ASTM D3342-90(2012)

(Test Method)Standard Test Method for Dispersion Stability of New (Unused) Rolling Oil Dispersions in Water

Standard Test Method for Dispersion Stability of New (Unused) Rolling Oil Dispersions in Water

SIGNIFICANCE AND USE

Each steel rolling mill and operation is particular as to the degree of stability of dispersion required to effect maximum efficiency of lubrication and cooling. This test method is designed to differentiate between coolants for this use. A similar situation is encountered with aluminum rolling mills, but significant differences in designated settling times be required outside the parameter of times used herein. Precision data have only been obtained relative to metastable dispersions for steel mill rolling oils.

SCOPE

1.1 This test method covers determination of the dispersion stability of dispersions of rolling oils in water. It is applicable to oils whose water dispersions are stable under moderate agitation, but which show at least some separation upon standing quiescent for ½ h, by rising of the oil particles.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.2, A2.1, and A2.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3342 − 90 (Reapproved 2012)

Standard Test Method for

Dispersion Stability of New (Unused) Rolling Oil

1

Dispersions in Water

This standard is issued under the fixed designation D3342; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mum efficiency of lubrication and cooling. This test method is

designed to differentiate between coolants for this use. A

1.1 This test method covers determination of the dispersion

similar situation is encountered with aluminum rolling mills,

stability of dispersions of rolling oils in water. It is applicable

but significant differences in designated settling times be

to oils whose water dispersions are stable under moderate

required outside the parameter of times used herein. Precision

agitation, but which show at least some separation upon

data have only been obtained relative to metastable dispersions

1

standing quiescent for ⁄2 h, by rising of the oil particles.

for steel mill rolling oils.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

5. Apparatus

standard.

3,4

5.1 Mixing Beaker, 5800 mL capacity, made of stainless

1.3 This standard does not purport to address all of the

steel, modified as shown in Annex A2.

safety concerns, if any, associated with its use. It is the

5.2 Combination Agitator and Temperature Control

responsibility of the user of this standard to establish appro-

4,5

Device.

priate safety and health practices and determine the applica-

4,6

bility of regulatory limitations prior to use. For specific

5.3 Babcock Centrifuge Bottles —The 165-mm cream test

warning statements, see 6.2, A2.1, and A2.5.

bottle, with 5 mL-neck permitting oil concentration readings

from0to10 %ispreferred.Thesebottlesshouldbemarkedfor

2. Referenced Documents

filling to the 50-mL level which will normally be found close

2

2.1 ASTM Standards:

to the junction of body and neck. Sulfonation bottles may also

D1126 Test Method for Hardness in Water be used.

D1293 Test Methods for pH of Water

5.4 Centrifuge, capable of whirling the Babcock bottles at

sufficient speed to give a clean separation of oil and water

3. Summary of Test Method

under the test conditions. A centrifuge giving a relative

3.1 The rolling oil is dispersed in a standard test water, in a

centrifugal force (rcf) of 5009 at the bottle tips has been found

standard container, under standard conditions of time,

to give good separations in 10 min.

agitation, and concentration.When the agitation is stopped, the

5.5 To calculate the rpm required to achieve the stated rcf,

resulting decrease in oil concentration at a specified point near

use the following formula:

thebottomofthecontainerismeasuredatcertaintimeintervals

and plotted.

rpm 5 1335=rcf/d (1)

where:

4. Significance and Use

rcf = relative centrifugal force,

4.1 Each steel rolling mill and operation is particular as to

the degree of stability of dispersion required to effect maxi-

1 3

This test method is under the jurisdiction of ASTM Committee D02 on The sole source of supply of the apparatus (beaker #2-584F) known to the

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of committee at this time is Fisher Scientific.

4

Subcommittee D02.L0.04 on Metal Deformation Fluids and Lubricants. If you are aware of alternative suppliers, please provide this information to

Current edition approved April 15, 2012. Published April 2012. Originally ASTM International Headquarters. Your comments will receive careful consider-

1

approved in 1990. Last previous edition approved in 2006 as D3342–90(2006). ation at a meeting of the responsible technical committee, which you may attend.

5

DOI:10.1520/D3342-90R12. The sole source of supply of the apparatus (the Porta-temp) known to the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or committee at this time is Precision Scientific Co.

6

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The sole source of supply of the apparatus (cream test bottle No. 12-705 or

Standards volume information, refer to the standard’s Document Summary page on sulfonation bottle No. 6-904) known to the committee at this time is Fisher

the ASTM website. Scientific.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3342 − 90 (2012)

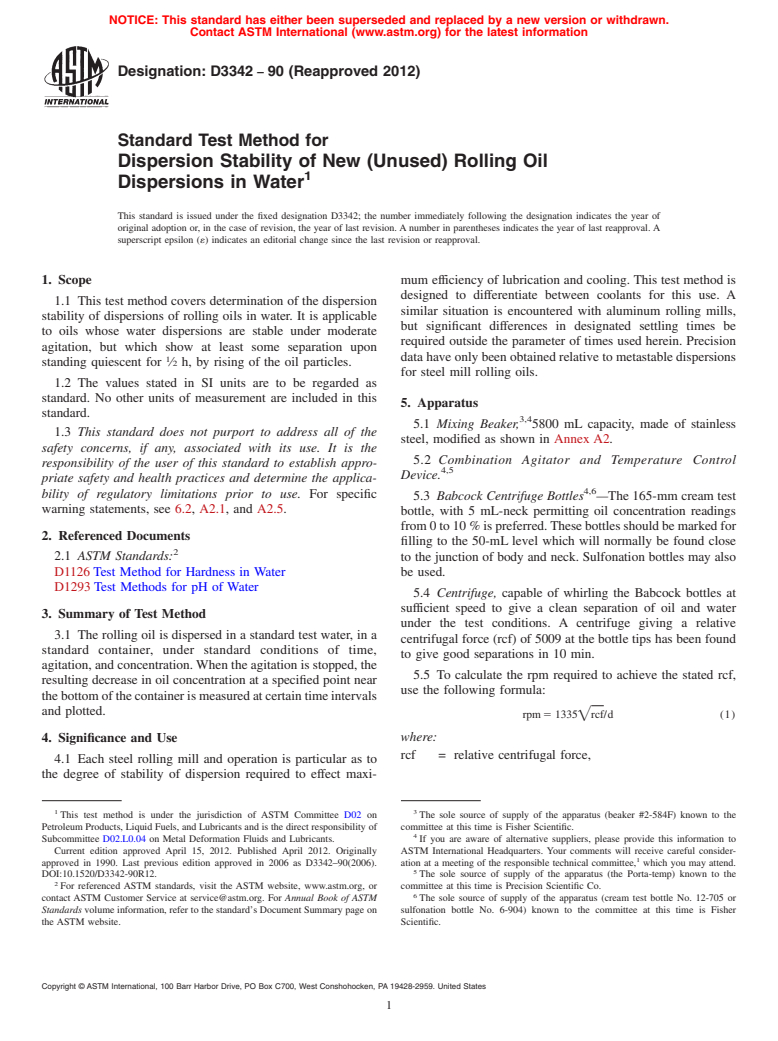

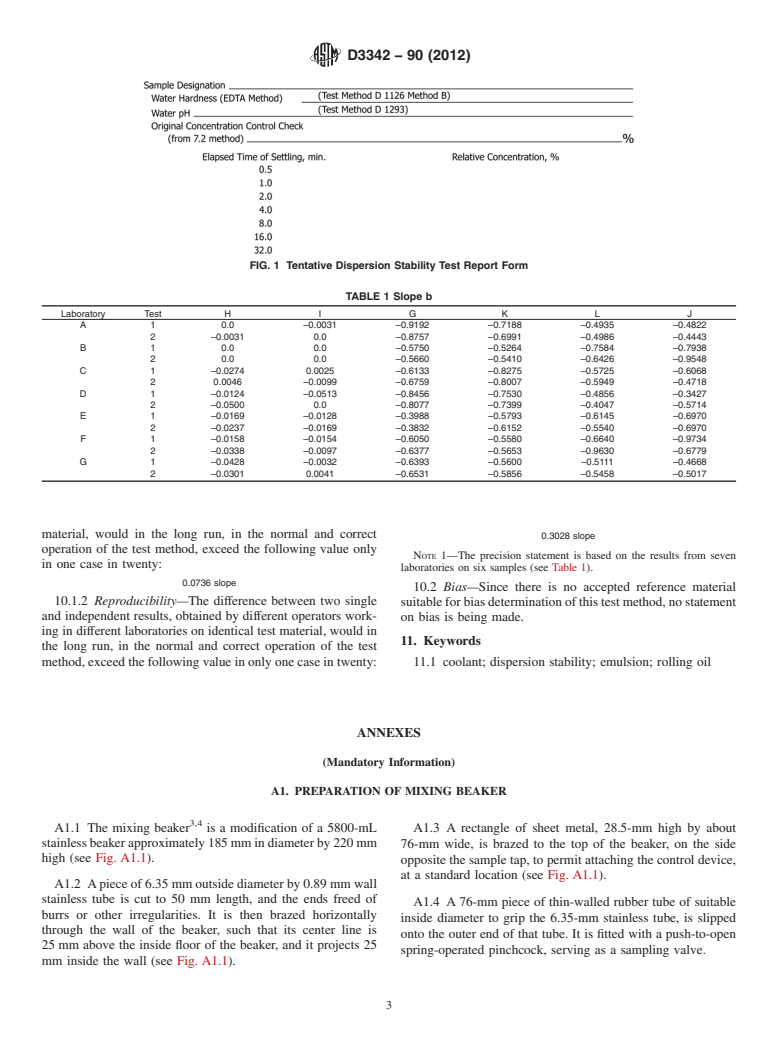

8. Calculation

d = diameter of swing measured between tips of opposite

tubes when in rotating position, mm, and

8.1 For the sample bottle taken as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.