ASTM F2544-06

(Test Method)Standard Test Method for Determining A-Weighted Sound Power Level of Central Vacuum Power Units

Standard Test Method for Determining A-Weighted Sound Power Level of Central Vacuum Power Units

SCOPE

1.1 This test method calculates the overall A-weighted sound power level emitted by central vacuum power units, intended for operation in domestic applications. This standard applies to the power unit only at the power unit location. To test the sound power level of a central vacuum at the users location, refer to Test Method F 1334.

1.2 A-weighted sound pressure measurements are performed on a mounted central vacuum power unit in a semi-reverberant room. This test method determines sound power by a comparison method for small noise sources, that is, comparison to a broad band reference sound source.

1.3 This test method describes a procedure for determining the A-weighted sound power level of small noise sources. This test method uses a non-special semi-reverberant room.

1.4 Results are expressed as A-weighted sound power level in decibels.

1.5 The values stated in inch pound units are to be regarded as the standard. The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2544–06

Standard Test Method for

Determining A-Weighted Sound Power Level of Central

1

Vacuum Power Units

This standard is issued under the fixed designation F 2544; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 820 Test Method for MeasuringAir Performance Charac-

teristics of Central Vacuum Cleaning Systems

1.1 This test method calculates the overall A-weighted

F 1334 Test Method for Determining A-Weighted Sound

sound power level emitted by central vacuum power units,

Power Level of Vacuum Cleaners

intended for operation in domestic applications. This standard

3

2.2 ANSI Standards:

appliestothepowerunitonlyatthepowerunitlocation.Totest

S1.10 Method for the Calibration of Microphones

the sound power level of a central vacuum at the user’s

S1.26 Method for the Calculation of the Absorption of

location, refer to Test Method F 1334.

Sound by the Atmosphere

1.2 A-weighted sound pressure measurements are per-

S1.43 Specifications for Sound Level Meters, IEC 804 and

formed on a mounted central vacuum power unit in a semi-

IEC 61672

reverberantroom.Thistestmethoddeterminessoundpowerby

S12.31 Precision Methods for the Determination of Sound

a comparison method for small noise sources, that is, compari-

Power Levels of Broad Band Noise Sources in Reverber-

son to a broad band reference sound source.

ant Rooms

1.3 This test method describes a procedure for determining

S12.32 Precision Methods for Determination of Sound

theA-weighted sound power level of small noise sources. This

Power Levels for Discrete Frequency and Narrow Band

test method uses a non-special semi-reverberant room.

Noise Sources in Reverberant Rooms

1.4 Results are expressed as A-weighted sound power level

S12.33 Engineering Methods for Determination of Sound

in decibels.

Power Levels of Noise Sources in a Special Reverberant

1.5 The values stated in inch pound units are to be regarded

Test Room

as the standard. The values in parentheses are for information

3

2.3 ISO Standards:

only.

ISO 3741, 3742, and 3743 are similar to and may be used in

1.6 This standard does not purport to address all of the

place of ANSI S12.31, S12.32, and S12.33 respectively

safety concerns, if any, associated with its use. It is the

3

2.4 IEC Standard:

responsibility of the user of this standard to establish appro-

60704.1 Test Code for the Determination of Airborne

priate safety and health practices and determine the applica-

Acoustical Noise Emitted by Household and Similar

bility of regulatory limitations prior to use.

Electrical Appliances

2. Referenced Documents

3. Terminology

2

2.1 ASTM Standards:

3.1 Unless otherwise indicated, definitions are in accor-

C 634 Terminology Relating to Environmental Acoustics

dance with Terminology C 634.

E 177 Practice for Use of the Terms Precision and Bias in

3.2 Definitions:

ASTM Test Methods

3.2.1 population, n—total of all of the units of the particular

E 691 Practice for Conducting an Interlaboratory Study to

model or type, or both, of central vacuum power units being

Determine the Precision of a Test Method

tested.

3.2.2 population sample or sample, n—three or more units,

1

This test method is under the jurisdiction ofASTM Committee F11 onVacuum randomly taken from the population.

Cleaners and is the direct responsibility of Subcommittee F11.25 on Sound

3.2.3 reference sound source, n—standard source of broad-

Measurement.

band sound with a certified set of sound power emissions.

Current edition approved July 1, 2006. Published July 2006.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

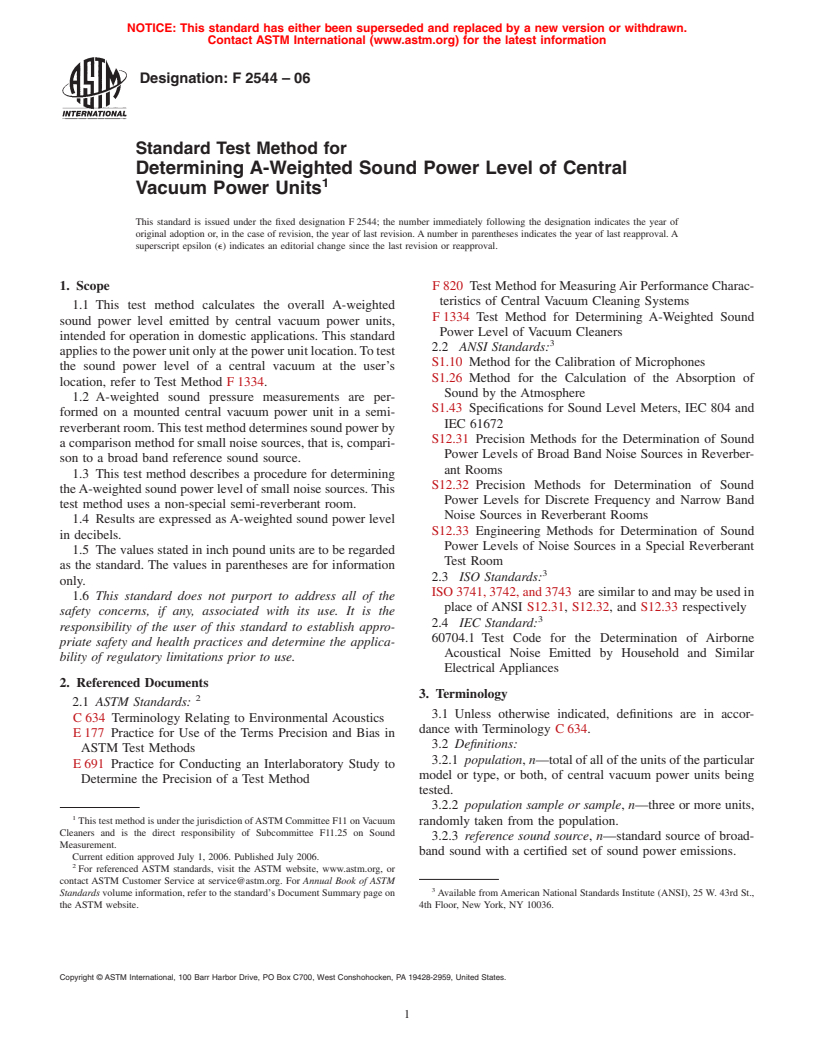

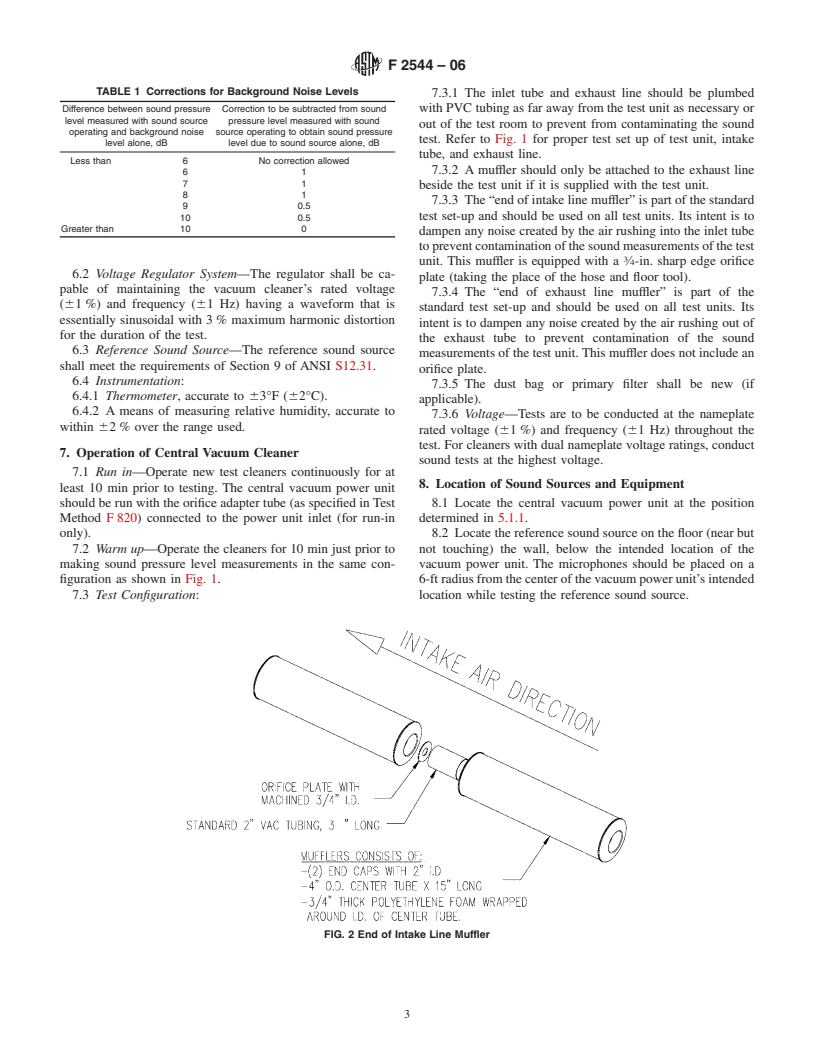

---------------------- Page: 1 ----------------------

F2544–06

3.2.4 source, n—device that emits sound. 60° apart from each other on the semi-circle at a height of 60

3.2.5 test unit or units, n—singlecentralvacuumpowerunit in. (1.5 m). The microphone should be oriented per the

of the model or type, or both, being tested.

microphone manufacturer’s instructions. Refer to Fig. 1 for

layout. These positions shall result in a standard deviation of

4. Significance and Use

thethreesoundpressuremeasurementsofnotmorethan2.3dB

4.1 The test results enable the comparison of A-weighted when measuring the re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.