ASTM D7394-13

(Practice)Standard Practice for Rheological Characterization of Architectural Coatings using Three Rotational Bench Viscometers

Standard Practice for Rheological Characterization of Architectural Coatings using Three Rotational Bench Viscometers

SIGNIFICANCE AND USE

5.1 A significant feature of this practice is the ability to survey coating rheology over a broad range of shear rates with the same bench viscometers and test protocol that paint formulators and paint QC analysts routinely use. By using this procedure, measurement of the shear rheology of a coating is possible without using an expensive laboratory rheometer, and performance predictions can be made based on those measurements.

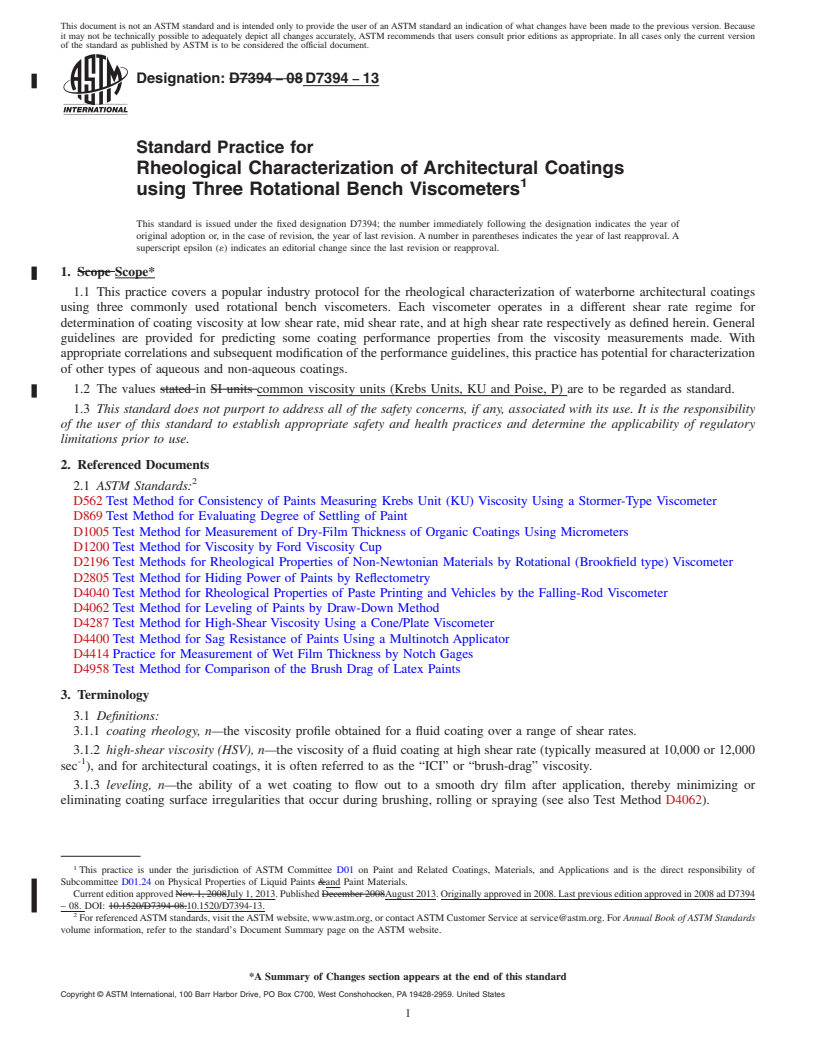

5.2 Low-Shear Viscosity (LSV)—The determination of low-shear viscosity in this practice can be used to predict the relative “in-can” performance of coatings for their ability to suspend pigment or prevent syneresis, or both. The LSV can also predict relative performance for leveling and sag resistance after application by roll, brush or spray. Fig. 1 shows the predictive low-shear viscosity relationships for several coatings properties.

5.3 Mid-Shear Viscosity (MSV)—The determination of MSV (coating consistency) in this practice is often the first viscosity obtained. This viscosity reflects the coatings resistance to flow on mixing, pouring, pumping, or hand stirring. Architectural coatings nearly always have a target specification for mid-shear viscosity, which is usually obtained by adjusting the level of thickener in the coating. Consequently, mid-shear viscosity is ideally a constant for a given series of coatings being tested to provide meaningful comparisons of low-shear and high-shear viscosity. With viscosities at the same KU value, MSV can also be used to obtain the relative Mid-Shear Thickener Efficiency (MSTE) of different thickeners in the same coating expressed as lb thickener/100 gal wet coating or g thickener/L wet coating.

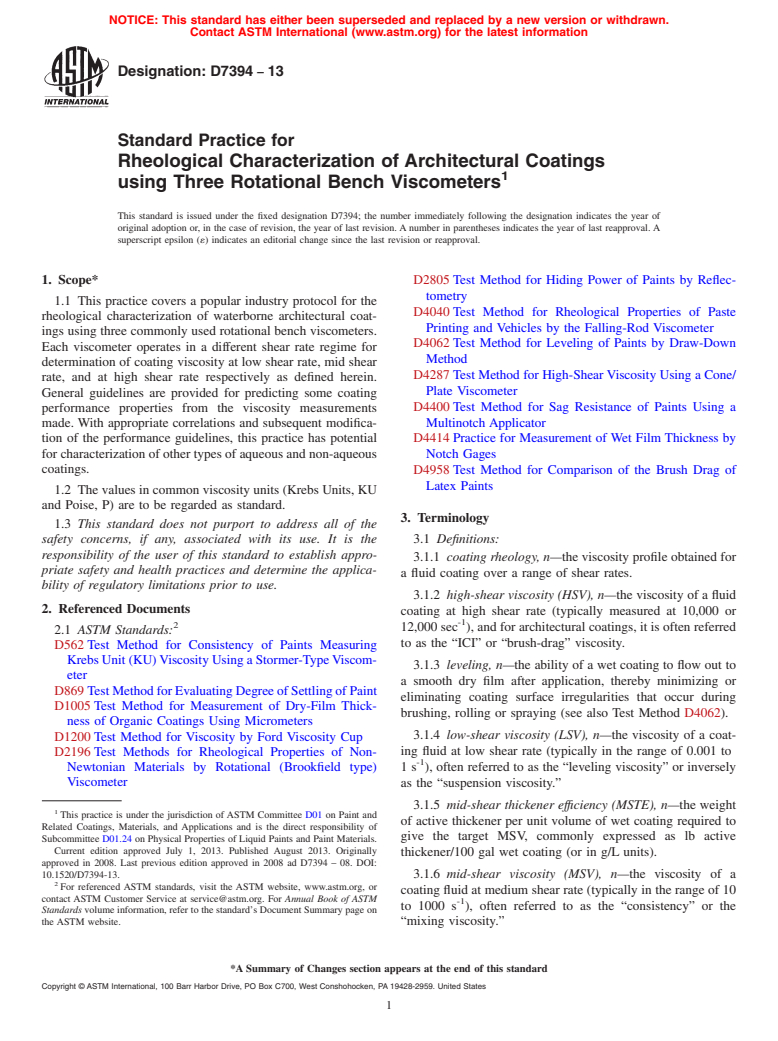

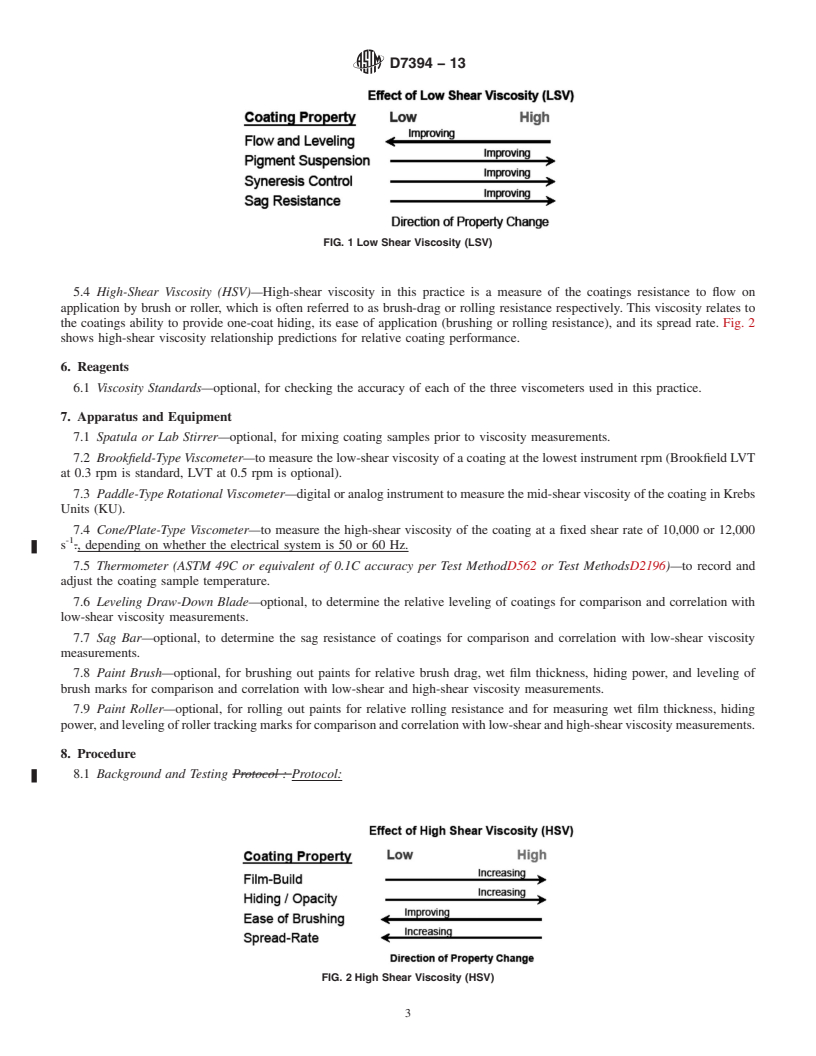

5.4 High-Shear Viscosity (HSV)—High-shear viscosity in this practice is a measure of the coatings resistance to flow on application by brush or roller, which is often referred to as brush-drag or rolling resistance respectively. This viscosity relates to the coatings ability to provide one-coat hiding...

SCOPE

1.1 This practice covers a popular industry protocol for the rheological characterization of waterborne architectural coatings using three commonly used rotational bench viscometers. Each viscometer operates in a different shear rate regime for determination of coating viscosity at low shear rate, mid shear rate, and at high shear rate respectively as defined herein. General guidelines are provided for predicting some coating performance properties from the viscosity measurements made. With appropriate correlations and subsequent modification of the performance guidelines, this practice has potential for characterization of other types of aqueous and non-aqueous coatings.

1.2 The values in common viscosity units (Krebs Units, KU and Poise, P) are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7394 − 13

Standard Practice for

Rheological Characterization of Architectural Coatings

1

using Three Rotational Bench Viscometers

This standard is issued under the fixed designation D7394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D2805 Test Method for Hiding Power of Paints by Reflec-

tometry

1.1 This practice covers a popular industry protocol for the

D4040 Test Method for Rheological Properties of Paste

rheological characterization of waterborne architectural coat-

Printing and Vehicles by the Falling-Rod Viscometer

ings using three commonly used rotational bench viscometers.

D4062 Test Method for Leveling of Paints by Draw-Down

Each viscometer operates in a different shear rate regime for

Method

determination of coating viscosity at low shear rate, mid shear

D4287 Test Method for High-Shear Viscosity Using a Cone/

rate, and at high shear rate respectively as defined herein.

Plate Viscometer

General guidelines are provided for predicting some coating

D4400 Test Method for Sag Resistance of Paints Using a

performance properties from the viscosity measurements

made. With appropriate correlations and subsequent modifica- Multinotch Applicator

tion of the performance guidelines, this practice has potential D4414 Practice for Measurement of Wet Film Thickness by

for characterization of other types of aqueous and non-aqueous

Notch Gages

coatings. D4958 Test Method for Comparison of the Brush Drag of

Latex Paints

1.2 The values in common viscosity units (Krebs Units, KU

and Poise, P) are to be regarded as standard.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.1 coating rheology, n—the viscosity profile obtained for

priate safety and health practices and determine the applica-

a fluid coating over a range of shear rates.

bility of regulatory limitations prior to use.

3.1.2 high-shear viscosity (HSV), n—the viscosity of a fluid

2. Referenced Documents

coating at high shear rate (typically measured at 10,000 or

-1

2

12,000 sec ), and for architectural coatings, it is often referred

2.1 ASTM Standards:

to as the “ICI” or “brush-drag” viscosity.

D562 Test Method for Consistency of Paints Measuring

KrebsUnit(KU)ViscosityUsingaStormer-TypeViscom-

3.1.3 leveling, n—the ability of a wet coating to flow out to

eter

a smooth dry film after application, thereby minimizing or

D869 TestMethodforEvaluatingDegreeofSettlingofPaint

eliminating coating surface irregularities that occur during

D1005 Test Method for Measurement of Dry-Film Thick-

brushing, rolling or spraying (see also Test Method D4062).

ness of Organic Coatings Using Micrometers

3.1.4 low-shear viscosity (LSV), n—the viscosity of a coat-

D1200 Test Method for Viscosity by Ford Viscosity Cup

ing fluid at low shear rate (typically in the range of 0.001 to

D2196 Test Methods for Rheological Properties of Non-

-1

1s ), often referred to as the “leveling viscosity” or inversely

Newtonian Materials by Rotational (Brookfield type)

Viscometer as the “suspension viscosity.”

3.1.5 mid-shear thickener effıciency (MSTE), n—the weight

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

of active thickener per unit volume of wet coating required to

Related Coatings, Materials, and Applications and is the direct responsibility of

give the target MSV, commonly expressed as lb active

Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint Materials.

Current edition approved July 1, 2013. Published August 2013. Originally

thickener/100 gal wet coating (or in g/L units).

approved in 2008. Last previous edition approved in 2008 ad D7394 – 08. DOI:

10.1520/D7394-13.

3.1.6 mid-shear viscosity (MSV), n—the viscosity of a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

coating fluid at medium shear rate (typically in the range of 10

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

-1

to 1000 s ), often referred to as the “consistency” or the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. “mixing viscosity.”

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7394 − 13

3.1.7 newtonian, n—a rheological term describing a fluid viscosity constant, meaningful comparisons

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7394 − 08 D7394 − 13

Standard Practice for

Rheological Characterization of Architectural Coatings

1

using Three Rotational Bench Viscometers

This standard is issued under the fixed designation D7394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice covers a popular industry protocol for the rheological characterization of waterborne architectural coatings

using three commonly used rotational bench viscometers. Each viscometer operates in a different shear rate regime for

determination of coating viscosity at low shear rate, mid shear rate, and at high shear rate respectively as defined herein. General

guidelines are provided for predicting some coating performance properties from the viscosity measurements made. With

appropriate correlations and subsequent modification of the performance guidelines, this practice has potential for characterization

of other types of aqueous and non-aqueous coatings.

1.2 The values stated in SI units common viscosity units (Krebs Units, KU and Poise, P) are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D562 Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer

D869 Test Method for Evaluating Degree of Settling of Paint

D1005 Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers

D1200 Test Method for Viscosity by Ford Viscosity Cup

D2196 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield type) Viscometer

D2805 Test Method for Hiding Power of Paints by Reflectometry

D4040 Test Method for Rheological Properties of Paste Printing and Vehicles by the Falling-Rod Viscometer

D4062 Test Method for Leveling of Paints by Draw-Down Method

D4287 Test Method for High-Shear Viscosity Using a Cone/Plate Viscometer

D4400 Test Method for Sag Resistance of Paints Using a Multinotch Applicator

D4414 Practice for Measurement of Wet Film Thickness by Notch Gages

D4958 Test Method for Comparison of the Brush Drag of Latex Paints

3. Terminology

3.1 Definitions:

3.1.1 coating rheology, n—the viscosity profile obtained for a fluid coating over a range of shear rates.

3.1.2 high-shear viscosity (HSV), n—the viscosity of a fluid coating at high shear rate (typically measured at 10,000 or 12,000

-1

sec ), and for architectural coatings, it is often referred to as the “ICI” or “brush-drag” viscosity.

3.1.3 leveling, n—the ability of a wet coating to flow out to a smooth dry film after application, thereby minimizing or

eliminating coating surface irregularities that occur during brushing, rolling or spraying (see also Test Method D4062).

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints &and Paint Materials.

Current edition approved Nov. 1, 2008July 1, 2013. Published December 2008August 2013. Originally approved in 2008. Last previous edition approved in 2008 ad D7394

– 08. DOI: 10.1520/D7394-08.10.1520/D7394-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7394 − 13

3.1.4 low-shear viscosity (LSV), n—the viscosity of a coating fluid at low shear rate (typically in the range of 0.001 to

-1

1 s ), often referred to as the “leveling viscosity” or inversely as the “suspension viscosity.”

3.1.5 mid-shear thickener effıciency (MSTE), n—the weight of active thickener per unit volume of wet coating required to give

the target MSV, commonly expressed as lb ac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.