ASTM F2392-04

(Test Method)Standard Test Method for Burst Strength of Surgical Sealants

Standard Test Method for Burst Strength of Surgical Sealants

SIGNIFICANCE AND USE

Materials and devices that function at least in part by adhering to living tissues are finding increasing use in surgical procedures, either as adjuncts to sutures and staples or as frank replacements for those devices in a wide variety of medical procedures. While the nature and magnitude of the forces involved varies greatly with indication and with patient specific circumstances, all uses involve, to some extent, the ability of the material to resist imposed mechanical forces. Therefore, the mechanical properties of the materials, and in particular the adhesive and cohesive properties, are important parameters in evaluating their fitness for use. In addition, the mechanical properties of a given sealant composition can provide a useful means of determining product consistency for quality control, or as a means for determining the effects of various surface treatments on the substrate prior to use of the device.

The complexity and variety of individual applications for sealant, even within a single indicated use (surgical procedure), is such that the results of a burst test are not suitable for determining allowable design stresses without thorough analysis and understanding of the application and sealant behaviors.

This test method may be used for comparing sealants for susceptibility to environmental changes, but such comparisons must be made with great caution since different sealants may respond differently to varying conditions.

As the true sealant strength is strongly dependent on the strength of the sealant/substrate interface, the selection of a proper test substrate is critical. Care must be taken when extrapolating in vitro test results to in vivo expectations. In vitro sealant optimization may not translate to expected in vivo performance due to differences in substrate surface, strength, and elasticity.

SCOPE

1.1 This test method provides a means for comparison of the burst or rupture strength of sealants on soft tissue. This test method can be used as a clinically relevant model for quality assurance, development, and comparative testing of different adhesives or adherends.

1.2 This test method measures only burst strength or "cohesive strength" of an adhesive/adherend system, and not the adhesive strength.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2392–04

Standard Test Method for

Burst Strength of Surgical Sealants

This standard is issued under the fixed designation F2392; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 cohesive failure—failure of the sealant during burst

testing.

1.1 Thistestmethodprovidesameansforcomparisonofthe

3.2.4 cohesive strength—the internal strength of the sealant,

burst or rupture strength of sealants on soft tissue. This test

sometimes referred to as the adhesive bulk strength.

method can be used as a clinically relevant model for quality

3.2.5 substrate failure—failure of the substrate during burst

assurance, development, and comparative testing of different

testing.

adhesives or adherends.

3.2.6 tissue sealant—asurfacecoatingtopreventleakageof

1.2 This test method measures only burst strength or “co-

body fluids.

hesive strength” of an adhesive/adherend system, and not the

adhesive strength.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 Materials and devices that function at least in part by

safety concerns, if any, associated with its use. It is the

adhering to living tissues are finding increasing use in surgical

responsibility of the user of this standard to establish appro-

procedures, either as adjuncts to sutures and staples or as frank

priate safety and health practices and determine the applica-

replacements for those devices in a wide variety of medical

bility of regulatory limitations prior to use.

procedures. While the nature and magnitude of the forces

2. Referenced Documents involvedvariesgreatlywithindicationandwithpatientspecific

circumstances, all uses involve, to some extent, the ability of

2.1 ASTM Standards:

thematerialtoresistimposedmechanicalforces.Therefore,the

D907 Terminology of Adhesives

mechanical properties of the materials, and in particular the

2.2 American Association for Tissue Banks (AATB) Stan-

adhesive and cohesive properties, are important parameters in

dard:

evaluating their fitness for use. In addition, the mechanical

Standards for Tissue Banking

properties of a given sealant composition can provide a useful

3. Terminology

means of determining product consistency for quality control,

or as a means for determining the effects of various surface

3.1 Definitions—Many terms in this test method are defined

treatments on the substrate prior to use of the device.

in Terminology D907.

4.2 The complexity and variety of individual applications

3.2 Definitions:

for sealant, even within a single indicated use (surgical

3.2.1 adhesive failure—failure of the sealant/substrate inter-

procedure), is such that the results of a burst test are not

face during burst testing.

suitable for determining allowable design stresses without

3.2.2 burst strength—the average pressure required to cause

thorough analysis and understanding of the application and

failure of the sealant, either by cohesive or adhesive mecha-

sealant behaviors.

nisms.

4.3 Thistestmethodmaybeusedforcomparingsealantsfor

susceptibility to environmental changes, but such comparisons

must be made with great caution since different sealants may

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

respond differently to varying conditions.

F04.15 on Material Test Methods.

4.4 As the true sealant strength is strongly dependent on the

Current edition approved May 1, 2004. Published June 2004. DOI: 10.1520/

strength of the sealant/substrate interface, the selection of a

F2392-04.

proper test substrate is critical. Care must be taken when

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

extrapolating in vitro test results to in vivo expectations. In

Standards volume information, refer to the standard’s Document Summary page on

vitro sealant optimization may not translate to expected in vivo

the ASTM website.

performance due to differences in substrate surface, strength,

Available from American Association for Tissue Banks (AATB), 1320 Old

Chain Bridge Rd., Suite 450, McLean, VA 22101. and elasticity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2392–04

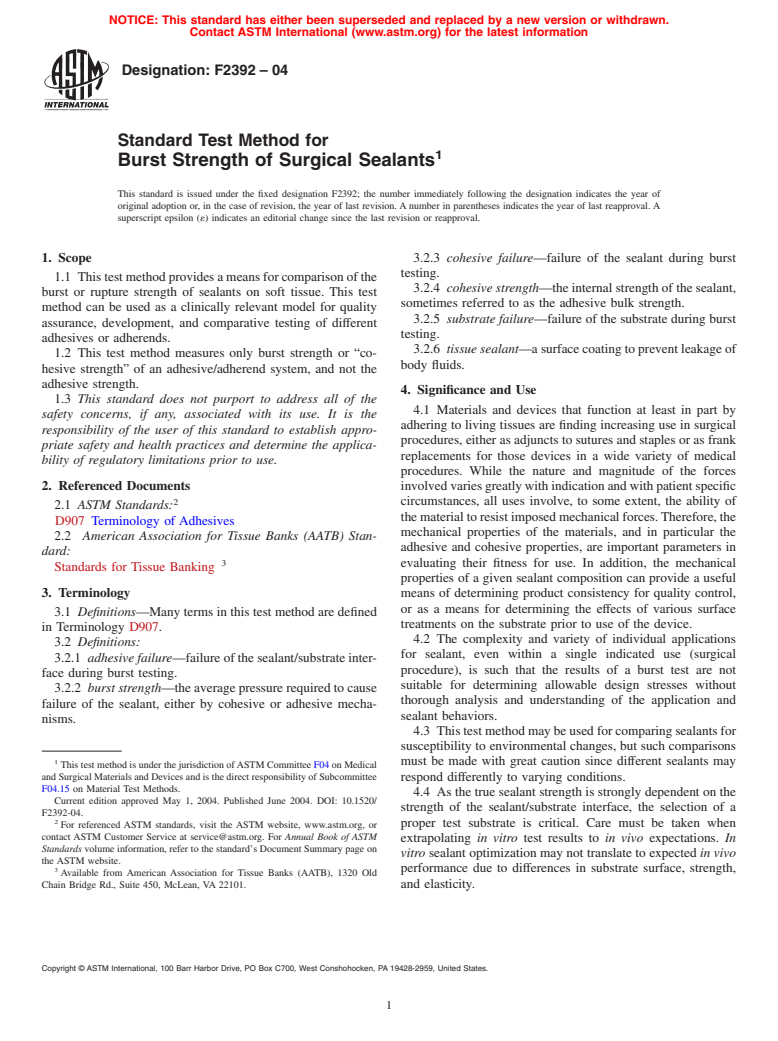

5. Apparatus pumps are particularly well suited for this type of testing since

they do not cause pulsatile flow. Peristaltic pumps have also

5.1 Testing Machine—A testing machine for determining

been used successfully since the pump tubing tends to dampen

the sealant strength and system failure mechanism and com-

pulsations.

prising essentially the following:

5.1.1 Test Fixture—A stationary fixture containing the test

NOTE 1—Saline is the typical fluid of choice. When air is used, a

substrate and applied sealant. Fluid flows into the fixture at a

reduction in pressurization rate is expected due to gas compressibility.

fixed rate, allowing for the pressurization of the sealed sub-

5.1.3 Pressure gage—Consisting of a gage and method of

strate.

capturing peak pressures. System sampling rate should be

5.1.2 Positive Displacement Fluid Pump—A pump provid-

adequate to capture peak burst pressures. Sensitivity and

ing a constant flow of fluid to the test fixture. The pump must

be capable of constant flow at pressures of interest. Syringe precision should result in less than 1 % error. The burst test

FIG. 1 Burst Test System (A), with an Exploded View of the Assembled Test Fixture (B),

and the Test Fixture Cross Sectional View (in.) (C)

F2392–04

system is shown in Fig. 1. The system (A) consists of a fluid lead to unacceptable variation in the test results, especially if

pump, a test fixture, and pressure gage connected by rigid the failure occurs in the adherend (substrate failure). Since the

plastic tubing. The test fixture (B) consists of a base, O-ring, purpose of quality control testing is to demonstrate consistency

and top. in the device, substitution of a model substrate is preferred so

5.2 Temperature-controlling Equipment—Must be capable long as it is demonstrated that the sealant does bond to the

of maintaining the test temperature to 62°C. If ambient adherend.Sincethebursttestfailuremechanismcandependon

laboratory conditions are employed, the same degree of control the amount of substrate deformation, attention to substrate

is required.Awater bath or environmental chamber capable of flexibility and elasticity is important to best match in vivo

maintaining 37°C is required for testing on tissue substrates. substrates.

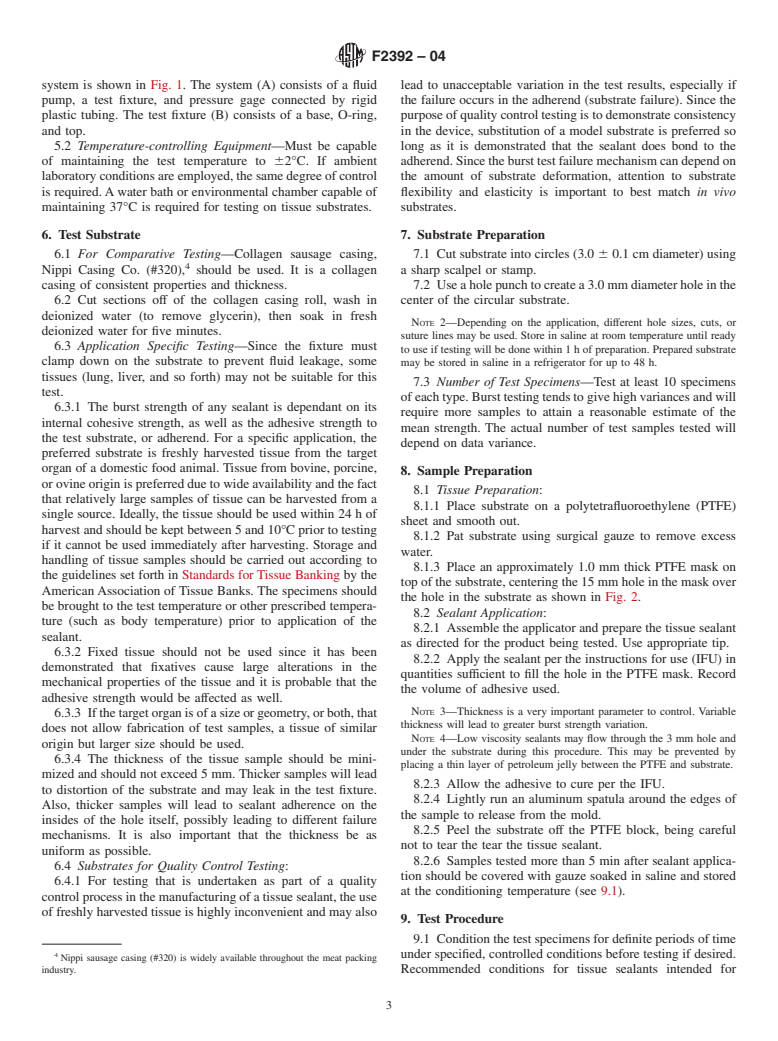

6. Test Substrate 7. Substrate Preparation

6.1 For Comparative Testing—Collagen sausage casing, 7.1 Cut substrate into circles (3.0 6 0.1 cm diameter) using

Nippi Casing Co. (#320), should be used. It is a collagen a sharp scalpel or stamp.

7.2 Useaholepunchtocreatea3.0mmdiameterholeinthe

casing of consistent properties and thickness.

6.2 Cut sections off of the collagen casing roll, wash in center of the circular substrate.

deionized water (to remove glycerin), then soak in fresh

NOTE 2—Depending on the application, different hole sizes, cuts, or

deionized water for five minutes.

suture lines may be used. Store in saline at room temperature until ready

6.3 Application Specific Testing—Since the fixture must

to use if testing will be done within1hof preparation. Prepared substrate

clamp down on the substrate to prevent fluid leakage, some may be stored in saline in a refrigerator for up to 48 h.

tissues (lung, liver, and so forth) may not be suitable for this

7.3 Number of Test Specimens—Test at least 10 specimens

test.

ofeachtype.Bursttestingtendstogivehighvariancesandwill

6.3.1 The burst strength of any sealant is dependant on its

require more samples to attain a reasonable estimate of the

internal cohesive strength, as well as the adhesive stren

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.