ASTM D5831-96

(Test Method)Standard Test Method for Screening Fuels in Soils

Standard Test Method for Screening Fuels in Soils

SCOPE

1.1 This test method is a screening procedure for determining the presence of fuels containing aromatic compounds in soils. If the contaminant fuel is available for calibration, the approximate concentration of the fuel in the soil can be calculated. If the contaminant fuel type is known, but the contaminant fuel is not available for calibration, an estimate of the concentration of the fuel in the soil can be determined using average response factors. If the nature of the contaminant fuel is unknown, the screening test method can be used to identify the possible presence of contamination.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5831 – 96

Standard Test Method for

Screening Fuels in Soils

This standard is issued under the fixed designation D 5831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope screening test method, refer to Terminology E 131.

1.1 This test method is a screening procedure for determin-

4. Summary of Test Method

ing the presence of fuels containing aromatic compounds in

4.1 A sample of soil is extracted with isopropyl alcohol, and

soils. If the contaminant fuel is available for calibration, the

the extract is filtered. The ultraviolet absorbance of the extract

approximate concentration of the fuel in the soil can be

is measured at 254 nm. If the contaminant fuel is available for

calculated. If the contaminant fuel type is known, but the

calibration, the approximate concentration of contamination is

contaminant fuel is not available for calibration, an estimate of

calculated. If the contaminant fuel type is known, but the

the concentration of the fuel in the soil can be determined using

contaminant fuel is not available for calibration, an estimate of

average response factors. If the nature of the contaminant fuel

the contaminant concentration is determined using average

is unknown, this screening test method can be used to identify

response factors. If the nature of the contaminant fuel is not

the possible presence of contamination.

known, the absorbance value is used to indicate the presence or

1.2 This standard does not purport to address all of the

absence of fuel contamination. Calcium oxide is added to the

safety concerns, if any, associated with its use. It is the

soil as a conditioning agent to minimize interferences from

responsibility of the user of this standard to establish appro-

humic materials and moisture present in the soil. Particulate

priate safety and health practices and determine the applica-

interferences are removed by passing the extract through a

bility of regulatory limitations prior to use.

filter.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 This screening test method is intended primarily for

D 2777 Practice for the Determination of Precision and Bias

2 field use to define the boundaries of soil contamination. If the

of Applicable Test Methods of Committee D-19 on Water

contaminant fuel is available for calibration, the approximate

E 131 Terminology Relating to Molecular Spectroscopy

concentration of the fuel in the soil can be calculated. If the

E 169 Practices for General Techniques of Ultraviolet-

fuel type is known, but the contaminant fuel is not available for

Visible Quantitative Analysis

calibration, an estimate of the contaminant fuel concentration

E 177 Practice for Use of the Terms Precision and Bias in

can be calculated using average response factors. If the nature

ASTM Test Methods

of the contaminant fuel is unknown, a contaminant concentra-

E 275 Practice for Describing and Measuring Performance

tion cannot be calculated, and the test method can only be used

of Ultraviolet, Visible, and Near Infrared Spectrophotom-

3 only to indicate the presence or absence of fuel contamination.

eters

5.2 Fuels containing aromatic compounds, such as diesel

E 691 Practice for Conducting an Interlaboratory Study to

4 fuel and gasoline, as well as other aromatic-containing hydro-

Determine the Precision of a Test Method

carbon materials, such as crude oil, coal oil, and motor oil, can

E 925 Practice for the Periodic Calibration of Narrow Band-

3 be determined by this test method. The quantitation limit for

Pass Spectrophotometers

diesel fuel is about 75 mg/kg. Approximate quantitation limits

3. Terminology for other aromatic-containing hydrocarbon materials that can

be determined by this screening test method are given in Table

3.1 Definitions—For definitions of terms used in this

1. Quantitation limits for highly aliphatic materials, such as

aviation gasoline and synthetic motor oil, are much higher than

This test method is under the jurisdiction of ASTM Committee D34 on Waste

those for more aromatic materials, such as coal oil and diesel

Management and is the direct responsibility of Subcommittee D34.01.05 on

fuel.

Screening Methods.

Current edition approved Oct. 10, 1996. Published December 1996. Originally

NOTE 1—The quantitation limits listed in Table 1 are approximate

published as D 5831 – 95. Last previous edition D 5831 – 95.

values because in this test method, the quantitation limit can be influenced

Annual Book of ASTM Standards, Vol 11.01.

by the particular fuel type and soil background levels. For information on

Annual Book of ASTM Standards, Vol 03.06.

how the values given in Table 1 were determined, see Appendix X1. Data

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5831

TABLE 1 Approximate Quantitation Limits for Various Fuel Types

This is a conditioning agent for removal of interferences

in Soils Based on 0.036 AU

caused by the presence of humic material or moisture, or both,

Limit of Quantitation (LOQ),

in the sample.

Material

mg/kg

7.3 Isopropyl Alcohol, Reagent Grade—Transportation of

Coal Oil 21

isopropyl alcohol for field testing must comply with current

Crude Oil 61

Department of Transportation (DOT) regulations.

Diesel Fuel 75

Used Motor Oil 162

Weathered Gasoline 170

8. Procedure

Unleaded Gasoline 316

Jet Fuel JP-2 378

8.1 Preparation of Standard Solutions:

Motor Oil 533

8.1.1 Weigh out 200 mg (weighed to 60.1 mg) of the fuel

Aviation Gasoline 1066

type of interest into a 100-mL volumetric flask and dilute to

Synthetic Motor Oil 1382

volume using isopropyl alcohol. This gives a 2000-mg/L

standard stock solution. Other standard solutions can be

prepared as needed by appropriate dilution of this stock

generated during the development of this screening test method and other

information pertaining to this test method can be found in the research solution. For example, to prepare a 200-mg/L solution of the

report.

fuel type of interest, pipet 5 mL of the stock solution into a

50-mL volumetric flask and dilute to volume using isopropyl

5.3 Extractable material, which scatters or absorbs light at

alcohol. For work in the field, a standard stock solution can be

254 nm, is a potential interference for this screening test

prepared by diluting 25 μL of a fuel standard (density can vary

method.

from; 0.75–0.90 g/mL) to 100 mL with isopropyl alcohol.

6. Apparatus

8.2 Sample Preparation:

8.2.1 Preweigh a 125-mL (4-oz), wide-mouth, glass sample

6.1 Glass Bottles, wide-mouth, 125-mL (4-oz) with

collection bottle having a polytetrafluoroethylene-lined lid.

polytetrafluoroethylene-lined lids.

Record the mass of the empty sample collection bottle to 60.1

6.2 Portable Scale, (for field testing) or laboratory balance,

g.

capable of weighing to 0.1 g.

8.2.2 Add 5 g (weighed to 60.1 g) of soil directly to the

6.3 Portable Stirring Device, (for field testing) or magnetic

preweighed sample collection bottle. Weigh the sample bottle-

stir bar and stirrer, which result in motion of all solids during

plus-sample, and record the mass of the soil sample added to

stirring.

the bottle to 60.1 g.

6.4 Syringe, disposable, plastic, 10-mL capacity.

6.5 Syringe Filters, disposable, 0.45-μm, in 25-mm polytet- 8.2.3 Add approximately5gof calcium oxide, prepared as

rafluoroethylene cartridges. specified in 7.3, to the soil, and stir with a spatula until a

6.6 Spectrometer Set, at 254 nm with a 1-cm path length, uniform dry mixture is obtained. If the soil contains an

quartz cell (cuvette). excessive amount of water (>50 %), add approximately 5 g

6.7 Volumetric Flasks and Pipets, for preparing standard more of calcium oxide.

solutions. 8.3 Sample Extraction and Analysis:

6.8 Laboratory Balance, capable of weighing to 0.0001 g.

8.3.1 Pour 50 mL of isopropyl alcohol into the sample

bottle.

7. Reagents and Materials

8.3.2 Stir the slurry for 3 min using a portable stirring

7.1 Purity of Reagents—Reagent grade chemicals shall be

device or magnetic stir bar and stirrer so that all solids are in

used in all screening tests. Unless otherwise indicated, it is

motion during stirring. A shorter stirring time or hand shaking

intended that all reagents shall conform to the specifications of

may decrease the extraction efficiency.

the Committee on Analytical Reagents of the American Chemi-

8.3.3 Allow the soil slurry to settle briefly, then remove the

cal Society where such specifications are available. Other

lid and draw the supernatant solution into a 10-mL disposable

grades may be used provided it is first ascertained that the

syringe. Attach a filter cartridge to the end of the syringe. Rinse

reagent is of sufficiently high purity to permit its use without

the sample cuvette with filtered extract. Then fill the cuvette

lessening the accuracy of the determination.

with filtered extract for analysis.

7.2 Calcium Oxide Powder, Reagent Grade—Use calcium

8.3.4 Calibration procedures specific to the spectrometer

oxide powder, reagent grade dried at 900°C for 12 h and stored

being used to perform the absorbance measurements must be

in a desiccator or tightly sealed glass container prior to use.

followed. Instrument instructions for spanning from 0 to 1

absorbance unit must be followed. Calibration is to be per-

formed using isopropyl alcohol to zero the instrument, and if a

Schabron, J. F., Niss, N. D., Hart, B. K., and Sorini, S. S., “Remote Chemical

calibration line is to be established, calibration standards

Sensor Development: A New Field Screening Method for Soil Fuel Contamination,”

prepared from the standard stock solution should be used (see

Laramie, WY, WRI-95-R016, 1995.

8.1.1). Calibration using three standards is recommended.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Calibration curves are nonlinear above 1 AU (>90 % of the

listed by the American Chemical Society, see Analar Standards for Laboratory

light absorbed). As a result, readings must be made below this

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

level. In addition, the extract absorbance reading must fall

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. between the absorbance readings of two calibration standards.

D 5831

NOTE 2—For general information on the techniques most often used in

should be performed as specified, except with no soil. If

ultraviolet analysis, see Practice E 169. For additional information on the

significant absorbance is noted, the various components should

performance of ultraviolet spectrophotometers, see Practice E 275. For

be tested individually by contacting them with isopropyl

information on evaluating the performance of an ultraviolet spectropho-

alcohol, and the problem component(s) should be replaced.

tometer to verify its suitability for continued routine use, see Practice

8.3.10 In this procedure, the conditioning agent inhibits the

E 925.

extraction of most humic materials, and there is very little, if

8.3.5 Read and record the absorbance of the extract at 254

any, background from inorganic materials. It is recommended,

nm.

however, that a blank soil sample should be tested by extract-

8.3.6 Determine an approximate or estimated concentration

ing contaminant-free soil of the same type and from the same

of a known fuel type in the filtered extract.

general area as the site being studied. If any absorbance is

8.3.6.1 If the contaminant fuel was used for calibration, an

measured for the blank, the sample values should be corrected

approximate concentration of the fuel in the extract can be

for this procedure.

calculated using a calibration line. Record this approximate

8.3.11 Also, it is recommended that one spike should be run

concentration of the fuel in the extract in milligrams/litre.

for every batch of samples or for every 20 samples, whichever

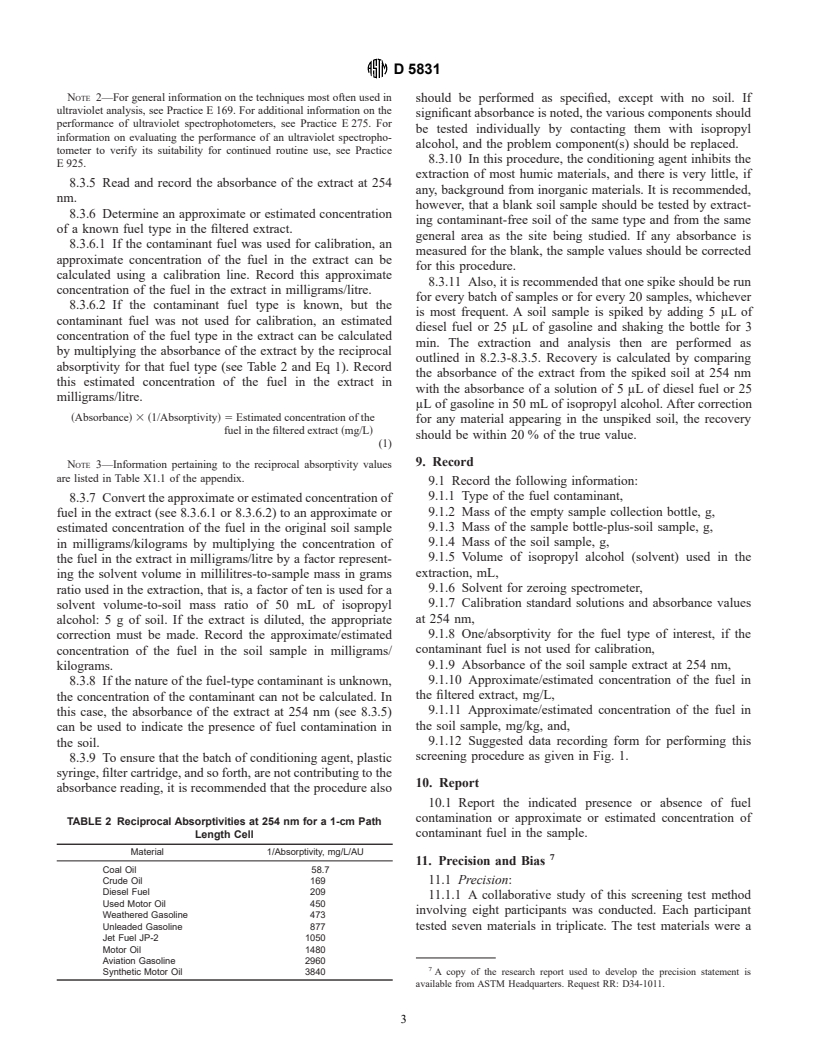

8.3.6.2 If the contaminant fuel type is known, but the

is most frequent. A soil sample is spiked by adding 5 μL of

contaminant fuel was not used for calibration, an estimated

diesel fuel or 25 μL of gasoline and shaking the bottle for 3

concentration of the fuel type in the extract can be calculated

min. The extraction and analysis then are performed as

by multiplying the absorbance of the extract by the reciprocal

outlined in 8.2.3-8.3.5. Recovery is calculated by comparing

absorptivity for that fuel type (see Table 2 and Eq 1). Record

the absorbance of the extract from the spiked soil at 254 nm

this estimated concentration of the fuel in the extract in

with the absorbance of a solution of 5 μL of diesel fuel or 25

milligrams/litre.

μL of gasoline in 50 mL of isopropyl alcohol. After correction

~Absorbance!3~1/Absorptivity!5 Estimated concentration of the

for any material appearing in the unspiked soil, the recovery

fuel in the filtered extract ~mg/L!

should be within 20 % of the true value.

(1)

9. Record

NOTE 3—Information pertaining to the reciprocal absorptivity values

are listed in Table X1.1 of the appendix.

9.1 Record the following information:

9.1.1 Type of the fuel contaminant,

8.3.7 Convert the approximate or estimated concentration of

9.1.2 Mass of the empty sample collection bottle, g,

fuel in the extract (see 8.3.6.1 or 8.3.6.2) to an approximate or

9.1.3 Mass of the sample bottle-plus-soil sample, g,

estimated concentration of the fuel in the original soil sample

9.1.4 Mass of the soil sample, g,

in milligrams/kilograms by multiplying the concentration of

9.1.5 Volume of isopropyl alcohol (solvent) used in the

the fuel in the extract in milligrams/litre by a factor represent-

extraction, mL,

ing the solvent volume in millilitres-to-sample mass in grams

9.1.6 Solvent for zeroing spectrometer,

ratio used in the extraction, that is, a factor of ten is used for a

9.1.7 Calibration standard solutions and absorbance values

solvent volume-to-soil mass ratio of 50 mL of isopropyl

at 254 nm,

alcohol:5gof soil. If the extract is diluted, the appropriate

9.1.8 One/absorptivity for the fuel type of interest, if the

correction must be made. Record the approximate/estimated

contaminant fuel is not used for calibration,

concentration of the fuel in the soil sample in milligrams/

9.1.9 Absorbance of the soil sample extract at 254 nm,

kilograms.

9.1.10 Approximate/estimated concentration of the fuel in

8.3.8 If the nature of the fuel-type contaminant is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.