact) failure, n—a condition in which

no contact appears to have occurred between the two layers of

autohesive, as evidence by visual inspection of the specimen

after destructive testing.

3.2.2 bond-conditioning time, n—the time elapsed between

making the bonded assembly and testing it or specimens made

from it.

4. Summary of Test Methods

4.1 The autohesive is conditioned to the temperature se-

lected for the coating application, the substrates are surfaced

flat, precut or cleaned, or both, as required, and then condi-

tioned to the temperature and humidity preselected for the

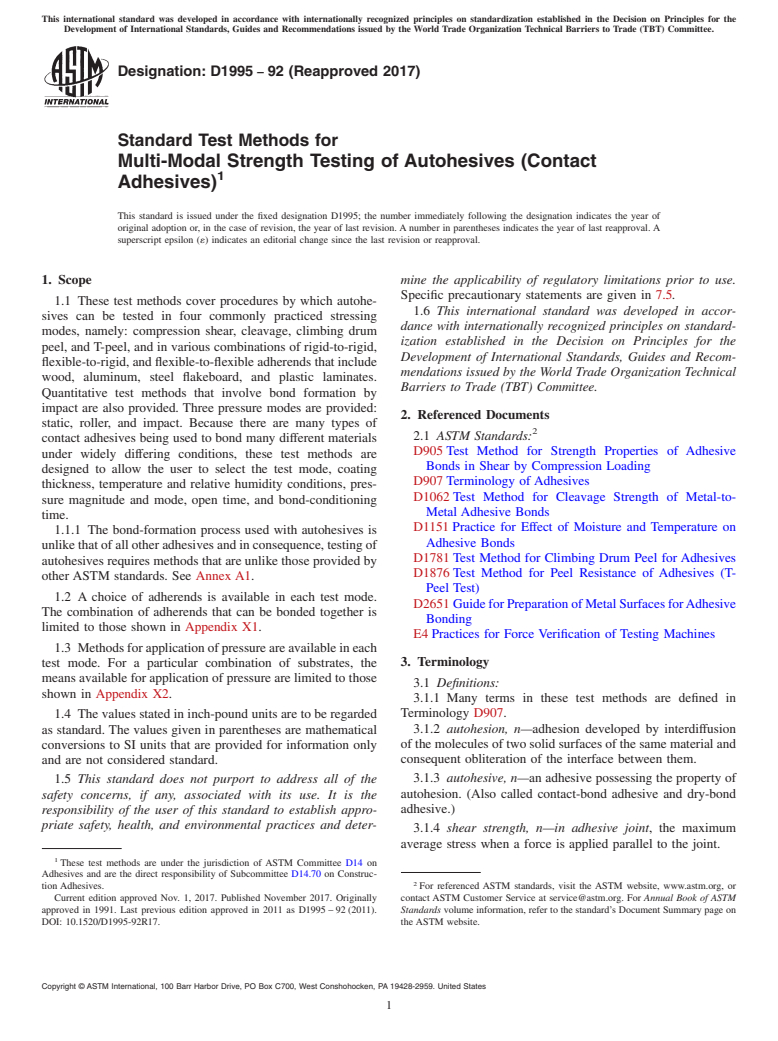

FIG. 1 One Type of Knife Applicator

coating application. Under controlled temperature and

humidity, a film of autohesive of predetermined wet-film

6. Apparatus

thickness is coated on to the substrates, and allowed to dry for

6.1 Testing Machines:

the duration of the open-assembly time. The coated materials

6.1.1 Test Methods D905, D1062, D1781, D1876, and

are brought together with light finger pressure, and bonded

Guide D2651 independently specify the testing machine rel-

assemblies are made by applying pressure. Pressure may be

evant to these test methods.

applied in one of three ways: static, impact, or roller. Assem-

6.1.2 To perform all tests in these test methods, the testing

blies are conditioned in a controlled environment for a speci-

machine must meet the following requirements:

fied time, the bond-conditioning time. Assemblies are cut into

6.1.2.1 Capability of performing tests in tension and com-

specimens where required.Assemblies requiring no cutting, or

pression; load range 4400 lb (2000 N).

precut specimens, are tested destructively in either of the four

6.1.2.2 Rate of movement of the cross-head must be con-

modes described in Sections 8, 9, 10, and 11.

stant and independent of any fluctuation of the load.

6.1.2.3 A range of cross-head speeds from 0.05 in./min

5. Significance and Use

(1.27 mm/min) to 2 in./min, (50 mm/min).

5.1 The application procedures in these test methods yield

6.1.2.4 The machine must be provided with a load-rate

films free of the irregularities, artifacts, and variations inherent

controller capable of controlling the load rate from 600 to 700

in brushing, spraying, or trowelling. Accordingly, these test

lbf/min (2700 to 3200 N/min).

methods measure the strength of autohesive bonds between

6.1.2.5 Autographic equipment to record the load-versus-

two autohesive films whose topography is characteristic of the

head movement.

autohesive itself rather than the artifacts of the application

6.1.3 Verification of the testing equipment may be made in

procedure. It is recommended that this information be consid-

accordance with the recommendations of Practices E4.

ered in extrapolating results from these test methods.

6.2 Equipment for Environmental Temperature and Humid-

5.2 The magnitude of the measured bond strengths also

ity Control—Equipment must be capable of maintaining rela-

depends on other factors such as film thickness, the manner in

tive humidity within 62 % of the selected value, and tempera-

which pressure is applied, the magnitude and duration of the

ture within 62°F (61°C) of the selected value.

application of pressure, and the temperature and humidity at

6.3 Applicators—Fixed or variable-gap applicators, com-

variousstagesofthetest.Accordingly,theseparametersshould

monly called knife applicators, may be used. The knife design,

be chosen in a manner consistent with the end use of the

shown in Fig. 1 or similar applicators provided with side

autohesive.

guide arms at least 1 in. (25 mm) long, are preferred.

5.3 In case of a dispute arising from differences in reported

Applicators shall be wide enough for the guide arms to ride on

results when using these test methods for acceptance testing of

the rider pieces and at least 1 in. (25 mm), away from the edge

commercial shipments, the purchaser and the supplier should

of center substrate during application, as in Fig. 2. Wide-

conduct comparative tests to diagnose the causes for lack of

wound-rod applicators may also be used for deposition of wet

repeatability between their laboratories. Competent statistical

films 0.002 to 0.010 in. (0.051 to 0.254 mm) thick. These

assistance is recommended for the investigation of precision.

applicators obviate the need for restraining devices to maintain

As a minimum, the two parties should select a group of test

flatness of sheet substrates while coating and are generally

specimens and visually examine their failure modes. The

average results from the two laboratories should then be

compared using Student’s t-test for unpaired data and an Available from Precision Gage and Tool Co., Dayton, Ohio 45410.

D1995 − 92 (2017)

FIG. 2 Applicator Placed on Material for Coating

preferred over knife applicators provided the required wet-film

thickness does not exceed 0.01 in. (0.254 mm). The wide-

wound portion of the rod should be at least 2 in. (50 mm)

longer than the adherend width. The wet-film thickness depos-

ited by all wide-wound-rod applicators is not predictable from

the diameter of the wire. Consult the manufacturer’s data.

6.4 Float-Glass Plate, ⁄4 in. (6 mm) minimum thickness,

minimum width and length 12 and 17 in. (0.3 and 0.4 m).

6.5 Restraining Devices, for coating sheet substrates while

using knife applicators, restraining devices are required to

maintain flatness.

6.5.1 Machinists’Flat Magnetic Table, recommended size 8

by 17 in. (0.2 by 0.4 m). (For steel only.)

6.5.2 Vacuum Table, minimum size 8 by 17 in. (0.2 by 0.4

m).

6.5.3 Whenever restraining devices in 6.5.1 and 6.5.2 are

not available and knife applicators are to be used, sheet

substrates can be rendered flat by taping their back sides to the

plate-glass with 1 in. (25 mm) wide double-coated pressure-

sensitive tape. The tape selected should allow removal of the

sheets without creasing them.

6.6 Pressure-Application Equipment—Several methods for

the application of pressure are provided. Selection is made by

the user on the basis of field-use requirements.

6.6.1 Static-Pressure-Application Equipment—Hydraulic

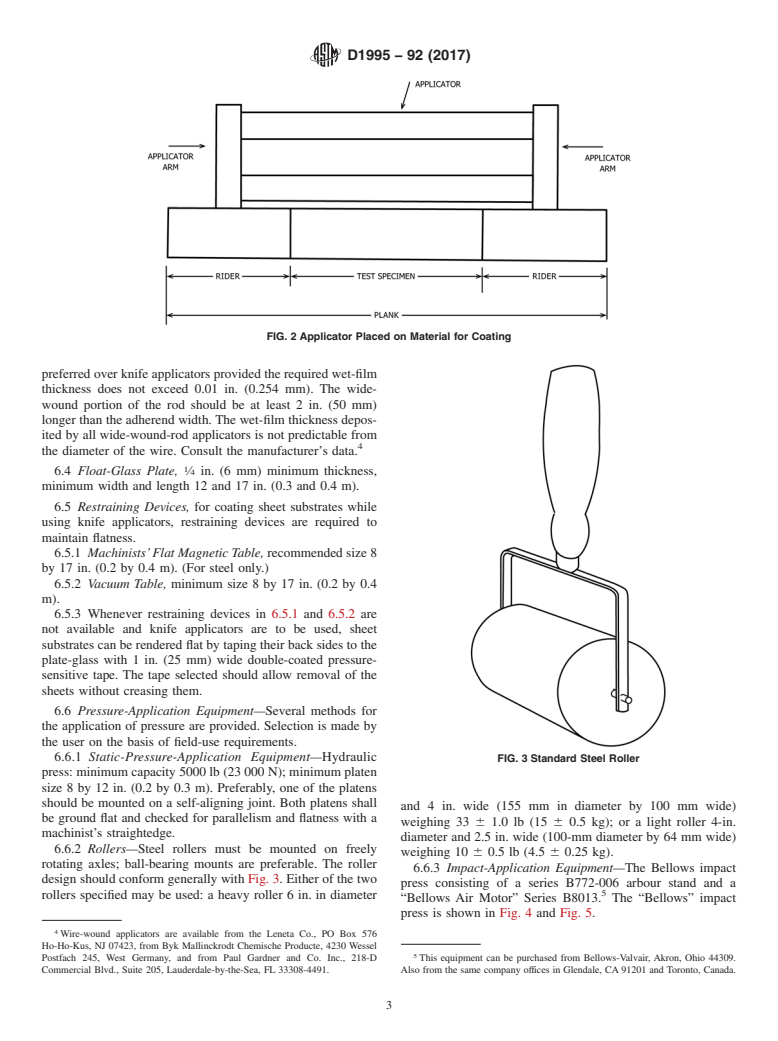

FIG. 3 Standard Steel Roller

press: minimum capacity 5000 lb (23 000 N); minimum platen

size 8 by 12 in. (0.2 by 0.3 m). Preferably, one of the platens

should be mounted on a self-aligning joint. Both platens shall

and 4 in. wide (155 mm in diameter by 100 mm wide)

be ground flat and checked for parallelism and flatness with a

weighing 33 6 1.0 lb (15 6 0.5 kg); or a light roller 4-in.

machinist’s straightedge.

diameter and 2.5 in. wide (100-mm diameter by 64 mm wide)

6.6.2 Rollers—Steel rollers must be mounted on freely

weighing 10 6 0.5 lb (4.5 6 0.25 kg).

rotating axles; ball-bearing mounts are preferable. The roller

6.6.3 Impact-Application Equipment—The Bellows impact

design should conform generally with Fig. 3. Either of the two

press consisting of a series B772-006 arbour stand and a

rollers specified may be used: a heavy roller 6 in. in diameter

“Bellows Air Motor” Series B8013. The “Bellows” impact

press is shown in Fig. 4 and Fig. 5.

Wire-wound applicators are available from the Leneta Co., PO Box 576

Ho-Ho-Kus, NJ 07423, from Byk Mallinckrodt Chemische Producte, 4230 Wessel

Postfach 245, West Germany, and from Paul Gardner and Co. Inc., 218-D This equipment can be purchased from Bellows-Valvair, Akron, Ohio 44309.

Commercial Blvd., Suite 205, Lauderdale-by-the-Sea, FL 33308-4491. Also from the same company offices in Glendale, CA 91201 and Toronto, Canada.

D1995 − 92 (2017)

6.8 Test Fixtures—The fixtures described in the ASTM

standards referenced in Section 2 were modified for the

purposes of these test methods.

6.8.1 The climbing drum prescribed in Test Method D1781

has been modified according to Fig. 6, Fig. 7, Fig. 8, Fig. 9.

The grooves in the drum customize it for use with the fixture

in Fig. 8 by allowing the retaining lips on the fixturing device

to fit into the grooves. This will unbalance the drum, but since

controls are run and these are subtracted from the test results,

the effect of the unbalance is nullified. The fixture in Fig. 8 is

also a modification of the fixture in Fig. 4 of Test Method

D1781. It does not require pre-drilling the test specimens.

6.8.2 The fixture required for the cleavage test, Fig. 10,isa

modification of the fixture in Fig. 1 of Test Method D1062.

6.9 Machinist’s Straightedge—A 12-in. (300-mm) machin-

ist’s straightedge (generally available from machinists’ shops)

is required. One of the lengthwise edges must be bevelled.

7. Test Materials

7.1 Checking Flatness of Materials—Lay the bevelled edge

of a machinist’s straightedge on the material perpendicular to

its surface and along its width. While shining a bright light

behind the straightedge, inspect the line of contact between the

edge and the material. If the material is flat, no light should

shine through. Make repeat observations at 2-in. (50-mm)

intervals lengthwise. See Fig. 11.

7.1.1 Material Dimensions—See Table 1.

7.2 Selection and Preparation of Maple Blocks—Selecthard

maple blocks, kiln-dried, (Acer saccharum or Acer nigrum)

having a minimum specific gravity of 0.65 based on oven-dry

weight and volume, from planks that are of straight grain, that

is, grain that runs parallel to the length of the plank, and free

FIG. 4 The Bellows Air Valve Used for Impacting Peel Specimens

from defects including knots, birdseye, cross grain, decay, and

anyunusualdiscoloration.(SeealsoTestMethodD905.)Select

pre-surfaced wood that is reasonably flat. To facilitate meeting

the flatness requirements, condition the wood to be cut

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.